© Eric Ngbanye Ntabe, 2020

A SCOR-Based Process Modelling Approach for Green

Performance Evaluation of Forestry Systems

Thèse

Eric Ngbanye Ntabe

Doctorat en sciences forestières

Philosophiæ doctor (Ph. D.)

A SCOR-Based Process Modelling Approach for

Green Performance Evaluation of Forestry Systems

Thèse

Présenté à la Faculté d‟Études Supérieures de l‟Université Laval pour l‟obtention

du grade de Philosophiae Doctor (PhD) en Sciences Forestières

Par

Eric Ngbanye Ntabe

Sous la direction de:

Professeur Luc LeBel, directeur de recherche

Professeur Alison Munson, codirectrice de recherche

iii RESUME

L‟élaboration d‟une approche de modélisation permettant aux industries forestières d‟évaluer l‟efficacité d‟utilisation de bois au long de la chaîne de valeur forestière est un moyen permettant de réduire l‟écart entre le volume récolté et le volume effectivement transformé. Au moment où, un vent de changement de paradigme visant à éviter la perte de bois le long de cette chaîne souffle sur le monde, il est opportun que l‟industrie des produits forestiers entreprenne une transition par laquelle, les options de gestion qui engendrent les technologies vertes soient intégrées dans le modèle de gestion classique. La présente étude s‟appuie sur l‟idée de l‟absence d‟un cadre de modélisation crédible pour la visibilité et l‟évaluation de la performance environnementale des activités de la chaîne de valeur forestière. Nous estimons que l‟adoption des pratiques environnementales, visant à maximiser l‟utilisation du bois sera un engagement plausible pour la comptabilité environnementale. De nombreux travaux récents sur le modèle Supply Chain Operations Reference (SCOR), référentiel mondial en termes d‟outils interprofessionnels de diagnostique pour la gestion des chaînes logistiques, ont été analysés afin d‟exposer les lacunes de recherche sur la base des critères environnementaux. Au regard des résultats de l‟analyse, nous avons conclu sur un énoncé normatif selon lequel, le modèle SCOR n‟est pas appliqué dans la gestion des ressources naturelles. Nous avons appliqué la méthode de recherche Design Science pour l‟élaboration d‟un cadre conceptuel, „Forest Supply Chain Operations Reference (f-SCOR) model, comme outil d‟aide à la décision pour la performance et le reporting environnemental le long de la chaîne de valeur forestière. L‟outil permet une bonne visibilité de la chaîne, et favorise une meilleure prise de décision ainsi que les processus organisationnels. Nous avons contextualisé les processus et fonctionnalités du modèle original SCOR et fait passé son composant pour la mesure du rendement au niveau 5. Les principaux indicateurs de performance et les paramètres environnementaux ont été conçus pour deux types de produits forestiers (des contreplaqués), tant dans la forêt que dans les usines, afin d‟évaluer l‟efficacité de l‟utilisation du bois le long de cette chaîne. Ce cadre a été soumis à une validation théorique par les spécialistes venant du Nigeria et de l‟Australie, ainsi qu‟une validation pratique par des acteurs de la filière contreplaqué, sur la base d‟une procédure de démonstration de faisabilité dans deux entreprises typiques du contreplaqué au Cameroun. Dans le module théorique, les données sur les avis des experts ont été soumises au test de Friedman, à l‟aide du logiciel XLSTAT, pour déterminer leur niveau de rapprochement de la qualité du modèle sur la base de trois critères d‟évaluations. Ce test a révélé une forte corrélation (p>0.448); α = 0.01 entre les avis. Ils ont déclaré que le modèle f-SCOR possède un niveau de précision satisfaisant, cadrant avec les réalités empiriques de la chaîne de valeur forestière. Le volet d‟application pratique a été mené par les acteurs de la chaîne de valeur du contreplaqué. Ces acteurs ont conclu que le modèle est convivial et représente acceptablement une chaîne de valeur du contreplaqué. Il convient de tester ce modèle sur d‟autres produits de l‟industrie forestière, ainsi que dans d‟autres régions afin d‟augmenter sa robustesse, sa portée et son champ d‟application.

iv ABSTRACT

The development of a modelling approach that allows forest industries to assess wood use efficiency along the forest value chain is a practical strategy that can reduce the gap between harvested volume and the proportion that is effectively transformed. While a changing paradigm to circumvent wood loss along the value chain is sweeping across the world, it is important for the forest products industry to make a transition in which value chain management options that stimulate green technologies are introduced into its traditional business model. This study is grounded in the view that there is lack of a reliable modelling framework for visibility and green performance evaluation and reporting of forest value chain activities. We argue that the introduction of green practices to maximize wood utilization is a plausible commitment to environmental accounting and reporting. A number of recent papers on the well-known Supply Chain Operations Reference (SCOR) model, the cross-industry de facto standard diagnostic tool for Supply Chain Management were analyzed to identify research gaps in relation to environmental criteria. Based on the results of the analysis, we concluded that SCOR model is not applied in natural resource management. We employed the design science research procedure to develop a conceptual framework known as Forest Supply Chain Operations Reference (f-SCOR) model, as a decision support tool for green performance and reporting along the forest value chain. The tool creates opportunities for management visibility of the supply chain spectrum. It also offers prospects for informed decision-making process, as well as organizational processes. We contextualized the processes and functionalities of the original SCOR model and extended its performance measurement component to Level 5, which is made-up of decompose tasks that are defined by the company. Key performance indicators and green metrics were developed for two plywood supply chain strategies, both in the forest and mill settings, to assess wood utilization efficiency along the chain. The framework was subjected to a theoretical validation by domain experts from Nigeria and Australia, as well as a practical validation by plywood Make agents, based on a proof-of-concept procedure in two typical plywood industries in Cameroon. In the theoretical module, data on the individual opinions of the experts was subjected to Friedman's Test, using XLSTAT software, to determine their degree of commonality regarding the quality of the model, based on three assessment constructs. The test revealed a high degree of correlation (p>0.448); α = 0.01 between the opinions. They agreed that f-SCOR model possesses a satisfactory degree of accuracy that is consistent with empirical realities of the forest value chain. The practical application component was conducted by Make agents of the plywood value chain. They concluded that the f-SCOR is user friendly and has an acceptable degree of representation of a real-world plywood value chain.This model should be tested using other forest industry products and in different regions to increase its robustness, scope and application domain.

v TABLE OF CONTENTS RESUME ... iii ABSTRACT ... iv TABLE OF CONTENTS ... v LIST OF TABLES ... x LIST OF FIGURES ... xi

LIST OF APPENDICES ... xiv

ACKNOWLEDGEMENTS ... xvi

PREFACE ... xviii

GENERAL INTRODUCTION ... 1

1.1. GENERAL OBJECTIVE OF THE STUDY ... 7

1.2. RESEARCH QUESTIONS ... 8

1.2.1. General Research Question ... 8

1.2.2. Sub Questions ... 8

1.3. OUTLINE OF RESEARCH METHOD... 9

1.4. THESIS CONTRIBUTION ... 12

1.5. THESIS LIMITATIONS ... 13

1.6. THESIS STRUCTURE AND ORGANIZATION ... 14

CHAPTER TWO ... 16

LITERATURE REVIEW OF THE SUPPLY CHAIN OPERATIONS ... 16

REFERENCE (SCOR) MODEL ... 16

Résumé ... 16

Abstract ... 17

2.1. INTRODUCTION ... 18

vi

2.2.1. Article search and selection procedure ... 19

2.2.2. Definition of assessment criteria elements ... 21

2.3. RESULTS ... 23

2.3.1. Presentation of the SCOR Model ... 24

2.3.1.1. SCOR management processes ... 26

2.3.2. Systematic literature review of the SCOR model ... 33

2.3.2.1. Article characterization by environmental considerations and the return process... ... 33

2.3.2.2. Article characterization by methodological consideration ... 40

2.3.2.2.1. Conceptual papers ... 40

2.3.2.2.2. Case study methodology ... 46

2.3.2.2.3. Simulation methodology ... 49

2.3.2.2.4. Survey methodology ... 53

2.3.2.2.5. Other empirical methods ... 55

2.3.2.3: Identification and analysis of knowledge gaps ... 56

2.3.2.4. Definition and analysis of gap assessment criteria elements ... 57

2.3.2.5. Gap analysis by methodological consideration ... 58

2.3.2.6. Gap analysis by year of publication ... 59

2.3.2.7: Gap analysis by supply chain strategy ... 63

2.3.2.8. Gap analysis by SCOR management process ... 64

2.3.2.9. Gap analysis based on environmental considerations ... 65

2.3.2.10. Gap analysis by SCOR component ... 67

2.3.2.11. Gap analysis by geographic distribution ... 67

2.4. CONCLUSION ... 70

LITERATURE CITED ... 73

vii

THE FOREST SUPPLY CHAIN OPERATIONS REFERENCE (f-SCOR) MODELLING

APPROACH ... 85

Résumé ... 85

Abstract ... 86

3.1. INTRODUCTION ... 87

3.2. METHOD ... 91

3.2.1. Selection of SCOR management processes ... 96

3.2.2. Data collection methods ... 97

3.2.2.1. Interviews ... 100

3.2.2.2. Questionnaire administration ... 101

3.2.2.3. Group discussions ... 102

3.2.3. Triangulation of data ... 103

3.2.4: Selection and definition of f-SCOR modelling elements ... 106

3.2.5. Definition of KPIs and Environmental Metrics ... 108

3.2.5.1. Hierarchical decomposition of f-SCOR Environmental Metrics ... 112

3.2.5.2: Association of KPIs and EMs with modelling elements of f-SCOR ... 116

3.2.5.3: Calculation of Environmental Metrics ... 122

3.3. RESULTS ... 123

3.3.1. Description of the observed forest value chain map ... 123

3.3.1.1. Case Study One ... 124

3.3.1.2. Case Study Two ... 126

3.3.2. The f- SCOR Modelling Approach ... 128

3.3.2.1: f-SCOR modelling approach for the Make process in the forest value chain ... 132

3.3.2.2: f-SCOR modelling approach for Deliver process in the forest ... 134

3.3.2.3: f-SCOR modelling approach for Source process at the plywood mill ... 136

3.3.2.4: f-SCOR modelling approach for Make process at the plywood mill ... 137

viii

3.3.2.6: f-SCOR modelling approach for Source process at the warehouse ... 140

3.3.2.7: f-SCOR modelling approach for Deliver process at the warehouse ... 141

3.4. CONCLUSION ... 143

CHAPTER FOUR ... 146

TESTING THE f-SCOR MODELLING APPROACH FOR USEFULNESS, EASE-OF-USE AND CONSISTENCY ... 146

Résumé ... 146

Abstract ... 147

4.1. INTRODUCTION ... 148

4.2. VALIDATION METHODS ... 150

4.2.1. THEORETICAL METHOD ... 150

4.2.1.1. Selection of domain experts ... 152

4.2.1.2. Analysis and Interpretation of Validation Questionnaire ... 153

4.2.2. PRACTICAL METHOD ... 154

4.2.2.1. The Cameroon forest industry sector ... 154

4.2.2.2. Presentation of the two case study value chains ... 159

4.2.2.3. Selection of employees for the industry application of f-SCOR ... 165

4.2.2.4. Data collection ... 166

4.2.2.5. Estimation of wood waste amounts ... 166

4.3. RESULTS ... 169

4.3.1. Theoretical Validation ... 169

4.3.2. Practical Validation ... 173

4.3.2.1. Results in the forestry subsystem ... 174

4.3.2.2. Results in the industry subsystem ... 181

4.4. CONCLUSION ... 191

ix

5.1. RESEARCH APPLICATION ... 199

5.2. STUDY LIMITATIONS AND FUTURE RESEARCH ... 200

LITERATURE CITED ... 202

x

LIST OF TABLES

Table 2.1: Description of assessment criteria elements used ... 22

Table 2.2: SCOR Business Process Reference Model ... 28

Table 2.3: Detailed outline of the SCOR model ... 30

Table 2.4: Summary of assessment results ... 57

Table 2.5: Article distribution by Year, author, journal and methodology ... 60

Table 3.1: Definition of Modelling Notations for SCOR Levels ... 106

Table 3.2: Comparison between f-SCOR and the original SCOR model ... 129

Table 3.3: Scientific foundation of f-SCOR modelling ... 130

Table 4.1: Expert opinions about to Perceived usefulness ... 170

Table 4.2: Expert opinions about Perceived ease-of-use ... 171

xi

LIST OF FIGURES

Figure 1.1: Effects of lack of a modelling framework for green performance measurement of

forest value chain activities. ... 3

Figure 1.2: General outline of research method ... 10

Figure 2.1: Schematic framework of SCOR Level 1 management processes ... 26

Figure 2.2: SCOR process levels depicting the hierarchical architecture of the model ... 29

Figure 2.3: Levels one and two GreenSCOR model infrastructure ... 32

Figure 2.4: Article distribution by research methodological approach ... 59

Figure 2.5: Article distribution by year of publication ... 60

Figure 2.6: Percentage distribution of articles by supply chain strategy ... 64

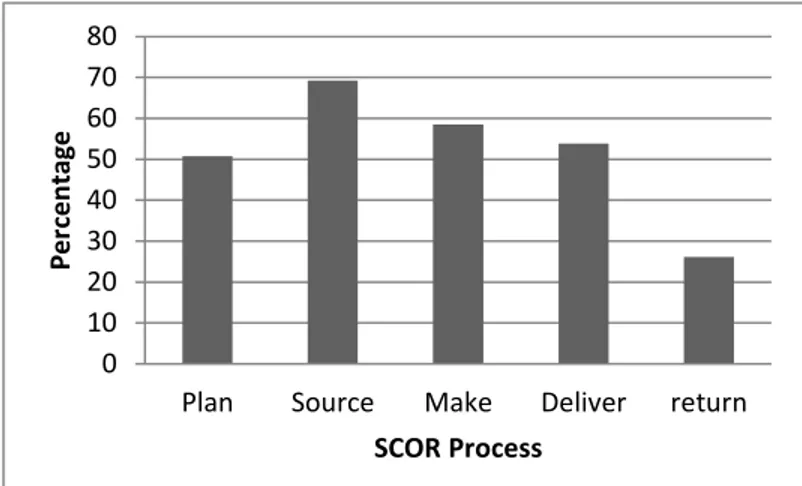

Figure 2.7: Article distribution by SCOR management process ... 64

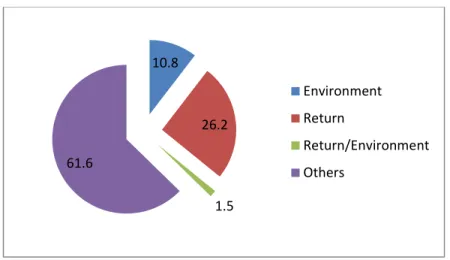

Figure 2.8: Percentage distribution of papers by environmental concerns ... 65

Figure 2.9: Method of involvement of the return process ... 66

Figure 2.10: Article distribution by SCOR component ... 67

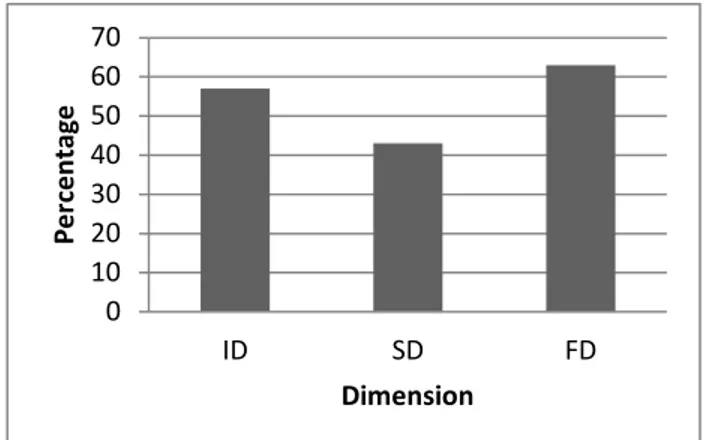

Figure 2.11: Percentage distribution of articles by continent ... 68

Figure 2.12: Percentage distribution of articles by inter-temporal, spatial and functional dimensions ... 69

Figure 3.1: Projected benefits of f-SCOR on the forest value chain ... 90

Figure 3.2: Design Science Research process model ... 93

Figure 3.3: Design Science approach applied for the construction f-SCOR ... 95

Figure 3.4: Selected SCOR Management Processes ... 96

Figure 3.5: Data triangulation framework ... 105

Figure 3.6: Metric decomposition structure for forest reconstitution rate ... 113

xii

Figure 3.8: Metric decomposition structure for product delivery performance ... 115

Figure 3.9: Green performance evaluation elements for Make process (technical production of timber) in the forest ... 117

Figure 3.10: Green performance evaluation elements for Make process (biological production of timber) in the forest ... 118

Figure 3.11: Green performance evaluation elements for Deliver process in the forest ... 119

Figure 3.12: Link between KPI, EM and f-SCOR process elements for Source process at the mill ... 120

Figure 3.13: Green performance evaluation elements for the Make process at the mill ... 121

Figure 3.14: Link between KPI, EM and f-SCOR process elements for Deliver process at the mill ... 122

Figure 3.15: Forest value chain map ... 123

Figure 3.16: A typical Level 2 thread diagram planning process for MTS plywood ... 125

Figure 3.17: Make-To-Stock plywood product flowchart ... 126

Figure 3.18: A typical Level 2 thread diagram planning process for MTO plywood. ... 127

Figure 3.19: Make-To-Order plywood product flowchart ... 127

Figure 3.20: f-SCOR modelling approach for Make management process in the forest ... 132

Figure 3.21: f-SCOR modelling approach for Deliver management process in the forest .... 135

Figure 3.22: f-SCOR modelling approach for Source management process at the mill ... 136

Figure 3.23: f-SCOR Modelling approach for Make Management Process at the millPlan .. 137

Figure 3.24: f-SCOR modelling approach for Deliver management process at the mill ... 139

Figure 3.25: f-SCOR modelling approach for Source management process at the warehouse ... 141

xiii

Figure 3.26: f-SCOR modelling approach for Deliver management process at the warehouse

... 142

Figure 4.1: Cameroon wood value chain ... 156

Figure 4.2: Virtual map for MTS and MTO plywood in Cameroon ... 160

Figure 4.3: Plywood production within the forestry and industry subsystems ... 164

Figure 4.4: f-SCOR modelling approach for MTS wood waste generation operations and FRR within the FVC ... 176

Figure 4.5: f-SCOR modelling approach for MTO wood waste generation operations and FRR within the FVC ... 178

Figure 4.6: Log off-cuts and saw lines at the millre 4.6: Log off-cutand Saw lines at the mill ... 182

Figure 4.7: Effects of log profile on wood loss ... 184

Figure 4.8: Wood waste types during peeling ... 185

Figure 4.9: Veneer off-cuts ... 187

Figure 4.10: f-SCOR modelling approach for MTS wood waste generation operations at the MVC ... 188

Figure 4.11: f-SCOR modelling approach for MTO wood waste generation operations at the MVC ... 190

xiv

LIST OF APPENDICES

APPENDIX 1: Purpose of the Study ... 227

APPENDIX 2: Announcement ... 228

APPENDIX 3A : Consent Form for Questionnaire ... 229

APPENDIX 3B: Consent Form for Interview ... 231

APPENDIX 4: Observation Guide ... 233

APPENDIX 5: Survey Items for Questionnaire ... 234

APPENDIX 6: Survey Items for Interview ... 236

APPENDIX 7: Methods for the Calculation of Environmental Metrics ... 238

APPENDIX 8: Description of Level 3 Process Categories ... 242

APPENDIX 9: Framework Validation Questionnaire ... 246

APPENDIX 10: Statistical Analysis of Theoretical Validation ... 248

APPENDIX 11: Photographic Data at the Mill Complexes ... 271

xv

xvi

ACKNOWLEDGEMENTS

I would like to thank my Supervisor Professor Luc LeBel and Co-Supervisor, Professor Alison Munson of Université Laval (UL) for their priceless scientific contributions and indefatigable support during the course of my study. While they consistently and rigorously steered me into achieving this lifelong goal, they equally nurtured me into a career researcher with new scientific frontiers. I lack words to express my deep gratitude. I am sincerely indebted to Professor Luis Antonio De Santa-Eulalia of Université de Sherbrooke for serving on my thesis committee and particularly for his useful critiques and profound ideas. His enthusiasm to generously put in his valuable time and accumulated knowledge was remarkable and instrumental. I would also like to acknowledge and profoundly thank Professor Damase Khasa of Université Laval for his inexorable advice and great words of encouragement throughout my study.

I am indebted to the „Projet d‟Appui à la Formation en Gestion des Ressources Naturelles dans le Bassin du Congo (FOGRN-BC)‟ financed by the Canadian Ministry of Foreign Affairs, Department of Foreign Affairs, Trade and Development (DFATD) formally known as the Canadian International Development Agency (CIDA) for offering me full scholarship. I also thank Professor Luc LeBel for providing financial support from NSERC Discovery Grant No. 203193 for workshops and seminars in Canada, USA and South Africa. Immense thanks also go to the staff of FORGN-BC for their unwavering administrative assistance throughout my years of study. Special thanks go to Mr Roger Fankap, Madam Marie-France Gevry and Madam Stephanie. I would also like to thank the experts who passionately conducted the theoretical and practical validation of the model that we constructed. In this regard, I wish to sincerely thank Professor John Akande, Forest Industry Expert and Deputy Vice Chancellor of BOWEN University, Nigeria; Dr Mark Brown, Director of Forest Industries Research Centre, University of the Sunshine Coast, Australia; Dr Nalin, Production Manager and Mr Yves Ngangue, employee at ALPICAM Douala and finally Mr Aoudu, former Production Manager at SCTB, Yaounde Cameroon. On a more personal note, I was privileged to be surrounded by outstanding friends and colleagues from whom I drew inspiration. Consequently, I express profound gratitude to Dr Shuva Gautam, Dr Elaine Mosconi, Dr Gregory Paradis and Mr Ricardo Cantu of PREFORT Lab and FORAC as well as Dr Djeugap Fovo. Finally, I wish to thank my family (my mom, wife and kids, my

xvii

brothers and sisters) for their patience, unconditional love, emotional support and prayers. They relentlessly stood by me when I needed them most.

xviii PREFACE

This work was carried-out under the supervision of Prof. Luc LeBel and co-supervised by Prof Alison Munson of Département des Sciences du Bois et de la Forêt, Université Laval Canada. Financial support was provided by „Projet d‟Appui à la Formation en Gestion des Ressources Naturelles dans le Bassin du Congo‟ (FOGRN-BC)‟ and Prof. Luc LeBel‟s NSERC Discovery Grant (No. 203193). The main contributions of this thesis are the following three articles of which I am the lead author:

1. E.N. Ntabe, L. LeBel, A.D. Munson, L.A.Santa-Eulalia (2015): A systematic literature review of the supply chain operations reference (SCOR) model application with special attention to environmental issues. International Journal of Production Economics, 169: 310– 332 (Thesis Chapter 2).

2. Ntabe, E.N.; LeBel, L.; Munson, A.D. and Santa-Eulalia, L.A.: A SCOR-based modelling formalism for enviromental performance evaluation of two forest supply chain strategies (Thesis chapter 3). This article shall be submitted to The Canadian Journal of Forest Research.

3. An exogenous validation method of a conceptual model for the tropical wood value chain (Thesis chapter 4). This article shall be submitted to International Journal of Forest Engineering.

1

GENERAL INTRODUCTION

The forest industry is important to the economies of many nations (Carlsson and Ronnqvist, 2005; D‟Amours et al. 2009; Trung and Leblon, 2011; Henderson and Munn, 2013; Andreas, 2015). Several researchers (e.g. LeBel and Carruth, 1997; Carlsson and Ronnqvist, 2004; D‟Amours et al. 2009; Greene et al. 2010; Ntabe et al. 2012; Mansoornejad et al. 2013; Shabani et al. 2013; Paradis et al. 2017; Elias and Hanne, 2018 and Frank et al. 2018) have made significant breakthroughs in the development and application of business models to solve financial optimization problems along forest supply chains. Despite this significant progress in financial modelling and solution capabilities, the sector is still confronted with many challenges. Among these, we call attention to environmental issues affecting green value chain management. Other authors (e.g., Walton et al. 1998; Nawrocka et al. 2009; Hu and Hsu, 2010; Bose and Luo, 2011; De Gobbi, 2011; Sindhi and Kumar, 2012; Belal et al. 2015 and Dietmar, 2018) have highlighted the importance of the environmental dimension in corporate performance. With an increasing global demand for tropical timber that is not matched by corresponding environmental requirements that ensure continued production of wood fiber, there are concerns that this may outweigh the natural response potential of the forest ecosystem. According to FAO (2001), global consumption of timber products will increase by 45% by the end of 2020. Adhikari and Ozarska (2018) also observe an annual increase of 4.4% since 2015. Furthermore, a forecast by FIM (2017) reveals that global timber demand will quadruple by the year 2050.

Consequently, there is growing concern about fulfilling the need for increasing demand for timber products without compromising the resource. Besides, with an increasing number of forest stakeholders paying greater attention to the environmental issues of business

2

organizations (Farooque and Ahulu, 2015) and the recent global endorsement of the first ever legally-binding agreement on climate change at COP21, the environmental criterion has gained wider global concern and has been brought to the forefront of corporate requirements for access to the market.

Unlike in past prevailing systems where the decision-making process focused only on economic factors, increasing human pressure on timber resources and the global agreement on climate stabilization requires forest industry managers to weigh not only the economics of their decisions, but their environmental effects as well. Consequently, the need to meet stakeholders' requirements, by shifting from traditional production to balancing with green practices along the forest value chain, has become an increasingly mandatory corporate responsibility (Hwang et al. 2010; Toppinen et al. 2012; Schrödl and Simkin, 2013; Braam et al. 2016). The consideration of green issues in the forest industry is now increasingly becoming a standard method of carrying-out business operations. Sinclair and Walton (2003) observe that environmental reporting can influence customer purchasing decisions. The introduction of ecological responsibilities into the business models of the forest products industry can therefore improve its competitive potential in the market place.

While the industry seeks to solve this problem by introducing green practices, it is constrained by the lack of a suitable performance management tool that can provide visibility as well as enable the evaluation and reporting of environmental performance along the supply chain. According to Lamming et al. (2001), visibility or sharing of information among partners in a supply chain increases transparency, while Chan (2003) acknowledges that supply chain visibility improves accuracy and reduces information delivery time. It provides insight on how the entire value chain spectrum works, how it tracks operations,

3

provides real time information, timely decisions, improved workflow, reduced risk and increased benefits.

As illustrated in Figure 1.1, the problem tree maps out a situational analysis that helps to clarify cause-effect relationships that affect green performance evaluation and reporting of the forest value chain. The absence of a reliable management support system for green performance evaluation leads to poor environmental performance and reporting of the activities of the forest value chain (Akman and Piskin, 2013). As an upshot of this absence, some forest industries in an effort to provide environmental details of their actions resort to unconventional evaluation methods and reporting mechanisms that do not frequently safeguard the reliability of data and the performance measurement indicators that are used.

Figure 1.1: Effects of lack of a modelling framework for green performance measurement of forest value chain activities.

Lack of a reliable instrument for tracking, measuring and reporting the

environmental performance of the forest value chain

(Farooque and Ahulu, 2015) Causes

Poor value chain environmental performance and reporting (Clarkson

et al. 2011)

Unreliable value chain environmental information

(Bodegom et al. 2008)

Difficulty identifying sources and causes of poor green

practices

Effect

Poor visibility of forest value chain operations (Bartlett et al. 2007) Unreliable data on forest

operations & forest residue (Minang et al. 2008)

Unreliable data on mill processing & wood waste (Minang et al.

4

Skillius and Wennberg (1998), Adams and McNicholas (2007) and Nor et al. (2016) note conclusive evidence in such environmental reporting of an absence of essential information (either because it is incomplete or lacking enough quantifiable data), often resulting from the shortcomings of the tools used in the data collection process.

Meanwhile, literature surveys (Schnetzler et al. 2009; Bai et al. 2010; Hwang et al. 2010; Sundarkani et al. 2010; Bai et al. 2012; Xiao et al. 2012, Benjaafar et al. 2013) divulge an emergent need for developing decision support systems that address issues associated with mitigating environmental problems in the supply chain. According to Benjaafar et al. (2013), this approach can reduce more carbon emissions at less cost than adopting low-energy consumption technologies. In some forest value chains where high wood waste generation has led to substantial reduction in industrial and round wood availability, such an approach can have significant environmental implications in terms of wood use efficiency. According to Schoening (1978) and Edwards et al. (2010), good utilization is a cornerstone for intelligent forest resource development. This assertion is substantiated by Abebe and Holms (2003) who state that, by increasing logging efficiency, forest management and processing efficiency, companies would require only one-third of the forest land that they now need for the same sawn wood production. Hence, a modelling framework that provides support information for the improvement of wood use along the forest value chain can have positive effects on the sustainable utilization of wood fiber. While this need for business organizations to respond to corporate environmental requirements has been largely reported in extant literature (Brophy and Starkey, 1996; Manetti, 2011; Xiao et al. 2012; Toppinen et al. 2012; Benjaafar et al. 2013; Farooque and Ahulu, 2015; Braam et al. 2016), environmental considerations in value chain decisions

5

have received limited attention (Hwang et al. 2010; Ntabe et al. 2015). More so, the voluntary nature of reporting gives business organizations the latitude to decide which environmental management programs to pursue and how the outcomes can be reported. Raiborn et al. (2011) equally observe failure in the financial accounting systems of the organizations to fully disclose environmentally-related costs. Meanwhile, Farooque and Ahulu (2015) endorse environmental reporting as an important communication channel that can improve engagement with stakeholders.

Environmental reporting has thus been frequently seen in numerous studies as being lopsided and self-laudatory (Manetti, 2011). The tendency is for companies to report preferred information using industry-specific performance metrics. Toppinen et al. (2012) corroborate that a growing number of companies in forest‐based industries are following what could be called a relatively defensive approach to corporate responsibility. Hence, Farooque and Ahulu (2015) draw attention to the lack of transparency and accountability in environmental reporting that render them less reliable for decision making and policy formulation. Kareiva et al. (2015) also observe a diversity of environmental reporting mechanisms with a majority of them lacking depth, rigor and quantification. Finally, Braam et al. (2016) caution that business organizations are increasingly held accountable for the impact of their decisions and activities on the environment.

Consequently, several methodologies such as certification and the use of modelling frameworks like the erstwhile Computer Integrated Manufacturing Open System Architecture (CIMOSA) (Kennedy, 1993) and more recently the Supply Chain Operations Reference (SCOR) model (Schnetzler et al. 2009; Hwang et al. 2010; Bai et al. 2010; Putthinoi et al. 2015; Tramarico et al. 2017), have since been experimented to achieve

6

environmental performance in an array of industries. The use of supply chain management techniques to improve the performance of the forest products industry has equally been recommended by Vahid et al. (2016).

The application of the SCOR model has been reported in the following industries to name a few: the professional services industry (Ellram et al. 2004), the lamp industry (Vanany et al. 2005), the tourism industry (Yilmaz and Bititci, 2006), transistor-liquid crystal display industry (Hwang et al. 2008), ethanol and petroleum industry (Russel et al. 2009), geographic information systems (Schmitz, 2008), the construction industry (Cheng et al. 2010; Pan et al. 2010), the automotive industry (Potthast et al. 2010), warehousing (Fattah et al. 2016), the pharmaceutical industry (Lhassan and Ali, 2017), the gas and oil industry (Wang et al. 2018) and the flight catering industry (Sundarakani et al. 2018). Given this strategic importance of the model in the supply chain management community, adapting it for environmental performance in the forest value chain should stimulate innovative opportunities for value capture such as low wood waste generation, reliable product supply and improved value chain relationships. It will equally provide a level ground for balanced reporting and increased visibility on green practices. Specifically, its application for the evaluation of wood waste in the forest and at the mill facility, can improve wood utilization efficiency, value chain environmental performance and company image. The reference framework can also contribute to mitigating the global problem of decreasing availability of high quality old-growth timber which has been reported by Vahid et al. (2016) as one of the major factors affecting the dwindling economic performance of the Canadian forestry sector.

7

According to a systematic literature review on the applicability of the SCOR model for evaluating environmental performance (Ntabe et al. 2015), which shall be explored in greater detail in Chapter 2, extant literature fails to provide a solution to these issues. Specifically, there is no SCOR-based modelling framework that is developed to capture the environmental aspects, particularly wood loss along the forest value chain. Besides, its GreenSCOR module, which is employed to model supply chain network structures and operations (Huan et al. 2004) is generic and can only be used to measure the total carbon footprint and total environmental footprint in the supply chain. It does not allow the prospect of achieving the set objective, which is to detect wood loss along the forest value chain.

Thus, this study aims to contribute towards the reduction of this research gap, as presented subsequently. Based on the above argument, we proposed the f-SCOR modelling approach to achieve the objective of this study. We hypothesize that by adapting the GreenSCOR model as a system engineering framework, to track, measure and report wood loss along the forest value chain, upper management shall be properly informed on the environmental impacts of their value adding operations. This would eventually provide more visibility to decision-makers, scholars and policy makers about the performance of forest value chains from the environmental standpoint.

1.1. GENERAL OBJECTIVE OF THE STUDY

This study seeks to propose a modelling approach for tracking, evaluating and reporting the environmental impacts of management decisions on wood loss along the forest value chain, through the development of a process modelling approach known as „The Forest Supply Chain Operations Reference (f-SCOR) model‟. This approach can be seen as a modelling

8

tool for the efficient utilization of wood raw material and reporting of environmental performance, which has the potential of being eventually adopted by the industry, by employing a well-stabilized formalism. It equally seeks to demonstrate the relevance of the approach through practical and industry-scale applications in typical forest value chains. As it shall be discussed later, in order to attain this general objective, we set-up as an “instrumental hypothesis” that the SCOR model is a relevant starting point for developing the modelling approach, since it is complete and has a well-adopted approach in the academia and industry (Huan et al. 2004; Hwang et al. 2008; Wang et al. 2010; Ntabe et al. 2015).

1.2. RESEARCH QUESTIONS 1.2.1. General Research Question

How can one efficiently and practically model a forest value chain to reveal its green performance in order to help companies first understand and later reduce their environmental impacts?

1.2.2. Sub Questions

1. Which modelling approach or guideline is most suitable to use?

2. Which forest value chain characteristics should be captured into the model?

3. Which environmental metrics are most fitting for the performance evaluation of the forest value chain?

4. How should the framework be operationalized in a real case industry-scale to help decision-makers, scholars and policy makers to assess the green performance of the forest value chain?

9 1.3. OUTLINE OF RESEARCH METHOD

In order to answer the aforementioned research questions and achieve the general objective of this study, we employed the Design Science Method (March and Smith, 1995; Hevner, 2007; Van Aken and Romme, 2009) also known by other authors (e.g. Martel, 1986) as Instrumental Research. This methodological concept is based on an iterative feedback loop investigation technique that is suitable for model development and validation. It requires the model builder to experiment the model in more than one situation and to make adjustments if necessary in order to increase its robustness. Martel (1986) and Mattessich (1978) recommend this approach for investigations in applied sciences. Instrumental reasoning according to Mattessich (1978), conveys a cognitive process that comprises both deductive and inductive logic. According to Martel (1986), instrumental research denotes all methodological creative activities that aim at designing instruments (systems and methods) for supporting an organization to achieve its objectives. Martel (1986), notes that this research design involves both synthesis and supplement analysis logic. The process also involves preference criteria and contribution to value judgements. Design Science research is concerned with the examination of a process leading to the acceptance of conceptual or factual systems for attaining preconceived goals and not with the forming and proving of analytical propositions, nor the formulation and verification of natural laws.

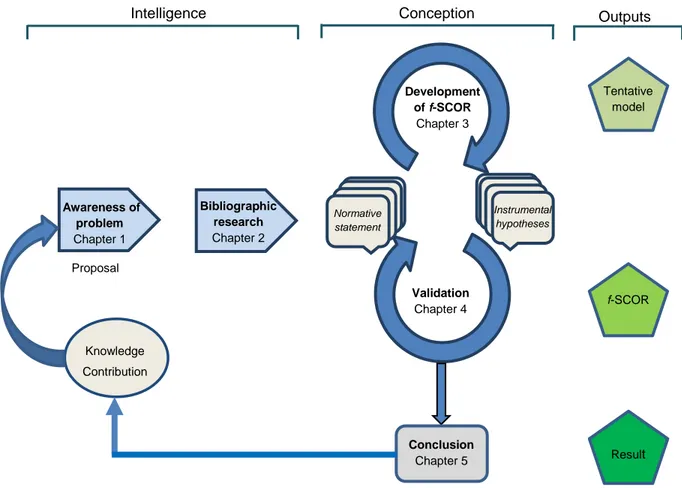

We employed the general procedure of Martel (1986) for instrumental research, consisting of the creation of a normative statement which values the research problem, and a set of instrumental hypotheses that lead to the creation of a factual or conceptual instrument (Figure 1.2).

10

Figure 1.2: General outline of research method (Based on Santa-Eulalia, 2009)

While Martel (1986) argues that these instrumental hypotheses cannot be tested, he states that their validity can be verified. The proposed instrument is acceptable if it helps users reach the proposed objectives. In this context, we are forced to be satisfied with a subjective estimation.

This methodological design is treated in three chapters of this study. The design philosophy is translated into a logical and perceivable concept, as illustrated in Figure 1.2. It describes three primary parts in the instrumental method: the intelligence phase, the conception phase and the outputs phase. Phase 1, the intelligence phase, requires acumen to define the system to be studied. Phase 1 in our case is a scholarly review of the industrial applications of the SCOR modelling framework with special focus on environmental

Intelligence Conception Development of f-SCOR Chapter 3 Validation Chapter 4 Instrumental hypotheses Normative statement Bibliographic research Chapter 2 Awareness of problem Chapter 1 Conclusion Chapter 5 Knowledge Contribution Proposal Outputs Result f-SCOR Tentative model

11

issues, as addressed in the supply chain management literature (chapter 2 of this study). The review enabled us to identify research gaps and to come-up with a normative statement with respect to the application of the SCOR template in natural resource management (NRM). The normative statement reveals that the SCOR model is generally not applied in natural resource management. This statement is the outcome of a logical conclusion of what is observed in the current studied system of supply chain management. However, the SCOR model seems to be a suitable tool for solving the present research problem. The remaining section of this study focuses on providing a solution to the question raised in the normative statement.

A normative statement according to Martel (1986) guides a researcher and enables him to translate the statement into a set of instrumental hypotheses at the creation stage. The intelligence phase is followed by the conception phase which involves the construction of the modelling instrument (f-SCOR). According to Santa-Eulalia (2009), the first step in this phase is the creation of the instrument. The normative statement in our case requires a set of hypotheses that can enable the adaptation of the GreenSCOR modelling framework for application in the forest products industry, as treated in chapter 3 of this study.

The f-SCOR model was used to generate environmental information on wood waste. We also contextualized the building blocks of the SCOR model, comprised of processes and their functionalities, and extended the performance measurement component in order to improve forest value chain management visibility. In chapter 4, the instrumental hypotheses are pre-validated with the aid of domain experts. Subsequently, we use an empirical procedure to demonstrate that f-SCOR is realistic and that it can be applied in a

12

real system through a proof-of-concept in two typical plywood production chains. The employed methodology shall be detailed later in Chapters 2, 3 and 4.

1.4. THESIS CONTRIBUTION

This study identifies the recurrent problem of poor practices and unreliable environmental accounting that hamper the sustainable management of wood raw material in the forest products industry. It provides a critical review of selected papers from extant literature, using a number of SCOR-based assessment criteria elements that were developed into an evaluation framework for critical analysis of research gaps of the template. The literature review identifies opportunities and research gaps that are linked to the application of SCOR model in the forest value chain.

The major contribution of this thesis is the development of a process modelling approach known as The Forest Supply Chain Operations Reference (f-SCOR) model that was experimented as a decision support tool for value chain visibility and green performance evaluation along the forest value chain. The study also identified Key Performance Indicators (KPI) and Environmental Metrics (EM) that were used as indices of interest for measuring green practices of the forest products value chains. This approach can serve logging operators and forest industry managers as a support tool for appropriate and timely decisions on value chain activities. The thesis draws attention to log harvesting and processing options that can reduce wood consumption and timber extraction from the forest rather than on post-log harvest solutions such as reuse and recycling of wood waste.

13 1.5. THESIS LIMITATIONS

Despite the strong design and other methodological schemes that were taken into consideration in this present study, a number of limitations remain evident. Firstly, the experimentation of the model was limited to two tropical forest value chains. This means that the impact of the findings might have limited scope as they may not fully translate into forest value chain scenarios in boreal forest countries like Canada and Sweden. However, the results can still be widely applicable since the model was built from the well-established cross industry SCOR model that has been experimented in several other disciplines around the world. More so, log harvesting and mill processing activities are similar in several regions, although there are variations in species characteristics and production efficiency. The design science research method and the model validation process were equally rigorously followed to ensure model clarity and robustness to enable its application in other contexts.

Another limitation of the study is the fact that this reference model which was built on the foundations of the SCOR model is a novelty in the supply chain management arena, as we did not find any such attempt in the literature. There is therefore bound to be limitations when breaking such new grounds. Some authors (e.g. Schnetzler et al., 2009) even note that adapting the SCOR model for the forestry sector requires a comparatively high degree of abstraction, experience and profound knowledge of the model. Furthermore, much will remain to be done to fill the identified research gaps in the knowledge base of green performance evaluation and reporting in the forest products industry. The use of domain experts for theoretical validation and the repetition of the validation process in two typical real-world situations can still be seen as exploratory, but it helped in improving the

14

initial model validity. Furthermore, since the study had to do with company image and economics, the assumption of honesty and truthful responses to certain sensitive questions might not fully reflect true personal judgments. Lastly, this study is limited by time as the forestry industry sector is constantly evolving. We however trust that the limitations uncover areas for future research and serve as a source of challenge and inspiration to future researchers.

1.6. THESIS STRUCTURE AND ORGANIZATION

This thesis is subdivided into five chapters. Chapter one is comprised of the general introduction that states the research context and problem description, objectives of the study, research questions as well as the contributions and limitations of the thesis. Chapter Two addresses sub research question 1. In this chapter, we first review different types of modelling approaches and guidelines that are found in existing literature, to determine their suitability for application in the forest supply chain. Subsequently, the SCOR model is identified and a scholarly review of primary literature, selected from a number of recent SCOR application papers is expounded. It explores research gaps in the application of the SCOR model. The chapter briefly presents the key questions addressed and the approach that was employed for the review. Results of the literature review are presented in three sections. Section one reviews environment related papers. Section two reviews other papers based on the different research methodologies used while section three identifies research gaps and presents the findings. Finally, Section 4 of the chapter outlines the conclusions by examining possibilities and recommendations for future research.

Chapter 3 deals with research questions 2 and 3. In this chapter, we describe the forest value chain and determine the main characteristics that can be captured for green

15

performance evaluation. The chapter employs the Design Science research method to develop a modelling methodological concept known as the Forest Supply Chain Operations Reference (f-SCOR) model as a response to research question 3. We also identify plausible indicators and environmental metrics for the green performance evaluation of the framework that are later incorporated into the f-SCOR model. The framework which is designed to help decision-makers, scholars and policy makers to assess the green performance of the forest value chain is also designed to provide reliable information for environmental reporting of value chain activities. The Source, Make and Deliver processes of the SCOR model are extended, customized and contextualized to achieve the general objective. Chapter 4 addresses research question (4) by experimenting f-SCOR through two case studies of the plywood production value chain. The model is subjected to a preliminary validation process for a proof-of-concept procedure. It employs the services of domain experts for the theoretical validation and forest value chain management personnel for the practical validation. The chapter highlights and discusses the empirical results of the case study. Chapter 5 provides the concluding remarks of the study.

16

CHAPTER TWO

LITERATURE REVIEW OF THE SUPPLY CHAIN OPERATIONS

REFERENCE (SCOR) MODEL

This chapter has been published as: E.N. Ntabe, L.LeBel, A.D.Munson and L.A.Santa-Eulalia (2015): A systematic literature review of the supply chain operations reference (SCOR) model application with special attention to environmental issues. International

Journal of Production Economics, 169(2015) 310-332.

Résumé

Les préoccupations actuelles relatives aux changements climatiques ont imposé la prise en compte de pratiques respectueuses de l'environnement comme conditions concurrentielles pour les chaînes logistiques. Par conséquent, il est de plus en plus indispensable pour les entreprises de faire une transition vers l'intégration de la performance environnementale comme élément constitutif du succès. A travers sa composante GreenSCOR, le modèle SCOR, qui est un outil de diagnostic des chaînes logistiques, peut servir d'outil stratégique pour cette performance. Cependant, aucune preuve de considérations environnementales dans l'application du SCOR dans un éventail d'industries au cours de la dernière décennie n'a été étudiée. Cet article utilise un certain nombre de critères et d'éléments d'évaluation SCOR pour passer en revue certains articles d'application du modèle, publiés entre 2000 et 2015, en accordant une attention particulière aux critères environnementaux. Les résultats révèlent que, bien que le paradigme innovant consistant à passer des entreprises individuelles aux ajustements de la chaîne logistique ait été adopté par les organisations commerciales, aucun article n'a expérimenté le modèle par une approche de la chaîne logistique de bout en bout. Alors qu'un intérêt généralement timide pour GreenSCOR a été observé, la distribution annuelle des articles montre une tendance positive dans le nombre de publications liés à l'environnement et au processus de retour. 10.8% des articles ont tenté la dimension environnementale du modèle tandis que 26.2% ont tenté le processus de retour. L'étude note que si le modèle SCOR convient à l'évaluation de la performance financière de la chaîne logistique, il est autant un outil d'aide à la décision pratique pour l'évaluation environnementale et les alternatives de décision concurrentes tout au long de la chaîne.

17

Abstract

The SCOR model is a cross-industry de facto standard diagnostic tool for supply chain management. Although it is rated as an excellent foundation for environmental accounting in the supply chain, evidence of environmental considerations in its application within an array of industries in the last decade has not been investigated in the Supply Chain Management literature. This chapter provides a detailed presentation of the SCOR Modelling Framework, its characteristics and functionalities. Subsequently, a number of SCOR assessment criteria and elements are employed to review 65 SCOR model application papers to highlight research gaps with special regard to environmental criteria. Articles are analyzed and presented with the aid of descriptive statistics. Results reveal that SCOR model is a proven tool for performance improvement in the supply chain. The results also indicate that although the innovative paradigm of moving from single firms to supply chain outfits has been embraced by business organizations, no paper experimented the model based on an end-to-end supply chain approach. The review notes timid interest in the environmental dimension and return process of the model, where only 10.8% of the papers addressed the environmental dimension, 26.2 addressed the return process, 1.5% addressed both the environmental concerns and the return process while 61.2% focused on financial and conceptual aspects of supply chains. Nonetheless, a positive trend was observed in its application.

18 2.1. INTRODUCTION

The rationale for application of the SCOR model in supply chain management as a mitigating tool for improved efficiency and reduction of waste has been reported in the literature (Dutta and Westenhoefer, 2008 and Luke, 2008). A wide application of the SCOR model has been reported in supply chain optimization (Bolstorff and Rosenbaum, 2003; Huan et al. 2004 and Cai et al. 2009). SCC (2010) also notes that the model can provide an excellent foundation for environmental accounting in the supply chain. Although SCOR is considered as a rigorous tool for evaluation of supply chains (Huan et al. 2004), Dutta and Westenhoefer (2008) and Luke (2008) conclude that there is little evidence associating the application of the model with environmental performance. Hwang et al. (2010) equally observe that research combining green performance evaluation and the SCOR model has remained rare.

In review of the SCOR literature, Li et al. (2011) reveal the absence of empirical research that links supply chain quality practices to supply chain performance. The authors conclude that process excellence and quality assurance are the main objectives of implementing the SCOR-model. Wang et al. (2010) also concede that while the SCOR model has become a topical issue, attracting not only the interest of enterprises, but industrial associations and governments, there is a scarcity of academic literature regarding its application, adoption, benefits, and limitations. In an effort to provide Supply Chain researchers and managers with baseline information on the industry applications of the model, this chapter presents the SCOR model and conducts a systematic literature review that identifies research gaps in sixty five recent application papers of the model with

19

special emphasis on environmental considerations. This work is a unique synthesis, as we did not find any similar review of SCOR applications during our literature search.

The rest of the chapter is structured as follows: the methods are outlined in section 2.2, followed by results in section 2.3. The results section is composed of two parts. In part one (section 2.3.1), the SCOR model framework is defined, its architecture including the building blocks, its functionalities as well as a description of sub modules. Part two (section 2.3.2) presents a critical literature review of SCOR model application papers. Finally, the conclusion of the chapter and recommendations for future research are presented in section 2.4.

2.2. METHODS

2.2.1. Article search and selection procedure

In the first phase, supply chain literature was consulted to obtain full details about the SCOR modelling framework. Phase two comprised of offering a scholarly review of selected scientific papers dealing with the model to identify research gaps in its industry application. In phase one, information on the SCOR model was obtained from the different periodical releases of the framework. Particular emphasis was laid on version 5.0 that carries the GreenSCOR component. The rest of the details were obtained from SCOR version 9. The results of the presentation of the SCOR modelling framework are found under section 2.3.

In order to conduct the literature review, a search of the ABI/INFORM global database, Google Scholar, SCOPUS and the ISI Web of Science search engines yielded a number of papers each, with several of them appearing in more than one search engine. We ensured an in-depth analysis of each article by narrowing our choice to 65 full-length

peer-20

reviewed papers dealing with the SCOR modeling framework and cutting across a spectrum of industrial applications.

Keywords were identified and used in the search process to obtain first-rate articles from the lot. Since we had primary interest in environment related papers, keywords were tailored bearing in mind the GreenSCOR model. Consequently, the expressions SCOR model, GreenSCOR, SCOR model and natural resource management, SCOR management processes were introduced into the search engines for papers in all available disciplines. The search for each keyword was facilitated by the use of other accompanying terminologies like “GreenSCOR model application" and “SCOR model and environmental issues”. The study applied Ahi and Searcy (2013) literature search approach in which other references cited in the papers that were identified were used as secondary sources to find other relevant articles. The filtering and selection steps were guided by the following criteria: must be a scientific article, published in a peer-reviewed journal; dealing with the SCOR model application; article not older than the year 2000. Since the GreenSCOR component of the model was developed in 2002 and introduced into SCOR version 5.0, the base year for the articles was limited to 2000. An appraisal of the scientific contribution of each article was conducted taking into account SCOR model management components. The dual approach to literature review (Kekäle et al., 2009) was employed to meet the requirement for scholarly review of the papers. It requires a synthesis of each paper, followed by a critical analysis of its content including the theories and methodologies that are employed. The following questions were addressed in the review exercise:

1. What is the Supply Chain Operations Reference (SCOR) Model? 2. Which research methodologies are employed by the authors?

21

3. How are the various SCOR elements addressed in the papers? 4. What are the key findings?

5. What proportion of the papers address the environmental component of the model? 6. Are any particular interests expressed in the different SCOR management processes? 7. What are the principal research gaps after two decades of development and application of this reference model?

The SCOR modelling framework was presented and a literature review of the papers conducted using a number of assessment criteria elements. A definition of the elements is presented in the subsequent section.

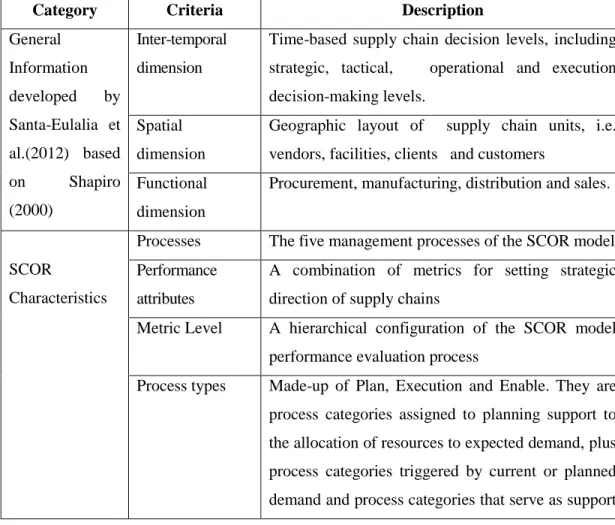

2.2.2. Definition of assessment criteria elements

Article characterization and gap analysis took into consideration article distribution by author(s), journal, year of publication, methodology applied, environmental concerns, geographic distribution, SCOR components and management processes. A number of SCOR criteria assessment elements were developed into an evaluation framework for critical analysis of the research gaps. Table 2.1 provides detailed information on the assessment criteria elements that were used. The framework applied three assessment standards (category, criteria and description) for the evaluation exercise. These elements were the different SCOR model components and attributes that interested the various authors of the reviewed papers. They were used in illustrating the scope and depth of SCOR model application in each of the papers. The SCOR items that were selected were those that provided greater insight in understanding the application of the model. The structure and organization of the review process is based on the assessment criteria elements on Table 2.1.

22

The general information section on Table 2.1 is based on the model developed by Santa-Eulalia et al. (2012). The authors develop a distributed planning analysis (DPA) model using supply chain integration concepts by Shapiro (2000) that can be translated into a multi-agent society. The DPA identifies the possible supply chain planning, scheduling and control functions at different levels of a typical supply chain. They equally introduce a new level (the decision dimension) to complement the three by Shapiro (2000). These autonomous supply chain entities are then built-up into a model known as the supply chain planning and scheduling cube where they can interact with one another. A synthesis of the findings was presented and interpreted under section 2.3.2.

Table 2.1: Description of assessment criteria elements used

Category Criteria Description

General Information developed by Santa-Eulalia et al.(2012) based on Shapiro (2000) Inter-temporal dimension

Time-based supply chain decision levels, including strategic, tactical, operational and execution decision-making levels.

Spatial

dimension

Geographic layout of supply chain units, i.e. vendors, facilities, clients and customers

Functional dimension

Procurement, manufacturing, distribution and sales.

SCOR

Characteristics

Processes The five management processes of the SCOR model Performance

attributes

A combination of metrics for setting strategic direction of supply chains

Metric Level A hierarchical configuration of the SCOR model performance evaluation process

Process types Made-up of Plan, Execution and Enable. They are process categories assigned to planning support to the allocation of resources to expected demand, plus process categories triggered by current or planned demand and process categories that serve as support

23

to the other processes

Supply chain strategy

It is the decoupling point of a product which can be MTS (Make-to-Stock), MTO (Make-to-Order) or ETO (Engineer-to-Order) product.

Practices Best practices and leading practices which are conducts that are applied to safeguard supply chain performance

Return A process of planning, implementing and controlling the inbound flow of defect or excess products to either recover value or ensure proper disposal.

SCOR version The different periodical releases of the SCOR model. Application information Modelling Software and technology

Any toolkit that is used in the modelling exercise

Modelling coupling

Interoperability of the conceptual characteristics of the SCOR model with other tools to provide modelling clarity and increased capabilities.

Industry sector Field or domain in which the SCOR model is applied.

2.3. RESULTS

The results present a detailed description of the SCOR model. Subsequently, results of the literature review are presented using both qualitative and quantitative evidence. We examined papers published between 2000 and 2018 that involved industrial applications of the model.

24 2.3.1. Presentation of the SCOR Model

The Supply Chain Operations Reference (SCOR) Model is a diagnostic tool for Supply Chain Management that enables users to understand the processes involved in a business organization and to identify the vital features that lead to customer satisfaction. Although some authors (Hwang et al. 2010) note that SCOR was founded by Pittiglio and McGrath, Advanced Manufacturing Research along with over 65 other enterprises of the Supply Chain Council in 1996, the template was initially developed by PRTM; a management consulting firm, now part of Pricewaterhouse Coopers LLP (PwC) in 1996. It was later endorsed by the Supply Chain Council (SCC), an independent and nonprofit organization and its affiliated members as a cross-industry de facto standard diagnostic tool for supply chain management.

Today, the council is a business consortium with thousands of member organizations worldwide that frequently add their best practices and commonly used metrics to improve the robustness and flexibility of the model. The SCOR model is a standard that analyses processes, evaluates performance and best practices of supply chains. SCOR model can be applied to analyze supply chain performance in a systematic way, aids in communication among all members in the chain, and can assist in the development of a design for better supply chain network (Hwang et al. 2010). The model benchmarks operational measurements to create a prioritized improvement portfolio that is directly tied to a company‟s balance sheet for improving performance and profitability (Li et al. 2011). The SCOR model represents a strong management tool that can systematically analyze, evaluate, control, measure and improve communication and existing supply chain process structures, based on a business process view of the supply chain, highlighting the

25

functional requirements of best practices identified (Milletia et al. 2009; Hwang et al. 2010). SCOR also defines and distinguishes between three process types which include Planning, Execution, and Enable process types. Planning processes balance aggregate demand across a consistent planning horizon and generally occur at regular intervals. Execution processes are triggered by planned or actual demand that changes the state of products. These include scheduling and sequencing, transforming materials and services, and moving product. Enable processes prepare, maintain and manage information or relationships upon which planning and execution processes rely (Guruprasad and Herrmann, 2006). The model configures the type of process and designs it to suit supply chain requirements. It also provides a methodology that enables companies to examine the configuration of their supply chains in order to better manage and improve their processes and activities.

SCOR is hence perceived to provide a simple though powerful standard for modelling supply chains (Kasi, 2005). It is considered by Hwang et al. (2008) as a standard for supply chain performance evaluation that has been widely embraced by many modern organizations and by Huang et al. (2005) as a useful strategic tool in the hands of upper management to tackle the complexity in supply chain management. While some SCOR elements like best practices are textual with just a certain degree of standardization, others (performance attributes and metrics) are fully standardized and set-up in a hierarchical structure (Milletia et al. 2009).

The best practices section of SCOR version 5 was modified to incorporate environmental management with the appellation GreenSCOR (SCC, 2008; SCC, 2009). GreenSCOR was introduced to leverage the effects of supply chain processes and activities

26

and to provide information on their environmental performance. The Model is organized around five primary management process building blocks (Plan, Source, Make, Deliver, and Return) that are further subdivided into process categories, elements, tasks and activities (Huan et al. 2004; Huang et al. 2005; Kasi, 2005; SCC, 2008; Schnetzler et al. 2009). Vanany et al. (2005) acknowledge that SCOR model has a comparative advantage in defining relationships between supply chain processes. SCOR is a process reference model which has as primary purpose to describe business process architecture (the way supply chain processes interact, how they perform and how they are configured). It enables the identification and elimination of redundant and unproductive activities as well.

2.3.1.1. SCOR management processes

SCOR model describes the supply chain as extending from the supplier‟s supplier to the customer‟s customer (Min and Zhou, 2002; Huang et al. 2005; SCC 2008; Schnetzler et al. 2009; SCC, 2010). The management processes of the model that include Plan, Source, Make, Deliver and Return are illustrated in Figure 2.1.

Figure 2.1: Schematic framework of SCOR Level 1 management processes (Adapted

from SCOR version 12.0)

Suppliers‟ Supplier

Suppliers Internal or External

Your Company Customer

Internal or External Customers‟ Customer Deliver Return Source Plan Return Return Deliver Source Return Make Deliver Source Return Plan Make Return Return Source Plan Enable Enable Enable Return Deliver Make