Any correspondence concerning this service should be sent to the repository administrator:

staff-oatao@inp-toulouse.fr

DOI:10.1016/j.apsusc.2012.11.098

Official URL:

http://dx.doi.org/10.1016/j.apsusc.2012.11.098

This is an author-deposited version published in:

http://oatao.univ-toulouse.fr/

Eprints ID: 8782

To cite this version:

Giraud, Isabelle and Franceschi-Messant, Sophie and Perez, Emile and

Lacabanne, Colette and Dantras, Eric Preparation of aqueous dispersion of

thermoplastic sizing agent for carbon fiber by emulsion/solvent evaporation.

(2013) Applied Surface Science, vol. 266 . pp. 94-99. ISSN 0169-4332

O

pen

A

rchive

T

oulouse

A

rchive

O

uverte (

OATAO

)

OATAO is an open access repository that collects the work of Toulouse researchers and

makes it freely available over the web where possible.

Preparation

of

aqueous

dispersion

of

thermoplastic

sizing

agent

for

carbon

fiber

by

emulsion/solvent

evaporation

Isabelle

Giraud

a,

Sophie

Franceschi-Messant

a,

Emile

Perez

a,∗,

Colette

Lacabanne

b,

Eric

Dantras

baLaboratoiredesI.M.R.C.P.,UMR5623CNRS,UniversitéPaulSabatier,31062ToulouseCedex09,France

bLaboratoiredePhysiquedesPolymères,CIRIMAT,InstitutCARNOT,UniversitéPaulSabatier,31062ToulouseCedex09,France

Keywords: Sizing Carbonfibers Composites Thermoplasticpolymer Aqueousdispersion Emulsion/solventevaporation

a

b

s

t

r

a

c

t

Inthiswork,differentsizingagentaqueousdispersionsbasedonpolyetherimide(PEI)wereelaboratedin ordertoimprovetheinterfacebetweencarbonfibersandathermoplasticmatrix(PEEK).Thedispersions wereobtainedbytheemulsion/solventevaporationtechnique.Tooptimizethestabilityandthefilm formationonthefibers,twosurfactantsweretestedatdifferentconcentrations,withdifferent concen-trationsofPEI.Thedispersionsobtainedwerecharacterizedbydynamiclightscattering(DLS)andthe stabilityevaluatedbyanalyticalcentrifugation(LUMiFuge).Theselecteddispersionsweretestedforfilm formationabilitybyscanningelectronmicroscopy(SEM),andthesizingperformancewasassessedby observationofthefiber/matrixinterfacebySEM.TheresultsrevealedthatanaqueousdispersionofPEI, stabilizedbysodiumdodecylsulfateasthesurfactant,ledtoverystablesizingagentaqueousdispersion withidealfilmformationandbetterinterfaceadhesion.

1. Introduction

Carbonfiberiswidelyusedasareinforcingmaterialin

com-posites,especiallyinadvancedcomposites[1,2].Ascarbonfibers

arebrittle,manyproblems,suchasfilamentbreakageandfluffing,

ariseduetomechanicalfrictionduringthemanufacturingprocess

[3–5].Therefore,carbonfibersaregenerallysizedorcoatedbya

sizinglayeronthesurface,whichisusuallyobtainedfroma

solu-tionoremulsionconsistingofpolymericcomponents[6,7].Sizing

easesfiberhandlingandcanalsoprovideacouplingagentforthe

fiber/matrixbond [8–11]. Thenatureof thesizingis oftenkept

secretbymanufacturersofcarbonfibers.However,sizingischosen

accordingtothenatureofthematrixandisgenerallyapre-polymer

orpolymer.Mostofthecompositesaremadefromepoxyresin,and

sizingagentsareoftenofthesamenature[5,12–14].Thisisa

prob-lemwhenthematrixisahigh-temperaturethermoplasticpolymer

sincethedegradationtemperatureofthistypeofsizingisaround

250◦C [15]. For polyimides, PEEK and other high-temperature

thermoplastic polymers,thefunctional groups provided bythe

traditionalepoxy-compatiblesizingdonotreactchemicallywith

thesepolymersandweakinterfacialshearstrengthsresult[16].

Moreover,forcompositesmoldedwithpolyimidesorPEEK,high

processingtemperaturesduringmanufactureandcontinuoususe

∗ Correspondingauthor.

E-mailaddress:perez@chimie.ups-tlse.fr(E.Perez).

inhigh-temperatureenvironmentsdegradetheepoxysizingand,

consequently,weakenthefiber/matrixinterface,producingvoids

anddelaminations[17–19].Alloftheseobservationsunderlinethe

importanceofhavingsizingthatissuitableforhigh-temperature

thermoplasticmatrices.Fromapracticalpointofview,thesizing

formulationshouldbeeasytouse,non-toxicandenvironmentally

friendly.Inthispaper,wereportthefirstexampleofpreparation

anaqueousdispersionofathermoplasticsizingagentforcarbon

fiberbyemulsion/solventevaporation.

2. Experimental

2.1. Materials

ThepolyetherimidePEI(Ultem1000)wasobtainedfromSabic®.

Thesodiumdodecylsulfate(SDS)andthechloroformwere

pro-videdbySigma–Aldrich,thebenzalkoniumchloride(BC)wasfrom

Fluka (C12 60%, C14 40%). The AS4 carbon fiber tow, provided

byHexcel,wastreatedunsizedandcontained12,000fibers.The

polyetheretherketone(PEEK)providedbyVictrexwasa 100mm

thickfilm.TheremoldingagentwasCIREX041WBfromSICOMIN.

2.2. PreparationofPEIdispersionsbyemulsion/evaporation

In order to reduce thetoxicity and to respect the

environ-ment,organicsolventsmustbeavoidedinthefinalsizingagent

formulation.Forthesereasons,wedecidedtoelaborateaqueous

Fig.1.Schematicrepresentationofthepharmaceuticalemulsification/evaporationprocess.

dispersions.Thesecanbemadebyavarietyofmethods[20–23]

leading,attheend,tostablehydrophobicparticlesinwater.The

preparationprocessdescribedherewaslargelyinspiredby

emul-sion/solventevaporation,anencapsulationtechniqueusedinthe

pharmaceuticalindustrytoprepareaqueousdispersionsof

poly-mernanoparticlesormicrospheres.

Emulsion/solvent evaporation involves a two-step process

(Fig.1):theemulsificationofa polymersolutioncontainingthe

encapsulatedsubstance,followedbyparticlehardeningthrough

solventevaporationandpolymerprecipitation.Duringthewater

emulsification, the polymer in solution in the volatile,

water-immisciblesolventisbrokenintomicrodropletsbytheshearstress

producedbyeitherahomogenizerorasonicatorinthepresenceof

asurface-activeagentuntilthepolymerprecipitates[24–27].

Thismethodwasusedtoprepareastableaqueousdispersionof

PEIasthesizingagent.Weusedtwodifferentsurfactants,sodium

dodecylsulfate(SDS)andbenzalkoniumchloride(BC)atdifferent

concentrations(0.3%,0.5%and1wt%).Thefinalconcentrationsof

PEIwere0.1%,0.3%,0.5%and1wt%.ThePEIdispersionat0.5wt%ina

0.5wt%surfactantsolutionwaspreparedasfollows.Ina5-mLflask,

0.1005gofPEIwasdissolvedin2mLofchloroform.Thissolution

waspouredintoanotherflaskcontaining20mLofthesurfactant

solution.Themixturewasemulsifiedbyultrasoundshearing(Vibra

Cell,BioblockScientific600W,20Hz).Theshearinglasted5minat

power4.Awaterbathwasusedtomaintainthesolutionatroom

temperature.Then,magneticstirringoftheemulsionat1200rpm

for12hallowedtotalevaporationofthechloroform.

2.3. CharacterizationofPEIdispersions 2.3.1. Particlesizeanalysis

Dynamiclightscattering(DLS)wasperformedusingaMalvern

InstrumentsNanoZSwithaHe–Nelaser(633nm)atascattering

angleof173◦andat25±1◦C.Thehydrodynamicmeandiameterof

thenanoparticleswasdeterminedusingthesoftwareprovidedby

MalvernInstruments.TheContinmodelwasappliedtoobtainsize

data.Alltheauto-correlationfunctionfitswerecheckedandfound

tobeinaccordancewiththeexperimentaldata.Fivemeasurements

weremadeoneachsamplewithanaccuracyofabout2nm.

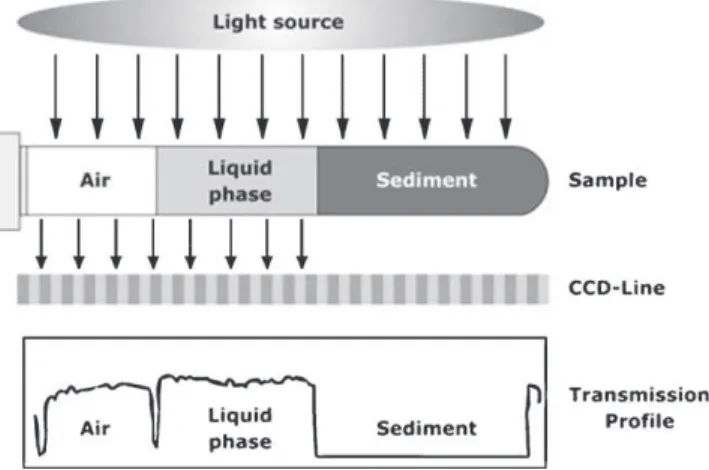

2.3.2. Evaluationofstabilityusinganalyticalcentrifugation

Aseparationanalyzer(LUMiFuge,L.U.M.Berlin,Germany)was

usedtodeterminetheseparationbehaviorofdispersionsunderthe

influenceofvariouscentrifugalforces(5–1000×g).Thisapparatus

isbasedona low-speedcentrifugecombinedwithan

optoelec-tronicmeasuringsystemthatrecordsthelighttransmissionover

theentire sample cuvette (Fig. 2). The cuvettes containingthe

suspensionare positioned in thehorizontal planeon therotor

ofthecentrifuge.Duringcentrifugationalightsourcepositioned

abovetherotoremitsradiation(near-infrared)ontothesample.

TransmittedlightisdetectedbyaCCDlinesensorbelowtherotor

planeandisanalyzedbyamicrocontroller,whichgeneratesa

light-transmissionprofileof thesampleareafor everymeasurement

step.

This technique is very appropriate for the study and

opti-mizationofverystableaqueousdispersions.Thecentrifugalforce

acceleratesthedestabilizationofthedispersionandrapidly

deter-minestheshelflifeofthedispersion[28].Moreover,thepossibility

ofstudying8samplesatthesametimeenablesdifferent

formu-lationstobecomparedimmediately[29,30].Thedispersionsare

naturallystableover6monthssowechosetosimulate3yearsof

aging.Thedataacquisitioncorrespondedto255profilesrecorded

everyeverysecondsat4000rpm.Thetemperaturewas20◦C.

2.4. Sizingtreatmentofcarbonfiberandcompositepreparation 2.4.1. Sizingofcarbonfiber

Differentmethodscanbeusedtosizecarbonfibers,such as

electrodeposition[31,32]orelectropolymerization[33,34],butthe

mostcommonisbathcoating.Wetestedthesizingatlaboratory

scaleso,inthiscase,themostsuitabletechniquewastospraythe

dispersiondirectlyontothefibersurface.Anunsizedfibertowwas

strainedbyaweighttokeepitvertical,allowinguniformspraying

ofthesizingatthefibersurface(Fig.3).Aftersizing,thefiberswere

driedatroomtemperature.

Fig.3. Schematicrepresentationofthesizingprocess.

2.4.2. Compositepreparation

WealsopreparedPEEK/unidirectionalcarbonfibersamplesat

laboratoryscale.Thesampleswerepreparedbyhotpress

mold-ing.ThepressusedwasaCarver4128CEequippedwithheating

plates.Theprocessingtookplaceinseveralsteps.Thesamplewas

firstprepared,thenmoldedinthehotpressandfinallycooledand

remolded.Inordertokeepallthecarbonfibersinthesame

direc-tionduringthedifferentsteps,thestrandsofcarbonfiberwere

insertedinafoldedPEEKfilm(Fig.4).

The sample was then placed in an aluminum mold

previ-ouslycoatedwiththeremoldingagent.Thenthemoldwasplaced

betweenthetwoplates,previouslyheatedto400◦C,andkeptin

contactfor15mintoallowthePEEKtomeltuniformly.6MPaof

pressurewasthenappliedfor30stoletthePEEKimpregnatethe

fibers.Finally,thesamplewasaircooledandremoldedatroom

temperature.Thefinalsamplecontained30wt%ofcarbonfibers.

2.5. CharacterizationofPEIfilmsandcomposite 2.5.1. Scanningelectronmicroscopy(SEM)analysis

Thedifferentsampleswereexaminedusingascanningelectron

microscope(JEOLJSM6700F)withanacceleratingvoltageof5kV.

Thefilmsobtainedafternaturaldryingatroomtemperaturewere

mountedonaluminumstubsand sputtercoatedwithgold.The

compositeswerefreezefracturedinordertoobservetherupture

faces.

3. Resultsanddiscussion

3.1. Sizingagentformulation 3.1.1. Stabilitystudy

We selected PEIas thesizing agent becauseit is a

thermo-plastic polymer with high heat resistance [35], miscible with

polyetheretherketone(PEEK)[36],andsolubleinchlorinated

sol-ventslikechloroform.Severalfactorsinfluencethestabilityofthe

dispersion,suchasthenatureandtheamountofsurfactant.

Usu-ally,thechoiceofsurfactantdependsonthenatureoftheparticles

and,in particular,theirsurface charge.SincePEIhasnospecial

charge,thesurfactantcanbeanionicorcationic.Itisalsoimportant

Fig.4. Schemeofthesamplepreparation.

Fig.5.Influenceofthenatureandconcentrationofthesurfactantonthemean particlediameter([PEI]=0.5wt%).

todeterminetherightquantityofsurfactanttomaintainastable

dispersion.PEIconcentrationisalsoanimportantparameter.The

emulsion/evaporationmethodisnotsuitableforthepreparation

ofconcentrateddispersionsbut,inthecaseofsizing,thisisnota

limitationbecausetheconcentrationofpolymerdoesnotexceed

1wt%[37,38].

First,westudiedtheinfluenceofthenatureandthe

concentra-tionofthesurfactant,andalsotheinfluenceofthePEIconcentration

onthecharacteristicsofthesizingdispersions.

Thefirstparametertobeconsideredwastheparticlesizeas

itiswellknownthatthesmallertheparticlesare,themore

sta-blethedispersionwillbe.Dynamiclightscatteringmeasurements

(DLS)wereperformedonallthedispersions.Theinfluenceofthe

surfactantonthemeandiameterofparticlescanbeseeninFig.5.

Themeandiametersoftheparticleswerelessthan100nmand

favored stabledispersions.The natureofthesurfactantdidnot

haveasignificanteffectontheparticlesizeeventhoughthe

par-ticlesseemedsmallerwiththeBCsurfactant.Ontheotherhand,

thediametersvariednoticeablywiththesurfactantconcentration.

Thehighertheconcentrationwas,thesmallerweretheparticles.

Atlowconcentration,therewasnotenoughsurfactantto

main-tainsmalldropletsofchloroformandthisdeterminedthefinalsize

oftheparticles.Althoughthesmallestparticleswereobtainedfor

1wt%,theconcentrationof0.5%waspreferredinordertominimize

theamountofsurfactantinthefinalformulation.

Thesamestudywasperformedtoobservetheinfluenceofthe

PEIconcentration(Fig.6).Theparticlesizeincreasedquitelinearly

withtheconcentrationforbothsurfactantsbutthemean

diam-eterremainedunder 100nm.This resultwasrelated toseveral

factors.Thefirstwastheratiobetweentheconcentrationof

surfac-tantandtheamountofchloroformphasecontainingthedissolved

PEI[23].Thesecondwastheviscosityoftheorganicphase[23].

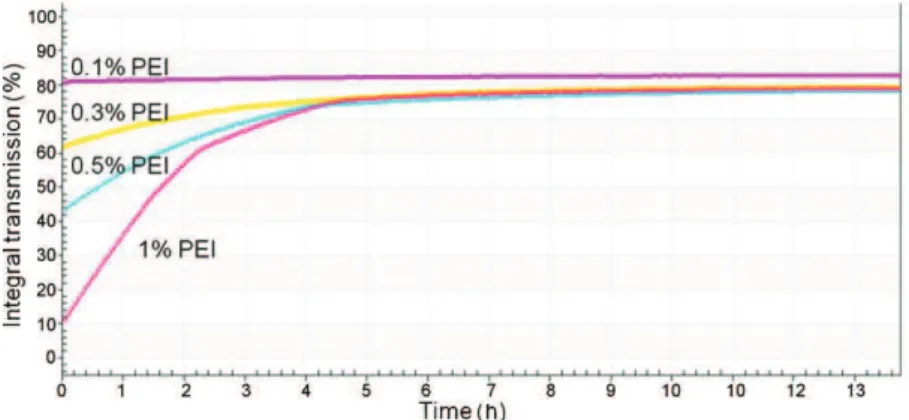

Fig.7.EffectofthePEIconcentrationontheclarificationkineticsfordispersionsat0.3%BC.

IncreasingthePEIconcentrationinchloroformincreasedthe

vis-cosityofthesolution.Giventhattheshearforceswerealwaysthe

same,whentheconcentrationofPEIwastoohigh,therewasnot

sufficientenoughavailabletocreatesmalldropletsofchloroform.

Theparticlesizeforthelowestconcentrationswasverysmall,

lead-ing,inprinciple, tothemoststable dispersions.However,for a

sizingformulation,thedispersionsmusthaveaminimumof0.5%

or1wt%ofPEI.

An interesting stability analysis consisted in determining a

destabilization velocity by accelerating the gravitation by

cen-trifugation. This kind of analysis could be performed withthe

“LUMiFuge”apparatus.Thistechniqueissuitabletooptimizevery

stabledispersions(stableformorethan6months).

Fromtheprofiles,anintegraltransmissionwascalculatedasa

functionoftime.Forinstance,theinfluenceofthePEIconcentration

onthestabilitycanbehighlightedimmediately(Fig.7).

Fromthisgraph,aclarificationvelocity,correspondingtothe

slopeofthefirstlinearpartofthecurves,wascalculatedbythe

“SEPView”software.Thesteepertheslope,themoreunstablethe

dispersion.Theclarificationvelocitywascalculatedforthedifferent

dispersionsandcomparedsoastohighlighttheeffectofdifferent

parameters.

AsshowninFig.8,thenatureofthesurfactantdidnothavea

significantinfluenceonthevelocity,exceptfor0.1wt%PEIsolution,

whereBCwaslessefficient.Consideringthesurfactant

concentra-tion,itseemsthat,from0.5wt%,thestabilityreachesaplateau.This

resultindicatesthatitisnotnecessarytousemorethan0.5wt%

surfactantsolutionstoincreasethestability.

As expected, the PEI concentration had a major impact on

thedispersionstability (Fig.9).Theclarificationvelocitytripled

between0.5%and1wt%.Althoughtheshelflifecannotbe

deter-mineddirectly from theclarification velocity, the real stability

Fig.8. Influenceofthenatureandconcentrationofthesurfactantontheclarification velocity([PEI]=0.5wt%).

periodextrapolatedfromthedatawasestimatedtobearound6

monthsforthe1%PEIdispersion.

Consideringtheaboveresults,boththetestedsurfactantswere

usable.However,benzalkoniumchloridemightbemoreinteresting

becauseofitsantimicrobialandlowfoamingproperties.

Concern-ingthedifferentconcentrations,agoodcompromiseseemstobe

0.5wt%ofsurfactantand0.5wt%ofPEI.

3.1.2. Filmformation

Forsizing,thecoating,andconsequentlytheformationofafilm,

isaveryimportantproperty.Alltheaqueousdispersionsprepared

wereabletoformfilmsafterwaterevaporation.Toensurethe

qual-ityofthefilm,twochosendispersionswereobservedbySEM.One

wasmadewithSDSandtheotherwithBC,andbothcontained

0.5wt%ofsurfactantand0.5wt%ofPEI.

ThesurfaceaspectofthePEIfilmobtainedwithSDSwasvery

homogeneous(Fig.10).Thecrackswereduetouncontrolled

evapo-ration.Thisparameterwillneedtobetakenintoaccountforfurther

applications.Themagnificationofthisfilmshowspartiallyfused

PEIparticles(Fig.11).Thisobservationistypicaloflatexfilm

for-mation,andisidealforahomogeneouscoating.

ThePEIfilmformedbytheBCdispersionwasverydifferent.

Fig.12isanSEMobservationofthisfilmshowingaheterogeneous

surface.Themagnificationshowsthat,infact,theparticlesformed

agglomeratesbutdidnotfuse(Fig.13).Thedifferenceinfilm

forma-tioncouldbeexplainedbytheabilityofthesurfactanttobedrained

outoftheevaporatingfilm[39–41].Wehavetoconsiderthe

affin-ityofthesurfactantwiththesurfaceofthePEIparticlestoexplain

thisbehavior.Itseemsthat,comparedtoBC,SDShasalower

affin-itywiththesurfaceoftheparticlesandismainlydrainedoutofthe

film,leadingtothefusionoftheunprotectedparticlesandfinally

toahomogeneousfilm.

Fig.9. InfluenceofthePEIconcentrationontheclarificationvelocity ([surfac-tant]=0.5wt%).

Fig.10.SEMobservationofthefilmfromtheSDSdispersion.

Fig.11.MagnificationofFig.10.

Fig.12.SEMobservationofthefilmfromtheBCdispersion.

Fig.13.MagnificationofFig.12.

Consideringthesefilmformationresults,thebestdispersions

forasizingapplicationseemtobethoseobtainedwithSDSasthe

surfactant.Itisveryimportanttoobtainahomogeneouscoatingon

thecarbonfibers.

3.2. Sizingevaluation

Theaimofthisstudywastoelaborateastableaqueous

disper-sionusableasathermoplasticsizingformulationforcarbonfibers.

Thesizing hasvariousroles,suchasfacilitating thehandlingof

fibersandimprovingtheinteractionsbetweenthematrixandthe

fibers.

Toevaluatetheeffectofthisnewsizing,PEEK/carbonfiber

com-positesweremade;onewithunsizedcarbonfibersandanother

withPEIsizedcarbonfibers.Thechosensizingwastheaqueous

dispersionwith0.5wt%ofPEIand0.5wt%ofSDS.Thebestwayto

highlighttheinfluenceofthesizingwastoobservethefiber/matrix

interface.Forthatpurpose,thecompositeswerefreezefractured

transversallyandobservedbyscanningelectronmicroscopy.

Fig.14correspondstoanunsizedcarbonfibercompositeand,as

wecansee,therearevoidsandnointeractionsbetweenthePEEK

matrixandthecarbonfibers.Incontrast,theinterfacebetweenthe

Fig.15. PEIsizedcarbonfibercomposite.

compositeandthePEIsizedcarbonfibersiscontinuous(Fig.15).

Inthiscase,thereisarealbondbetweenthePEEKandthecarbon

fibers.Theseobservationsconfirmnotonlythatthesizingremains

duringthecompositeprocessingbutalsothatthematrixandthe

carbonfibersareconnectedbythesizingagent.

4. Conclusions

Theanalysesperformedonthedifferentaqueousdispersions

revealedthatthequantityofparticleswasasignificantfactorfor

stability.TheparticlesizeincreasedgreatlywiththePEI

concentra-tion,whichtendedtodecreasethestabilityofthedispersion.The

LUMiFugestudyconfirmedthisresult.ThebestPEIconcentration

obtainable bytheemulsion/evaporation technique was0.5wt%.

Thedispersions werestable1 yearat 0.5wt%,nevertheless the

dispersionat1wt%remainedstablefor3months.Concerningthe

natureofthesurfactant,benzalkoniumandSDSallowedstable

dis-persionstobeobtained.Nevertheless,thebenzalkoniumdispersion

didnotformahomogeneousfilmandsowasnotsuitablefor a

sizingapplication.Incontrast,withSDSdispersion,thefilmwas

reallyuniformandweobservedacoalescencephenomenon

typi-caloflatexfilmformation.Theconcentrationofthesurfactantalso

hadaninfluenceontheparticlesizeandstability,and0.3%wasnot

enoughtoobtainagooddispersion.Thegaininstabilityobtained

at1%didnotjustifytheuseofsuchaconcentrationconsidering

thattherewasonly0.5wt%ofPEI.Sothebestconcentrationof

surfactantwas0.5wt%.

Consideringalltheresults,thechosendispersionforsizingwas

0.5%PEIand0.5%SDS.Theefficiencyofthisnewsizingagent

aque-ousdispersionwasappreciatedthroughSEMobservations,which

showedacontinuousinterfacebetweenthecarbonfibersandthe

PEEKmatrix.

Acknowledgements

WethankMrJ.M.Bergerat,AIRBUSIndustry,ToulouseFrance,

for useful discussions and advice. The financial support of FUI

INMAT2andAIRBUSisgratefullyacknowledged.WealsothankMr

D.KemmishandMrA.WoodfromVictrexInc.,fortheirinsightful

commentsandfruitfuldiscussions.

References

[1] P.Morgan,CarbonFibersandTheirComposites,CRCPressTaylor&Francis Group,NewYork,2005.

[2] D.D.L.Chung,CarbonFiberComposites,Butterworth-Heinemann,Newton, 1994.

[3] B.Fernandez,A.Arbelaiz,A.Valea,F.Mujika,I.Mondragon,PolymerComposites 25(2004)319–330.

[4]W.Chen,Y.Yu,P.Li,C.Wang,T.Zhou,X.Yang,CompositesScienceand Tech-nology67(2007)2261–2270.

[5] A.Paipetis,C.Galiotis,CompositesPartA:AppliedScienceandManufacturing 27(1996)755–767.

[6] N.Dilsiz,J.P.Wightman,Carbon37(1999)1105–1114. [7] R.B.Guan,Y.G.Yang,J.T.Zheng,Fibercomposites1(2002)23. [8] T.Q.Li,M.Q.Zhang,H.M.Zeng,Polymer40(1999)4307–4313.

[9] S.-L.Gao,J.-K.Kim,CompositesPartA:AppliedScienceandManufacturing32 (2001)775–785.

[10]L.T.Drzal,M.J.Rich,M.F.Koenig,P.F.Lloyd,TheJournalofAdhesion16(1983) 133–152.

[11]Z.Dai,F.Shi,B.Zhang,M.Li,Z.Zhang,AppliedSurfaceScience257(2011) 6980–6985.

[12] Z.Dai,B.Zhang,F.Shi,M.Li,Z.Zhang,Y.GU,AppliedSurfaceScience257(2011) 8457–8461.

[13]P.Ren,G.Liang,Z.Zhang,PolymerComposites27(2006)591–598.

[14]V.S.Mironov,M.Park,J.Kim,S.H.Lim,C.R.Choe,JournalofMaterialsScience Letters20(2001),1211–1211.

[15]A.Bledzki,E.Fabrycy,A.Kwasek,JournalofThermalAnalysisandCalorimetry 29(1984)989–994.

[16]D.M.Blackketter,D.Upadhyaya,T.R.King,J.A.King,PolymerComposites14 (1993)430–436.

[17]T.K. O’Brien, Journal of Reinforced Plastics and Composites 7 (1988) 341–359.

[18]P.Davies,W.J.Cantwell,H.H.Kausch,JournalofMaterialsScienceLetters9 (1990)1349–1350.

[19]A.Todoroki,H.Kobayashi,CompositesScience andTechnology52(1994) 551–559.

[20]S.Freitas,H.P.Merkle,B.Gander,JournalofControlledRelease102(2005) 313–332.

[21]C.Zhang,G.Zhang,V.Ji,H.Liao,S.Costil,C.Coddet,ProgressinOrganicCoatings 66(2009)248–253.

[22]P.R.Nepal,M.-K.Chun,H.-K.Choi,InternationalJournalofPharmaceutics341 (2007)85–90.

[23] M.Li,O.Rouaud,D.Poncelet,InternationalJournalofPharmaceutics363(2008) 26–39.

[24]T.R.Tice,R.M.Gilley,JournalofControlledRelease2(1985)343–352. [25] K.S.Soppimath,T.M.Aminabhavi,A.R.Kulkarni,W.E.Rudzinski,Journalof

Con-trolledRelease70(2001)1–20.

[26]S. Freiberg, X.X. Zhu,International Journal of Pharmaceutics 282 (2004) 1–18.

[27] Z.ElBahri,J.-L.Taverdet,JournalofAppliedPolymerScience103 (2007) 2742–2751.

[28]M.Kuentz,D.Röthlisberger,EuropeanJournalofPharmaceuticsand Biophar-maceutics56(2003)355–361.

[29] T.Sobische,H.Heb,H.Niebelschütz,U.Schmidt,ColloidsandSurfacesA: PhysicochemicalandEngineeringAspects162(2000)1–14.

[30]T.Sobische,D.Lerche,ColloidsandSurfacesA:Physicochemicaland Engineer-ingAspects331(2008).

[31]A.Bismarck,A.F.Lee,A.S.Sarac,E.Schulz,K.Wilson,CompositesScienceand Technology65(2005)1564–1573.

[32]A.S.Sarac,E.A.Parlak,E.Sernath,T.Cakir,JournalofAppliedPolymerScience 104(2007)238–246.

[33] B.Lin,R.Sureshkumar,J.L.Kardos,ChemicalEngineeringScience56(2001) 6563–6575.

[34]C.Dalmolin,S.C.Canobre,S.R.Biaggio,R.C.Rocha-Filho,N.Bocchi,Journalof ElectroanalyticalChemistry578(2005)9–15.

[35]R.Torrecillas,A.Baudry,J.Dufray,B.Mortaigne,PolymerDegradationand Sta-bility54(1996)267–274.

[36]G.Crevecoeur,G.Groeninckx,Macromolecules24(1991)1190–1195. [37]R.L.Zhang,Y.D.Huang,L.Liu,Y.R.Tang,D.Su,L.W.Xu,AppliedSurfaceScience

257(2011)3519–3523.

[38]D.D.L. Chung,CarbonFiberComposites,Butterworth-Heinemann,Newton, 1994,pp.91–93.

[39]E.Kientz,Y.Holl,ColloidsandSurfacesA:PhysicochemicalandEngineering Aspects78(1993)255–270.

[40] J.Mallégol,J.-P.Gorce,O.Dupont,C.Jeynes,P.J.McDonald,J.L.Keddie,Langmuir 18(2002)4478–4487.

[41]A.Tzitzinou,P.M.Jenneson,A.S.Clough,J.L.Keddie,J.R.Lu,P.Zhdan,K.E. Treacher,R.Satguru,ProgressinOrganicCoatings35(1999)89–99.

![Fig. 5. Influence of the nature and concentration of the surfactant on the mean particle diameter ([PEI] = 0.5 wt%).](https://thumb-eu.123doks.com/thumbv2/123doknet/3579942.104967/4.892.456.823.920.1125/fig-influence-nature-concentration-surfactant-mean-particle-diameter.webp)