OATAO is an open access repository that collects the work of Toulouse

researchers and makes it freely available over the web where possible

Any correspondence concerning this service should be sent

to the repository administrator:

tech-oatao@listes-diff.inp-toulouse.fr

This is an author’s version published in: http://oatao.univ-toulouse.fr/20547

To cite this version:

Ciumag, Mihaela Raluca

and Gibilaro, Mathieu

and Massot, Laurent

and

Laucournet, Richard and Chamelot, Pierre

Neodymium electrowinning into

copper-neodymium alloys by mixed oxide reduction in molten fluoride media. (2016) Journal

of Fluorine Chemistry, 184. 1-7. ISSN 0022-1139

Official URL: https://doi.org/10.1016/j.jfluchem.2016.02.001

Open Archive Toulouse Archive Ouverte

Neodymium

electrowinning

into

copper-neodymium

alloys

by

mixed

oxide

reduction

in

molten

fluoride

media

M.

Ciumag

a,b,

M.

Gibilaro

a,*

,

L.

Massot

a,

R.

Laucournet

c,

P.

Chamelot

aaLaboratoiredeGénieChimiqueUMRCNRS5503,UniversitéPaulSabatier,118routedeNarbonne,31069ToulouseCedex9,France bCEA-TechMidi-Pyrénées,135avenuedeRangueil,31400Toulouse,France

cCEAGrenobleLITEN,17ruedesMartyrs,38054GrenobleCedex9,France

ABSTRACT

Thepossibility ofneodymiumelectrowinningfromneodymiumoxideusing areducingagent(RA) producedin-situbysolventreductionwasinvestigatedinmoltenLiF–CaF2–Li2Obetween900!Cand

1040!C.Nd2O3galvanostaticelectrolyseswereperformedandreactionproductswereanalyzedbySEM,

XRDandelectron-probemicroscopy.Metallicneodymiumwasnotdirectlyobtained,duetoseveral limitationsforNd2O3reduction:lowelectricalconductivity,unfavourablePilling–Bedworthcoefficient

andformationofadenseinsulatingCaOlayeronthesamplesurface.

Consequently,thereductionofapelletmadeofaneodymiumoxide-metallicoxidemixturewascarried outasanalternativepathway.Nd2O3-CuOreductionledtometallicneodymiumproductionintheform

ofliquidCu-Ndalloys.Areactionmechanismwasproposedbasedontheseexperimentalresults:

1.Introduction

Needs of metallic neodymium and its alloys are lately increasing,particularly in the fields of magnetism, energy and hightechnology,asinpermanentmagnets,lampphosphorsand rechargeable NiMH batteries [1]. Neodymium is industrially produced by both calciothermic reduction of NdF3, requiring

severalpurificationsteps,and bymoltensaltelectrolysis,which enablescontinuousoperationandismoresuitableformassmetal production.

Metallicneodymiumelectrodepositioncantakeplaceinfused chloridesalts[2–13],butthisprocesshasseveraldrawbacks,such astheevolutionofchlorinegasattheanodeandlowfaradicyield. Thus,neodymiummetaliscurrentlyproducedbyelectrowinning fromneodymiumoxideinamoltenfluoridemediacontaininghigh amountsofNdF3(upto87mass%)[14].

Severalauthorssuggesteddifferentreductionmechanismsof Nd2O3inNdF3-basedmoltensalt[16–19],butnoagreementhas

been found yet. Stefanidaki et al. [15,16] detailed neodymium

production in LiF–Nd2O3 and LiF–NdF3–Nd2O3 systems. In LiF–

Nd2O3nocharacteristicsignalforneodymiumoxidereductioninto

metalwasobservedandmetallicneodymiumdepositiondidnot occurin this molten mixture.In LiF–NdF3–Nd2O3, fluoride and

oxyfluoride complexes such as [NdF6]3" and [NdOF5]4" were

proposedtobeformed,andmetallicneodymiumwasobserved. Thefollowingelectrontransfermechanismwassuggested: Cathode:[NdF6]3"+3e"!Nd(s)+6F"

Anode:3[NdOF5]4"!3/2O2(g)+3Nd3++15F"+6e"

The authors concludedthat electrowinning of metallic neo-dymiumcanbeperformedbycontrolledcell–voltageelectrolysis inLiF–NdF3–Nd2O3.

Thudumetal.[17]proposedadifferentreductionpathwayfor Nd2O3inLiF-CaF2-NdF3,suggestingboth[NdFO5]4"and[NdF6]3"

complexeswerereduced tometallic neodymium,dependingon theOF/Fmolarratio:forlowratios,[NdF6]3"wasreduced,whereas

aboveacriticalvalue,[NdFO5]4"wasreduced.

DysingerandMurphy[18]testedNd2O3reductioninLiF–CaF2–

1060!C, andhighlightedseveral side reactionsoccurringatthe

anode:

Theauthorsconcludedmetallicneodymiumelectrowinningfrom LiF–CaF2–NdF3–Nd2O3wasonlypossibleathighcurrentdensity

(1Acm"2)andhightemperature(T>1021!C=Ndfusion

tempera-ture).

Fe–NdalloyswereobtainedbyMorriceet al.[19],byNd2O3

electrolysisonreactiveironcathodeat990!CinLiF–NdF

3(89mass

%).Later,Nd2O3electrolysisinfusedfluoridesforFe–Ndfabrication

was patented by Pechiney [20]. Alloys were obtained by long duration (>25h) Nd2O3 electrolyzes on reactive iron cathode,

performedinLiF–NdF3–BaF2–B2O3,between750!and1000!C,and

atconstantcellvoltage.

Nowadays, neodymium is industrially produced by Nd2O3

reduction inNdF3-basedmixtures(NdF3>70mass%[21])using

Mo, W or Fe as cathodic materials [22]. Nevertheless, several drawbackscanbepointedoutforthisprocess:

– ThesolubilityofNd2O3isonly5mass%(at1100!C)[23],which

makestheoxidefeedingintotheelectrolytedifficulttocontrol andcanleadtoformationofsludgeatthecellbottom[24]. – Theoverallcostoftheindustrialprocessishighduetotheprice

ofNdF3($1000euros/kg).

Theaimofthisworkistoinvestigatealowercostproduction process for neodymium electrowinning from Nd2O3 in molten

fluoridemedia,inabsenceofNdF3(LiF–CaF2eutecticscontaining

Li2O2mass%),byanewapproach:theneodymiumoxideisusedas

solidpelletsatthecathode,similarlytotheFFC—Cambridge[25]

andOSprocesses[26],andnomoreasthefeedmaterial(current industrialprocess).Thetwomainadvantagesofthisapproachare: firstly, Nd2O3solubilitylimitation,encountered for the

conven-tionalelectrolyticsystem,iseliminated.Secondly,theoverallprice oftheprocessisreduced,duetothelowercostofLiF–CaF2–Li2O:

1kgofLiF–CaF2–Li2Omixturecosts200euros($60mass%LiFat

100euros/kg,$40mass%CaF2at60euros/kgand2mass%Li2Oat

4800euros/kg);while1kgofLiF–NdF3mixturecosts$750euros

($30 mass % LiF at 100euros/kg, and 70 mass % NdF3, at

1000euros/kg).

Withthisnewapproach,Nd2O3electroreductionwasstudiedby

linear voltammetry and galvanostatic electrolyses at different operating parameters:temperaturesfrom900!Cto1040!C and

imposed currents from 0.15 to 0.8A. Elemental analyses of compositionsandmicrostructures(SEM,XRDandelectron-probe microanalyser)wereperformed,andthelimitingfactorsforNd2O3

reduction intoNdinmoltenfluorides, inabsenceofNdF3,were

elucidatedforthefirsttime.

Nd2O3electroreductioninpresenceofanelectricalconducting

metallic oxide was also investigated.Indeed, this strategy was already shown to be suitable for preparing Nd–Co alloys by electrochemical reduction of Nd2O3–Co3O4 mixtures in molten

chloridemedia[27].Otherrareearthsalloyswithheavymetals, suchasLa–Ni[28],Ce–Co[29],Ce–Ni[30],Tb–Fe[31]andTb–Ni

[32],werealsoobtainedbyelectrochemicalreductionofrareearth oxidesandmetallicoxidesmixtures.

Inthisstudy,theelectrochemicalbehaviourofNd2O3–CuOwas

investigatedatdifferenttemperaturesbylinearvoltammetryand

constantcurrentelectrolyses.Analysisofmicrostructuresshowed formation of Cu–Nd alloys and allowed proposing a reduction pathway.ForhighpuritymetallicNdrecovery,afurtherseparation of Cu and Nd can be easily realised with electrorefining, by exploitingtheelectrochemicalpotentialsofthetwoconstituents. 2. Resultsanddiscussion

2.1.Preliminarydiscussionandsolventselection

Rareearth oxides can beelectrochemically reduced by two differentpathways,dependingontheirelectricalconductivity: 1.Highlyconductiveoxidesaresubjecttodirectelectrochemical

reductionbyFFC—Cambridgeprocess[25],wheretheoxideis reducedintometalonthecathodesurface.

2. Oxides presenting low electrical conductivity are subject to indirectreductionbyOSprocess[26].Inthiscase,areducing agent(producedbysolventreduction)reactswiththerareearth oxidetoformametallicphase.

Nd2O3 has a very low electrical conductivity (

s

650!,0,2barO2= 1,45% 10"6V

"1cm"1[33])thereforeitisexpectedtobereducedfollowingtheindirectOSprocess,asillustratedintheequation: Nd2O3+3xRA!2Nd+3RAxO (1)

whereRAisthereducingagentandRAxOistheoxidizedformof

thereducingagent.

The reducing agent (RA) couldbe an alkaline (K,Na, Li)or alkaline-earth metal (Ca) obtained by cathodic reduction of fluoride solvents (KF, NaF, LiF, CaF2). The Gibbs energy of the

reaction(

D

rG!)betweenneodymiumoxideandthereducingagentindicateswhethertheneodymiumoxideisreducedintometallic neodymium or not: if

D

rG! is negative, the reduction ofneodymiumoxidebythealkalineoralkaline-earthis thermody-namicallyachievable.AspresentedinTable1,neodymiumoxide canbereducedintometallicneodymiumbyCaonly.

Nevertheless,becauseofCaF2toohighfusiontemperature(1

418!C), a lower working temperature was chosen: LiF–CaF

2

eutectics(Tfusion=767!C).BecausethereductionpotentialsofLi+

andCa2+areclose(ELi+/Li=

"5.31VvsF2/F"andECa2+/Ca="5.33

VvsF2/F"),theirsimultaneousreductionatthecathodesurface

wasalreadyobserved[34].

Table1

StandardfreeenergydataforNd2O3reductionwithdifferentalkaliand alkaline-earthmetals,followingequation(1)at900!C.

RA K Na Li Ca

2.2.ElectrochemicalcharacterizationinLiF–CaF2bylinearsweep

voltammetry

ToprovideO2"ionsinthemolten

fluoridemediaandensurethe anodicreaction,Li2Owasused.Gibilaroetal.[35]showedinLiF–

CaF2–Li2Omixture,Li2Ohadtobemaintainedataconcentration

higherthan1mass%topreventtheAuanodeoxidationand to ensuretheoxidationofO2"intogaseousO

2[36].

Inthiswork,Nd2O3reductionmechanismwasstudiedinLiF–

CaF2–Li2O(2mass%).Thelinearvoltammogramobtainedat10mV.

s"1and900!C,ispresentedinFig.1,comparedwiththesolvent.

Thetwocurvesdisplaynosignificantdifference,meaningthat nospecificNd2O3 electrochemicalreactionoccurs.Therefore,its

reduction isindirectand theproposedreaction pathwayisthe following:

Cathode:Ca2++2e"!Ca (2)

Spontaneousredoxreaction:Nd2O3+3Ca!2Nd+3CaO (3)

Anode:2O2"

!O2+4e" (4)

The Ca reducing agent [34] produced on the Mo cathode reducestheneodymiumoxideintometallicneodymium,andthe resultedO2"ionsareoxidizedintogaseousO

2onthegoldanode.

2.3.Galvanostaticelectrolysesofneodymiumoxide 2.3.1.Neodymiumoxidereduction

ToinvestigateNd2O3reduction,experimentswerecarriedout

inconstantcurrentmode.Becausestablereferenceelectrodesin

fluoridesaltsarenotavailableyet(noaccuratecontrolofcathodic potential), the constant potential mode was not used during electrolyzes.

Several reduction tests were performed in LiF–CaF2–Li2O

(2mass%) at900!C. ThetheoreticalchargeQ

thneededfor the

reductionofoneneodymiumoxidepelletiscalculatedasfollows: Qth¼mNd2O3

MNd2O3

nF ð5Þ

whereQthisthetheoreticalchargecalculated(C),mNd2O3isthe

oxidepelletweight(g),MNd2O3istheoxidemolecular weight

(336.48g.mol"1),nisthenumberofelectronsexchangedpermole

ofNd2O3,FistheFaradayconstant(96,480Cmol"1).

The pellet cross-section after electrolysis at I="0.4A and t=1320s(500%Qth),observedbySEM,showsthreedifferentzones

(Fig.2).Quantitativeelectron-probemicroanalysisallowed iden-tifyingthecompositionofthesezones,asfollows:

– Theinternalzone(1)ismainlyNdOF,formedbyspontaneous decomplexationofNd2O3:

Nd2O3+2F"!2NdOF+O2" (6)

ThisphenomenonwasalsoobservedbyNourry[37]whenadding O2"ionsin

LiF–CaF2–NdF3.

– Zone2isformedbyrecrystallizedfluoridesalts(LiFandCaF2).

– AdenselayermainlycomposedoflowelectricalconductingCaO, formedbyO2"andCa2+co-precipitation,isobservedoverallthe

surfaceoftheneodymiumoxidepellet(zone3).TheCaOlayer actsasabarrier, limitingthediffusionofO2"fromthepellet

towardsthemoltensalt,preventingtheNd2O3reductiontotake

place.ThisphenomenonexplainstheabsenceofmetallicNdat theendofelectrolysis.

2.3.2.Temperatureinfluence

ToincreaseCaOsolubilityinLiF-CaF2(from0.5mol%at730!C

to2.9mol%at1000!C,[38])andtoattempttoremovethelayeron

the sample surface, experiments were performed at higher temperature,whereliquidmetallicneodymiumcouldbeformed.

Fig. 3 illustrates the cross-section of Nd2O3 sample after

electrolysisat1040!Cand"0.4A(500%Q

th).

Asexpected,noCaOlayerwasformedonthesamplesurface, but X-ray diffractommetry (Fig. 4) didnot highlight either the presenceofmetallicNd.

WhencomparingFig.2(900!C)andFig.3(1040!C),itcanbe

pointedout thatthepelletstructureand compositionchanged: Nd2O3chemicaldecomplexationat900!CledtoNdOF,whileat1

040!C Nd

2O3 clusters appeared, enhancing significantly the

Fig. 1.LinearsweepvoltammogramsonMogridinLiF–CaF2–Li2O(2mass%Li2O)at 10mVs"1and900!C.Continuousline:solvent,dottedline:Nd2O3pellet.

porosity. This phenomena was also confirmed by the X-ray diffractogram (Fig. 4) where Nd2O3, LiF and CaF2 are present,

butnoNdOFwasdetected.

To investigate the temperature effect, a Nd2O3 pellet was

exposedat1040!Cinthemoltensaltbathwithoutpolarisation,

andSEManalysisshowedsimilarstructurestothosepresentedin

Fig.3.Batsanovetal.[39]hadalreadyobservedasimilarbehaviour of neodymiumoxide powder (grain size 1–10

m

m) under high pressure and temperature, where 100–1000m

m crystalline aggregateswerecreated.Theinfluenceoftheappliedcathodiccurrent(from 0.15Ato 0.8A)andneodymiumoxidepelletsfabrication(pressureapplied for sinterizing the oxide powder from 2 to 4tcm"2) was also

studied,butmetallicneodymiumwasstillnotobtained.

To resume, Nd2O3 electrochemical reductiondidnot lead to

metallicneodymium,whatevertheoperatingparameters. More-over,severallimitingphenomenawerehighlighted:

1RelatedtoNd2O3physicochemicalcharacteristics:

- low electrical conductivity (

s

650!C,0,2barO2=1,45% 10"6V

"1cm"1)[33];

- unfavourable Pilling-Bedworth coefficient (VNd/VNd2O3=0.89).

Pilling–Bedworthruleconsiderations[40],asillustratedbyLi etal. [41]and Gibilaroetal. [42],indicatethat duringoxide reduction,ifthemolarvolumeoftheformedmetalVmissmaller thanthemolarvolumeoftheoxideVo,themetalobtainedis porousenoughtoallowthemoltensaltelectrolyteaccessingthe underlying oxide. For neodymium, themetal tooxide molar volume ratio is VNd/V Nd2O3=0.89, meaning that volume

constrictionisnotenoughduringNd2O3conversionintometal:

themetallicneodymiumformedwouldthusactasadiffusion barrier.

2Relatedtosolvent:

- neodymiumoxidecanonlybereducedbyCametal,limitingthe selectiontoCaF2-basedsolvents;

- inCaF2-based solvent, at900!C, theprecipitationof a dense

insoluble CaO layer on the sample surface is observed, preventingNd2O3reduction.

2.4.Reductionofneodymiumoxideinpresenceofcopperoxide ToobtainmetallicNd,theadditionofanelectricalconducting oxideintheneodymiumoxidepelletwastested.CuOwaschosen foritsgoodelectricalconductivity(

s

127!C=10"1V

"1cm"1[43]) and its favourable Pilling–Bedworth coefficient VCu/VCuO=0.56Fig.4. X-raydiffractogramofNd2O3pelletafterelectrolysis(I="0.4A,500%Qth)at1040!CinLiF–CaF2–Li2O(2mass%). Fig.3.MicrographofNd2O3pelletcross-sectionafterelectrolysis(I="0.4A,500%

[36], enhancing pellet porosity. CuO is therefore expected to undergodirectelectrochemicalreductionintometallicCu,andto confirmit,CuOreductionin LiF–CaF2–Li2O(2mass%) wasfirst

studied. The linear voltammogram obtained at 10mVs"1

(vol-tammogramcinFig.5,I)displaysareductionsignalat"1.3VvsPt, assigned to the direct electrochemical reduction of CuO into metallicCu,followingtheequation:

CuO+2e"!Cu+O2" (7)

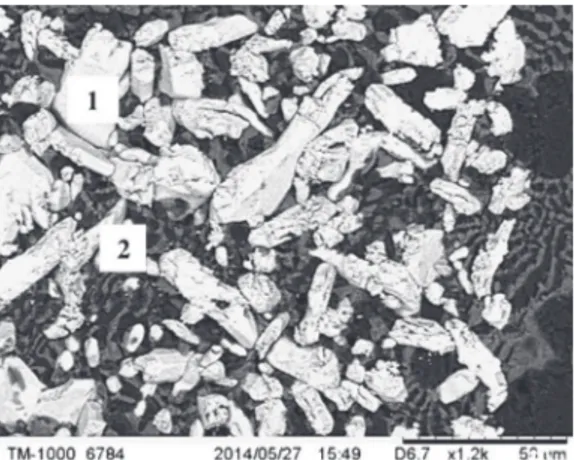

Moreover,theelectrolysisof aCuOpelletat"0.15Aand 900!C

confirmedthis result: 100

m

mto1000m

mmetallic Cu clusters (micrographinFig.5,II)wereobtained.The current efficiency was also calculated, following the equation:

h

¼mexperimental mtheoreticalwheremexperimentalisthemassofthemetallicdepositobtainedby

electrolysis(g)andmtheoreticalisthetheoreticalmassofmetallic

depositexpectedtobeobtainedbyelectrolysis(g),calculatedas following:

mtheoretical¼I)t!

n)F)Mmetal

whereIistheintensityoftheimposedcurrent(A),tiselectrolysis duration(s),nisthenumberofexchangedelectronspermoleof metallic oxide (n=2 for CuO!Cu reduction), F is the Farady constant(96480Cmol"1), and M

metalis theatomicmassofthe

metal(forCu,M=63,54gmol"1).

The calculated current efficiency for CuO reduction into metallicCuwasverycloseto100%.

Nd2O3reductioninpresenceofCuOwasfurtherinvestigated.

Cu–Ndphasediagram[44]presentsseveralliquidandsolidalloys, andcompositionofNd2O3–CuOpelletswaschosentobeinthe

zonewhereliquidalloysareformed:65atomic%Ndand35atomic %Cu.ThelinearvoltammogramofNd2O3–CuOat10mVs"1inLiF–

CaF2–Li2O(2mass%)(voltammogrambinFig.5,I)showsalsoa

reduction signal starting from "1.4V vs Pt, due to the direct electrochemical reduction of CuO. Additional cathodic signals, between"1.0and"1.3VvsPt,wereassignedtoimpuritiespresent inthesolvent(comparedtovoltammogramainFig.5,I)andinthe 99%purityCuO(comparisonwithvoltammogramcin Fig.5,I). Afterelectrolysis at"0.15A (500% Qth)and 900!C, thesample

presentedseveralzones(Fig.5,III):

– Zone 1, composed of NdCu4, NdCu5 and NdCu6 droplets

(size< 50

m

m);– Zone2,composedofrecrystallizedLiFandCaF2;

– Zone3,composed ofNdOFandCaO,but nocompactlayeris observedonsamplesurface.

TheseresultsconfirmNd2O3reductionispossiblewhenCuOis

simultaneouslypresent,leadingtoformationofCu–Ndalloys,and amulti-stepreductionmechanismwasproposed,asfollows:

1ststep:ChemicaldecomplexationofNd2O3intoNdOF:

Nd2O3+2F"!2NdOF+O2" (6)

2nd step: CuO direct reduction at the cathode, leading to metallicCu,behavingasreactivecathode:

Mocathode:CuO+2e"

!Cu+O2"+porosity (7)

3rdstep:NdOFreductiononthesurfaceofmetallicCu,leading toCu-Ndalloys:

Metallic Cu reactive cathode: Cu+NdOF+3e"!Cu–Nd+O2"+

F" (8)

Thethirdstepofthismechanismwasconfirmedbyelectrolysesof Nd2O3-Cu metallic powder mixture, which also led to the

formation ofCu–Nd alloys.Nourryetal. presentedalso similar results, showing that Nd3+reduction oncopper cathodeled to

formationofCu–Ndalloys[37,45,46].

Fig.5. ILinearsweepvoltammogramsinLiF–CaF2–Li2O(2mass%)at10mVs"1and900!C.Dottedline:solvent,continuousline:Nd2O3–CuO,interruptedline:CuO.II,III Micrographsofpelletscross-sectionsafterelectrolyses(I="0.15A,500%Qth)at900!CinLiF–CaF2–Li2O(2mass%).II.CuO;III.Nd2O3–CuO:65atomic%Nd"35atomic%Cu.

Several authorsprovedthereductionof rareearth oxidesin presenceofmetallicoxidestobesuitableforobtainingrareearth alloysinmoltenchlorides.Moreover,theyalsoproposedreduction mechanismswherethemetallicoxide(Co3O4,NiO,Co3O4,Fe2O3)

wasfirstreducedonthecathode,followedbythereductionofrare earthoxideandformationofalloys[27–32].

ThecurrentefficienciesforNd2O3reductioninpresenceofCuO

ormetallicCupowdercouldnotbeestimated,duetothelackof homogeneityof thesample andthe smallsizeof Cu–Ndalloys droplets (<50

m

mdiameter,Fig.5,III),whichcouldnotbefully recoveredtobeweighted.Nevertheless,whenNd2O3–CuOelectrolyseswereperformedat

higher temperature (1040!C), coalescing of Cu–Nd droplets

occurred (size$500

m

m to 2mm), facilitating theirrecovery at theendofelectrolysis.Inthiscase,theglobalcurrentefficiency couldbeestimatedusingtheequation(8)anditsvaluewas$70%. The remaining30% current fractioncould berelatedtosolvent reduction(Ca+andLi+)anduncompleterecoveryandseparationof Cu–Ndalloysfromthesalt.Thereductionofneodymiumoxideinpresenceofcopperoxide presentsseveraladvantages:

- CuO directreductionledtocreationofporosityin thepellet, enablingthepenetrationofmoltensaltinthebulkofthesample and thusenhancingtheinteractionbetweenthesolvent, the metallicCuobtainedbyreductionandtheneodymiumoxide; - Underpolarization,themetalliccopperobtainedbyCuOdirect

reduction behaves as reactive cathodic material, leading to formationofCu–Ndalloys.

TorecoverhighpuritymetallicNd,CuandNdseparationcanbe easilyaccomplishedbytheelectrorefiningprocess,duetothelarge differencesoftheirelectrochemicalpotentials:inLiF–CaF2at840!

C,ECu2+/Cu=2.83V/Li+/LiandENd3+/Nd=0.35V/Li+/Li[37].Thus,Nd

fromCu-NdalloyscanbeselectivelyoxidizedintoNd(III),which willbefurtherdepositedashighpuritymetallicNdonthecathode. Meanwhile, pure metallic Cu remaining at the anode can be recycledandreusedforNd2O3reduction.

3. Conclusions

Inmoltenfluoridemedia,thereductionofNd2O3wasshownto

beindirect,similartotheOSprocess.Nevertheless,reductionof neodymiumoxideintometallicneodymiumdidnotoccurwhen usinganinertcathodicmaterial(Mo),regardlessoftheoperating parameters(temperature,current,fabricationoftheoxidepellet). Thelimitingfactorswererelatedtothe:

1.PhysicalcharacteristicsofNd2O3:lowconductivityand

unfav-ourablePilling-Bedworthcoefficient.

2. Solvent: Indirect reduction of Nd2O3 in molten salts is

thermodynamicallyachievable(

D

rG!< 0)forCa-basedsolvents only,whenmetallicCaisobtained.However,adenseinsoluble CaO layer was formed overall the sample surface, acting as diffusionbarrierforO2",preventingthereductionoftheoxidepellet.

Moreover,Nd2O3behaviorwasinfluencedbytemperature:at

900!C, the oxide was decomplexed into insoluble chemically

stable NdOF, while at 1040!C it ledto formation ofcrystalline

aggregates. Thus, electrowinning of metallic neodymium from neodymiumoxidecannotbeperformedinmoltenfluoridemedia inabsenceofNdF3.

Addition of a conductive metallic oxide to the neodymium oxidewasfurtherinvestigated.WhenNd2O3–CuOandNd2O3–Cu

pelletswereelectrolyzed,metallicneodymiumwasrecoveredas

alloyedCu–Nddroplets,andathighertemperature(T>1040!C)a

bettercoalescencewasobserved.Thefollowingreduction mecha-nismwasproposed:

TheCu,initiallypresentinmixturewithNd2O3orproducedby

CuOdirectelectroreduction,actsasadepolarizingreactivecathode forNd3+(NdOF)reduction,leadingto

Cu–Ndalloys.Thisstrategyis theonlyoneviable forobtainingmetallicNdfromneodymium oxideinmoltenfluorideswithoutNdF3.Furthermore,highpurity

metallicNdcanberecoveredbyasimpleelectrorefiningprocess, while the metallic Cu can be recycled and reused for Nd2O3

reduction. 4. Experimental

Thecelldesignconsistedinavitreouscarboncrucibleplacedin acylindricalvesselmadeofrefractorysteel.Theinnerpartofthe cellwallwasprotectedagainstfluoridevapoursbyagraphiteliner. Experimentswereperformedunderinertargonatmosphere.The moltensalt(200g)wascomposedofLiF-CaF2eutectic,dehydrated

byheatingundervacuumfromroomtemperatureuptomelting point(767!C).Li

2Opowder(Cerac99.5%)wasusedtoprovideO2"

ionsinthebath,toensuretheanodicreaction(2O2"

!O2+4e").

Nd2O3(Aldrich99.9%),CuO(Merck99%)andCumetallicpowder

(Goodfellow99.8%)wereusedintheformofpelletssinteredby applyingapressureof3.2tcm"2toseveralmilligrams(from100to

300mg) of powder, at 25!C. The pellets, attached with a

molybdenumgridconnectedtothecurrentleadbyamolybdenum wire,wereusedasworkingelectrodes.Theauxiliaryelectrodewas agoldwireorplate,withalargesurfacearea(S=3cm2),andall

potentialswerereferredtoa platinumwire (0.5mmdiameter), actingasaquasi-referenceelectrodePt/PtOx/O2".

The electrochemical experiments were performed with an AutolabPGSTAT 30potentiostat-galvanostat.Afterresin embed-ding and polishing, the cathode bulk was examined with a scanningelectronmicroscopeSEM(LEO435VP)equippedwith and EDS probe (Oxford INCA200). XRDcharacterisations were performed with an Equinox 1000 diffractometer. Quantitative analysis wereperformed witha Cameca SXFive electronprobe microanalyser.Nevertheless,neitherSEM-EDSnorelectron-probe microanalysisdonotprovidedataonLi.Meanwhile,SEM-EDSdo notprovidedataanalysisonlightelementssuchasfluorideand oxygen.

References

[1]K.Binnemans,P.T.Jones,B.Blanpain,T.VanGerven,Y.Yang,A.Walton,M. Buchert,J.CleanerProd.51(2013)1–22.

[2]E.Morrice,E.S.Shed,T.A.Henrie,U.S.Bur.MinesRep.Invest.7146(1968). [3]E.Morrice,M.M.Wong,Miner.Sci.Eng.11(1979)125–136.

[4]Y.Qiqin,L.Guanqun,F.Zhongan,S.Lichang,RareMet.8(1989)9. [5]M.F.Chambers,J.E.Murphy,U.S.Bur.MinesRep.Invest.9391(1991). [6]A.Kaneko,Y.Yamamoto,C.Okada,J.AlloysCompd.193(1993)44–46. [7]C.Shiguan,Y.Xiaoyong,Yu.Zhongwing,Lu.Qingtao,RareMet.13(1994)46. [8]J.E.Murphy,D.K.Dysinger,M.F.Chambers,LightMet.(1995)1313–1320. [9] D.W.Dees,J.P.Ackerman,UniversityofChicago,USPatent0045835A1,(2004). [10]Y.H.Kang,S.C.Hwang,H.S.Lee,E.H.Kim,J.Met.Process.Technol.209(2009)

5008–5013.

[11] R.Fujita,H.Nakamura,K.Mizuguchi,S.Kanamura,T.Omori,K.Utsunomyia,S. Nomura,KabushikiKaishaToshiba,USPatent0314260A1,(2010). [12] B.H.Park,I.C.Choi,J.-M.Hur,J.Chem.Eng.Japan45(2012)888–892. [13]E.-Y.Choi,J.W.Lee,J.J.Park,J.-M.Hur,J.-K.Kim,Chem.Eng.J.514(2012)207–

208.

[14]S.Seetharaman(Ed.),TreatiseonProcessMetallurgy,vol.3,Elsevier,2014,pp. 995–1069.

[15]E.Stefanidaki,C.Hasiotis,C.Kontoyannis,Electrochim.Acta46(2001)2665– 2670.

[16]E.Stefanidaki,G.M.Photiadis,C.Kontoyannis,A.Vik,T.Østvold,J.Chem.Soc. (2002)2302–2307.

[17]R.Thudum,A.Srivastava,S.Nandi,A.Nagaraj,R.Shekhar,Min.Process.Extr. Metall.(Trans.Inst.Min.Metall.C)119(2010)88–92.

[18]D.K.Dysinger,J.E.Murphy,USBur.MinesRep.Invest.9504(1994). [19]E.Morrice,E.Shedd,T.Henrie,USBur.MinesRep.Invest.7146(1968). [20] Y.Bertaud,AluminiumPechiney,EuropeanPatentEP0289434(A1),1988. [21]D.Chen,SolutionofNeodymiumandformationofslimeduringthe

neodymiumelectrolysis,J.RareMet.32(2008)482–483Translatedfrom ChinesebyJ.Wang,inChinese.

[22]W.Li,Utilizationrateofneodymiumoxideinproducingmetallicneodymium, Non-ferrousSmelting4(50)(2001)35–36TranslatedfromChinesebyJ.Wang. [23]E.Morrice,R.G.Reddy,Solubilityofrareearthoxidesinfluoridemelts,

SymposiumonHighTemperatureandMaterialsChemistry,Berkeley, California,1989.

[24]X.Guo,J.Sietsma,Y.Yang,1stEuropeanRareEarthResourcesConference2014, MilosIsland,Greece,4–7September,2014,pp.149.

[25]G.Z.Chen,D.J.Fray,T.W.Farthing,Nature407(2000)361–364. [26]K.Ono,R.O.Suzuki,J.Min.MetalsMat.Soc.54(2002)59–61. [27]A.M.Abdelkader,D.J.Hyslop,A.Cox,D.J.Fray,J.Mater.Chem.20(2010)

6039–6049.

[28]B.J.Zhao,L.Wang,L.Dai,G.G.Cui,H.Z.Zhou,J.AlloysCompd.468(2009) 379–385.

[29]L.Dai,S.Wang,Y.-H.Li,L.Wang,Trans.NonferrousMet.Soc.China22(2012) 2007–2013.

[30]Y.Zhang,H.Yin,S.Zhang,D.Tang,Z.Yuan,T.Yan,W.Zheng,J.RareEarths30 (2012)923–927.

[31]G.Qiu,D.Wang,M.Ma,X.Jin,G.Z.Chen,J.Electroanal.Chem.589(2006) 139–147.

[33]K.A.GschneiderJr.,L.Eyring,HandbookonthePhysicsandChemistryofRare EarthsCh.27,North-HollandPublishingComp.,1979,pp.386.

[34]M.Gibilaro,S.Bolmont,L.Massot,P.Chamelot,J.Electroanal.Chem.726(2014) 84–90.

[35]M.Gibilaro,L.Cassayre,O.Lemoine,L.Massot,P.Chamelot,J.Nucl.Mater.414 (2011)169–173.

[36]L.Massot,L.Cassayre,P.Chamelot,P.Taxil,J.Electroanal.Chem.606(2007)17– 23.

[37]C.Nourry,Thèsededoctoratdel’UniversitéPaulSabatier,Toulouse(2007)51. [38]D.-G.Kim,M.-A.VanEnde,C.Liebske,C.vanHoek,S.vanderLaan,P.Hudon, I.-H. Jung,9thInternationalConferenceonMoltenSlags,FluxesandSalts,Beijing, China,27–30May,2012,pp.110.

[39]S.S.Batsanov,A.A.Deribas,FizikaGoreniyaIVzryva1(1965)103–108English version:Combustion,ExplosionandShockWaves1(1965)77–80(10.1007/ 2FB00757157)..

[40]N.B.Pilling,R.E.Bedworth,J.Inst.Met.29(1923)529–591. [41]W.Li,X.Jin,F.Huang,Angew.Chem.Int.Ed.49(2010)3203–3206. [42]M.Gibilaro,J.Pivato,L.Cassayre,L.Massot,P.Chamelot,Electrochim.Acta56

(2011)5410–5415.

[43] A.A.Samokhvalov,N.A.Viglin,B.A.Gizhevskîi,N.N.Loshkareva,V.V.Osipov,N. I. Solin,Y.P.Sukhorukov,Zh.Eksp.Teor.Fiz.103(1993)951–961English version:J.Exp.Theor.Phys.76(1993)462–468(http://www.jetp.ac.ru/cgi-bin/ dn/e_076_03_0463.pdf)..

[44] BinaryAlloyPhaseDiagrams,S.E.,ASMInternational,1996.

[45]C.Nourry,L.Massot,P.Chamelot,P.Taxil,J.Appl.Electrochem.39(2009) 927–933.

[46]C.Nourry,L.Massot,P.Chamelot,P.Taxil,J.Appl.Electrochem.39(2009) 2359–2367.