Publisher’s version / Version de l'éditeur:

Polymer, 20, 11, pp. 1423-1430, 1979-11

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effect of titania pigment on the residual strain, glass transition and

mechanical properties of a PMMA coating

Croll, S. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=f3845348-56e0-40a4-a7c5-a588194f1718 https://publications-cnrc.canada.ca/fra/voir/objet/?id=f3845348-56e0-40a4-a7c5-a588194f1718--

-,,Ser

TH1

M21dno.

888

National Research Council of Canada

cop. 2Conseil national de recherches du Canada

ELDQ..- - - - _-- --,

THE EFFECT OF TITANIA PIGMENT ON THE

RESIDUAL STRAIN, GLASS TRANSITION AND

MECHANICAL PROPERTIES OF A PMMA COATING

by

S. G. Croll

Reprinted from

POLYMER

Vol.

20,No.

11, 1979 p. 1423-

1430B t D G RES,

L I B R A R Y

srr

mu~i~,~)rtt~csfw~-

- -

DBR Paper No.

888Division of Building Research

SO

MMAIRE

L ' a u t e u r e t u d i e l ' e f f e t d ' u n pigment s u r l a d e f o r m a t i o n r e s i d u e l l e , l e

module e t l a t e m p b r a t u r e d e t r a n s i t i o n v i t r e u s e ( T

)d ' u n e l a q u e

g

P M M A . I1 d e t e r m i n e l e s d e f o r m a t i o n s r e s i d u e l l e s e n m e s u r a n t le

r e t r e c i s s e m e n t r e l a t i f d e s r e v e t e m e n t s s e c s a p r k s e n l k v e m e n t d ' u n

s u p p o r t d e f e r - b l a n c .

L e p o l y m k r e u t i l i s e e s t du p o l y m e t h a c r y l a t e

d e m e t h y l e , l e s o l v e n t du tolu'ene e t l e pigment d u bioxyde de t i t a n e

( r u t i l e ) , q u i e s t un pigment blanc tr'es c o u r a n t .

Effect of titania pigment on the residual

strain, glass transition and mechanical

properties of a

PMMA coating

S. G . Croll

Materials Section, Division of Build!ng Research, National Research Council of Canada, Ottawa, Canada K 1A OR6

(Received 23 April 1979)

INTRODUCTION

Polymeric coatings such as paints, varnishes and inks tend t o shrink as they dry. This is true whether the coating dries due t o chemical change or purely physical change, e.g.. sol- vent evaporation. The area of a coating is constrained t o remain at its original wet size by adhesion t o a nomially rigd substrate so volume changes are accommodated by a change in thickness accompanied by fluid flow. After the coating solidifies and can n o longer flow, however, subse- quent chemical change or solvent loss produces an internal strain in the plane of the coating as it proceeds to its final dry state. Unfortunately, this internal strain, or stress. sel- dom disappears completely after the normal viscoelastic relaxation in the polymer but remains to threaten the c o - hesive and adhesive properties of the system. Because re- duction in residual stress may extend the service life of a coating and bring about considerable financial and raw materials saving, greater understanding of this phenomenon is required.

This paper is concerned with the effect of pigment on the residual strain, modulus and glass transition temperature

(TK)

of a I'MMA lacquer.Ijrevio~~s work' on clear, unpignlented laccluers. which dry only by evaporation a f the solvent, has shown that the residual stress, or s t r d n , is independent of dry coating thich- ness o r initial solution concentration. In these systems the solidification point has been identified as that point at whi.ch

the Tg

o f the polymer solvent mixture coincides with ambient temperature.The literature on residual stresses2.\s mainly concerned with che~nically cured, convertible coatings. There is infor- mation. however, on an aluminium powder-filled polysty- rene lacquer4 for which the internal stress decreases with increasing filler content.

One might expect the tiller (pigment) simply to reduce the residual strain by dilution, but data are presented here which show that the bituation can beconre more complicated when polymer, solvent and pigment interact and the coat- ing thickness varies. It i s possible for the modulus of a coating to increase or decrease with increasing pignicnt content depending on the interaction between the consti- tuents and the si7e and shape of the pigmcnt particles. In the system studied here, the modulus increased.

In the current experiments residual strain was measured as the relative shrinkage of dry coatings upon release frorn

0032-38611791111423-08502.00

O IPC Busiriess Press

a tlnplate substrate. Tlic poly mcr used was poly~ncthyl- methacrylate, the solvent was toluene and the ptgmcnt was rutilc titanium dioxide. a very common white pigment. THEORY

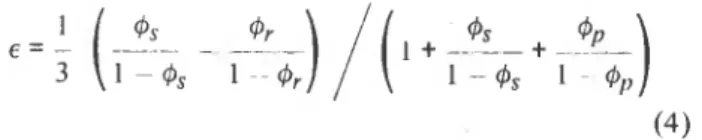

A phenomenological theory has previously been proposed t o explain the residual strain in clear lacquers. In this src- tion it is extended in a silrlple way to account for the e f t e ~ t of pigment.

This investigation is concerned only with the final. equilibrium value o f t h e internal strain. A complete study of how it arises as the coating solidifies would be a much Inore complicated undertaking.

It is assumed the residual strain is due only t o the differ- ence between the volume fraction of solvent present in the coating when it solidifies,

4,.

and the volume fraction re- tained in the 'dry' film, @,.. Prior t o solidification the coat- ing mixture can flow t o accommodate the volume change under the constraint o f constant area. When the coating solidifies, however, further loss of solvent volume results in an internal strain in the plane of the coating because the area cannot change due to adhesion t o the substrate, where- as the thickness dimension is always free t o contract. It is assumed that the coating would contract isotropically. if free, and that loss o f solvent produces an internal bulk strain within the coating, equivalent t o an isotropic linear strain field.Residual strairt arld solvent loss

In this subsectton an expression is derlved for the res~dual strain In terms of the volume of solvent lost after the coat- Ing s o l l d ~ f ~ e s .

The volume fraction of solvent IS expressed as a f r a c t ~ o n of the volume o f the polymer and solvent c o r n b ~ n e d , as i t would be In a free clear film. Hence, at the solid~ficallor~ pcl~nt vol of solvent 4s = V + vol of solvent '. vol of solvcn~ = 4 s

v

1 4 i

where V = v o l ~ ~ n l c o f polymer present.

Effect of titania pigment on a PMMA coating: S. G. Croll

Sin~ilarly i l l the dry film order t o bring the value of TK back to coincide with am- bient requires a greater concentration of solvent in the

Qr I.' mixture. Since the solvent retained in the dry film does

vol o f solvcn t = not alter significantly upon addition of pigment, the in-

I 0,.

creased shrinkage observed in some pigmented films, com- pared with the corresponding clear film, may be attribut- V remains constant in the colculatron because @, is measured

able t o the greater difference in solvent concentration be- for free unstrained films.

tween the solidification point and the final dry state. T l ~ u s the loss in volume of solvent after soliditication,

A V , is If the pigment does not affect the glass transition of the

polymer, then the concentration of solvent in the polymer at solidification will not be changed either. Thus one might A v =

(

@J -- -? - ) v -

( 1 ) expect a decrease in the over-all residual strain as the p ~ g -i

4

1 @, ment is merely diluting the mixture.In order t o test these ideas the depression e f Tg by sol- l'lle pigment volume fraction.

@,,

.

is expressed as the vent was measured not only in clear coatings but in a pig- fraction of pigment with respect t o polymer+

pigment. mented formulation.Hence the volume of pigment in a film, which remains un- changed. is given by

EXPERIMENTAL KIlSULTS @/) i'

pigment volume = . - The coatings were made using polymethyl~nethacrylate, 1 Oil I'MMA (duPont Elvacite 201 0 ) dissolved in reagent grade

toluene. A commonly used pigment, r u t ~ l e titanium dioxide, 1 11cn the total volume of the film at solidification. V T . was chosen; the grade used was Titanox RA (97 per cent

is given by pure). An examination by scanning electron microscope

showed that the pigment particles were spherical and that a

"'

1

representative diameter was 0.3 p m , which is typical for v 7 . = v I + + - .

(?) this type of pigment.

1 4 s 1

4/,

(

4s All measurements were performed at 2 3 ( + 0 . 5 ) ' ~ andThe bulk strain, A V j V T . is eqi~ivalent t o an isotropic 50(+2) per cent R.H. linear strain, E . in the usual manner

Residual strain measurements

I AV This type of measurement has been described before'.

E = ~ ( 3 ) An area is masked off on a tinplate substrate (60 x 1 0 m m )

3 VT and the coating applied using a drawdown blade. After the

coating is completely dry, checked by weighing, it is released which can be expressed using equations ( 2 ) and (3) as from the substrate by mercury amalgamation. Subsequent

contraction in its length is monitored using a travelling

1 4 s

E = -

(

- - -0 . )

/

(

+ . 4s -- + -"

microscope until it reaches a final steady value. The original 3 l Q s 1 - @ s 1 ~ $1, length of the coating on the substrate is used t o calculate(4 the relative shrinkage, or residual strain. This is a simpler procedure than measuring the residual stress and can be readily carried o u t o n many samples at T o calculate the residual strain, E , values of @,, @,. arid , @,

are necessary. Direct measurements of

@,.

and Gp are possible, as explained in the experimental results section. To obtain a value of @,, one must first identify the solidification6 0 conditions.

Coating solidification

Solidification occurs when the wet coating first behaves

like a solid rather than a viscous liquid, i.e., when large- $ 4 0 - scale nlolecular motion ceases in the polymer. It resembles E

e

the glass-rubber transition in solid polymers: above the C ) V) dtransition temperature,

T',

large-scale molecular motion is o allowed; below, the polyrner 'solidifies' into a more rigid Pstructure. &! 2 0 -

Incorporating a solvent i n t o a polymer will lower Tg

considerably, the depression increasing with solvent con- centration. The depression can be readily measured and for this work @, is chosen as the solvent concentration that

fi

-

-

Y

-

I - I

depresses Tg to the ambient temperature. As will be seen 0 5 0 100 150

later, it is necessary t o allow for the diffuse nature of the Coat~ng th~ckness, prn

glass transition in an, as yet, empirical fashion.

Figure lla) Extreme examples of the effect of coating thickness

l'hc addition o f pignlerit (filler) frequently increases on residual strain (shrinkage). Line represents mean value. 0 , 5% Ihc value o f

?;.

In this case GS will increase because in pigment all adhered; 0.49% pigment all detachedEffect of titania pigment on a PMMA coating: S. G. Croll

-7- ' -- - difference between pigmented and clear mixtures. At greater

i

concentrations the peak in specific heat became rather in-/;OO.

1

distinct because of the low proportion of polymer. Even

..

!+ , 30% by volume pf pigment represents over 60% by weight

i

I

0' because of large differences in density between PMMA,F

'

+.

'

/'

1 196 kg/rn3, and rutile TiOz, 4 2 0 0 kg/m3... uj . 1 ,

;'

n : 7 1:

.

,'

9"

'

* .

* I

I I Adherlng Detached IA peak in specific heat was found at 5 0 t o 60°C which

was due t o the titania pigment. The phase diagram for titanium dioxide is quite complicated, but there is a change consistent with the experimental finding. Generally the peaks due to polymer and pigment could be distinguished. I

I

A wide range of moulding temperature and pressure was- -.L I used in an attempt t o obtain a solventless mixture of PMMA

C 2 0 4 0 6 0 60 and titanium dioxide pigment by compression moulding.

Coat~ng th~ckness, p m It was found inlpossible to combine more than about 10% Figure 116) Effect of coating thickness on residual strain for an by volume of pigment. When tested in the DSC the corn-

intermediate 20% pigment content. Solid line represents mean pression moulded sample showed n o perceptible difference

value for adhering coatings in TK from the original resin.

once. Measuring the residual strain is also a more direct Measurement of solvent content

test of the theory than measuring the equivalent stress (see In order t o measure the toluene content of a film, clear

Ref 1). or pigmented, it was first redissolved in reagent grade car-

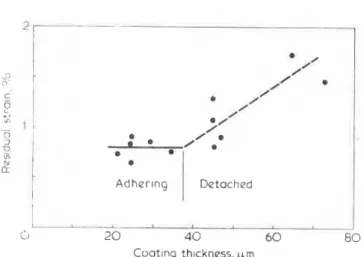

Examples o f the results obtained are presented in bon tetrachloride. The resulting solution was then analysed F ~ g z ~ r r s l ( a ) and ( b ) . Those coatings which remained ad- in a gas chromatograph using the thermal conductivity de- hered t o the substrate when dry gave one value of residual tector (ASTM E260 and D3271). The initial concentration strain. independent of coating thickness, as found pre- of the coating with respect t o the carbon tetrachloride was viously fur clear lacquers'. Those which spontaneously known and the ratio o f carbon tetrachloride t o toluene was detached gave a larger value. At low pigment concentra- determined from the ratio o f the peak areas o n the chroma- tions, <1-070, thin coatings adhered and gave the low strain togram. Thus the proportion of tolsene retained in the result; thicker coatings detached and gave a higher result dried coating was easily calculated. The retained solvent which became constant for very thick coatings. It was volume is expressed in this paper as a fraction of the solvent- noted that the thickest coatings were the first t o detach. polymer total. The solvent concentration in the mixtures ' For pigment content >20%, all the coatings detached. used in the Tg measurenients was also measured in this Some o f them broke into many pieces, particularly at high manner.

pigment concentrations. If only two or three breaks occur- red then a value of residual strain was observed that was

consistent with that obtained from whole specimens. Gene- I

rally. if a specimen broke into three pieces or more it was discarded.

Figure 2 displays the variation of residual strain with pigment concentration for both the attached and detached type of specimen with the bars representing one stantlard deviation. At 68% pigment concentration all the coatings detached, but still gave only a very low value of shrinkage.

k'jjceect of solvent arzd pigment on T,

It is necessary to know the effect solvent and pigment have on the glass transition of the polymer in order t o cal- culate @,, the solvent concentration at which the coating mixture solidifies.

A Differential Scanning Calorimeter (DSC), duPont 900.

was used coriventiorlally t o measure TK over a range of heating rates 0.2 t o 3-OKImin. The temperature at which the appropriate rnaximum occurred in the specific heat was plotted as a function of heating rate and extrapolated graphically t o zero heating rate in order t o obtain

Tg.

The results are presented in Figure 3. This procedure appcared t o be sufficiently accurate and consistent for the purposes of this investigation.Differing concentrations o f solvent were obtained by

drying specimens from solution at various elevated ( 7 0 " ~ ) 0 2 0 4 0 6 0

i.

8 0 and depressed temperatures (room temperature t o -70°C). P~gment concentratton, O / ~ v / vThe glass temperature o f only one pigmented mixture,

3W0 by volume, was measured. At lower concentrations Figure 2 Residual strain as a function of pigment concentration

0 , mean .value ( t l std. dev.); m, highest value; --, predicted

o f pigment the effect o n T, was t o o small t o g v e a reliable value

P O L Y M E R , 1979, Vol 20, November 1425

Effect of titania pigment on a PMMA coating: S. G. Croll

Solvent concentrat~on, O/ov/v

Figure 3 Variation of Tg with solvent concentration a, clear films;

o,30% pigmented films

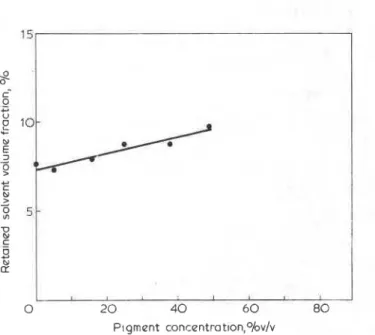

In Figure 4 the variation of retained solvent as a function of pignient volume concentration is presented. There appears to be a small increase with pigment concenfration. When fitted to a straight line by a least squares analysis it gives the following results:

slope = 4.2 x lo-* (std. error 5.5 x

intercept = 7.4

x

(std. error 1.5x

The samples used in the measurement were of a variety of thicknesses and had been drying for about 12 weeks. They were, in fact, the same specimens used to measure internal strain.

Measurement o f pigment volume concentration

The proportion of pigment was determined by ashing a known weight of freed coating in an oven at 4 8 0 ' ~ for two hours. At this temperature solvent and polymer either evaporated or decomposed into gaseous products leaving the titanium dioxide pigment as a residue; it was then weighed.

Knowing the solvent content and the densities of the various constituents allowed the calculation of the pigment volume concentration as a fraction of the pigment---polymer total.

Effect o f pigment on the mechanical properties of the coating

To decide whether a particular residual strain endangers the integrity of a coating requires knowledge of its break- ing strain. Free films, the same size as the residual strain specimens, were tested in tension on a conventional testing machine at a strain rate of 2 x l o p 4 s-l.

For unpigmented films, the breaking strain ranged be- tween 1.2 and 1.8% for those that failed within the gauge length. For pigmented films the value reduced t o between 0.5 and 0.7% with no discernible trend with pigment concentration.

In the case of the pigmented films, it was possible to obtain a value for the initial slope of the stressstrain curve,

i.e., Young's modulus. This is plotted as a function of pig- ment volume concentration in Figure

5.

Fitting a least squares straight line to the data up to 25% v/v pigment gives the solid line on the graph.slope = 2.19 (std. error 0.26) intercept = 1.96 (std. error 0.043) DISCUSSION

The mechanical properties and the glass transition are dis- cussed first because these results aid the understanding of the residual strain measurements.

Mechanical properties

As one might expect, the inclusion of an inorganic pig- ment in the polymer made it more brittle, the breaking strain was reduced to 0.6% from 1.5% for the clear,coating. There was no crazing visible in the clear coating prior to breaking.

As the volume concentration of titania increased so did the modulus of the composite, see Figure

5.

There are several theories5 which predict this increase and these results are compared with two of the more recent ones.Firstly, that of chow6 relates the modulus of a compo- site to that of its components, assuming perfect adhesion between the two and that the pigment particles interact with each other. This theory generates the dashed curve in Figure 5. The parameter values used to generated the theoretical curves are as follows:

Modulus of polymer = 1.96 GPa (least squares intercept) Poisson's ratio polymer = 0.4 (assumed)

Modulus of rutile titania = 328 GPa Poisson's ratio rutile titania = 0.21

The last two values are the average of the Reuss and Voigt estimates for homogeneous particles of a tetragonal mate- rial. The elastic constants were obtained from the litera- ture'. It can be seen that the curve does not describe the data.

Figure 4 Variation of toluene retained in the PMMA-toluene matrix as a function of the volume fraction of rutile pigment

Effect of titania pigment on a PMMA coating: S. G. Croll

0 10 20 ? 9 4 0 P~grnent concentrat~on, O / o ~ / ~

F ~ g u r e 5 Variation o f modulus with pigment content ' , experl-

mental values; --- interacting particles + adhesion; - -

- -

non- interacting particles + adhesion; - . - non-interacting part~cles tslipping

Secondly, the theory of Takahashi et al.' predicts tlie composite modulus assuming that the pigment particles arc spherical and d o not interact with each other. Tlie lower dashed line, Figzrre 5, represents the prediction il' free slipp- ing, i.e., n o adhesion. is allowed between pigment and polymer. The upper dashed line is the prediction for per- fect adhesion between the two. It is obvious that tlie case where the pigment and polymer slip with respect to one another fits the ex periniental data closely. The other dashed line for perfect adhesion is consistent with tlie dashed curve at low values o f pigment concentration where tlie interac- tion between pigment particles would be slight.

The rather high experimen tal value for the rnodulus a t

38% pigment volume concentration likely indicates a degree

of interaction between particles a t this level of pigmentation. Comparison with the various theories o f composite modulus indicate that in this case the pigment particles d o not interact u p t o 25% pignlent concentration and that when the conlposite is stressed there is a complete loss of adhesion between pigment and poly mer.

(;lass transition fetnperurure

There is indeed an increase in the glass transition o f

PMMA when rutile titania is added, but only it seeriis in

tlie presence o f a solvent, toluene. It proved very difficult t o compression mould PMMA and this pigment, and tlle resultant mixture showed n o appreciable increase in T K .

This must mean that there is n o interaction between tlie two unless the polymer is dissolved in a solvent that allows it to wet the pigment surface and thus adhere. Conclusions drawn from the previous section on mechanical properties are consistent with this.

Tlie degrce of compatibility between components of a mixture might be expressed by their respective solubility p r a m e t e r s 9 . Since these properties for PMMA, an organic polymer. and titania, a ~netallic oxide, are widely diffcrent the two are unlikely t o adhere o r interact rnuch.

Possibly a pigment influences the glass transition only

i l il is wettcd by ilic polymer. O ~ l l c r w i x i t niay bc ntccs- sary lo aid ~ntcractlon by using a suitable solvent as a welt- ing agent. Any surface treatment of the pignient during rnanu facture will also be significant in this respect.

It is interesting t o note in I.'igzrre .? that there is a11 approxin~ately constant difference in Tq b e t w c e ~ ~ t l ~ e two curves. independent of solvent concentrat i o l ~ .

I - ~ g ~ r r c ~ 4 sl~ows that the c o ~ l c c n t r a t i o ~ i of toluene re- tained by the film illcreases slightly wit11 pi, (lnient conccn- tration when expressed as a fraction of the total polynlcr- solvent volume. It niay be that the pipilent surfucc adsorbs solvent and n o c l i a n g occurs in the polynicr n ~ a t r i s . Tlie grapll niay not trulq. be linear. but tliesc cllan, (yes . ; I I - ~ SO

slight that they will have little effect vn subscqi~enr calculations.

Detrichctl twurilrgs. .I lie upper br;ulcli of tlie data pre- sentcd in i'igf/rc,2 represents the slirinkagc in t l ~ o s c films that s p o ~ ~ taneously peeled oft' the subst rate as they dried. In these coi~tings the inlernal strain (stress) is large enough t o initiate failure of the adhesive bond and there is sufficient strain energy t o overcome tlie work of adhesion and create new surface area, thus tlie coating detaches.

Adhesion of coatings with pigment concentrations of greater than about 30% is poor and all the coatings detached sooner or later. It seems that tlie polynier does not wet the pigment well, thus pigment particles may come into direct contact with the substrate. Hcllce. witli I~igh pig- ment loading there niay be co~nparatively little polymer in contact with the substrate to provide adhesion. Sponta- neous peeling does niean that the coatings are not con- strained and can shrink as they will. C'onseclucntly, the possibility of internal darnagc is much reduied and the polymer and pigment can adhere and interact.

In Figure 2, the values of internal strain frolii the coat- ings that detached quickest (in general, the thickest coat- ings) are displayed. They are the largest values and are probably more typical of tliis type of heliaviour. Those points with the one-standard deviation bars represent the average value recorded for all those films which eve~itually detached. Uccause most coatings have dried partially under internal stress, there is a considerable chance o f internal damage which will tend t o reduce the value of shrinkage measured.

The value of strain at 68% pigment by volunie is very low, in contrast to the ever increasing values up to 48% shown. The pigment is much stiffer than the ~iiatrix and at a concentration such that there is a significant chance o f many pigment particles touching, the over-all strain should diminish considerably. In a perfectly dispersed s y s t e ~ n o f spheres, such as the pigment particles, tlie particles will toucll when the spheres (diameter = 2 r ) have only the minimum cubic space (side = 2r) to occupy. The packing

in this case is equivalent t o a simple cubic lattice. A more complete treatment of pigment packing is given by ~ierwagen".

The volume fraction of

*,,

a t tliis initial touch ing concentration is given byEffect of titania pigment on a PMMA coating: S.

G.

CrollI

which gives from equation ( 4 ) a value for the residual strainI Ll

0 2 0 4 0 6 0 8 0

Solvent concentrat~on, O/ov/v

Figure 6 Determination of solidification point from variation of

Tg with solvent and plgrnent content

In other words for above 53% the shrinkage of the fill~is s h o d d diminish greatly because a significant part of their linear dimensions will colnprise touching pigment particles. 'This effect may also depress the values of shrinkage recorded at

GL>

below 52%.The densest form of packing for spheres is face-centered cubic or hexagonal close packed which amounts to a

GP

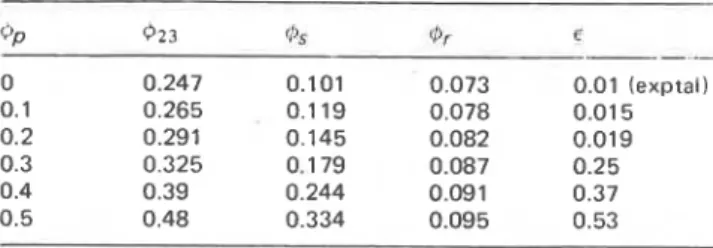

of 74% so it is hardly surprising that the shrinkage of films with 68% pigment volume is so small.The data in Figures 3 and 4 can be used in equation (4) to predict the internal strain in the detached pigment coatings.

For the clear film

and $5 can be deduced from equation (4), setting

GP

equal t o zero, which givesBut the value of solvent content, which reduces the Tg to room temperature (23OC), 4 2 3 . is 0.247. Thus A$, which represents the width of the glass transition, can be found

In this calculation

@,.

via A$, has been used as an adjust- able parameter.Now for the 30% pigmented film, it can be seen from the graphs that

and

Using A$ obtained from the clear film above we have

This is in very good agreement with the cxperilnental result, as can be seen in I.'igzrre 2.

It seenis that equation (4), which predicts the value of the residual strain from the effect pigment has on the glass transition, is successful at 30% pigment concentration.

The next part of this section extends the data to cover the full range of pigment concentration.

Calculatiorz c?f'T, und E over complete

G p

rangeThere is an equation which has been used t o model the intluence of filler on Tg in polymers11. Its form is essentially

where

ATK = increase in glass transition

,

= pigment volume fraction 1 $,, =polymer volume fractionK = constant for a particular polymer- pigment system.

There is some detail in K, but it is unnecessary for the pur- poses of this treatment.

Although equation (5) does not appear t o have been used previously for systems containing significant amounts of solvent it will be used t o construct further Tg-solvent frac- t ~ o n curves for different pigment concentrations. Thus $23 and Qs can be deduced for other values of

GP

and hence values for E obtained using equation (4).Flrst a value of K can be deduced from the experimental data o n clear and 30% pigmented films. As noted before

-

there is a remarkably constant difference between the two Tg-solvent fraction curves of some 12"C, which means that the value ofK

obtained is approximately independent of solvent concentration. Over the experimental range of sol- vent concentration,K

varies from27.3

t o 30.1,an

avw@ge value being 28.4(ATg

= 12.2'~).

Curves of Tg versus solvent content can be interpolated for

GP

of 10 and20%

and a r t r a p d a t e d for $p of 40 and 50%. Where extrapolation outside: the expsrimcntd renge of solvent content was nwgssaey, the average value ofK

was used, within that range there was a particulsr v d u e of K for each concentration o f solvent. The constructed curves are shown in

Figure 6 ,

along withthe

expqrimental curves o f Figure 3. Values of $23 can be deduced from these curves, and reduced to $,, assuming that44

obtained from clear films remains applicable.@,.

is,

of course. ob- tained from Figure 4. Table 1 gives these values for each value o f 4,

together with the prediction for E using equation (4).The upper full line in Figure 2 shows the prediction which i s in very close agreement with the experimental points. It not only demonstrates that the theory proposed for residual strain is successful but

that

equation (5) can be extended t o cover the variation inTg

in systems containing pigment and solvent. I t is worthnoting

that the same value of A$ was used in dl pigment concentrations.which i s

essentially assuming that the glass transition has the same effective width independent of pigment content.Effect of titania pigment on a PMMA coating: S. G. Croll

Table 1 Predicted values o f residual strain, c, and solidification point, 6,. as a function o f pigment fraction, cpp

1)isparity I)ctweei~ tlie predicted a n d experimental values a t liigl~ values of@,, can easily be accounted for. I t niay be tliat the touching o f pigtiicnt particles reduces the ~neasurctl slirinkage from the ideal value. cven below 52% pigment c o n t e n t . Any error in the experimental cul.vcs for T,,

us

would be magnified with extrapolation. I t niay well be that A@ is n o t a c o n s t a n t o r that K is n o t constant over such a wide range. Bearing all tliis in mind. the cotnbina- tion o f extrapolation a n d assumption provides a vcry good description o f tlie data.

Adlleri~rg coatbzgs. This branch o f t h e strain vcrsus pig-

nicnt conccntration graph represents the situation wherein the coating reriiains adhered t o the substrate.

T h e thinner coatings that remained :~ttacIied t o tlie tin- plate substrates as they dried displayed a slight decrease in residual strain c o m p a r e d with tliat o f the clear c o i ~ t i n g . In this case the coating is always constrained by adhesion t o the substrate, a n d t h u s under stress, s o if there is a p o t e n - tially large internal strain, as in the detached samples. it must be relieved in some way.

O n e possible explanation is t h a t t h e pigment particlcs o r agglomerates thereof, produce strcss concentrations pronioting local crazing in the polymer, which relicves tlie over-all strain in the coating. No crazes o r cracks could be detected. however. using either t h e optical o r scanning elcc- tron lnicroscope a n d only very few itnpcrfections c u i ~ l d be found using an electrical breakdown nlcthod (ASTSI 1)1(>70).

However, the microscopy did reveal Benard cells (k'iglrrc 7) and strain relief may occur at their boundaries.

There is a n alternative explanation. In thin coatings. the total internal strain energy developed as tlie pigmcntcd polymer solidities is insufficici~t to overcome tllc adliesio~l t o tlie substrate. l.f the cohesive strength o f tlie pol\ riel-

prevents cracking then the coating will be u n d c r stress ancl tlie interface bctwecn polymer and pignient m a y fail. T h ~ s is consistent with the rcsults o f the previous scction wliicli showed that the modulus (measured ~lrider stress) o f the polymer pigment composite was best niodelled if tllcrc was n o adhesion between pigment and binder. 111 this case.

there will be n o interaction bctwecn polymer and p i g n ~ e n t . n o change in glass transitton. arid t l ~ c polymer will n o t solidify until the Ivwcr holvent concentration o f all unpip- m c n t e d . clear, lilnl is rcacllcd.

[)sing c q u a t i o ~ ~ ( 4 ) t o predict tllc residual str;ri~l In pig- mcntcd coatings. \vliilc retaining the valucs o f y, and

+,-

obtllined for an u n p ~ g m c n t c d coatrng gives the lower > ( ~ l i d line in I-lglrre 13, which gives excellent ;Igrccmcnt with t l ~ cexlxrinlental rcbillts. tsscntially, 111e ovcr-all residual strain o f the coating is decreased by the presence o f ~)igrlrcnt.

1:or this particular coatlng fi)r~iiulalion one is lcd t o believe the second explanation hccause o f tlic agrcclrlcnt between theory and c s p c r i r l ~ c n t anrl in the abscncc ol' s t r ; ~ i n rclicving dati~age l o the coating. I t scclns that this is a case o f adllcsivc failure hetween pigl~lcnt and pulylncr.

Although t h e reidual strain is comparatively sniall in this branch of tlie d a t a , i t is still significant compared with t h e breaking strain o f even t h e clear coating (-1.5%) and must be regarded as detrimental i n practical usagc.

The explanation probably depends o n tlie particular formulation. Among tlie factors tliat should he taken i n t o consideration are adhesion t o the substrate. adhesion be- tween polymer and pigment. pigment particle size and shape.

( I ) Residual strain measurements have been made o n a I'MMA lacquer pigmented with titania. Tliere irppears t o be t w o regimes. One o f increasing strain with pigment concentration in thick a n d highly pigmented coatings that d e t a c l ~ from t h e substrate; the second is o f decreasing residual strain in thin, adhering coatings. Both types are rnodelled well by a thcory t h a t relates the residual strain t o the difference between t h e solvent concentration pre- sent at solidification a n d tliat in the final 'dry' coating. The idea central t o tliis theory is t h a t the solvent concen- tration present a t the point when t h e coating solidifies is essentially thc a m o u n t o f solvent neccssary t o depress t h e glass trimsition o f tlie pigmented polymer t o ambient temperature.

( 2 ) In thicker coatings, particularly a t high pigment content,

tlie rcsidual internal strain is h i d l and tlie adhesion between coating and substrate fails, i t . , the coating spontaneously peels off. It is then free t o shrink. The theory presented describes tlie observations well in this case if tlie solidifica-

F ~ g u r s 7 Surface of attacheJ pigmented coating ( x 6 7 optical microscope) showing Benard cells and some pigment agglomeration

POLYMER, 1979, Vol 20, November 1429

Effect of titania pigment on a PMMA coating: S. G. Croll tion point (glass transition) is allowed to change with pig- ment content.

(3) For thinner coi~tings, a t low pignlcnt concentrations, (<20%), the residual strain decreases slowly with pigment content but remains a large fraction of the strain t o break. 111 this case, there seems t o be insufficient strain energy t o promote adhesive failure will1 the substrate. instead the strain appears t o cause the polymer-pigment bond t o break. ('onsequently. the polyrner solidifies as it does in a clear coating, unaffected by the presence o f pigment. This pro- duces a lower level o f residual strain compared witli the thicker coatings. Again this behaviour is modelled well by the theory.

(4) Data are presented o n the effect of both pigment and solvent on t l ~ e glass transition of the p o l y ~ n e r . It appears that there is a constant difference in T R , independent of solvent concentratio11 between the pigmented and clear films for this system at leasl.

( 5 ) Ecluntion 5. wliicll relates the change in TK with pig- ~ t l c n t concentration. used in conjunction with the theory predicting internal strain, equation 4. successfi~lly extended the range of the predictions. even in the presence of solvent. ( 6 ) Tlie assumption tllal the width o f the glass transition (expressed in tel-111s ol'sulvent content) is independent of pigment concenlrat ion appears t o hold.

( 7 ) The effect of the titania on the Tg o f the PMMA was orlly a few degrees. Indeed. the presence uf solvent seerlied necessary t o aid the interaction since compression mould- ing pigment into the polymer resin had n o not~ceable effect. (8) Stressesintroduced in making the polymer-pigment composite may cause the bond between the two t o fail and thus prevent interaction and a change in T g . Further, for an interaction to occur between polymer and pigment one might expect that they sl~ould be conlpatible, expressed by their solubility parameters, for example.

(9) The increase in modulus with pigment content was ~tlodelled well by a theory which assumes there is n o inter-

action between pigment particles and n o adhesion between the pigment and matrix.

(10) Measuring residual stress in coatings requires adhesion between coating and substrate in all cases, which means that considerable information about the coatings that de- tach, and thus the whole system. would not have been gathered, whereas, measuring the residual strain by shrink- age does embrace the whole spectrum of results.

ACKNOWLEDGEMENTS

The author would like to thank Mr. R. E . Myers for per- forming much o f the experimental work. This paper is a contribution from the Ilivision of I3uilding Research. National Research Council of Canada, and is published with the approval of the Director of the Llivision.

REFERENCES

Croll, S. C;. J. f'uirrt Teclr, 1979, 51, 648. 64.~68

Prosscr, J . I-. f'uir~r Res. ilssrr. (Or.K.) T(,c11. Rep. ~ ~ / 8 / 7 - 7 1972

Zubov. P. I. a n d Sukhareva, L , A . Colloid.1. (JSSR, 1977.

3 8 , 4 , 587-598

Lewis, A. I:. and l:orregtal, L. J . "Trcat~se o n C o a t ~ n g s ' . ( I d R. R. blycrs a n d J . S. 1-ang). I)ekkcr. Ncw York, 1969, 2.

C h . 3

S a t o , K . Prog. Org. C~oar.. 1976, 4 , 4. 271-302

C h o w , T. S. J. Polj~rn. Sci

.

I'olyn~. I'11y.s. b'dr~.. 1978, 16, 6, 959--965l l a n d b o o k of Physical Constants. Rev. 1,;dn. (Ed. S. P. Clark, J n r ) . Geol. Soc. A m . 1966

Takahasi, K., Ikeda, M., Ilarakawa, K., T a n a k a , K . a n d Sakai, T. J. Polj8111. Sci.. Polyrn. Phys. lidn.. 1978, 16. 3 . 41 5 - 4 2 5

Itansen, C. M. J. Paint. Tech., 1967, 39, 51 1, 5 0 5 5 1 0 Bicrwagcn, (;. P. J. Paint Tech., 1972,44, 5 7 4 , 4 6 55