Computer-aided Tooling Design for Manufacturing Processes

Texte intégral

Figure

![Figure 10. A sample part to illustrate the identi-fication of the optimal parting direction [5]](https://thumb-eu.123doks.com/thumbv2/123doknet/14445266.517641/7.918.503.835.283.490/figure-sample-illustrate-identi-fication-optimal-parting-direction.webp)

Documents relatifs

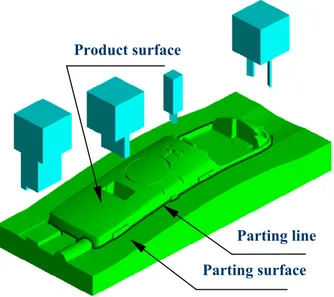

By merging the wedges on two incident half-edges into one set of wedges on an edge, unnecessary wedges can be efficiently pruned during the wedge propagation process and the number

Therefore the main objective of this article is to present the conceptual structure of the CAFD system and to develop the information support for the entire fixture design

This document deals with the Computer Aided Geometric Design with a short presentation of the Minkowski-Lorentz space.. This space gen- eralizes to R 5 the one used in the

The basic idea in this paper is the following : the design of an integrated or printed circuit may be viewed as a transition between a completely disordered state

Therefore, this study focuses on a comprehensive approach for identifying essential potentials and limitations of apps along with analogue media that

To realise the full potentials of functional gradation, a computer-aided framework for the planning and optimisation of this manufacturing process chains will be

Our preliminary results indicate that the clinical outcome and sensitivity to treatments is associated with a phenotype and is therefore predictable by the

In this 49 study, three experimental cases for evaluating a workpiece 50 localization repeatability will be considered: (1) changes in 51 geometric parameters of a fixture