HAL Id: hal-02875249

https://hal.archives-ouvertes.fr/hal-02875249

Submitted on 19 Jun 2020

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of

sci-entific research documents, whether they are

pub-lished or not. The documents may come from

teaching and research institutions in France or

abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est

destinée au dépôt et à la diffusion de documents

scientifiques de niveau recherche, publiés ou non,

émanant des établissements d’enseignement et de

recherche français ou étrangers, des laboratoires

publics ou privés.

Modelling martensitic transformation in titanium alloys:

The influence of temperature and deformation

Pedro E.J. Rivera-Díaz-Del-Castillo, Madeleine Bignon, Emmanuel Bertrand,

Franck Tancret, Pedro Rivera-Díaz-Del-Castillo

To cite this version:

Pedro E.J. Rivera-Díaz-Del-Castillo, Madeleine Bignon, Emmanuel Bertrand, Franck Tancret, Pedro

Rivera-Díaz-Del-Castillo. Modelling martensitic transformation in titanium alloys: The influence of

temperature and deformation. Materialia, Elsevier, 2019, 7, pp.100382. �10.1016/j.mtla.2019.100382�.

�hal-02875249�

ContentslistsavailableatScienceDirect

Materialia

journalhomepage:www.elsevier.com/locate/mtla

Full

Length

Article

Modelling

martensitic

transformation

in

titanium

alloys:

The

influence

of

temperature

and

deformation

Madeleine

Bignon

a,b,

Emmanuel

Bertrand

a,

Franck

Tancret

a,

Pedro

E.J.

Rivera-Díaz-del-Castillo

b,∗a Institut des Matériaux Jean Rouxel (IMN), Université de Nantes, CNRS, Polytech Nantes, Rue Christian Pauc, Cedex 3, Nantes 44306, France b Department of Engineering, Lancaster University, Lancaster LA1 4YK, UK

a

r

t

i

c

l

e

i

n

f

o

Keywords: Titanium alloys Martensite TRIP Superelasticitya

b

s

t

r

a

c

t

Newtheoryispresentedtodescribetheoccurrenceofplasticity-inducedtransitionsintitaniumalloys.The ap-proachisabletopredictthecompositiondependenceoftransformationinducedplasticity(TRIP),superelasticity, aswellasmartensiteformationuponquenching.Martensiteformationintheabsenceofstressisconsideredas theresultofacompetitionbetweenelasticstrainenergyandchemicaldrivingforce.Assumingthattheformation ofmartensiteistheresultofathermallyactivatednucleationprocessfollowedbyathermalgrowth,a nucle-ationparameterispostulatedtodescribetheconditionsunderwhichmartensiteisformeduponquenching;the parameteraccountsfortheratiobetweentheavailablethermalenergyandanenergybarrierfornucleation, sug-gestingthat𝜔phaseisnotthemainfactorcontrollingmartensiteinhibition.Thisnucleationparameterisable todescribe,forthefirsttime,martensiteoccurrencein130alloysfromtheliterature,quantifyingthemartensite starttemperature(Ms)reportedfor49alloyswithgreatprecision.Anempiricalparameter([Fe]eq)isproposed

and,whencombinedwiththeMsprediction,itallowstodefineregionswithinwhichTRIPandsuperelasticity

occur.BydefiningthresholdvaluesfortheMs,the[Fe]eqandthenucleationparameter,candidatealloyslikely

todisplayTRIP,superelasticityormartensitictransformationuponquenchingcanbeidentified.Asaresult,this methodcanbeadoptedtodesignalloyswithtailoredplasticitybehaviour.

1. Introduction

Titanium alloys are used for various industrial applications in-cluding aircraft, medical devices andmarine structures [1]. Among them,metastable𝛽 alloyshavereceivedspecialattentionduetotheir deformationbehaviour,sometimesdisplayedastransformationinduced plasticity(TRIP),twinninginducedplasticity(TWIP),shapememoryor superelasticityeffects.Superelasticity,observedinavarietyofsystems includingnickelalloys,ferrousalloysandtitaniumalloys[2,3],isthe capacityofanalloytoreturntoitsoriginalshapeuponunloadingeven afterhavingbeendeformedtostrainsofupto7%or8%.Thisproperty isused,forexample,inorthodonticwires[4].Alloyspresentingshape memorycan recover their original shape uponheatingafter having been deformed. Shape memory alloys have been used for various applicationssuch ascivilstructures[5], actuatorsin robotics[6] or biomedical implants [7]. TRIP alloys exhibit excellent ductility and goodworkhardeningrate.Benefitcanbe takenfromtheirrelatively lowinitialyieldstresscombinedwithahighworkhardeningrateto manufacturepartsofintricateshapes;theyareeasilyformableandthe

∗Correspondingauthor.

E-mailaddress:p.rivera1@lancaster.ac.uk(P.E.J.Rivera-Díaz-del-Castillo).

finishedpartscanreachahighyieldstress,whilekeepingsignificant ductility.Automotive industryhasadoptedTRIPsteelsforstructural partssuchasbumpers,andalthoughseveralstudiesonTRIPtitanium alloys insist on their suitability for biomedical implants [8], their propertiesmaketheminterestingcandidatesforstructuralapplications aswell.

Thedeformationbehaviourof𝛽 titaniumalloysisstrongly composi-tiondependentandisgenerallyassumedtobecontrolledbythestability ofthehightemperaturebody-centredcubic(BCC)𝛽 phase[9].This sta-bilitycanbeincreasedby𝛽 stabiliserssuchasFe,Mo,VorCrandit canbedecreasedbyelementsstabilisingthelowtemperature hexago-nalclose-packed(HCP)phasesuchasAlorO.Aminimumquantityof𝛽

stabilisersisnecessarytoretaintheBCCphaseatroomtemperatureand itisreportedthattheleaststable𝛽 alloysexhibitstress-induced marten-sitetransformation,leadingtoTRIPeffectwhenthemartensiteis me-chanicallystableorsuperelasticitywhenitisunstable.Uponincreasing theconcentrationin𝛽 stabilisers,thedeformationmodeisbelievedto switchtotwinning,andwhentheirconcentrationisfurtherincreased, thedeformationonlyoccursbydislocationglide[9]inasinglestable𝛽

https://doi.org/10.1016/j.mtla.2019.100382

Received12June2019;Accepted18June2019 Availableonline6July2019

2589-1529/© 2019ActaMaterialiaInc.PublishedbyElsevierLtd.ThisisanopenaccessarticleundertheCCBYlicense. (http://creativecommons.org/licenses/by/4.0/)

Fig.1. (a)ReproductionoftheBo–Md map from[10].Thefourcolouredzonescorrespond tothefourexpectedtypesofbehaviour accord-ingtoMorinaga’smethod.(b)Alloysfromthe literaturedisposedonthemapfromMorinaga. Theexperimentallyobservedbehaviourofthe alloysisindicatedbythecolour ofthe bul-lets(orbytheirnumber,withnumbercodeas showninAppendixA.)(Forinterpretationof thereferencestocolourinthisfigurelegend, thereaderisreferredtothewebversionofthis article.).

phase.However,themechanismsinvolvedinthestress-induced trans-formationsarenotfullyunderstoodyet.

AnumberofcriteriahavebeenadoptedtodesignTRIPandTWIP titaniumalloys.Ausefultooltopredict𝛽 phaseretentionisthe em-piricalMoequivalent([Mo]eq)parameter[9].Thecriterionbasedon

thisparameterisreliablebutdiscardsacertainnumberof𝛽 alloysthat havebeenshowntodisplayTRIP.ThemostfamousdesigntoolforTRIP andTWIPalloysisthemethodinitially proposedbyMorinagaetal. [10],sometimescalled“BondOrdermethod”.Itconsistsinmapping al-loysasafunctionoftwocomposition-dependentelectronicparameters: thebondorderbetweenatoms(Bo)andthemetald-orbitallevel(Md). ThepositionoftheTi-alloysonthemapallowstoidentifytheir defor-mationbehaviour.Theoriginalmapin[10]isreproducedinFig.1a. Althoughthis approachhasprovenits effectivenessin designing nu-merousnewTRIP/TWIPcompositions[11–13], itdisplayssome lim-itations.Theso-called phasestabilitymaphasbeendetermined from existingsystems,butsomeTRIPorTWIPalloyslieoutsidethedrawn borders(seeFig.1b),sothatitislikelythatmanyothersexistin un-exploredcompositionranges.Oneaimofthisworkistoproposeanew approachtodesignalloysundergoingmartensitictransformationupon deformation.

Amodel combiningthermodynamics andmicromechanicsis pro-posedhere to describethe martensiteformation. It is assumed that

thenucleationofmartensiteduringquenchingisathermallyactivated process requiring an energy barrier to be overcome. An expression forthis barrierissuggested,leadingtothedefinitionofanucleation parameter that allowstopredict whethermartensitic transformation occursuponquenching.Consideringthatmartensitegrowthistheresult of a competitionbetween elasticstrain energyandchemicaldriving force,amartensitestabilisationtemperature(𝑀∗

𝑠),whichcorresponds

to the experimental Ms when the energy barrier can be overcome,

is calculated. Then,a criterion combining 𝑀∗

𝑠 and a new empirical

parameter([Fe]eq)isproposedtoidentifythecompositiondependence of TRIP, superelasticity or slip/twinning. This is the first approach capabletopredicttheoccurrenceandcompositiondependenceofsuch widerangeoftransformationanddeformationbehaviours.

2. Microstructureatroomtemperature

Inordertodesignalloysdisplayingtailoreddeformationbehaviour suchasTRIP,TWIP,superelasticityorshapememoryeffect,itisfirst re-quiredtopredicttheirmicrostructureatroomtemperature.Quenched titaniumalloyscanberoughlydividedintotwocategories.Firstly, al-loysthatformmartensiteuponquenching,andwhichmicrostructureat roomtemperature(priortodeformation)iseitherfullymartensiticor amixtureof martensiteand𝛽 phase.Themartensitecaneitherhave

anHCP structure,designatedas𝛼′,oranorthorhombiccrystal struc-ture,designatedas𝛼″[14].Thealloysofthiscategorywillhereonbe referredtoasmartensitic.Thesecondcategoryconsistsofalloysthat exhibitonly𝛽 phaseatroomtemperature.Theywillhereonbereferred

toas𝛽 alloys.ItisgenerallythoughtthatthelatterhaveanMsbelow

roomtemperature,butnoexperimentalevidencesupportsthis hypoth-esis:somemetastable𝛽 alloyshavebeenquencheddowntocryogenic temperaturesandstilldisplaynomartensite[15,16].Thepurposeofthis sectionistoproposeamethodtopredictwhetheranalloyis marten-siticafterquenching,andtocalculateMsifitismartensitic.Therangeof

factorsinfluencingthetransformationincludetheGibbsfreeenergy,the elasticenergy,thepresenceofmartensitenucleationsites,thegrainsize andthequenchrate.Theseareaccountedforinthetheorypresentedin thisandtheforthcomingsection.

2.1. Martensitestarttemperaturecalculation

2.1.1. Model

InordertoestimatetheMstemperature,thechangeinenergyΔG

associatedwiththemartensiteproduct,treatedhereasanellipsoidal inclusionin theBCC𝛽 phase, is computedasdescribed byWollants etal.[17].

Δ𝐺=2𝜋𝑟2𝛾 −4

3𝜋𝑟

2𝑐(Δ𝑔

𝑐ℎ−Δ𝑔𝑒𝑙) (1)

wherecisthesemithicknessofthemartensiteellipsoidalinclusion,ris itsradius,Δgch1isthevolumetricchemicaldrivingforce.Δ𝑔𝑐ℎ=𝑔𝛽−𝑔𝛼′

whereg𝛽 and𝑔𝛼′ arerespectivelytheGibbsfreeenergiesoftheBCC

andtheHCPphases.Thisquantityiscomputedemploying thermody-namicsoftware(Thermo-Calc®)and’TCTI1’thermodynamic titanium

database2,andbyassumingthatthefreeenergyoftheorthorhombic

phase𝛼″canbeapproximatedbythefreeenergyoftheHCPphase𝛼′

(discussedinSection5.3).Δgel isthevolumetricelasticstrainenergy

inducedbythepresenceoftheplate;𝛾 istheinterfacialenergyperunit areaofproductphase.Theinterfacialandelasticenergiesopposethe transformation.

Computationoftheelasticstrainenergy

Theeigenvaluesofthestraintensordescribingthetransformation fromtheBCCstructuretotheorthorhombicorHCPstructureare[14]:

𝜆1= 𝑎𝛼𝑖−𝑎𝛽 𝑎𝛽 (2) 𝜆2= 𝑏𝛼𝑖−√2𝑎𝛽 √ 2𝑎𝛽 (3)

1 Theconventionadoptedhereissuchthatthedrivingforceispositivewhen

thetransformationispromoted

2 Calculationswereperformedaswellwiththeconcurrentdatabase’TTTI3’

whichproducedsimilarresults.Anotherdatabasespecificto𝛽 titaniumalloys labelled’Ti-Gen’hasbeenproposedbyYanandOlson[18].Tovalidatethis database,theseauthorsshowedthattheycouldobtaingoodagreementbetween experimentalvaluesofMs,andvaluesofMsextractedfromTi-Gendatabase.

However,themodeltheyusedtocomputeMsincludedbothvaluesfromthe Ti-Gendatabaseandfittingparameters.Therefore,potentialinaccuracyinthe databasewouldbecorrectedbythefittingparameters,sothattheadequacyof Ti-GencanonlybeprovenintheframeofthisMsmodel.Assoonasother

equa-tionsareusedtocomputeMs,wethereforehavenoguaranteeoftheaccuracy

ofthedatabase.SincetheapproachusedhereisdifferentthanYan’sapproach, usingTi-Genhasnotbeenattempted.Inaddition,elementspresentineither TTTI3orTi-Genwouldallowtheirapplicationtoamuchreducednumberof alloysthanTCTI1.

𝜆3=

𝑐𝛼𝑖−√2𝑎𝛽 √

2𝑎𝛽

(4) wherea𝛽 isthelatticeparameteroftheBCCstructure,𝑎𝛼𝑖,𝑏𝛼𝑖 and𝑐𝛼𝑖 arethelatticeparametersofthemartensiticphase,where𝛼idesignates 𝛼′ifthemartensiteisHCPand𝛼″ifitisorthorhombic.Theexpression forthelatticeparametersasafunctionof compositioncanbe found intheliteratureforbinaryalloys,andtheelementalcontributionsare assumedtobeadditive.Theexpressionsemployedforlatticeparameters calculationareprovidedinAppendixB.

Theelasticstrainenergyiscomputedbyconsideringanellipsoidal martensiteplateinaninfinitehomogeneousisotropicelasticmedium. Themartensiteisconsideredtobeelasticallyisotropic.Thestraintensor isdividedintoitsdeviatoricandhydrostaticcomponents,assuggested byOlsonandCohen[19],sothattheelasticstrainenergyΔgelcanbe

dividedintoatransformationvolume-changeterm(Δ𝑔𝑒𝑙𝑑𝑖𝑙)anda shape-changeterm(Δ𝑔𝑠ℎ𝑎𝑝𝑒𝑒𝑙 ),withΔ𝑔𝑒𝑙=Δ𝑔𝑒𝑙𝑑𝑖𝑙+Δ𝑔𝑠ℎ𝑎𝑝𝑒𝑒𝑙 .

Thevolumechange isapproximated byapuredilatationandthe associatedelasticenergyiscomputedasdescribedbyEshelby[20]: Δ𝑔𝑑𝑖𝑙𝑒𝑙(𝑇)=2 9 (1+𝜈) (1−𝜈)⋅ 𝜇(𝑇)⋅ (Δ𝑉 𝑉 )2 (5) where𝜈 isthe Poisson’sratio,taken hereas equalto 13,𝜇(T) is the shear modulusattemperatureT, computedasdescribed by Galindo-Nava[21]:

𝜇(𝑇)=𝜇𝑅𝑇(𝑘1+𝑘2𝑇) (6)

where𝜇RTisthecomposition-dependentshearmodulusatroom

tem-perature(RT),obtained byamixture rule,Tis theabsolute temper-ature,k1 andk2 arethefittedconstants describedin [21]andyield

𝑘1=1+192(1+.63689𝜈) and𝑘2=−02(1+.07193𝜈). Δ𝑉

𝑉 istherelativechangeinvolumeaccompanyingthe

transforma-tion: Δ𝑉 𝑉 = (1 3(𝜆1+𝜆2+𝜆3)+1 )3 −1 (7)

Theshapechangeisapproximatedbyapureshearandiscomputed asdescribedbyEshelby[20]: Δ𝑔𝑠ℎ𝑎𝑝𝑒𝑒𝑙 (𝑇)=𝜇(𝑇)⋅ 𝜋 2 (2−𝜈) (1−𝜈)⋅ 𝜖 2⋅ 𝑐 𝑟 =𝐾(𝑇)𝑐𝑟 (8)

K(T)isintroducedinEq.(8)toshortenthenotation,𝜖 istheshear com-ponentofthestrainassociatedwiththephasetransformation[19]and iscompositiondependentviathelatticeparameters:

𝜖 = √ 1 6 ( (𝜖1−𝜖2)2+(𝜖2−𝜖3)2+(𝜖3−𝜖1)2 ) (9) where𝜖1,𝜖2and𝜖3aretheeigenvaluesofthedeviatoriccomponentof

thestraintensor(𝜖𝑖=𝜆𝑖−31(𝜆1+𝜆2+𝜆3))

ComputationofMs Bycombining(1),(5)and(8): Δ𝐺(𝑇)=2𝜋𝑟2𝛾 −4 3𝜋𝑐𝑟 2(Δ𝑔 𝑐ℎ(𝑇)−Δ𝑔𝑑𝑖𝑙𝑒𝑙(𝑇) ) +4 3𝜋𝑐 2𝑟𝐾(𝑇) (10)

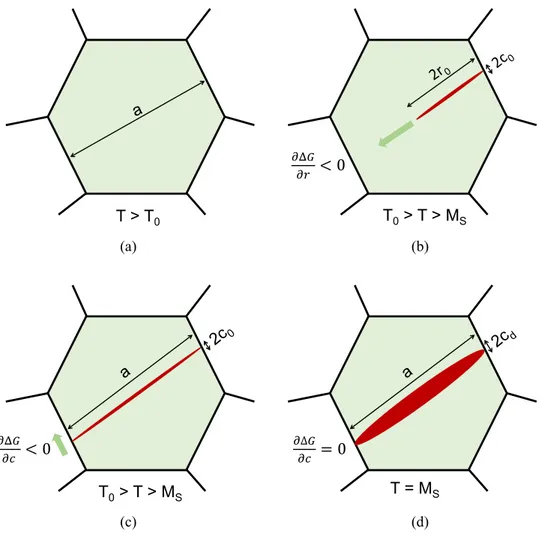

Above T0, nucleationcannotoccurandthe alloyonly displays𝛽

phase(Fig.2a).Thenucleationofaproductembryoofsemi-thickness

c0andradiusr0occursbelowthetemperatureatwhichtheHCPand

BCCGibbsfreeenergiesareequal(T0).Then,asexplainedbyWollants

et al.[17], whenthe temperatureis suchthat 𝜕Δ𝐺𝜕𝑟 <0, theembryo growsradially(increaseofr,Fig.2b), untilitisblocked byastrong obstacle (e.g. a grain boundary) andreaches aradius a/2, wherea

isthesizeoftheparentgrain(Fig.2b).Fromthatpoint,theparticle continuestothickeninthedirectionnormaltotheplateplane(increase ofthesemi-thicknessc),untilitreachesastatesuchthatthegrowth does not allow thesystem to further reduce its energyand a local equilibriumisreachedattheinterfacebetweentheparentandproduct

Fig.2. Martensitenucleationandgrowth.(a) BCC𝛽 phaseatatemperatureaboveT0(b)A

martensiteembryonucleatesandstarts grow-ingradially(c)Radialgrowthisstoppedbya grainboundaryandthethickeningstarts.(d)A localthermoelasticequilibriumisreachedand thethickeningstops.Furthercoolingis neces-saryforthethickeningtocontinue.

phases (Fig. 2d).The condition for such anequilibrium is: 𝜕Δ𝐺

𝜕𝑐 =0

[17]. When a product plate is formed from an existing defect, this conditionisobtainedbyderivatingEq.(10):

Δ𝑔𝑐ℎ−Δ𝑔𝑑𝑖𝑙𝑒𝑙 −2𝐾𝑐

𝑟=0 (11)

Letuslabelcdtheminimaldetectablesemi-thicknessfora marten-siteplate.Thisdetectablesemi-thicknessissetto50nm;thisroughly matchestheusualminimalthicknessthatisexperimentallyreported3.

Then,ifaisthegrainsize,wedefinethemartensitestabilisation tem-perature𝑀∗

𝑠 asthetemperatureatwhichaplateofmartensitereaches

adetectablesize:

Δ𝑔𝑐ℎ(𝑀𝑠∗)−Δ𝑔𝑒𝑙𝑑𝑖𝑙(𝑀𝑠∗)−2𝐾(𝑀𝑠∗) 𝑐𝑑

𝑎∕2 =0 (12)

Anyfurthercoolingleadstofurtherthickening,untilthemartensite finishtemperatureisreached(Mf)andthetransformationiscomplete.

Themartensitestabilisationtemperature𝑀∗

𝑠 isdefinedasthehighest

temperatureatwhichmartensitecanreasonablyexperimentallybe ob-servedifnucleationhashappened,andshouldthereforebeveryclose fromtheexperimentalmartensitestarttemperature.

3 For example,Gao etal. investigatedthe deformed microstructure of a

TWIP/TRIPtitaniumalloyatdifferentstrainlevels[12];fortheloweststrain atwhichmartensiteplateswereobserved,theywereapproximately100nm thick(50nmsemi-thickness).Verydetailedmicrostructuralinvestigationwas alsoperformedbyZhangetal.inaTRIP/TWIPalloy;theyreportedthepresence of30–150nmthickmartensiteplates[22].Itthereforeseemsreasonableto as-sumethatinthegeneralcase,thepresenceofafewplatesofmartensiteless than100nmthickmightgounnoticed,whichjustifiesthechosendetectable limit.

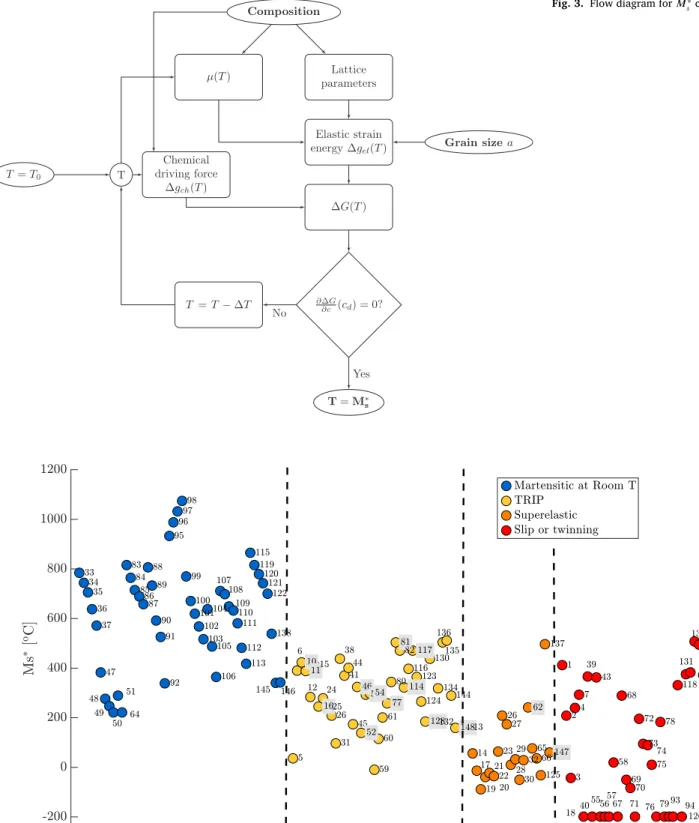

𝑀∗

𝑠isobtainedbyiterativelycomputingthequantityonthelefthand

sideofEq.(12)fordifferenttemperatures.Sincetheelasticstrainenergy dependsonthestructureofthemartensite(𝛼″or𝛼′),𝑀∗

𝑠 iscalculated

twiceforeachcomposition,byassumingbothanHCPmartensiteand anorthorhombicmartensite(seeAppendixB).Theretained𝑀∗

𝑠 isthe

highestofboth.AflowdiagramforthiscalculationisshowninFig.3. Themartensitetemperaturecalculatedhereistakentobethatat which a plate of martensite reaches a detectable size. The compu-tation of 𝑀∗

𝑠 is thus based on a criterion regarding the growth of

themartensiteandnotitsnucleation.Indeed,theequationsdescribed above arevalidforanexistingmartensiteplate.𝑀∗

𝑠 iscomputedby

assuming that the nucleationhasalready taken place ata tempera-turesomewhereinbetween𝑀∗

𝑠 andT0.Thislastpointisdevelopedin

Section2.2.

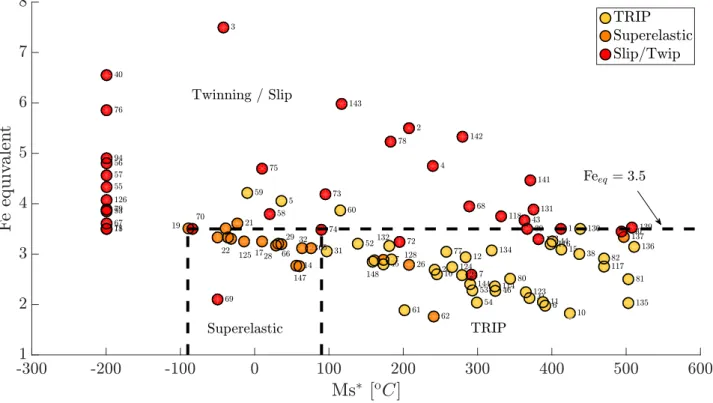

Themethoddescribedabovehasbeenappliedtocalculatethe𝑀∗

𝑠

temperatureofalloysfromliterature.Sincethecalculationdependson the grain sizea, which is not alwaysreported, anaverage valueof 100𝜇mhasbeenassumedforallalloys(thegrainsizedependencywill bediscussedinSection5.3).Fig.4showsthecalculated𝑀∗

𝑠 for

differ-entalloystogetherwiththeirtypeofbehaviourduringplastic deforma-tion.ReferringtoFig.4,whenthe𝑀∗

𝑠 isapproximatelybelow−100°C,

martensiteisnotreported,neitheruponquenchingnortheapplication ofanexternalstress.Thealloysforwhichthe𝑀∗

𝑠 isaroundorjust

be-lowroomtemperaturearemostlysuperelastic.Forthesealloys,whenan externalstressisapplied,thedrivingforcenecessaryforthemartensitic transformationissuppliedbytheexternalwork,butwhenthestress isremoved, themartensiteisnolongerstableandreversesbackto𝛽

phase.TRIPalloysentirelyretainthe𝛽 phasefollowingquenching,but the𝑀∗

𝑠 formostofthemliesintherange100–300°C.Nevertheless,the

calculationof𝑀∗

Fig.3. Flowdiagramfor𝑀∗

𝑠 calculation.

Fig.4. Calculated𝑀∗

𝑠 foralloysgroupedasmartensiticatroomtemperature,TRIP,superelasticorslip/twinning(fromlefttoright,thedottedlinesseparatethe

differenttypesofbehaviour).Thehorizontalaxisisonlytospreadthealloysinthepanel.ThealloyswhichnumberiswritteninagreybackgrounddisplayTRIP, buthavealsobeenseenmartensiticundercertainexperimentalconditions.Whenthecalculationsindicatedthattherewasnotemperatureforwhichmartensiteis thermomecanicallymorestablethan𝛽,the𝑀∗

𝑠 hasbeensetto−200°.ThenumbercodeforeachcompositionisshowninAppendixA. TRIPalloys,whenanexternalstressisapplied,themartensitic

trans-formationisinducedanddoesnotreversewhentheloadisreleased, whichmeansthatthemartensiteis probablystableat room temper-atureandthatitcannotbeassumedthatMsliesbelowroom

tempera-ture.Themodelrightlypredictsthatmartensiteshouldbestableatroom temperature.

In the case of TRIP alloys, it may seem paradoxical that the calculated 𝑀∗

𝑠 liesabove room temperaturewhen the experimental

evidenceshowsthatnomartensiteformsuponquenching.Thereason forthisisthatthe𝑀∗

𝑠 computationimplicitlyconsidersthatmartensite

nucleationhasalready taken placewhenthe𝑀∗

𝑠 is reached.It may

Fig.5. Calculated𝑀∗

𝑠 andexperimentalvaluesforMsobtaineduponquenching.ThenumbercodeforeachcompositionisshowninAppendixA.

quenching, andthatat roomtemperaturetheexternalwork triggers nucleation.Oncethemartensitehasnucleatedduetoexternalwork,the growthcan athermallystart.Asaconsequence,itseemsnecessaryto haveatoolthatallowstopredictifthenucleationofmartensiteislikely tooccuruponquenching,orifthenucleationrequiresexternalwork.

Fig.5showsacomparisonbetweenthecalculated𝑀∗

𝑠 andthe

ex-perimentalMs,whenthisexperimentalMs ismeasuredduringcooling

andthetransformationoccursintheabsenceofexternalstress.Some martensiticalloysappearinFig.4butnotinFig.5,thesecompositions areknowntobemartensiticafterquenchingbutnoinformationwas foundregardingtheirMs.

2.2. Martensitenucleationuponquenching

TRIPalloysdisplay𝛽 microstructureafterquenching,eventhough

𝑀∗

𝑠computationindicatesthatmartensiteshouldbestableatroom

tem-perature(seeFig.4).Thecompetitionbetweenmartensiteand𝜔phase isaplausiblehypothesistoexplaintheabsenceofmartensite[18]. Al-though𝜔formationduringcoolingmayplayaroleinmartensite in-hibition,thermodynamiccalculationssuggestthatitisnotnecessaryto invoke𝜔phaseformationtoexplainthestabilisationof𝛽 phaseatroom temperature,aswillbediscussedinSection5.2.Thepurposeofthis sec-tionistoproposeanexplanationforthestabilisationofthe𝛽 phaseat roomtemperature,andamethodtoquantifyit.

2.2.1. Model

OlsonandCohen[23]haveshownthatthefirststepofthetransition fromtheBCCtoHCPphasecanberationalisedasthedissociationofa

1

2[111]screwdislocationona(1̄10)planeintothreepartialsaccordingto

thereaction12[111]=1

8[110]+ 1 4[112]+

1

8[110][24].Assumingthatthe

latticeopposestheglideofthedissociatingpartials,anenergybarrier mustbeovercomeforthedislocationtosplitintopartials(corresponding toahighenergytransitionstatebetweenBCCandHCP,ortotheenergy necessaryforthefirststepsofthedissociationofaperfectdislocation intopartials).Thisenergybarriercould,forexample,besimilartoa Peierlsbarrier(asitrepresentsanoppositiontotheglideofapartial dislocation),andthus,iftheenergybarrierperdislocationis labeled

E∗,itcouldhaveaformsuchas[25]:

𝐸∗(𝑇)=𝜒𝑏3𝜇(𝑇) (13)

where𝜒 isaconstantindependentfromcomposition,bisthemagnitude oftheBurgersvectorofthescrewdislocation,calculatedas𝑏=1

2

√ 3𝑎𝛽. Thisenergybarrierisassumedtobeovercomebythermalfluctuations. Foracharacteristicdislocationvibrationoffrequencyf0,theenergy bar-rierissuccessfullyovercomeataratef[25]:

𝑓(𝑇)=𝑓0⋅ exp(−𝐸∗(𝑇)∕(𝑘𝑇)) (14)

wherekistheBoltzmannconstant.Thenucleationrateofmartensiteis expressedas:

𝑑𝑁

𝑑𝑡 =𝑁0⋅ 𝑓(𝑇)=𝑁0⋅ 𝑓0⋅ exp(−𝐸∗(𝑇)∕(𝑘𝑇)) (15)

whereN0isthenumberdensityofpotentialnucleationsites.Ifthe cool-ingoccursatacoolingrate𝑄=−𝑑𝑇𝑑𝑡,fromEq.(16)comes:

𝑑𝑁 𝑑𝑇 =− 𝑁0 𝑄 ⋅ 𝑓(𝑇)=− 𝑁0 𝑄 ⋅ 𝑓0⋅ exp(−𝐸∗(𝑇)∕(𝑘𝑇)) (16)

BydividingthecoolingprocessinelementaryΔTtemperaturesteps, thenumberofembryosthatnucleateateachstepyields:

Δ𝑁(𝑇)=||||𝑑𝑁

𝑑𝑇Δ𝑇||||=

𝑁0⋅ |Δ𝑇|

𝑄 ⋅ 𝑓(𝑇) (17)

ThenucleationofmartensiteisassumedtostartaroundT0asthe maximumtemperatureatwhichamartensiticembryocanpotentially form,anditisthereforethetemperatureatwhichthethermalenergy fornucleationismaximumandtheenergybarrierisminimum(the bar-rierisproportionaltotheshearmoduluswhichlinearlydecreaseswith temperature).SincethereisnomartensitenucleusaboveT0,thenumber

densityN(T0)ofmartensiteembryosnucleatingduringthefirststepof

thetransformationcanbeapproximatedby(𝑑𝑁

𝑑𝑇

)

𝑇0

⋅ Δ𝑇.Thus, accord-ingtoEqs.(14)and(17):

Fig.6. Nucleationparameter,calculatedforalloysfromtheliterature.Thehorizontallineisthethresholdthatisfoundtoseparatethemartensiticalloysfromthe

𝛽 alloys.Thehorizontalaxisisonlytospreadthealloysinthechart.Thealloysreferredtoas“martensiticor𝛽” aretheonesthathavebeenreportedmartensiticor

𝛽 dependingontheexperimentalconditions.ThenumbercodeforeachcompositionisshowninAppendixA.

𝑁(𝑇0)=

𝑄0

𝑄 ⋅ 𝑁0⋅ exp(−𝐸∗(𝑇0)∕(𝑘𝑇0)) (18)

where𝑄0=|Δ𝑇| ⋅ 𝑓0

Thenumberofmartensitenucleiappearingatanylowertemperature intervalisassumedtoscalewiththenumberdensityofnucleiatT0,so

thatthetotalnumberofnucleishouldberoughlyproportionaltoN(T0).

Therefore,thereshould exista criticalnumberdensityof martensite nucleiNm,suchthatnucleationcanbeconsideredasoccurringonlyif N(T0)>Nm.FromEqs.(13)and(18),theconditionforthemartensite

nucleationuponquenchingis:

𝑘𝑇0 𝜇(𝑇0)𝑏3 > 𝜒 ln(𝑁0 𝑁𝑚 𝑄0 𝑄) (19)

OnthelefthandsideofInequation(19),thetermkT0istheavailable

thermalenergyfornucleationatthefirststagesoftransformationand theterm𝜇(T0)b3isproportionaltotheenergybarrierfornucleation.The

term 𝑘𝑇0

𝜇(𝑇0)𝑏3thereforescaleswiththeratiobetweenanavailablethermal

energyandarequiredenergyfornucleation;itwillhereonbereferredto as“nucleationparameter”.Thenucleationparameterstronglydepends oncomposition,throughthepartitionlessequilibriumtemperatureT0

between𝛽 and𝛼′,comingfromThermo-Calc®,andthroughtheshear

modulus.Inequation(19)indicatesthatmartensitecannucleateduring coolingonlyifthenucleationparameterexceedsacertainvalue,which willbereferredtohereonas“criticalnucleationparameter”.Thiscritical nucleationparameterdepends onthecoolingratebutiscomposition independent.Byseparatingthealloysfromtheliteratureintotwogroups (martensiticand𝛽),andcomputingforeachofthemthevalueofthe nucleationparameter,thevalueofthecriticalnucleationparametercan thuseasilybefitted.

2.2.2. Applicationtoalloysfromliterature

Thenucleationparameteriscomputedfordifferentalloysfromthe literature asshown in Fig.6, whereitis clearthat acritical nucle-ationparametersetas[ln(𝑁0

𝑁𝑚

𝑄0

𝑄)]−1⋅ 𝜒 =1.24⋅ 10−2allowstoseparate

martensiticfrom𝛽 alloys.Thisvalueisassumedtobevalidfora con-ventionalcoolingrate.Thenucleationparameterisalsocalculatedfor

Fig.7.Calculationofthenucleationparameterforbinarysystems.Thedotted lineshowsthethresholdexpectedtodelimitatethemartensiticalloysfromthe

𝛽 alloysafterquenching.

binarysystems,andshowninFig.7.Theblackdottedlineshowsthe limittoretain𝛽 atroomtemperature.Inordertocomparethiswith theavailableexperimentaldata,thecriticalcompositionsnecessaryto retain𝛽 atroomtemperatureareextractedfromtheliteratureand gath-eredinTable1.Thethresholdof1.24⋅ 10−2isalsousedtocalculate,

foreachbinarysystem,thecriticalcompositionnecessarytoretain𝛽 at roomtemperature.Thesecalculatedvaluesareplottedasafunctionof experimentaldatafromTable1inFig.8.

3. IdentifyingTRIP,superelasticandslip/TWIPalloys

Thissectionproposes parameterstoidentifyTRIP,superelasticity, andalloysdeformingbydislocationsliportwinning.Inthiswork,TRIP effectisdefinedastheformationofmartensiteupondeformation

with-Fig.8. Calculationofthecriticalconcentrationtoretain𝛽 uponquenchingfor differentbinarysystemsasafunctionoftheexperimentaldata.Thehorizontal linesrepresenttheexperimentalrangesofcriticalcompositionsfoundinthe literature,whichreferencesareshowninTable1.Thedottedlineisshownfor reference.

Table1

Criticalcompositionsnecessarytoretain𝛽 phaseuponquenchinginbinary al-loys,extractedfromtheliterature.

Element Minimum concentration necessary to retain 𝛽 upon quenching in wt % Fe 3.5 [26] , 5.8 [27] , between 3.08 and 4.07 [28] Cr 6.5 [26] , 7.6 [27] , between 5.4 and 6.5 [28] Mo 10 [26] , 9.5 [27] V 15 [26] , 15.8 [27] , about 15 [28] W 22.5 [26] , 30 [27] , between 20 and 25 [28]

Nb 29 [29] (high quenching rate) 36 [27]

Ta 45 [26] , 68 [27]

outreversionto𝛽 uponunloading,whereas thealloysreferredtoas superelasticaretheonesinwhichthemartensitethatformsupon de-formationreversesuponunloading.Sofar,no solutionwas foundto predicttwinningoccurrence,so thealloysreferredtoas“TRIP” may alsodisplaytwinning,asoftenobservedexperimentally.Alloysreferred toas“sliportwinning” mayormaynotdisplayTWIPbutdonotdisplay martensitictransformation.

IdentifyingslipandTWIPalloys

Inthepresentsection,wefocusonalloysthatarefully𝛽 atroom tem-perature.Astheconcentrationin𝛽 stabilisersincreases,thedeformation behaviourgenerallyswitchesfromstress-inducedmartensite(TRIPor superelasticity),toTWIPordislocationslip.Thistransitioncannotbe explainedsolelybythevalueof𝑀∗

𝑠(Fig.4).Itisassumedthat,forsuch

alloysthecriticalstressfortriggeringthenucleationof martensiteis toogreatandthattwinningordislocationglideisenergeticallymore favourable.Thecriticalstresstotriggermartensite,dislocationglideor twinningcouldnotbeassessedinthepresentwork.Anempirical cri-terionisinsteadproposed;inspiredbutdifferingfromthe[Mo]eq.The

[Mo]eqhadbeenbuiltthankstoexperimentaldataonbinaryalloysin

order topredict thetendencyofanalloytoretainthe𝛽 phaseupon

quenching.TheproposedFeequivalent([Fe]eq)criterionistailoredto

experimentaldatainorder todescribethetendencytoretain𝛽 upon

deformation.

ThesuggestedcriterionusesFeasareferenceelementbecauseithas thestrongeststabilizingeffectonthe𝛽 phase.Theproposed “[Fe]eq”

criterionisobtainedinthefollowingway:thecoefficienttoeachterm inEq.(20)isobtainedbydividingthecriticalconcentrationofFe

nec-Table2

Criticalcompositionsnecessarytoretainthe𝛽 phaseupondeformationinbinary alloys,calculatedandextrapolatedfromdataavailableintheliterature.

Element Adopted limit wt.% composition for SIM

Alloys used as references

Fe 3.5 Ti–10Mo, Ti–10Mo–1Fe [30]

Cr 9 Ti–10Cr [31]

Mo 14 Ti–13Mo [32] , Ti–14Mo [33]

V 20 Ti–16V [32] , Ti–20V [34]

W 25

Sn 27 Ti–3Mo–6Sn–8Zr at%, Ti–3Mo–6.5Sn–8Zr at%

[35]

Nb 43 Ti–40Nb, Ti–43Nb [36]

Ta 75 Ti–72Ta [37]

Zr 90 Ti–3Mo–7Sn–4Zr at%, Ti–3Mo–7Sn–5Zr at% [35]

Al − 18 Ti–15–Mo–5Zr, Ti–15Mo–5Zr–3Al [34]

essarytoretain𝛽 underdeformationintheTi–Fesystembythecritical concentrationnecessarytoretain𝛽 underdeformationinthegiven bi-narysystem.Whenthiscriticalcompositionwasnotfoundinthe litera-ture,ithasbeenextrapolatedfrommulticomponentalloys.Inthecaseof CrandFebinarysystems,nocompositionhasbeenreportedtodisplay TRIP;therefore,itisassumedthat,forthesestrong𝛽 stabilisers,the crit-icalconcentrationtoretain𝛽 upondeformationisverycloseto,orlower thanthecriticalcompositiontoretain𝛽 atRT.Thecriticalcompositions consideredforthe[Fe]eqexpressionaregatheredinTable2,together

withthecompositionsthatwereusedtodeterminetheirvalues.Sincein thecaseoftheTi–Fesystem,thecriticalconcentrationnecessaryto

re-tain𝛽 upondeformationhasbeenevaluatedto[Fe]=3.5wt%(Table2),

thecompositionssuchthatthe[Fe]eqexceeds3.5%areexpectedto

in-hibitthemartensitictransformationunderdeformation.Theassessment ofthiscriteriononmulticomponentalloyswillbepresentedlater.

[ Fe ] 𝑒𝑞 = 3 . 5 ⋅ ( [ Fe ] 3 . 5 + [ Cr ] 9 + [ Mo] 14 + [ V ] 20+ [ W ] 25 + [ Sn ] 27 + [ Nb ] 43 + [ Ta ] 75 + [ Zr ] 90 − [ Al ] 18 ) ( wt% ) (20)

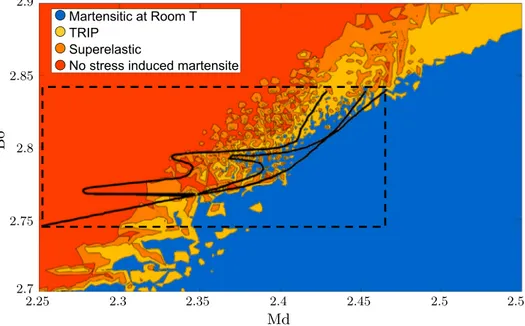

IdentifyingTRIPandsuperelasticalloys

Whenmartensitetransformationisinducedbyanexternalwork,the productphasecaneitherremainorreverseto𝛽 afterunloading.The firstcasecorrespondstoTRIPalloys,thesecondtosuperelasticalloys. Oncethealloysthatcannotformmartensiteunderstressareidentified viaan[Fe]eqbelow3.5wt%,the𝑀𝑠∗computationcanseparate

supere-lasticfromTRIPalloys(Fig.9).Ifthe𝑀∗

𝑠 exceeds90°C,itislikelythat

themartensitereversetemperatureis aboveroomtemperature; once thenucleationistriggeredbyanexternalwork,martensiteisexpected toformandtoremainafterunloading.Thus,thesealloysareexpected todisplayTRIP.If−90°C < 𝑀∗

𝑠 < 90°C,theenergyprovidedbythe

external stressmayenablethegrowthof themartensite,butits sta-bilityatroomtemperatureisnotsufficienttoremainoncetheloadis removed.Thus,thealloyswith−90°C<𝑀∗

𝑠 <90°Careexpectedto

dis-playsuperelasticity.If𝑀𝑠<−90°C,itisunlikelythattheexternalstress

providesenoughworkforthemartensitetogrow.Thus,thealloyswith

𝑀∗

𝑠 <−90°Careexpectedtodisplaysliportwinningonly.Therefore,

combinedwiththe[Fe]eqcriterion,the𝑀∗

𝑠calculationallowstopredict

thetypeofdeformationbehaviourof𝛽 alloys.

Regionsin𝑀∗

𝑠 -[Fe]eqspaceidentifyingsystemsundergoingslipor

twinning,TRIPorsuperelasticityeffectsareshowninFig.9

4. Criteriafortailoreddeformationbehaviour

Thecriteriadescribedabovecanbecombinedtopredictifa com-positionislikelytodisplaymartensiteuponquenching,superelasticity, TRIPorSlip/TWIPeffect.Thepredictionprocedureissummed upin Fig.10.

Fig.9. Mapofthealloysfromtheliterature.Thethreeregionscorrespondingtotheindicateddeformationbehaviourareoutlinedbytheblackdottedlines.The coloursofthebulletscorrespondtotheexperimentallyobservedbehaviour.Whenthecalculationsindicatedthattherewasnotemperatureforwhichmartensiteis thermomecanicallymorestablethan𝛽,the𝑀∗

𝑠 hasbeensetto−200°.ThenumbercodeforeachcompositionisshowninAppendixA.(Forinterpretationofthe

referencestocolourinthisfigurelegend,thereaderisreferredtothewebversionofthisarticle.)

Fig.10. Suggestedproceduretopredictthebehaviouroftitaniumalloysas afunctionoftheircomposition;thevalueof𝑀∗

𝑠 istheonethatiscalculated

accordingtotheproceduredescribedinthisarticle

Theperformanceofthemodelindiscriminatingthemicrostructure atroomtemperatureisdisplayedinFig.6,andtheperformancein iden-tifyingthedeformationbehaviourof𝛽 alloysisshowninFig.9.

5. Discussion

5.1. Thermallyactivatedmartensitenucleation

Toexplainwhysomecompositionsretain𝛽 atroomtemperature, theassumptionofathermallyactivatednucleationprocessseemstobe supportedbyexperimentaldata.Jepsonetal.havedemonstratedthat martensitictransformationcanbeinhibitedinTi–Nballoysby quench-ingatextremelyhighcoolingrates[29].Theirobservationsare consis-tentwithathermallyactivatednucleationmechanism;thehigherthe coolingrate,thelesstimeisspentatT0andtheloweristhedensity

numberofmartensitenuclei(Eq.(18)).Thisdependencyonthecooling rateisexpressedinEq.(19).Foragivencomposition,thenucleation parameter isconstantbutthecriticalvaluefornucleationparameter increaseswiththequenchingrate,whichsuggeststhatthemartensitic transformationcanbeinhibiteduponquenchingifthecoolingrateis highenough;thisisconsistentwithJepson’sexperimentalwork[29]. Ontheotherhand,iftheenergybarriertomartensitenucleationistoo high,itmaybethatthemaximalquenchingratethatallowsmartensite nucleationisverylow.Ifitistoolow,diffusioncanoccurduring cool-ing,insuchawaythatnoquenchingrateallowsmartensiteformation uponquenching.

Moreover,thecommonstatementaccordingtowhich𝛽 alloyshave anMsbelowroomtemperatureisnotinagreementwithexperimental

observations.Forexample,theformationofmartensiteinTi–10V–2Fe– 3AlwasinvestigatedbyDuerigetal.[16]onsixspecimensofthesame composition.Afterquenching,onesampleshowedevidenceof marten-sitictransformationandthefiveothersexhibiteda𝛽 microstructureat roomtemperature.These𝛽 alloyswerecooleddownto−170∘Candstill

ofaround200MPainducedmartensitetransformationthatdidnot re-verseto𝛽 afterunloading.Thedeformedspecimenswerethenheated andthemartensitewasfoundtoreverseto𝛽 around200∘C.The

vari-abilityofthemicrostructureatroomtemperaturebetweenthe differ-entspecimens(𝛽 ormartensite)forthiscompositionisconsistentwith theproposednucleationparametercriterion;indeed,forthis composi-tion,𝑘𝑇0∕[𝜇(𝑇0)𝑏3]=1.31⋅ 10−2liesveryclosetothecriticalthresholdof

1.24⋅ 10−2.Then,iftheM

stemperaturewasactuallybelowroom

tem-perature,itwouldhavetoliebelow−170∘C.Themartensitereverse

temperaturehasbeenshownbyexperimenttobearound200∘C,and

anMsbelow−170∘Cwouldimplyahysteresisofmorethan300∘C

be-tweenthedirectandreversemartensitetransformation.Thisisunlikely, sincethehysteresisformartensitetransformationintitaniumalloys typ-icallyliesaround10∘Cwhenitcanbe measured.Otherexperiments

performedonTRIPalloysshowthatthemartensiteformedduring de-formationreversesto𝛽 attemperaturesexceedingroomtemperatureby morethan100∘C[38,39].Moreover,isothermalformationof

marten-sitethatdoesnotinvolveanydiffusionhasbeenobservedinatleast threedifferenttitaniumalloys[40,41].Forthesethreecases,the tem-peratureatwhichmartensiteisothermallyformedisbeloworaround thecalculatedmartensitestabilizationtemperature𝑀∗

𝑠.Thissupports

thestatementthatmartensiteformationin titaniumalloysisa diffu-sionlessthermallyactivatedprocess.Therefore,thehypothesisthatthe martensitestabilisationtemperature𝑀∗

𝑠 liesaboveroomtemperature

forTRIPalloys,andthatmartensitenucleationrequiresexternalstress, whilegrowthoccursmainlyathermally,seemstobeconsistentwith ex-perimentalevidence.Theexistenceofsuchatransformation,wherethe nucleationisthermallyactivatedbutthegrowthisathermal,hasbeen reportedbyLaughlinetal.[42],whereitisdesignatedasanisothermal. Cottrellalsosupportstheideathatmartensitenucleationisthermally activated[43].

Moreover, this statement allows to explainthe difference of be-haviourbetweensuperelasticandTRIPalloys.Itissometimesbelieved thatthedifferencebetweenTRIPalloysandsuperelasticalloysliesin thefactthatmartensiteissomehowstabilizedbyplasticdeformation (or“stressinduced”)inTRIPalloyswhereassuperelasticityisobserved whenmartensiteformationoccursbeforeplasticdeformation(“strain induced”).However,inTRIPalloys,martensitesometimesformsunder stressbeforeplasticdeformationoccurs,asshownbythe characteris-ticdouble yieldingonthestress–strain curve[44],andstillremains uponunloading.Thismeansthatplasticdeformationisnotnecessary tostabilisethedeformationinducedmartensite.Conversely,a signifi-cantpartofthemartensitethatformsupondeformationin superelas-ticalloysreverseseveninheavilyplasticallydeformedsamples[45], whichmeansthatplasticdeformationaloneisnotsufficienttoexplain thestabilisationofdeformationinducedmartensiteinthecaseofTRIP alloys.Therefore,theconcomitancebetweenplasticdeformationand martensiteformationisnotnecessarytoexplaintheoccurrenceofTRIP effect.Ontheotherhand,thermodynamiccriteria(via𝑀∗

𝑠 calculation)

allowtoseparatesuperelasticfromTRIPalloys.Inbothcases,external worktriggersmartensitenucleationatroomtemperature.For supere-lasticalloys,𝑀∗

𝑠liesaroundroomtemperatureandMfliesbelowroom

temperature;themartensiteisunstableatroomtemperature,which ex-plainsthereversionto𝛽 phaseuponunloading.ForTRIPalloys,𝑀∗

𝑠 is

faraboveroomtemperature,martensiteismorestablethan𝛽 phaseat roomtemperature,andoncethetransformationistriggered,mostofit remainsandisunabletoreverseto𝛽 uponunloading.

5.2. Roleofthe𝜔phase

Thestabilisationof𝛽 phaseisoftenattributedtoathermal𝜔phase [18,46],whichformationduringquenchingwouldoccuraboveMsand

inhibit the martensitic transformation [18]. Assuming that 𝜔 phase formsattemperaturesaboveoraroundMsduringcooling,itwould

in-deedbelikelythatmartensiteformationisinhibited,duetoa competi-tionbetweenbothphases[46].However,theideathat𝜔phase

system-aticallyformsaboveMsinalloysthatretain𝛽 phaseuponquenching

isnotsupportedbythermodynamiccalculations.Thethermodynamic database‘TCTI1’ofThermo-Calc®hasbeenusedtocompute,foralloys

fromliterature,thetemperature𝑇𝜔

0 atwhich𝜔phaseand𝛽 phase

ex-hibitthesamefreeenergy.𝑇𝜔

0 isexpectedtobethehighesttemperature

atwhich𝜔transformationcanpossiblyoccuruponquenching.Formost alloysexperimentallyknowntoretain𝛽 phaseatroomtemperature,the computed𝑇0𝜔waslowerthanthecalculated𝑀∗

𝑠.Thissuggeststhatthe 𝜔phasenucleatesbelowthetemperatureatwhichmartensiteshould haveformed,andthattheabsenceofmartensitecannotbeattributed tothepriorpresenceof𝜔.Moreover,ithasbeenshownthatmartensite and𝜔phasecancoexistatroomtemperatureafterquenching,andthat the𝜔particlescouldtransformto𝛽 upondeformation,beforefurther transformingintomartensite[47];implyingthatthepresenceof𝜔isnot necessarilyanobstacletomartensiteformation.Therefore,althoughit certainlyplaysaroleinthedeformationbehaviouroftitaniumalloys,it seemsthatthecompetitionbetween𝜔andmartensiteisnotnecessaryto explaintheretentionof𝛽 atroomtemperature.Thenucleation parame-terproposedinthiswork,ontheotherhand,suggestsanexplanationfor

𝛽 retention,quantitativelysupportedbycalculationsandqualitatively

consistentwithexperimentalevidence.

5.3. Msprediction

The martensite stabilisation temperature 𝑀∗

𝑠, which is the

high-esttemperatureatwhichmartensiteis observedifnucleationis pos-sible,showsgoodagreementwithexperimentalmeasurementsof Ms,

as can be seen in Fig. 5. However, it should be noted that among the54compositionsthataredisplayedinFig.5,43correspondto bi-naryalloysand11tomulticomponentalloys,becauselimited informa-tionisavailableontheMs ofquenchedmulticomponentalloys4. The

modelforthe𝑀∗

𝑠 temperaturedoesnotworkwellforalloys

contain-ingasignificantconcentrationoftin(Fig.5).Thereasonforthisisnot clear.OtherMsmodelsthatincludetinalsohaddifficultieswithsuch

alloys([18]).

Inbinarysystems,themartensitegenerallyhasanHCPstructure un-tilacriticalcompositionatwhichthetransitiontoorthorhombic struc-tureoccurs.The𝑀∗

𝑠 calculationisperformedbyassimilatingthefree

energyoftheorthorhombicphasetotheoneoftheHCPphase.Yanand Olsonmadethisassumptionbefore,andjustifieditbythecontinuity oftheMstemperatureattheHCP/orthorhombictransitioncomposition

[18].Inthepresent𝑀∗

𝑠 calculation,althoughthedifferencebetween

orthorhombicandHCPphasecannotbeconsideredwhenperforming thermodynamiccomputation,itistakenintoaccountinthecalculation oftheelasticstrainenergy.Someauthorshaveempiricallycalibrated thevalueofthefreeenergyinordertoaccountforthedifference be-tweenfreeenergiesoftheHCPphaseandtheorthorhombicphase[18]. Sincegoodagreementbetween experimentalandcalculatedvaluesis obtainedwiththemodelproposedhere(Fig.5),whichisfreeoffitting parameters,wesuggestthatitisreasonabletoapproximatethefree en-ergyof𝛼′′bytheoneof𝛼′.

SeveralattemptshavebeenmadetopredicttheMstemperaturein Titaniumalloys.Galindo-Navasuggestedamodelfreeoffitting parame-terstocalculatetheMstemperatureinbinaryalloys,butitdoesnot

con-sidermulticomponentalloys[21],andmainlyfocusesonhigh tempera-tures.Neelakantanetal.[48]aswellasYan[18]proposedanapproach basedonGhoshandOlson’stheory[49].These twomodelsprovided goodresults.However,theydidnotcalculatetheelasticstrainenergy, butusedinsteadalinearfunctionoftheatomicfractionsofthealloying elements,supposedtoincludebothelasticstrainenergyandfrictional work,andfittedfromexperimentaldata.Inthepresentwork,the calcu-lated𝑀∗

𝑠 isthetemperatureatwhichtheenergyofamartensiteplate 4M

sissometimesestimatedwhileapplyingalowstressduringcooling(for

example50MPain[37]).TheMsmeasurementsobtainedwithindirectmethods

ofdetectablesizereachesalocalminimum(Eq.(12)).Thisminimum ofenergy,bydefinition,doesnotdependontheworkdissipatedduring thetransitionfromonestatetotheother,andthereisthusnoneedto computeanyworkrelatedtointernalfrictiontodetermine𝑀∗

𝑠 asitis

definedhere.Iffrictionalworkthatopposesthetransformationistobe consideredinthemodel,itshouldbeincludedbothduringgrowthand nucleationundertheformofanenergybarrier.Inthecaseofmartensite induceduponquenching,themainsourceofenergytoovercomethe nu-cleationbarrieristhermal.Asmartensitegrowthisveryfast,itcannot beassumedthatgrowthrequiressignificantthermalactivation.Thus,if somefrictionalworkopposesmartensitegrowth,itsmagnitudehasto besmallerthanthenucleationbarrier,insuchawaythatovercoming thenucleationenergybarrierbythermalenergyallowstoovercomethe energybarrierformartensitegrowthaswell.Sincetheenergybarrier fornucleationisnotexplicitlycalculatedinthiswork,theproposed nu-cleationparameterobtainedbycollective fittingalreadyincorporates theeffectoffrictionalwork.

The computation of 𝑀∗

𝑠 takes into account the grain size effect

Eq.(12).Notethatthecalculationswereperformedbyassumingagrain sizeof100μm.Aslongasthegrainsizeisintherange20–100μm,the

𝑀∗

𝑠calculationwasfoundnottobeverysensitivetograinsize;the

max-imaldifferencebetweenthe𝑀∗

𝑠 calculatedfor20μmandtheonefor

calculatedfor100μmwas30∘C.The𝑀∗

𝑠 stronglyvarieswithgrainsize

onlyforsmallergrains.𝑀∗

𝑠 decreaseswhenthegrainsizeisreduced,

becausetheelasticstrainenergyincreases.Thedecreasingof theMs

withdecreasinggrain sizehasbeenconfirmedinsteels[50,51].This grainsizedependencysuggeststhatmartensitegrowthbecomesmore andmoredifficultifthemicrostructureisrefined.Inparticular,if twin-ning occursinconjunction withmartensitenucleation, thefreepath formartensiteradialgrowth(seeFig.2b)canbeconsiderably dimin-ished.Inthe𝛽 grains containingtwins,the𝑀∗

𝑠 can thereforebe

dra-maticallydecreased.Forexample,inthecaseofTi–12Mo,the𝑀∗

𝑠fora

standardgrainsizeof100𝜇mis437∘Candstableplatesofmartensite

areexpectedtoformupondeformation(whichis consistentwith ex-periments;TRIPeffectisdisplayedinthisalloy[22]).Ifmultipletwins nucleateinagrain,reducingtheapparentgrainsizeto,say,600nm,the

𝑀∗

𝑠 fallsto1∘C.Withsuchavalueof𝑀𝑠∗,anyplateofmartensitethat

wouldformbetweenorinsidethetwinswouldbeexpectedtoreverse uponunloading.ThismighthelpexplainingwhyinTRIP/TWIPalloys, themicrostructureafterdeformationoftenconsistsofamixture of𝛽 andmartensite,andnotof100%martensite,despiteasometimesvery high𝑀∗

𝑠.InalloysdisplayingbothTRIPandTWIP,alimitedamount

ofmartensitehasalreadybeenreportedtoreverseto𝛽 uponunloading, eventhoughmostofthemartensiteremainedafterdeformation[22,52]. Thisseemstobeconsistentwiththegrainsizedependencyadvanced here.

Intheend,theproposedmodelfor𝑀∗

𝑠 providesaratheraccurate

predictionofMs overawiderangeofcompositionsandalloys,while

beingphysically-basedandusingminimal fittingasopposedtomost existingmodels.Fig.5isobtainedwithoutanyadjustableparameter, andtheonlydata-derivedparameteristhethresholdvalueofthe nucle-ationparameter 𝑘𝑇0

𝜇(𝑇0)𝑏3 fromFig.6toaccountforthermallyactivated

nucleation.

5.4.Comparisonwithusualdesigntools

Microstructureprediction

Thetypeofmicrostructureformedatroomtemperaturecanbe pre-dictedwithgoodaccuracy:martensiticmulticomponentalloyscanbe identified,asshowninFig.6.Moreover,theproposednucleation param-etercriterion(kT0/[𝜇(T0)b3])seemstobeaphysicallyrelevantindicator

sinceitallowstopredictforeachbinarysystemthecritical composi-tionnecessarytoretain𝛽 atroomtemperature,asshowninFig.8and Table1.Thecriterionthatisusedintheliteraturetopredictthe possi-bilitytoretain𝛽 atroomtemperatureisthe“molybdenumequivalent”

([Mo]eq)[26]calculatedasfollows:

[Mo]eq =[Mo]+0.67[V]+0.44[W]+0.28[Nb]+0.22[Ta]

+1.6[Cr]+1.25[Ni]+1.7[Co]+2.9[Fe]−1.0[Al](wt.%) (21) Thecoefficientstotheconcentrationsinthe[Mo]eqcalculationhave

beenestablishedinthefollowingway:foreachalloyingelement, the criticalconcentrationtoretain𝛽 atroomtemperatureintheTi–Mo sys-tem(10wt%)isdividedbythecriticalconcentration(experimentally observed)necessarytoretain𝛽 atroomtemperatureforthegiven ele-ment.Itisgenerallyacceptedthatanalloycanretain𝛽 atroom temper-atureif[Mo]eqisgreaterthan10%.

Forbinaryalloys,bothcriteria([Mo]eq andthenucleation param-eter)-Inequation(19)givesimilar(andcorrect)results.However,the equation ofthe[Mo]eq hasbeendefinedsoastoprovidecorrect

re-sultsforbinaryalloys,sothechallengeremainsonthepredictionfor multicomponentalloys.Forthose,thenucleationparametercriterion maypresentanadvantage.Themicrostructurepredictionissuccessful for92%ofthealloyswiththenucleationparametermethod,andfor 88%ofthealloyswiththe[Mo]eq method.Thenucleationparameter criterionalsointegratestheeffectofZrandSn,absentinthe[Mo]eq.

Consequently,althoughthe[Mo]eqisareliabletooltopredictthe

mi-crostructure, thenucleationparameterpresentstheadvantagesof of-feringaphysicalexplanationforthe𝛽 retention,ofallowingmore ac-curatepredictionsandofbeingapplicabletoamorediversepaletteof elements.

Deformationbehaviourprediction

Thedeformationbehaviourof𝛽 alloyscanbefairlywellpredicted aswell.Themethod presentedinFig.9tocategorizethedifferent 𝛽

alloysgivesreasonabletrends.Twocompositionshave𝑀∗

𝑠 >90°Cand

stilldisplaysuperelasticity(Ti–31Nb–9Zrat%andTi–3Mo–10Zr-–5.5Sn at%).BothofthemhaveahighconcentrationinZr,andthe𝑀∗

𝑠 may

bemispredictedbecauseofawrongestimationoftheinfluenceofZr on the lattice parameters. Formost of the other wrongpredictions, thecompositionsinvolvedareclose fromthebordersdefinedby the threshold.

Regardingtheretentionof𝛽 upondeformation,theproposed[Fe]eq

assumesthattheeffectofeachalloyingelementinmulticomponent sys-temscanbeextrapolatedfromitsindividualeffectinbinarysystems.It isbuiltinasimilarwaytothe[Mo]eq,butwhilethe[Mo]eqequationis

establishedwiththecriticalconcentrationsnecessarytoretain𝛽 upon

quenchinginbinaryalloys,theproposed[Fe]eqisbasedonthecritical

concentrationsnecessarytoretain𝛽 upondeformation.Twoelements thatarenotincludedinthe[Mo]eqequation,ZrandSn,aretakeninto

accountinthe[Fe]eqcriterion.Thesetwoelementsareoftenconsidered

tobeneutralwithrespecttothe𝛽 stability,becausetheyhavelittle in-fluenceonthe𝛽 transustemperature.However,ithasbeen experimen-tallyshownin [35]thattheconcentrationinZrandSnsignificantly influencesthedeformationbehaviourof𝛽 titaniumalloys.

The method presented here offersa new approach for designing martensitic,TRIP,orsuperelasticalloys,differingfromthetraditional Bo–Mdmethod[10].Todiscussitsaccuracy,literaturedatacollected forthisworkisgatheredonaBo–Mdmap(Fig.1b).The correspond-ingzones aredisplayedin Fig.1a. Itcan beseen thattheboundary betweenmartensiticandnonmartensiticalloysisrelativelywell pre-dictedbyMorinaga’smap,andthatmostofthealloysdisplayingTRIP areindeedinthe“TRIP–TWIP” zone.However,anappreciablequantity ofmartensiticalloysareinthepredictedTRIP–TWIPzone,someTRIP alloysareoutsidetheTRIP–TWIPzone,andsotheboundariesdonot seemtodescribeveryaccuratelythedeformationbehaviour.Moreover, thesignificantnumberofTWIPalloysintheSlipzonedoesnot sup-porttheideathataclearzoneseparatesTWIPfromslip(65%ofthe alloysfromAppendixAknowntodisplayTWIParenotintheTRIP– TWIPzoneoftheBo–Mdmap).Additionally,asdiscussedabove,the

Fig.11. Expectedbehaviourasafunctionof theBo andMd parameters,accordingtothe methoddescribedinthiswork.Morinaga’smap has been superimposed to the chart (plain lines)forcomparison purpose;thebehaviour expectedinthezonesdelimitedbyblacklines, accordingtoMorinaga’s map,isdisplayed in

Fig.1a.

statementthattheboundarybetweenTRIPandmartensiticalloysis de-finedbytheequationMs=RoomTemperature(RT)isquestionable,so

itshouldnotbeassumedthattheMsisconstantonthelinedisplayed as“Ms=RT” inFig.1a.Thelinesseparatingthetypesofbehaviourhave

beendrawnwithexistingalloys,andnophysicalbackgroundjustifies thepeculiarshapeobtained.

The method proposed in this work on the other hand, is semi-empirical,meaningthatitusesempiricalthresholdswithmodelsthat relyonphysicalbases(for𝑀∗

𝑠andthenucleationparameter).The

quan-titiestobecalculatedinordertopredictthebehaviourcanbecomputed withasimplecodethatrunsefficiently.Althoughthemethoddoesnot relyentirelyonphysics,itgivessome leadstobetterunderstandthe compositiondependencyofmartensiteformation,andallowstopredict withgoodconfidence thebehaviourof thealloys, ascanbe seen in Fig.9andFig.6.Itoffersadvantagescomparedtothecurrent meth-ods.ThecompositionspacetobeexploredisnotlimitedbytheBo–Md combinationsdefinedbytheframeofthemap(Fig.1a)andacriterion isproposed totargetsuperelasticity.Inordertocomparethe predic-tionsobtainedwiththestabilitymapwiththeonesobtainedwiththe presentwork,themethoddescribedherehasbeenappliedtoasetof ap-proximately6000compositionschoseninsuchawaythattheyfillthe spaceoftheBo–Mdmap.Thecorrespondingpredictionsaredisplayed inFig.11.Theoverallshapeofthemartensiticzoneisroughlysimilar totheoneofthephasestabilitymapof[10](Fig.1a),butaccording tothepresentcalculationmethod,thereshouldbemanyTRIPregions inthemiddleofthemartensitearea.Theregionscorrespondingtothe differentdeformationmechanismsassessedwiththemethodpresented hereareveryscatteredintheBo–Mdspace;thissuggeststhatthe val-uesofBoandMdmaynotbethemostphysicallyrelevantparameters todescribethedeformationinducedtransformationsintitaniumalloys. ThemethodproposedinthisworkcanbeusedtodesignTRIP/TWIP alloys;itiscapabletodeterminethecompositionaldependenceofTRIP andsuperelasticityeffects.Itmayconstituteausefultooltodesign𝛽

titaniumalloysexploringnovelrangesofcomposition.

6. Conclusion

Anewmodel isproposed todescribethemartensitic transforma-tionintitaniumalloys-eitheruponquenchingordeformation-asa

functionoftheircomposition.Althoughitusesadhocthresholdsand oneempiricalcriterion([Fe]eq),theproposedmodelreliesonphysical

approachestodeterminemartensitenucleationandgrowth.The nucle-ationparameter (kT0/[𝜇(T0)b3])allowstodeterminethetypeof

mi-crostructurepresentatroomtemperature,the[Fe]eq and𝑀𝑠∗criteria

thenallowtoidentifythedeformationbehaviourofthe𝛽 alloys.When

𝑘𝑇0∕[𝜇(𝑇0)𝑏3]>1.24⋅ 10−2,martensiteisexpectedtoformupon

quench-ing. Otherwise,thealloyretains𝛽 at roomtemperature.Ifthealloy displaysonly𝛽 phaseatroomtemperature,itdeformsbyslipor twin-ningif[Fe]eq > 3.5orif𝑀𝑠∗<−90∘C,whereasitcanformmartensite

upondeformationotherwise.Amongthealloysthatcanformmartensite upondeformation,superelasticityisexpectedif−90∘C<𝑀∗

𝑠 <90∘C,

whereasTRIPisexpectedif𝑀∗

𝑠 >90∘C.

Thisapproachcanprovideexplanationsforsomecharacteristic fea-turesoftitaniumalloysthathadnotquantitativelybeenmodeledsofar. Theassumptionofathermallyactivatedmartensitenucleationmay ex-plainwhysomealloyingelementsallowtoretainthe𝛽 phaseatroom temperature.Thedeterminationofamorepreciseexpressionforthe en-ergybarriertomartensitenucleationcouldconstitutethefocusofsome futurework.The𝑀∗

𝑠 modelrelieson thermodynamicsand

microme-chanics andoffersanexplanationforthecompositiondependenceof TRIPandsuperelasticeffects.Thecombinationofthesemodelsallows todiscriminatemartensitic,TRIP,superelasticandTWIP/Slipalloysand maybeusedasadesigningtoolfortailoreddeformationbehaviour.

Declarationofinterests

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluence theworkreportedinthispaper.

Acknowledgment

TheworkofMBhasbeensupportedbyDGA(FrenchMinistryof De-fense).PEJRDDCisgratefultotheEngineeringandPhysicalSciences Re-searchCouncil EPSRChttps://doi.org/10.13039/501100000266.K.for theprovisionoffundingviagrantEP/L025213/1(DesigningAlloysfor ResourceEfficiency),andtotheRoyalAcademyofEngineeringfor fund-inghischair.

AppendixA.Alloysfromtheliterature

n Alloy composition (w %) a Microstructure Ms Deformation mechanism Ref

1 Ti–10Mo–1Fe 𝛽 TWIP {332} [30] 2 Ti–10Mo–3Fe 𝛽 Slip [53] 3 Ti–10Mo–5Fe 𝛽 Slip [53] 4 Ti–15Mo–1Fe 𝛽 Slip [54] 5 Ti–10V–3Fe–3Al–0.27O 𝛽 TRIP [55] TWIP {332} stress-induced 𝜔 6 Ti–8Mo–4Nb–2V–3Al 𝛽 TRIP [56] [57]

7 Ti–9.6Mo–4Nb–2V–3Al–0.25Fe 𝛽 Apparently no TRIP [56]

8 Ti–11Mo–4Nb–2V–3Al 𝛽 No information [56]

9 Ti–29Nb–13Ta–4.6Zr 𝛽 ? [58]

10 Ti–10V–2Cr–3Al 𝛽 and a bit of 𝛼″ ? TRIP [59]

11 Ti–10V–1Fe–3Al 𝛽 and a bit of 𝛼″ TRIP [59]

12 Ti–3Al–5Mo–7V–3Cr 𝛽 TRIP [60]

TWIP {332}

13 Ti–31Nb–9Zr 𝛽 Superelastic (grain size 1 𝜇m ) [61]

14 Ti–38Nb–1.4Al 𝛽 Superelastic [62] 15 Ti–9Mo–6W 𝛽 TRIP [11] TWIP {332} stress-induced 𝜔 16 Ti–32Nb 𝛽[27] or 𝛼″ [36] TRIP [36] [63] [27] 17 Ti–40Nb 𝛽 Superelastic [36] 18 Ti–43Nb 𝛽 Slip [36] 19 Ti–2Mo–37Nb Superelastic [36] 20 Ti–3.3Mo–33Nb Superelastic [36] 21 Ti–5Mo–29Nb Superelastic [36] 22 Ti–30Nb–19Ta Superelastic [36] 23 Ti-34Nb–9Zr Superelastic [36] 24 Ti–15Nb–12Zr at % 𝛽 [64] 25 Ti–16Nb–12Zr at % 𝛽 [64] 26 Ti–17Nb–12Zr at % 𝛽 Superelastic [64] TRIP? 27 Ti–18Nb–12Zr at % 𝛽 Superelastic [64] 28 Ti–19Nb–10Ta at % 𝛽 Superelastic [64]

29 Ti–12Nb–20Ta at % 𝛽 Partial superelasticity [64]

30 Ti–13Nb–20Ta at % 𝛽 Partial superelasticity [64]

31 Ti–62Ta–2Nb 𝛽 TRIP [64] 32 Ti–61Ta–4Nb 𝛽 Superelastic [64] 33 Ti–2Mo 𝛼′ 780 [65] 34 Ti–3Mo 𝛼′ 740 [65] 35 Ti–4Mo 𝛼′ 700 [65] 36 Ti–6Mo 𝛼″ 610 [65] 37 Ti–8Mo 𝛼″ 515 [65] 38 Ti–12Mo 𝛽 TRIP [33] TWIP ({332} and {112})

39 Ti–14Mo 𝛽 pure TWIP [33]

40 Ti–13V–11Cr 𝛽 Slip [66]

41 Ti–5Al–5Mo–5V–3Cr 𝛽 TRIP [67]

42 Ti–5Mo–6V–3Cr–3Al 𝛽 TWIP{112} and {332} [68]

No information regarding TRIP

43 Ti–11.5Mo–6Zr–4.5Sn 𝛽 (quenched -195°C)) TWIP {112} and{332} [34] [15] 44 Ti–13Mo 𝛽 TRIP [32] 45 Ti–16V 𝛽 TRIP [32] [69] TWIP stress-induced 𝜔 46 Ti–13V 𝛽[38] or 𝛼″ [28] TRIP [38] [28,38] 47 Ti–4Al–9V–1.2Fe 𝛼″ 483 [18] 48 Ti–3.2Al–14.6V 𝛼″ 493 [18] 49 Ti–15.15V–3.17Al 𝛼″ 463 [18] 50 Ti–15.6V–3.1Al 𝛼″ 423 [18] 51 Ti–13V-3A–0.6Fe 𝛼″ 453 [18]

52 Ti–13V–3Al–1Fe at 𝛽 + a bit of 𝛼″ TRIP [39]

53 Ti–13V–1Al at 𝛽 + 𝛼″ [38]

( continued on next page )

(continued)

n Alloy composition (w %) a Microstructure Ms Deformation mechanism Ref

54 Ti–13V–3Al at 𝛽 + 𝛼″ over 350 [18,39] 55 Ti–16V–2Fe–2Al 𝛽 Slip [70] 56 Ti–16V–2Fe 𝛽 Slip [70] 57 Ti–16V–2Fe–Al 𝛽 Slip [70] 58 Ti–16V–Fe 𝛽 TWIP {332} [70] stress-induced 𝜔

59 Ti–14V–2Fe–Al 𝛽 TWIP {332} mainly [70]

detection of stress-induced 𝛼″

60 Ti-12V-2Fe-Al 𝛽 TWIP {332} mainly [70]

detection of stress-induced 𝛼″ 61 Ti-16.1V-4Al 𝛽 TRIP [39] [71] 62 Ti-15.4V-4Al 𝛽 + ordered 𝛼″ [71] 63 Ti-13V-3Al-1.5Fe at 𝛽 ? [39] 64 Ti-13V-3Al-0.5Fe at mainly 𝛼″ 𝐴 𝑠 = 240 [39] 𝐴 𝑓 = 281 Ms ≈ 250? 65 Ti-25Ta-25Nb 𝛽 Superelastic [72] 66 Ti-25Ta-24Nb 𝛽 Superelastic [3] [73] TWIP ({332} and {112}) 67 Ti-25Ta-30Nb 𝛽 TWIP {332} [73] 68 Ti-15Mo-5Zr 𝛽 TWIP {332} [34] 69 Ti-20V-6Al 𝛽 Slip [34] 70 Ti-20V 𝛽 TWIP {332} [34] 71 Ti-20V-0.15O 𝛽 TWIP {332} [66] 72 Ti-15Mo-5Zr-3Al 𝛽 Slip [34] 73 Ti-3Al-8V-6Cr-4Mo-4Zr 𝛽 Slip [34] 74 Ti-15V-3Cr-3Al-3Sn 𝛽 Slip [34] 75 Ti-8Mo-8V-2Fe-3Al 𝛽 Slip [34] 76 Ti-13V-11Cr-3Al 𝛽 Slip [34] [10] 77 Ti-10V-2Fe-3Al 𝛽 or 𝛼″ + 𝛽 TRIP [16] 78 Ti-12Mo-6Zr-2Fe 𝛽 TWIP [10] 79 Ti-20V-3Sn 𝛽 TWIP [34] 80 Ti-4Al-7Mo-3V-3Cr 𝛽 TRIP [74] TWIP 81 Ti-10Mo 𝛽 + 𝛼″ TWIP {332} [53] (segregation) ( + TRIP?) 82 Ti-7Mo-3Cr 𝛽 TRIP [12] TWIP{332} and {112} 83 Ti-1Cr 𝛼′ 800 [28] 84 Ti-2Cr 𝛼′ 750 [28] 85 Ti-3Cr 𝛼′ 700 [28] 86 Ti-3.5Cr 𝛼′ 650 [28] 87 Ti-4.2Cr 𝛼′ 620 [28] 88 Ti-1.91V 𝛼′ 807 [28] 89 Ti-4.24V 𝛼 727 [28] 90 Ti-6.9V 𝛼 627 [28] 91 Ti-8.5V 𝛼 527 [28] 92 Ti-12.7V 𝛼 327 [28] 93 Ti-22V 𝛽 TWIP {112} [75] 94 Ti-28V 𝛽 TWIP {112} [75] 95 Ti-2.9Al 𝛼 918 [29] 96 Ti-5.9Al 𝛼 960 [29] 97 Ti-9Al 𝛼 1015 [29] 98 Ti-12.3Al 𝛼 1060 [29] 99 Ti-1Fe 𝛼 760 [28] 100 Ti-2Fe 𝛼 675 [28] 101 Ti-2.5Fe 𝛼 630 [28] 102 Ti-3Fe 𝛼 575 [28] 103 Ti-4Fe 𝛼 475 [28] 104 Ti-12W 660 [28] 105 Ti-18W 480 [28] 106 Ti-21.9W 350 [28] 107 Ti-9.1Nb 759 [29] [48] 108 Ti-10Nb 720 [29,48] 109 Ti-13Nb 680 [29] [48] 110 Ti-14Nb 650 [29,48] 111 Ti-17Nb 578 [29,48] 112 Ti-22Nb 485 [29] [48] 113 Ti-25Nb 387 [29,48] 114 Ti-29Nb 𝛽 or 𝛼″ 307 [29,48] 115 Ti 855 [29] [28] 116 Ti-12Mo-5Zr 𝛽 TRIP [76] TWIP {332} 117 Ti-11Mo 𝛼″ [77] or 𝛽 [29]

(continued)

n Alloy composition (w %) a Microstructure Ms Deformation mechanism Ref

118 Ti-15Mo 𝛽 TWIP {332} [54] 119 Ti-10Zr 777 [48] 120 Ti-17.5Zr 727 [48] 121 Ti-24.42Zr 652 [48] 122 Ti-32.52Zr 627 [48] 123 Ti-25Nb-2Ta-3Zr 𝛽 TRIP [78] 124 Ti-25Nb-10Ta-1Zr-0.2Fe 𝛽 TRIP [78] 125 Ti-38Nb-3Zr-2.1Ta 𝛽 Superelastic b [79] TWIP 332 126 Ti-50Nb 𝛽 TWIP {112} [80] stress-induced 𝜔 127 Ti-15Ta 𝛼 760 [29]

128 Ti-62Ta 𝛼″ or 𝛽 stress-induced Martensite c [37] [81]

129 Ti-72Ta 𝛽 stress-induced Martensite d [37]

130 Ti-8.5Cr-4.5Sn 𝛽 TRIP [82]

TWIP {332}

131 Ti-10Cr 𝛽 TWIP {332} [31]

132 Ti-25Nb-3Zr-3Mo-2Sn 𝛽 TWIP {332} mainly [83]

TWIP {112} TRIP stress-induced 𝜔 133 Ti-6Cr-4Mo-2Al-2Sn-1Zr 𝛽 TWIP {332} [84] TWIP {112} stress-induced 𝜔 134 Ti-10V-4Cr-1Al 𝛽 TWIP {332} [52] TWIP {112} TRIP (unstable) 135 Ti-5Al-2Sn-4Zr-4Mo-2Cr-1Fe 𝛽 TRIP [85]

136 Ti-3Mo-8Zr-5Sn at% 𝛽 TRIP [35]

137 Ti-3Mo-9Zr-5.5Sn at% 𝛽 Superelastic [35]

138 Ti-3Mo-5Zr-4Sn at% 𝛼″ [35]

139 Ti-3Mo-6Zr-7Sn at% 𝛽 Slip [35]

140 Ti-3Mo-10Zr-6Sn at% 𝛽 Slip [35]

141 Ti-10Ta-4Fe 𝛽 Slip [86] 142 Ti-7Ta-5Fe 𝛽 Slip [86] 143 Ti-12Nb-5Fe 𝛽 Slip [86] 144 Ti-13V at 𝛽 TRIP [38] 145 Ti-16Nb-4Sn at 𝛽 + 𝛼″ 87 [87] 146 Ti-16Nb-5Sn at 𝛽 + 𝛼″ − 53 [87]

147 Ti-24Nb-3Al at mainly 𝛽 − 13 superelastic [62]

148 Ti-35Nb 𝛽 or 𝛼″ 175 TRIP [88] [89]

149 Ti-35Nb-3Sn 𝛼″ 77 [88]

AppendixB. Compositiondependenceofthelatticeparameters

Whenthecompositiondependencywasnotfoundintheliterature, theeffectof thealloyingelementwaseitherignored orobtained by extrapolation(liketheeffectofZrandSnintheorthorhombicphase).

xiistheatomicfractionofelementi.

BCC(V,Mo,Fe,Crfrom[27],Nbfrom[14],ZrandSnfrom[35]):

𝑎𝛽 =3.274+0.043𝑥Nb−0.1259𝑥Mo−0.2𝑥V−0.55𝑥Fe−0.15𝑥𝑊

+0.044𝑥Ta+0.11𝑥Sn−0.4𝑥Cr+0.31𝑥ZrÅ

HCP(Zrfrom[90],Mo,Nb,Tafrom[91],V,W,Fefrom[92],Cr from[93]): 𝑎𝛼′=2.959−0.083𝑥Fe−1.3𝑥𝑊 +0.22𝑥Zr−0.26𝑥Cr−𝑥VÅ 𝑏𝛼′= √ 3𝑎𝛼′Å 𝑐𝛼′=4.68+0.2381𝑥Mo+0.5𝑥Nb+0.5𝑥Ta−0.4𝑥𝑊−0.4𝑥V +0.1𝑥Fe+0.5𝑥Zr−1.6𝑥CrÅ

b Thealloyisnotreferredtoassuperelasticin[79]butafterunloading,many

martensiteplatesreverseto𝛽.

c noinformationonwhetheritisTRIPorsuperelastic(mostlikelyTRIP). d noinformationonwhetheritisTRIPorsuperelastic.

Orthorhombic(ZrandSnfrom[35],TaandNbfrom[73],Mofrom [91],V,Wfrom[92],Crextrapolatedfrom[67]),FeandAlextrapolated from[18]: 𝑎𝛼′′ =2.89+1.37𝑥Nb+3𝑥Mo+0.6𝑥Ta+2.43𝑥𝑊+2.05𝑥Sn+𝑥V +3𝑥Cr+0.9𝑥Zr+0.083𝑥Al+0.0223𝑥FeÅ 𝑏𝛼′′ =3.02 √ 3−1.68√3𝑥Nb−3 √ 3𝑥Mo−1.21𝑥Ta− 1.42 √ 3𝑥𝑊 −2.64𝑥Sn −0.28𝑥Zr−√3𝑥V−5.67𝑥Cr−0.018𝑥Al+0.0504𝑥FeÅ 𝑐𝛼′′ =4.734−0.184𝑥Nb−1.5𝑥Mo−0.4𝑥Ta−0.57𝑥𝑊+0.23𝑥Sn +0.4𝑥V−2.67𝑥Cr+0.3𝑥Zr−0.0535𝑥Al−0.0326𝑥FeÅ

Asexplainedinthetext,inordertocomputeMs,theelasticenergy

wascalculatedbothfortheHCPandfortheorthorhombicstructure,by assumingthatthecompositiondependenceofthelatticeparametersfor eachstructurecanbeextrapolatedindomainswheretheydonot ex-ist.Foreachalloy,twoMswereobtained(oneforeachstructure)and

theretainedonewasthegreatestofboth.Forallbinarysystemsexcept forTi–V,thisextrapolationofthelatticeparametersallowedtofindthe criticalcompositionatwhichthetransitionfromHCPtoorthorhombic happens.ForalloyscontainingVanadiumhowever,theextrapolationof thecompositiondependencyofthelatticeparametersoftheHCP struc-tureindomainswherethisstructuredoesnotexist(V>6%at[92])did notallowtofindthecriticalcompositionwhereorthorhombicstructure

![Fig. 1. (a) Reproduction of the Bo–Md map from [10] . The four coloured zones correspond to the four expected types of behaviour accord-ing to Morinaga’s method](https://thumb-eu.123doks.com/thumbv2/123doknet/11555596.296740/3.892.59.589.83.723/reproduction-coloured-correspond-expected-behaviour-accord-morinaga-method.webp)