O

pen

A

rchive

T

OULOUSE

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

This is an author-deposited version published in :

http://oatao.univ-toulouse.fr/

Eprints ID : 16009

To link to this article : DOI : 10.1016/j.apor.2016.01.009

URL :

http://dx.doi.org/10.1016/j.apor.2016.01.009

To cite this version :

Kamsu-Foguem, Bernard Information

structuring and risk-based inspection for the marine oil pipelines.

(2016) Applied Ocean Research, vol. 56. pp. 132-142. ISSN

0141-1187

Any correspondence concerning this service should be sent to the repository

administrator:

staff-oatao@listes-diff.inp-toulouse.fr

Information

structuring

and

risk-based

inspection

for

the

marine

oil

pipelines

Bernard

Kamsu-Foguem

∗UniversitédeToulouse,LaboratoiredeGéniedeProduction(LGP),EA1905,47Avenued’Azereix,BP1629,65016TarbesCedex,France

Keywords: Experience Knowledge Inspection Maintenance Riskassessment Equipmentfailure Intelligentpigging Safety Environment Offshoreproduction

a

b

s

t

r

a

c

t

Theproposedworkisincorporatedintotheresearchthemeconcerningthemaintenanceandinspection ofsensitivefacilitiesinproductionsystems.Itisessentialtopromotethemethodologicaldeployment ofinspectiontechniquestoensurethegoodfunctioningofservicesprovidedbycomplexproduction systemsaswellastheirdifferentcomponents.Weusearisk-basedinspectionmethodologyoffering anorganizedanalysiswithknowledgesharingforcollaborativepossibilitiesinamultidisciplinary con-textanditconsistsofthefollowingsteps:dataacquisitionandinformationcollection,failureanalysis (probabilityandconsequences),riskassessment,inspectionplan,mitigationandrevaluation.The appli-cationofthismethodologycanimprovethemaintenancemanagementstrategiesofindustrialcompanies. Theinspectiondepartmentisabletoforecastitspotentialfailure,rootcausesandimpactsonthesafe operationoftheconsideredproductionsystem,basedonareliableinventoryofexistingsituationsand reviewoptionsforcontinuousimprovementinmaintenancemanagement.Inparticular,weaddressed theapplicationofaRisk-BasedInspection(RBI)methodologyintheFrenchpetroleumcompanywith operationsonthewestcoastofcentralandsouthernAfrica.Theincorporationofexpertknowledgeinto riskassessmentishelpingtofindthebestpreventiveplanforpipelineinspectioninthecasestudy.

1. Introduction

Thecurrentmanagementframeworksofindustrialenterprises

mustintegrateengineeringstandardsandrecommendedpractices

toreflecttheincreasingcomplexityofproductionsystems.In

addi-tion,thelegislationrequiresthatenterprisescomplywith

appli-cablenormativerulesbyusingindustrialpracticesthatare

envi-ronmentallyandlogisticallysustainable.Incertaincircumstances,

Abbreviations:Ath,AllowedminimumTHickness;CMIMS,Computerized Main-tenanceandInspectionManagementSystem;Cof,Consequenceofthefailure; CL,CorrosionLikelihood;CR,CorrosionRate;EFF,Effectiveness;ESD,Electrical SchematicDiagram;FPSO,FloatingProduction,StorageandOffloading;HSE,Health, SafetyandEnvironment;HV,High-Voltage;HMI,Human–machineinterface;LAY, Lay-out;Lof,Likelihoodoffailure;LV,Low-Voltage;MAOP,MaximumAllowable OperatingPressure;MOP,MaximumOperatingPressure;MOGA,Multi-Objective GeneticAlgorithm;NCL,NaturalCorrosionLikelihood;P&ID,Pipingand Instru-mentationDiagram;PCS,ProcessControlSystem;PFD,ProcessFlowDiagram;PSS, ProcessSafetySystem;PLC,ProgrammableLogicController;RBI,Risk-Based Inspec-tion;RCM,ReliabilityCentredMaintenance;SLD,Single-LineDiagram;ST,State; SLD/C,StructuraldesignorconstructionfailureLikehood;SLthird,Structuralfailure thirdpartyLikehood;SLmec,StructuralmechanicalfailureLikehood;SLnat, Struc-turalnaturalfailureLikehood;SL,StructureLikelihood;SAP,Systems,Applications &ProductsinDataProcessing;UFD,UtilityFlowDiagram.

∗Tel.:+33624302337;fax:+33562442708. E-mailaddress:Bernard.Kamsu-Foguem@enit.fr

thelawobligescompaniestomakeriskinformation(threat

cryp-togramsandtheassociatedriskandsafetydescriptions)available

ontheindustrial sites.Theincreasingcomplexity ofoiland gas

installationsandoperations,alongwithgrowingpublicawareness

toensurehigherlevelsof safety,hasputgreatpressure onthe

designersandoperatorstofindinnovativesolutionstoensuresafe

aswellaseconomicallyviableoperation[1].Reliabilityand

Main-tenancewithtoolssuchasRCM(ReliabilityCentredMaintenance)

andRBI(Risk-BasedInspection)contributetocollaboratively

work-ingtowardsseekingreasonableandpracticalsolutionsinthe

indus-trialsettings[2].Inscientific literature,therearedifferent

cate-goriesofriskanalysisandrisk-assessmentmethodsandtechniques

(qualitative, quantitative and hybrid approaches) [3]. A varied

rangeofmethodologiespresentlyinuseforrisk-basedinspection

includesmarketableandinternalsoftwarepackagesparticularto

explicitplants[4].Inthecomplexproductionsystems,thework

packageofmaintenanceengineeringisimportanttoensure

conti-nuityofservices,optimizeproductioncapacity,improvesafetyand

reducetheenvironmentalimpact.RiskBasedInspection(RBI)isan

interestingmaintenanceperspectivewithanincrementalstepwise

procedureusedtoexaminesensitiveequipmentsuchaspressure

vessels,heatexchangersandpipingincomplexindustrialplants

[5]. RBI providesa modellingprocess for organizationsto

con-trolitsreliability,safetyandhealthaspects,ensuremaintenance

complianceandtoiterativelyimprovethetechnicalperformance

and cost of projects [6]. However, the implementation of the

RBIrequiresstructuredandcoherentinformationmanagementin

ordertomaximizeitsintegrationinthetargetcomputerized

man-agementinformationsystemformaintenanceandinspection.The

aimofthisworkistoproposeaconceptualapproachproviding

structuredinformation forsemanticmodellingof the

hierarchi-calorganizationofcomponentsthatcharacterizeallthesensitive

areasofacomplexsystemthatmustbeinspectedorverifiedbythe

RBImethod.Thissemanticmodellingwillformalizethetaxonomic

organizationofequipmentandinstrumentsoftheconsidered

sys-tem.These componentsare classifiedaccordingto theirnature

throughthestudyofessential documentsandinformation

pro-videdbyvendorsandthemanufacturerofthesystem.Theobtained

structured information canbe transferred totheComputerized

MaintenanceandInspectionManagementSystem(CMIMS)forthe

managementissues(analysisanddiagnosis)orengineeringissues

(tasklists).

The paper is structured as followed. Section 2 exposes a

backgroundoftheriskbasedinspectionmanagement.Section3

presentstheindustrialchallengeoftheriskbasedinspection

man-agement.Section4presentsthesuggestedmethodology.Section

5.1describesanillustrativecasestudyforpetroleumpipelines.

Sec-tion5.2deliversananalysisofthisstudy.Sections6and7presents

theresultsanddiscussionbasedonresearchfindings.Finally,

Sec-tion8givestheconclusionandunderlinesboththerelatedworks

andthechallengesthatlayahead.

2. Background

2.1. Practicesofrisk-basedinspection

Risk-basedInspection(RBI)offerspracticalwaysforthe

imple-mentationofaninspectionprocessthatprovidestomaintenance

actorsamethodofassessingtheprobabilityandeffectoffailure,

evaluatingrisklevelandgeneratingthekindsofrelevantactions

thatcanleadtodevelopmentofrequiredriskmanagementpolicies

[7].TherearedifferentillustrationsofRBIpracticeswhichincrease

costeffectiveactionsandcanbeconsideredaspromising

develop-mentstoshiftfromareactivetoaproactivemaintenance

manage-mentinvariousdomains.Wementionasexamplesthe

implemen-tationofriskassessmentincivilengineeringapplications[8].Inthe

petrochemicalandchemicalindustries,thedeploymentofonline

andofflineinspectionprocedurestoequipmentsuchaspipelines

hasledtosubstantialimprovementsinoperationalreliabilityand

thepreventionofincidents(e.g.ManagementofCorrosion)[9,10].

Innuclearengineeringanddesign,therearecurrentpracticesand

trendsin the risk-basedinspectionand maintenance for safety

evaluation[11].TheRBImethodwasusedtoassesstheriskof

large-scalecrudeoiltanksinordertodeterminetheacceptableriskand

internalinspectionintervaloftanks[12].Therearesome

exam-plesoftheapplicationofrisk-basedmethodsinindustrialcoal-fired

boilerswithsomeinterestingresults[13].RBIprogrammesarealso

establishedforreliabilityanalysispurposesinheavywaterplants

withtheassessmentoffailurepressureandestimationofthe

fron-tierstatefunctionalanalysis[14].TheRBImethodsarealsoadopted

andusefulintheoffshorewindenergyindustryfortheorganization

ofmaintenancelogisticswithsignificantinfluencesonimportant

costparametersofenergyproduction[15–17].

Ingeneral,themajorityofindustrialapplicationsofRBI

method-ologiesareusedintherefinerysystemsandpetrochemicalsectors

[18].RBIaddressesclearlythethreats(personneldeathandinjury,

damage totheenvironment and financialloss) to theintegrity

oftheassetanditisperformedforpipingandvessels,including

heatexchangers,tanks,pressurevessels,andfilters[19].Pipeline

systeminspectionscanbedoneeitherinternallyorexternallyas

continuousinspectionsoverthecompletepipelinelengthoraslocal

inspectionsforparticularsectionsorlocalzonesinorder[20]:

•In-Lineinspections(ILI)ofpipelinesaregenerallyaccomplished

usingapig.Thepigmovesthroughthepipelineguidedbythe

floworfluidormaybepulledbyavehicleoracable.Itgathers

dataasitturnsthroughthepipeline.Thetechnicalresourcesmay

beautomaticorself-containedormaybeactivatedfromoutside

thepipelineviaadataandpowerconnexion.Diversetechnical

resourcescanbecombinedinapigtrain.Theinternalinspection

techniquescomprisesMagneticFluxLeakage,Ultrasound

Tech-nology(UT),Laser-opticalinspectiontool,GeopigandCalliper.

•Externalinspectionsaregenerallyaccomplishedusingaremotely

operated transporter equipped with diverse inspection

tech-niques and resources.Thiscanfor instancebetechniquesfor

visualinspections(videorecording)andphysicalmeasurements

(steelelectrochemicalvoltagemeasurements).External

inspec-tioncanalsobeaccomplishedbya divingteam.Theexternal

inspection techniquescomprises Visual/Video/photo,sidescan

sonar (SOund NAvigation Ranging), Multibeam Echosounder

(MBE),Crossprofiler,Pipetracker,Subbottomprofiler,Stabbing,

EddyCurrentandExternalUT(UltrasonicTesting).

Thescopeoftheseinspectionsmethodsencompassesall

pres-sure systems in the industrial site, and they can be used to

inspectpipes/otherstaticequipmentandtakethegeometric

mea-surements(diameter,wallthickness,metalloss,crackandother

defects). The selection of inspection method is based on

opti-mizing anumber offeatures thatsymbolizeeach technique:(i)

Confidenceinidentifyingtheestimateddamagestate,(ii)Costof

technique/method,includinghumanandtechnicalresources,and

(iii)Magnitudeofmaintenancesupportnecessarytoperformthe

work(scaffolding,processshutdown,openingofequipment).

2.2. Principlesforriskevaluation

The RBI evaluation is used to engender an inspection plan

at desired detail level of the consideredsystem withadequate

time allowing tonot exceeded therisk limit, to keep track of

degradationprocesseswiththepotentialselectionofthe

appro-priatemitigationaction.Riskacceptancelimitsforinspectionplan

ningresultingfrommaintargetsrelatedtoavailability,profitand

safetycanimplypuremaintenanceengineeringacceptancecriteria

suchasacceptablewallthickness(requirementforpressure

retain-ingpurposes).Theriskevaluationisbasedonconsequencesand

probabilitiesoffailuresthatareevaluatedinadistinctway,under

thefollowingassumptions[21]:

•Theconsequencesofsystemfaults,lossofmainfunctionsand

sub-functions,areindependentoftheequipmentcarryingout

thefunctions.

•Theactualequipmentandtheoperationalconditionsaffectthe

probabilityoffailure.

TheoutcomeoftheRBIprocessisdeterminationof[22]:

•locationandextentofinspectionsandconditionmonitoring,

•inspectionmethods,

•inspectionintervals.

The consequences of main function failures are evaluated

accordingtotheeffectontheenterprise,activitysector,industrial

siteandsystemlevelregardingtheproductionlossanddirectcost

measuredininterruptionandeconomicterms,whileconsequences

Table1

Generalconsequenceclassification[21].

Class Health,SafetyandEnvironment(HSE) Production Cost(exclusiveproductionloss) High Potentialforseriouspersonnelinjuries.

Rendersafetycriticalsystemsinoperable. Potentialforfireinclassifiedareas. Potentialforlargepollution.

Stopinproduction/significantreducedrate ofproductionexceedingXhours(specify duration)withinadefinedperiodoftime.

Substantialcost–exceedingYNOK (specifycostlimit)

Medium Potentialforinjuriesrequiringmedicaltreatment. Limitedeffectonsafetysystems.

Nopotentialforfireinclassifiedareas. Potentialformoderatepollution.

Briefstopinproduction/reducedrateof productionlastinglessthanXhours (specifyduration)withinadefinedperiod oftime.

ModeratecostbetweenZ–YNOK (specifycostlimits)

Low Nopotentialforinjuries.

Nopotentialforfireoreffectonsafetysystems. Nopotentialforpollution(specifylimit)

Noeffectonproductionwithinadefined periodoftime.

InsignificantcostlessthanZNOK (specifycostlimit)

Table2

Theclassificationofequipmentaccordingtheirtechnologicalcomplexity.

Technologicalcomplexity Low Medium High

Equipment

Staticequipment withoutinstruments

Lowspeedrotaryequipment(speed≤3000rpm) Highspeedrotaryequipment(speed>3000rpm) Pipelines Verticalpumps(power<500kW) Allcompressors

Storagetanks Controlandsafetyvalves Gasturbines

Incinerators Electricalcomponents(voltage<400V) Rotaryhydraulicequipment ... Instrumentation Electricalcomponents(voltage>400V)

classifiedwithregard topredeterminedconsequencecategories

andapprovalcriteria.

Concerning the evaluation of failure probabilities, this is

indirectly expressed by the maintenance characteristics and

operationalexperiences.Essentially,theequipmentfailuremodes,

operationalconditions,locationandexternalenvironmental

fac-torsarefundamentalelementscontributingtothecalculationof

theprobabilitiesoffailureaccordingtothefunctionsthe

equip-mentsupportsandapplicablegenericmaintenanceconcepts.These

genericconceptsareissuedfromthecollectionofbestpractices

ofmaintenanceactions,strategies andmaintenancedetails(e.g.

structuredanalysisidentifyingfailuremodesandfailurecauses)

foranenterprise.

Thegeneralconsequenceclassification(definedinTable1)is

madeinaccordancewithcriteriaforHealth,safetyand

environ-ment(HSE),ProductionandCost(exclusiveproductionloss)

Theconsequenceclassificationmethodologyisappliedfor

cat-egorizing of static mechanical equipment with the purpose of

selecting critical equipment for furtheranalysis and prioritizes

themforin-depthriskevaluationsasthebasisforpreparationof

inspectionandmaintenanceprogrammes.

Thetechnologyofequipmentis afactor influencing

mainte-nance activities. Therefore it is possible to classify equipment

accordingtothetechnologicalcomplexityneededtoexecutethe

maintenanceengineering.Someexamplesofequipmentclassified

accordingtotheirtechnologicalcomplexityareprovidedinTable2.

3. Industrialchallenge

Ingeneral,themaintenanceandinspectionactivitiesare

con-ductedincompliancewiththeconsideredenterprisepolicywith

thefollowingobjectives:

•Safetyandhealthofpersonnelandfacilities

•Carefortheenvironment

•Sustainedoperationandperformance oftheinstallationsover

time

•Maintainassetintegrity

•Retainedinvestmentcapitalvalueofplantandstructures

•Compliancewithapplicablelocallegislation

Thepurposeofinspectionactivitiesistoestablishabasisfor

preparationandoptimizationofmaintenanceplansforindustrial

sites. The principles of risk analysis are essential for selection

andprioritizationofrelevanttypesofsiteequipmentand

associ-atedmaintenanceactivities.Forinstance,theriskassessmentand

inspectionprocesscanbefocusedonstaticprocessequipmentin

industrialfacilities,duetechnicalorfunctionaldeclines.

Theprocess-basedinspectionrequiresknowledgeofthe

follow-ingelements[22]:

•damagemechanismwhichdependsonmaterialproperties,

inter-nalfluidcompositionsandtheexternaloperationalenvironment

–influentialtheprobabilityoffailure,

•consequenceofleakfailurewithrespecttopersonnel,

environ-mentdamagesandfinanciallosses.

Thecombinationoftheabovecharacterizestheriskoffailure

requiringthereductionormitigationofassociatedconsequences

withintheindustrialsystem.

Inparticular,theworkpackageofinspectionprovidesthe

enter-prise inspectionteam withthedocumentsfor thedefinitionof

theinspectionstrategy,programmeandplanforeachofthe

sys-tems.Foreachdocument,someinformationisneeded:TAGnumber

(documentnumber),supplierdocumentnumber,title,kindof

doc-ument(drawing,datasheet,suppliermanual,etc.)anddisciplines

(mechanical,electrical,inspection,fabricmaintenance,

instrumen-tation,methodsandmaintenanceengineering).

Inordertomakethedescriptionofanhierarchicalarrangement

ofsystemcomponents,thefollowingdocumentsareuseful:

•PipingandInstrumentationDiagram(P&ID):aP&IDisadiagram

thatdefinesalltheelementsofachemicalprocess.TheP&ID

con-tainstheinstruments,equipment,valvesandotherswiththeir

designations.

•ProcessFlowDiagram(PFD):aPFDisadiagramusedtodescribe

themaincomponentsofachemicalprocess.Onlyequipmentin

directcontactwiththechemicalproductsandthetransportation

thereof(pumps,hoses,etc.)arerepresented.

•UtilityFlowDiagram(UFD):thesameprincipleasthePFD.

•Single-LineDiagram(SLD):aSLDprovidesabasicunderstanding

ofthefunctionsofthecomponentsofasystem.Itsvisionisvery

simplified.

•ElectricalSchematicDiagram(ESD):anESDisagraphic

repre-sentationofanelectricalcircuit.Itshowsthecircuitcomponents

intheformofstandardizedsymbols,aswellaspowerandsignals

betweenthesecomponents.

•Equipmentlist.Itidentifiesalltheequipmentthatispresentin

theP&ID,PFD,UFD,LAY,SLDandESD.

3.1. Hierarchicalarrangementforthepreparationofinspection andmaintenance

Theproperdocumentationandclassificationofthecategories,

characteristics,andinterrelationshipsoftheobjectsthatactually

orprimarilyexistforaspecificapplicationfieldisrecognizedas

animportantandfundamentalactivityinsupportofthe

imple-mentation of the information modelling [23]. The hierarchical

arrangementofdifferentsubsetandelementsofatargetsystem

canbeusefulinassociationwithmakingselectionsastohowthe

inspectionplanningprocessistobeexpressedandformalized.The

levelofdetailingmaybeaugmentedforthehigh-riskfunctionsand

relatedsubsystemsandelements.Itpossibletoestablishthe

func-tionalhierarchyandthetechnicalhierarchyofsystemelements

(e.g.part,component,pipeorequipment)thatcanbe

character-izedby aunique identification(i.e.atag number)allowingthe

traceabilityofinspectionandmaintenanceprocesses.

3.1.1. Technicalhierarchy

Thetechnicalhierarchyisthefoundationonwhichan

effec-tiveinspectionprogrammeandmaintenancemanagementshould

bebuilt.Itdefinesthetechnicalstructureoftheindustrialsiteby

describingfunctionallocationswithuniqueidentifiers.The

tech-nicalhierarchyoffersanoutlineofequipmentunitsbelongingto

thesametechnicalgroup,andindicatesthephysicalrelationship

betweenmainequipment,instruments,valves,etc.Thegoalofthe

technicalhierarchyisasfollows:

•displaytechnicalinterdependenciesoftheinstallation;

•extractionoftags,equipmentandspareparts;

•extractionofdocumentsanddrawings;

•extractionofhistoricalinspectionandmaintenance datafrom

ComputerizedMaintenanceandInspectionManagementSystem

(CMIMS);

•scheduling of operations (e.g. relationshipsdue to shutdown

etc.);

•costallocationandextraction;

•schedulingandorganizationoftheinspectionandmaintenance

programme;

•schedulingofcorrectivework.

Technicaldrawings(e.g.flowandone-linediagrams,P&IDs,etc.)

canbeusedtoclassifypackagesandmainequipmentthatcanserve

asasuperiortagforthelinkedinstruments,valvesandothertypes

ofequipment.Thelevelonwhichtheinspectionandmaintenance

objectsareestablishedisdirectedbypracticalconsiderations(e.g.

traceability,consequenceclassificationandcostinganalysis)and

thedifferentneeds(preventiveandcorrectiveactions)to

super-viseandcheckthedifferentinspectionactivitiesandmaintenance

programmes.

3.1.2. Functionalhierarchy

Thefunctionalhierarchyisalogicaldiagramconnectingallthe

industrialsitefunctionscharacterizedasfunctionalunitsormain

functionsandsubfunctions.Thelevelofdetailingofthefunctional

hierarchymayvary,buttypically4to5levelsaresufficient.Sub

functionsareconnectedtoequipment/maintenanceobjectinthe

technicalhierarchy.

Eachequipmentwithinonesubfunctionisgiventhe

equiva-lentclassificationbecauseafault,errororfailureonanyofthese

equipment(identifiedbythetagnumbers)willcausetheidentical

consequenceonthemainfunction.

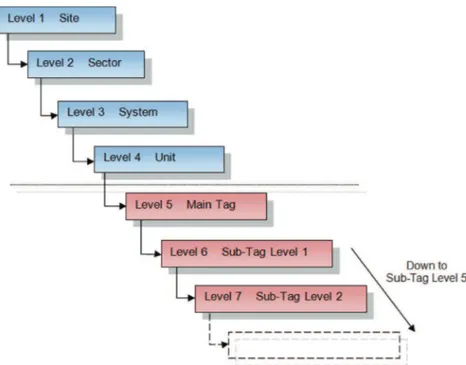

Thebreakdownbyactivitysectorshowsthatthecomponents

of systems in theindustrial site areclassifiedin thefunctional

hierarchyorganizedinatreewithdifferentlevels(fromlevel1

systemtovarioussub-Taglevels).Wecanseebelowthelevelsof

thedescribedhierarchy(Fig.1).

Thecontentsofvariouslevelsofthefunctionalhierarchyare

describedinTable3.

Table3

Thecontentsofvariouslevelsofthefunctionalhierarchy.

Level1Site Thesiteisageographicallocationoftheequipment.Forexample,projectfacilities‘CLOV’arelocatedinblock17withthecode‘CLO’. Level2Sector Thesectordescribesasetoftheprocesssystem.Thiscorrespondstoasingleinstallationsection.ForexampleforCLOV,wehavethe

followingdescription.

Code Designation Description

FPSOT Topside AllthatisonthedeckoftheFPSO

FPSOH Hull Insidetheshell

FPSOA Accommodation Thelivingquarters

BUOY Buoy Buoyofloadingoperations

SUB Subsea Underwaterworkplaces

Level3System Asystemisasetofinterdependentequipmentsharingcommonfunctionalcharacteristics.Forexample,thetreatmentofwaterfrom theinjectionwellscomprisesallfunctionalhandlingunitscontributingtotheinjectionofwater:filtration,treatmentandinjection. Level4Unit Asetofequipmentdedicatedtoaspecificprocessorautilityfunction(forexample,waterfiltrationwithinthewatertreatment

system).Aunitisapartoftheinstallationwhichisoperativelyindependent.Itisalsoanentitywhichmaybecontrolled.Theunitis identifiedbyacodeofthesubsystems.

Level5MainTag Thetagrepresentsauniquefunctionalidentificationofadeviceinasite.Allequipmentsubjecttomaintenance,inspectionor certificationmustbetag(e.g.pumps,boats,boilersand,vessels).Tagsaredefinedmainlyduringtheengineeringphaseandarelisted onthefollowingprojectdocuments:P&ID,PFD,UFDandEquipmentList.

Level6Sub-Tag Thisconcernsthecreationofothersub-levelsfromthemain-tag.Thesub-tagscanfacilitatethedescriptionofinstrumentstoidentify. Aninstrument,suchasapressuretransmitter,isalwaysconnectedtoanautomatedcontrolandsafety.Theinstrumentsbelongtoone ofthefollowingcategories:

•ProcessControlSystem(PCS)(e.g.electronicmodules,ProgrammableLogicController(PLC),Human–machineinterface(HMI)). •ProcessSafetySystem(PSS)(e.g.valvesandactuators).

•ProcessControlInstrumentation(e.g.gauges,detectors,indicators,transmitters,switches).

Thestructuraldescriptionoftheorganizationofthefunctional

hierarchyisfurthercomplementedbythefunctionaldescriptions

aboutkey features and capabilities of theequipment. Thiscan

helpthemanagertopossiblysetalternativesthatcoulddetermine

thecharacteristicsandsettingsthatareavailable[24–26].

There-fore,theusercanconsultthistechnicalannotationonanorganized

source for any updated information regarding the functional

descriptions,e.g.methanolstoragedrumcontroldevices,methanol

storagedrumleveltransmitterornitrogensupplyshutdownvalve

ofequipmentandinstrumentsarethecomponentsofthesystem

understudyinapetroleumproject.Thesefunctionaldescriptions

arereallyhelpfulinpracticalwaysinworkingwithrepairand

over-haulservices,partsprovisioning,supportservicesandengineering

services.

3.2. Maintenancepackagesandroutes

Inaddition,usingthelistofequipment,themaintenance

pack-agescanbepreparedbysimplyassigninggroupstoeachoftheinput

componentsbasedonfactorssuchasfunctionality,ergonomicsor

criticality[27].Inthecontextofpetroleumactivities,apackageisa

setofequipmenthandlingthesamemainfluidand/ordedicatedto

aspecificprocessfunction.Apackageisaportionofanindustrial

facilitythathasamaximumofoperationalautonomy.Itisalsoan

entitythatcouldbecommissionedanddismantledtofacilitatea

reorganizationorasafetyissue.

Sometypicalpackagesidentifiedarelistedbelow:

•GasCompressorpackage: Compressor/Motors(electric)/Electric

heaters/Instrumentation/Valves(ManualandActuated)/Control

Panel.

•Pump package: Pump with sealing and cooling

system/High-Voltage (HV) – Low-Voltage (LV) electric Motors/Electric

heaters/Instrumentation/Valves(ManualandActuated)/Control

Panel.

•Combustion Engine package: Diesel Engine with air starting

system,radiator(cooling)/ElectricalGenerator/Instrumentation/

Valves(ManualandActuated)/ControlPanel.

•Boiler package: Boiler/Control and monitoring system/

Instrumentation/Controlandsafetyvalves.

•Vessels package: Control and monitoring system/

Instrumentation/Controlandsafetyvalves.

Arouteisasequenceofsimilarequipment,combinedtosimplify

maintenancetasks.Therearethreedifferenttypesofroute:

•Routetype1:Appliedonauniquearea,unitorzone.This

equip-mentoftenbelongstothesametechnicalclasswhichmeansthat

theworktoperformwouldbethesame.

•RouteType2:Appliedonmultipleareas,unitsorzones.

•Individual Equipment:Applied onuniqueequipment,

indepen-dentlyoftherest.

Thenextstepistousefunctionaldescriptionsmoreeffectively

toimprovecriticalityanalysesandRisk-BasedInspectionmethods.

4. Methodology

Incontrasttothesystemsinonshoreproductionsites,systems

inoffshoreproductionsitesoperateinextremelydifficult

condi-tions,e.g.water,airandotheraspectsofthenaturalandhuman

environment.Weapplytheriskbasedinspectiontoallpipelines

(onshoreandoffshore)andrisersoperatedbysubsidiariesofthe

Frenchpetroleumcompanywithoperationsonthewestcoastof

centralandsouthernAfrica.Thiscoversthefollowingcategoriesof

pipelinesandrisers:

•Theoffshoresteelpipelines,

•Theonshoresteelpipelines,

•Thestaticsteelrisers,

•Thesteelcatenaryrisers.

Inthiscontext,theobjectivesoftheapplicationoftheRiskbased

InspectionMethodologyarethefollowing:

•Listingofthefacilitiesoperatedwithinaproduction centreto

identifypotentialfailuremodesandhigh-riskareas.

•Estimationofthevalueoftherisksassociatedwiththe

opera-tionsofeachdeviceinaproductioncluster,basedonaconsistent

methodology.

•Organizationofappropriateinspectionplansresultingfromthe

identificationofpotentialfailuremodesandriskassessment.

•Developmentofmechanicalchanges,bothtotheprocessesand

Data and information collection Consequence of failure Probability of failure Risk ranking Inspection plan Mitigation (if any)

Reassessment Risk assesment process

Fig.2.Theriskbasedinspectionorganizationprocess[39].

Fig. 2 highlights the methodology for risk based inspection.

Thismethodologyrequiresachievementofsevenmainactivities

encompassingdataandinformationcollection,riskassessment

pro-cesscomposedofprobabilityof failureratingand consequenceof

failure rating,riskrankingin riskmatrix, inspectionplan,

mitiga-tion(incase ofneed)and re-assessment[28].Thismethodology

is normally used to define a risk based inspection plan

itera-tively.

The risk matrix is interesting for engagement in

mainte-nancepreparation,inspectionprogrammingandfororderingwork

orders.Itispossibletouseavariablenumberofclassesfor

conse-quencesasforprobabilities.Forexample,thewidelyusedriskscale

(low,medium,high)orthecolourscheme(red,yellow,green)of

equipmentprovidemeanstovisualidentificationofriskacceptance

criteria(e.g.unacceptable,undesirable,acceptable,negligible)with

theemphasisplacedonpriorityareasofintervention.

Anexampleofariskmatrix(usingprobabilitiesoffailuresand

consequencesoffailure)isshowninFig.3.Thisriskmatrixdisplays

threerisklevels,indicatedthroughcolourcoding:

•Green–Lowrisk–Riskisacceptable.Generally,actionneedsto

betakentoguaranteethatriskremainswithinthisacceptable

region;normallythisinvolvesoperatorround,cleaning,general

visualinspectionstocheckthattherehavebeennoalterationsin

equipmentcondition.

•Yellow – Medium risk – Risk is acceptable. Action (such as

Non-Destructive Testing,functional tests and other condition

monitoring processes) should betaken tomeasure extentof

Table4

Relevantdataconcerningtheinternalpartofpipelines.

Depth Internalpartofpipeline Externalpartofpipeline Total

Inbodyofpipe Weldarea Inbodyofpipe Weldarea

≥70% – – – – – 60%to<70% 1 – – – 1 50%to<60% 1 – – – 1 40%to<50% 5 2 – – 7 30%to<40% 20 21 – – 41 20%to<30% 59 23 – – 82 10%to<20% 357 7 – – 364 Total 443 53 – – 496

degradationsothatactioncanbetakentoguaranteerisksdonot

riseintotheredhigh-riskregion.

•Red–Highrisk–Risklevelisunacceptable.Actionmustbetaken

toreduceprobability,consequenceorboth,sothatriskremains

intheacceptableregion.

TheimplementationoftheRBItherefore needstocollectall

thedata;typeofequipment,thematerialused,theoperating

con-ditions,safetysystems,thecostoffailureetc.,relatedtosubsea

pipelineproduction and injectionof water and gas production

centresonanExcelfiletocreateadynamicdatabase.Thisisthe

firststepandthemostimportantpartofthemethodologyasit

willdefinethequalityofinspectionplans.Therefore,onehasto

understandthetypesofinformationrequired,thickness,length,

operating pressure, maximum allowedpressure, etc.,and their

influenceontheresults.Inadditionapermanent judgementon

valuesandinformationfoundisnecessaryinordertoavoid

pos-sibleerrors.Thecollectionofinformationforthedevelopmentof

RBImustensuretheaccesstoindustrialdatabasesthatcontainall

theinformationrelatedtoeachdefinedbusiness,productionsite

orprojects(productionlinedrawings,technicaldocuments,plans,

alignmentsheetswithgeographiccoordinatesandsystem

spec-ifications).For eachRBIplan, twotypesof information,specific

orgeneric,canbeidentified.Ontheonehand,someinformation

isspecific,forthepipelineidentification,thefollowing

informa-tionisused:sectionidentification,sectionfunction,couplingtype,

presenceofthermalinsulation,nominalthickness,shoreapproach,

overpressureprotection system,safety factor thickness, quality

control(manufacturing),fabricationtype,constructioncodestatus,

pipelinecrossing,elevation,rockdumping,diameter,Maximum

AllowableOperating Pressure(MAOP)and MaximumOperating

Pressure(MOP).Ontheotherhand,certaininformationisgeneric

e.g.forthedetectionsystemavailable,thefollowinginformationis

used:materialgrade,climate,shippinglane/trafficmaritimearea,

anchorage zone,fishing trawlingactivities,presence of iceberg,

cargoactivity,seismicarea,faultcrossing,coastalorfragile

sys-temareaanddeepoffshore.Theyarethesameforallthepoles?

ofproduction,becausethepipelinesarelocatedinanareawhere

thereisnoseatraffic,icebergs,orearthquakes,asallpipelinesare

indeepoffshore.Allinformationontheworkingenvironmentof

thesesubseacomponentshavemuchmoreinfluenceoninspection

intervals.

Theorganizationandverificationoftechnicaldataaretwo

nec-essarystepsinanydatacollectionactivityforthesakeofclarity,

coherenceand consistencyofinformation sources[29].Inorder

to facilitate the exchange of information on maintenance and

inspectionmanagement theExcelform iswidelyused toenter

informationintothedatacollectionsystemandsuchinformation

maybeexportedtovariousotherprogrammessuchasSystems,

Applications&ProductsinDataProcessing(SAP),amongothers.

5. Analysis

5.1. Situationofinternalpartofpetroleumpipelines

We are interested here only in the internal portion of the

pipelines.Therearetwopointsofcorrosionbymorethan50%deep.

Thenominalwallthicknessis17.5[mm]whichcanbereducedup

to50[%]asaresultofcorrosion.

Thecorrosionrateiscalculatedfromthicknessdataavailable

fromequipmentinspections.Intotalthereare492pointsof

corro-sionwithvaryingdepthsbelow70%(asdescribedinTable4).

Theequivalentallowedmaximumdepthis80%.Table4shows

certainrelevantdataconcerningtheinternalpartofpipelines.The

datapresentedinthistablearerealandtheyarecollectedby

intel-ligentpiggingthatisahighlysophisticatedinstrumentmeasuring

pipelinewallthicknessandmetallossbydirectmeasurementof

thethicknessofthepipelinewall.

After the first inspection of the internal part of pipelines,

corrosionisfoundwithadenseandregulardistributionofthe

dete-riorationatthebaseandalongtheinternalparts.Theinspectionof

pipelinescandetectmetallossandcorrosionthrough

electromag-neticwaves.

Thecorrosionrateiscalculatedfromthicknessdataavailable

fromequipmentinspections.However,ifcorrosionratescannotbe

determinedfromthicknessinspectiondata,conservativeestimates

may beestablished using expert opinions fromknowledgeable

materials.Themaximumcorrosiondepthinbodyofpipeisbased

onTable4forthepresenceofoneoccurrenceintheinterval60%to

<70%(0.64*17.5=11.2mm).Theresultisaconservativevaluefor

theestimatedcorrosionrate,butitisnotalwaysthecase.Thereis

acleardistinctionbetweencorrosionratesinbodyandweldarea.

ThemaximumcorrosiondepthinweldareaisbasedonTable4

forthepresenceoftwooccurrencesintheinterval40%to<50%

(0.50*17.5=8.75mm).

5.2. Therealizationoftheimplementationplan

Step1:theidentificationoftheprobabilityoffailureto

estab-lishariskmatrix.Inthegeneral,theprobabilityoffailurecanbe

determinedasalinearcombinationofcorrosion(i.e.environment)

andstructuralinducedfailure.Theweightsusedinthelinear

com-bination dependonthecontextual assumptions and inspection

techniquesthatareusedintheriskbasedinspectionmethodology.

Intheconsideredcontext,itisassumedthatcorrosion(i.e.

environ-ment)andstructuralinducedfailurehaveanequitablecontribution

topipelinefailure.Inaddition,CLandSLarelevelsofprobability

whichareinbetweenthenumbers1and5,1≤CL≤5and1≤SL≤5

then1≤0.5*CL+0.5*SL≤5.

Thelevelofprobabilityisgivenbythefollowingformula:

•CorrosionLikelihood(CL)isusedtoestimatethecorrosionand

StructureLikelihood(SL)isusedtoestimatethestructural

fail-ure(construction,design,mechanicalandothers).Theseverity

ofeventsisspecifiedwithprobabilitylevelsdescribingfive

lev-elsofprobabilitywhichareinbetweenthenumbers1and5,with

1beingthelowestand5beingthehighest:1-VeryLow,2-Low,

3-Moderate,4-Highand5-VeryHigh.

•CL=NCL−EFF−ST

•NaturalCorrosionLikelihood(NCL):theprobabilitylevelof

naturalcorrosion(withoutmitigation).

•Effectiveness(EFF):thelevelofeffectivenessofmitigations

ormaintenanceiftherewere.

•State(ST):theinternalstateofthepipelineduetothe

corro-sion.

•InordertofindtheNCL,onemustcalculatetheratioofthe

CorrosionRate(CR)andtheAllowedminimumTHickness(Ath),

with:

•CR=maximum depth of corrosion/age of the

pipeline=11.2/8=1.4mm/year.

•Ath=it is calculated by multiplying the allowed

maxi-mum depth by the nominal value (allowed maximum

depth×nominalvalue).InthecasestudyAthis80%ofthe

nominalvalue.Ath=0.8*17.5=14mm.

•So,Ath/CR=10mm/mm/year.

•Thisratioof10mm/mm/yearcorrespondstoaNCL=4.

•FortheEFF,thevalueiszero(=0),becausetherewasno

miti-gation,maintenance,norinspection.

•TheSTisthemaximumpercentageofmetallostsofar,64%.

•SotoconcludeCL=4.0−0.64=3.36.Duringthecalculationsof

theprobabilityleveloffailureand risklevel,theresultsare

generallyroundedupwards,sowewilltakearoundingvalue

withCL=4.

•SL=(SLmec+SLD/C)+SLthird+SLnat

•StructuralmechanicalfailureLikehood(SLmec)=itcorresponds

totheprobabilitylevelofamechanicalfailure.

•Structuraldesignorconstruction failureLikehood(SLD/C)=it

correspondstotheprobabilitylevelofafailureinthedesignor

construction.

•StructuralfailurethirdpartyLikehood(SLthird)=itisthe

prob-abilitylevelofafailureduetoanexternalevent.

•StructuralnaturalfailureLikehood(SLnat)=itistheprobability

levelofafailurecausedbythenaturalenvironment.

•SLnatandSLthirdarezerovaluesbecausetherehasneverbeena

failurecausedbytheenvironmentorbyanexternalevent.Also

nofailureinthedesignnorconstructionhavebeenidentified

andnomechanicalfailurehasbeenobservedsincetheputting

intooperationofthisproductionsite.

•Theassessmentofthefacility’smanagement system

evalua-tionconsistsofaseriesofinterviewswithplantmanagement,

operations,inspection,maintenance,engineering,training,and

safetypersonnel[30].Asregardstheprocesssafety

informa-tion,one shouldaddressthequestionregarding thequality

controlproceduresin placeand practicedtoensurethat all

identified materials meet specifications when received and

used.

•However,noneofthesefailuresareindicatedbecausetherewas

nothingobserved,andintheabsenceofanyotherinformation

tothecontrary,itwasassumedthatthevalueofthevariableSL

isthelowestpossiblevaluei.e.SL=1.

Finally,wehaveLof=50%CL+50%SL=2+0.5=2.5.Thisresultis

roundedupwards,sowewilltakearoundingvaluewithLof=3.

Step2:thecalculationoftheconsequenceoffailureisclassified

onascale rangingfrom1to5.Therearethreetypesof

conse-quences:thestaffsafety,environmentalimpactandpollution,with

thefinancialandeconomicimpact.Thescaleoftheconsequenceis

Table5

Relationsbetweenproductionlossandfinancialconsequence.

Productionloss Financial

consequence Productionloss>5daysofaffiliatesaverageproduction 5

Lossbetween1and5daysofaffiliatesaverageproduction 4 Losslessthan1dayofaffiliatesaverageproduction 3

Limitedloss 2

Negligibleproductionloss 1

givenbythefollowingformula:

Consequenceofthefailure (Cof)

=MAX[pollution;financialconsequences;personnelsafety]

FortheCof,wetakethehighestvalueamongthethree

conse-quences.Inordertodeterminetheseverityoftheconsequences

andthereforethelevelofrisk,wemadesomeassumptionsabout

thepossiblefailuremodesandwetooktheonewiththehighest

probabilitylevelandcriticality.Theassumptionsare:

•Thepressureofthewaterisapproximately140barsandthe

pres-sureoftheoperations(inside)isabout60barsinthepresenceof

ahole,thismeansthereforethattheseawaterentersthe

flow-lineduetothepressuredifference.Sothereisnopollution,no

impactenvironmental,nofinanciallossandnodangerto

per-sonnelsafety.

•Whenproduction is shut downontheright section,one can

switchtheentireproductionontheleftlinethusavoiding

finan-cialconsequences.Buthowevermanyoperationsoccur.Toswitch

theproductionontheleftline,onemustknowitscapacityto

receivetheentireproductionoftherightline.Allthese

param-eterscandecreaseoilproductioncapacitysignificantly,sothere

willbesignificantfinancialconsequences.

•The considered section of the production site is in subsea

andawayfromtheFloatingProduction,StorageandOffloading

(FPSO),thereforetheconsequencesfordirectpersonnelsafetyis

zero.

Inourcontext,wewillalwaystakethemostunfavourablecase

forthecalculationofdifferentconsequences,thismeansthatwe

must stoptheproduction activitiesinthisparticular petroleum

site.Sointhiscase,therearefinancialconsequences.Inpractice

itincludesthelossesgeneratedbytheproductionlossthatisless

than1dayofaffiliatesaverageproduction.Asitcanbeinferredfrom

Fig.5. Experiencemodelincorporatingproblem-solvingtechnique[23].

Table5,withrespecttothefinancialconsequence,thecriticality

coefficienthasthevalueCof=3.

Theoveralllevelofriskofthestudiedpipeline(including

prob-abilitylevelofcorrosionandtheprobabilitylevel ofastructure

failure)intheconsideredproductionsiteiscalculatedbythe

fol-lowingformula:

GlobalRisk =Likelihood(GlobalProbability)

×Consequence(Severity)=Lof∗Cof=3∗3=9

6. Results

Thedefinitionofinspectionintervalsbyusingrelevantdevices

toperformvariousinspectionoperationsonapipeline.Particularly,

intelligentdevicesareverysmartinstrumentdevicesthatcontain

electronicsandsensorsthatgatherseveralformsofdataduring

theirinspectiontourthroughthepipeline.Onemustcalculatethe

levelofrisk,takingintoaccountthelikelihoodofcorrosionandthe

criticalityoftheconsequences:

CorrosionRisk=Likelihood(Probabilityofcorrosion)

×Consequence(Severity)=CL∗Cof=4∗3=12

Thecolouredriskmatrix(asshowninFig.4)isintendedto

dis-playthatasProbabilityofFailure(PoF)andConsequenceofFailure

(CoF)increase,theriskbecomessignificant.

Thenwe compare this result ona risk matrix to determine

thetype ofrisklevel(lowwithgreencolour,mediumwith

yel-lowcolourandhighwithredcolour).Withalikelihoodhavingthe

value4andaconsequencehavingthevalue3andaccordingtothis

colouredriskmatrix,amediumlevelofriskisshown.

Theindicativeinformationontheinspectionplanisprovidedin

Table6.Itcanbeseenfromthistablethatwecandeterminethe

intervalofthenextinspectionbysmartinstrumentsusing

elec-tromagneticacoustictransducerstocheckforgeneralcondition,

potentialfailuresandnormaloperationofthepipelines.Inourcase

thelevelofriskisaverageandvalueofCLis4,sothenextinspection

bysmartinstrumentswillbein4years.

Domainexpertsalsobelieved,inthesecasesbasedonpersonal

experience,thattheywouldhavetochooseaCLwithvalue5anda

consequencewithvalue5,becausetheytookintoaccountthefact

thatthereisnoinjectionofacorrosioninhibitor(catalyst)inwells.

SowithaCLhavingthevalue5andaCofhavingthevalue5theyfind

anintervalof2years,butotherparameters(suchasthestatusof

otherinterconnectedsystemsforexample)areinvolvedwiththeir

associatedimpactsoninspectionactivities.Basedonthese

circum-stances,aspecificinterventionbythemaintenanceengineeringis

Table6

Indicativeinformationontheinspectionplan.

Corrosionrisk=High Corrosionrisk=Medium Corrosionrisk=Low CL Interval CL Interval CL Interval 1 Max(15,Ti−T0) 1 Max(20,Ti−T0) 1 Noinspection

2 10 2 12 2 15

3 5 3 8 3 10

4 3 4 4 4 5

5 2 5 3 5 Notapplicable

atthismomentnotbeingplanned;thereforetheintervalofthe

inspectionplanisreduced.

Asaresultitisconsideredthatanintervalofoneyearisthebest

preventiveplanforpipelineinspectioninthecasestudy.

7. Discussion

As a complement to theexplicit knowledge extracted from

availabledataandinformationthatareregularlyusedintheRBI

processes,it isindispensabletoidentifytheimplicitknowledge

appliedbydomainexperts,andmoreoverthestepwiseprinciples

ofproblem-solvingmethods.In petroleumindustry,asinmany

other complex domains, the part of implicit knowledge in the

expertproblem-solvingprocesshasanimportantimpactonthe

resultsattained. Hence,themodelled experiencefeedback

pro-cessesintegratethedescriptionofmoredetailedexplanationin

knowledgeacquisitionandinterpretationproblem-solving

meth-ods. In order to acquire knowledge from experience feedback

processes,aconceptualmodel(context,analysis,solutionand

les-sonlearned)incorporatingproblem-solvingmethodstogenerate

explicitknowledgefrompracticalexperiencesispresentedinFig.5.

Theprincipalcategoriesofknowledgeacquisitiontechniques

includesthesefiveelements[31]:(i)Interviewswithobservations

and protocol analyses, (ii) Classification techniques for

identi-fication of conceptual domain vocabulary, (iii) Exploitation of

recorded cases, (iv) Extraction of associations rules, (v)

Identi-fication of patterns of reasoning. These recognized knowledge

acquisitiontechniquesareoperativeinrevealingtherulesand

con-straintsunderpinningtheexpertreasoning,soitispossibletogive

explicitoutlineanda formalbackgroundtoknowledge

compo-nentsdeployedbydomainexperts.Infact,theexplicitspecification

ofconceptualvocabulariesoftheexperienceswiththeassociated

problemsolvingmethodsmeaningfullyimpactsthewayinwhich

theRBItakesplace,assupportedbytheirinfluenceinthe

formal-izationofinformationandknowledgeacquisition.

8. Conclusion

Maintenanceandinspectionengineeringisacomplextaskthat

requiresexperiencedknowledgetoallowthegoodmanagement

oftherequirementsanalysis,planningandinspectionoperations,

maintenance,repairoroverhauloftheconsideredsystem.

Partic-ularly,inthepetroleumdomain,themaintargetfortheinspection

process is themanagement of reliable systemintegrity sothat

performanceincompliancewithenvironmentalandtechnical

stan-dardsisefficientlyretainedthroughthesystem’slifecycle.

Inthisdocument,wedescribearesearchapproachusingarisk

basedinspectionmethodologytoimprovethecapabilityand

asso-ciatedmaintenanceservicesconcerningtheeffectivefunctioning

ofthetechnicalsystemsinoffshoreproductionsites.Theachieved

resultswiththeproposedapproacharetangiblesincetheyallow

thedeterminationofthoroughinspectionofthepipelinesandwhat

theoptimumintervalcyclesareforthenecessaryinspectionplan.

Theproposedapproachisapplicabletothecompanydiscussedin

thispaperanditisalsoagenericmethodwhichcanbeapplied

inanypetroleumorO&Gcompanies.Itmaybeappliedtoother

systemsorsectorsofactivitieswithsensitivecomponentsinorder

toinformthemabouttheriskanalysisthatrequires

Knowledge acquisition and interpretation problem-solving

methodsfromexperiencefeedbackprocesses(e.g.valuablecase

studies of expertise in sedimentary petrography [32]) can be

included in risk assessment of inspectionplanning. The useof

previousinformation fromsimilarcontexts would improve the

anticipationoffuturedevelopmentsincomplexsystemsintime.

Thegeneratedlessonslearntcouldmakeausefulcontributionto

theunderstandingoffailureprediction,andthetimescalestoreach

thesefailuresandpossiblyincludingthestudyofthepotential

con-sequences.Thisistoprovidedomainexpertswithadatabaseof

historicaldataontheconsideredsystemwithitspropertiesand

environmentalconstraints,takingintoaccountthedamageithas

sustainedduringageing.Helpedbysuchaninformationbase,the

experthasatoolforriskanalysisinwhichreferencecanbemade

todeterminetheexpecteddevelopmentsandmechanismscausing

damageandtheirsequenceleadingtothesystemfailure(failure

scenarios).Thecriticalityassessmentofthesescenariosintermsof

occurrence,severityanddetectabilityandtherootcauseanalyses

allowtoidentifythemostcriticalscenariosandpredictthe

circum-stancesoftheiroccurrence.Forinstance,therearesomeestablished

proceduresforsafetyassessmentprobabilitiesbasedonthe

eval-uationofGermanoperationalexperienceforpipingsystemswith

differentdiameters[33].

Nevertheless,duetothecomplexityanduncertaintyofthe

refin-ing andpetrochemical unitsand risks,operationalanalysesare

difficulttoachievebyusingrisktechniqueswithclassicallogic[34].

Likewise,afuzzylogicframeworkcanbeengagedinthe

establish-mentofanRBIprogrammeforsystemsofthepetroleumindustry.

Theadvantageofthisapproachliesinitsabilitytoinclude

con-textualexperiencesalongwithacceptabledeterministicmodelsin

theinformationprocessing[35].Alsotheinspectionmanagement

departmentcanorderriskreductiondecisionmakingsusingrisk

prioritizationoftheassetfailures[36].Thereforetheuseof

appro-priatemethodsandapproaches,carefulinvestigationduringthe

riskanalysisphase,anditscomprehensiveandorganizedresults

areessentialtomakeproperrisk-basedinspectiondecisions[37].

Alternatively, a RBI methodology might be combined with

Multi-ObjectiveGeneticAlgorithm(MOGA)fordefiningefficient

inspectionprogrammesintermsofinspectioncostsandrisklevel

[38]. Finally, RBI couldbe included in a largerframework; for

example,anapproachgivingmulti-attributedecision-makingwith

aggregated risk analysis [4] or experience feedback strategies

[41–44].

Acknowledgments

TheauthorsaregratefultoMs.ValerieStevensforhis

proofread-ingandeditingservice.Wealsothanksomeanonymousreviewers

fortheirhelpfulfeedbackandobservationsonpreviousversionof

thepaper.

References

[1]KamsuFoguemB,RigalF,MaugetF.Miningassociationrulesforthequality improvementoftheproductionprocess.ExpertSystAppl2013;40(4):1034–45.

[2]CalixtoE.Reliabilityandmaintenance.Gasandoilreliabilityengineering;2013. p.119–67[Chapter3].

[3]MarhavilasPK, Koulouriotis D, GemeniV. Risk analysis and assessment methodologiesintheworksites:onareview,classificationandcomparative studyofthescientificliteratureoftheperiod2000–2009.JLossPrevProcess Ind2011;24(5):477–523.

[4]KhanFI,SadiqR,HaddaraMM.Risk-basedinspectionandmaintenance(RBIM): multi-attributedecision-makingwithaggregativeriskanalysis.ProcessSaf EnvironProt2004;82(6):398–411.

[5]El-ReedyM.Risk-basedinspectiontechnique.GulfProfessionalPublishing; 2012[Chapter8]ASIN:B00DGSWO4S.

[6]SuttonI.Maintenanceandinspection.Plantdesignandoperations;2015.p. 24–45[Chapter2].

[7]BaiY,BaiQ.Risk-basedinspection.Subseapipelineintegrityandrisk manage-ment;2014.p.213–32[Chapter9].

[8]FaberMH,StewartMG.Riskassessmentforcivilengineeringfacilities:critical overviewanddiscussion.ReliabEngSystSaf2003;80(2):173–84.

[9]BrittonCF.4.36–Corrosionmonitoringandinspection.Shreir’sCorrosion,vol. 4;2010.p.3117–66.

[10]RichardsonJA.4.40–Managementofcorrosioninthepetrochemicaland chem-icalindustries.Shreir’sCorrosion,vol.4;2010.p.3207–29.

[11]JovanovicA.Risk-basedinspectionandmaintenanceinpowerandprocess plantsinEurope.NuclEngDes2003;226(2):165–82.

[12]ShuaiJ,HanK,XuX.Risk-basedinspectionforlarge-scalecrudeoiltanks.JLoss PrevProcessInd2012;25(1):166–75.

[13]PriceJWH.10 –Risk-basedinspectionandlife managementinboilersin coalpowerplants.Coalpowerplantmaterialsandlife assessment;2014. p.265–87.

[14]SantoshA,VinodG,ShrivastavaOP,SarafRK,GhoshAK,KushwahaHS. Reliabil-ityanalysisofpipelinescarryingH2Sforriskbasedinspectionofheavywater plants.ReliabEngSystSaf2006;91(2):163–70.

[15]ToftHS,BrannerK,BerringP,SørensenJD.Defectdistributionandreliability assessmentofwindturbineblades.EngStruct2011;33(1):171–80.

[16]NielsenJJ,SørensenJD.Onrisk-basedoperationandmaintenanceofoffshore windturbinecomponents.ReliabEngSystSaf2011;96(1):218–29.

[17]ShafieeM.Maintenancelogisticsorganizationforoffshorewindenergy: cur-rentprogressandfutureperspectives.RenewEnergy2015;77:182–93.

[18]ChangM-K,ChangR-R,ShuC-M,LinK-N.Applicationofriskbasedinspectionin refineryandprocessingpiping.JLossPrevProcessInd2005;18(4–6):397–402.

[19]RecommendedPracticeDNV-RP-G101.Riskbasedinspectionofoffshoretop sidesstaticmechanicalequipment,DETNORSKEVERITAS(DNV);2010.

[20]RecommendedPracticeDNV-RP-F116.Integritymanagementofsubmarine pipelinesystems,DETNORSKEVERITAS(DNV);2009.

[21]NORSOK STANDARDZ-008. Criticalityanalysisfor maintenancepurposes issuedbyNTS(NorwegianTechnologyCentre)Rev.2;2001.

[22]NORSOK STANDARDZ-008. Criticalityanalysisformaintenancepurposes, issuedbyNTS(NorwegianTechnologyCentre).3rded;2011.

[23]KamsuFoguemB,CoudertT,GenesteL,BelerC.Knowledgeformalization inexperiencefeedbackprocesses:anontology-basedapproach.ComputInd 2008;59(7):694–710.

[24]Kamsu-Foguem B. Knowledge-based support in Non-Destructive Testing for health monitoring of aircraft structures. Adv Eng Inform (ADVEI) 2012;26(4):859–69.

[25]Kamsu-FoguemB,FonbeyinHA.Experiencemodelingwithgraphsencoded knowledgeforconstructionindustry.ComputInd2015;70:79–88.

[26]Kamsu-FoguemB,NoyesD.Graph-basedreasoningincollaborativeknowledge managementforindustrialmaintenance.ComputInd2013;64(8):998–1013.

[27]Kamsu-FoguemB,FondjaWandjiY,Tchuenté-FoguemG,TchoffaD. Experi-encedknowledgeforthedescriptionofmaintenancepackages.JManufSyst 2014;37(Part1):448–55.

[28]ElayaPerumalK.ProcediaEng2014;86:597–605.

[29]Kamsu-FoguemB,MathieuY.Softwarearchitectureknowledgeforintelligent lightmaintenance.AdvEngSoftw2014;67:125–35.

[30]API.APIRP581–Riskbasedinspectiontechnology.2nded.Washington,DC: AmericanPetroleumInstitute;2008.

[31]BreukerJ.Acognitivescienceperspectiveonknowledgeacquisition.IntJHum ComputStud2013;71(2):177–83.

[32]Abel M,Lima SilvaLA, Campbell JA, De Ros LF. Knowledge acquisition andinterpretationproblem-solvingmethodsforvisualexpertise:Sstudyof petroleum-reservoirevaluation.JPetSciEng2005;47(1–2):51–69.

[33]BergH-P,GersinskaR,SieversJ.Procedureforprobabilisticsafetyassessmentof leaksandbreaksofpipingsystems.IntJPressVesselsPip2010;87(2–3):94–9.

[34]WeiW,ChengG,HuH,ZhouQ.Riskanalysisofcorrosionfailuresofequipment inrefiningandpetrochemicalplantsbasedonfuzzysettheory.EngFailAnal 2013;32:23–34.

[35]SinghM,MarkesetT.Amethodologyforrisk-basedinspectionplanningof oilandgaspipesbasedonfuzzylogicframework.EngFailAnal2009;16(7): 2098–113.

[36]Sa’idiE,AnvaripourB,JaderiF,NabhaniN.Fuzzyriskmodelingofprocess operationsintheoilandgasrefineries.JLossPrevProcessInd2014;30:63–73.

[37]ArunrajNS,MaitiJ.Risk-basedmaintenance–techniquesandapplications.J HazardMater2007;142(3):653–61.

[38]dasChagasMouraM,LinsID,DroguettEL,SoaresRF,PascualR.A multi-objectivegeneticalgorithmfordeterminingefficientrisk-basedinspection programs.ReliabEngSystSaf2015;133:253–65.

[39]API.APIRP580–Recommendedpracticeforrisk-basedinspection.2nded. Washington,DC:AmericanPetroleumInstitute;2009.

[40]ISO.ISO17776–Petroleumandnaturalgasindustries–offshoreproduction installations–guidelinesontoolsandtechniquesforhazardidentificationand riskassessment.1sted.Geneva,Switzerland:TheInternationalOrganization forStandardization(ISO);2000.

[41]PotesRuizPA,KamsuFoguemB,GrabotB.Generatingknowledgein mainte-nancefromexperiencefeedback.Knowl-BasedSyst2014;68:4–20.

[42]PotesRuizPA,KamsuFoguemB,NoyesD.Knowledgereuseintegratingthe col-laborationfromexpertsinindustrialmaintenancemanagement.Knowl-Based Syst2013;50:171–86.

[43]JabrouniH,KamsuFoguemB,GenesteL,VaysseC.Analysisreuseexploiting taxonomicalinformationandbeliefassignmentinindustrialproblemsolving. ComputInd2013;64(8):1035–44.

[44]JabrouniH,KamsuFoguemB,GenesteL,VaysseC.Continuousimprovement throughknowledge-guidedanalysisinexperiencefeedback.EngApplArtif Intel2011;24(8):1419–31.

Dr.BernardKamsuFoguemiscurrentlyatenured Asso-ciate Professor at theNational EngineeringSchool of Tarbes(ENIT)ofNationalPolytechnicInstituteofToulouse (INPT)andleadshisresearchactivitiesintheProduction EngineeringLaboratory(LGP)ofENIT-INPT,aresearch entity(EA1905)oftheUniversity ofToulouse.Hehas aMaster’sinOperationalResearch,Combinatoricsand Optimization(2000)fromNationalPolytechnicInstitute ofGrenoble,andaPhDinComputerScienceand Auto-matic(2004)fromtheUniversityofMontpellier2.He gottheHabilitationàDirigerdesRecherches(HDRfor “accreditationtosuperviseresearch”)fromUniversityof Toulouse in2013,reflectingaconsistentresearchand

typicallyaround30publicationsinpeerreviewedjournals.Hehasobtainedthe status ofVisitingProfessor atinternationaluniversities: UnitedKingdom(e.g. OxfordBrookesUniversity,Oxford),Finland(e.g.AaltoUniversity,Helsinki Uni-versityofTechnology,VTTTechnicalResearchCentreofTampere,Universityof Oulu,ÅboakademiofTurkuUniversity).HiscurrentinterestsareinKnowledge DiscoveryandDataMining,KnowledgeRepresentation,FormalVisualReasoning, Ontology-basedSemanticAnalysis,KnowledgeExploitationforremote Collabo-ration,DecisionSupportSystemsandIntelligentSystems.Applicationdomains includeindustrialContinuousImprovementprocesses,Telemedicineservicesand HealthInformationSystems.Heisamemberoftheeditorialboardofseveral jour-nals:forinstanceheisamemberofEditorialTeamofArtificialIntelligenceResearch (AIR)andAssociateEditorforBMCMedicalInformaticsandDecisionMaking.Heis amemberofthethematicgroup:e-HealthofInterOP-VLab(InternationalVirtual LaboratoryforEnterpriseInteroperability).

![Fig. 2. The risk based inspection organization process [39].](https://thumb-eu.123doks.com/thumbv2/123doknet/3137244.89321/7.892.216.693.84.285/fig-risk-based-inspection-organization-process.webp)

![Fig. 5. Experience model incorporating problem-solving technique [23].](https://thumb-eu.123doks.com/thumbv2/123doknet/3137244.89321/10.892.204.675.82.151/fig-experience-model-incorporating-problem-solving-technique.webp)