Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Technical Translation (National Research Council of Canada), 1956

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=f70ef449-6737-4ee9-a4ae-6a69088ef856 https://publications-cnrc.canada.ca/fra/voir/objet/?id=f70ef449-6737-4ee9-a4ae-6a69088ef856

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Resistance of porous materials to rain

Croiset, M.; National Research Council of Canada. Division of Building Research

Title:

NATIONAL RESEARCH COUNCIL OF CmADA

Technical Translation TT-632

Resistance of porous materials to rain,

(~gsfstance lq eau de pluie des materia- poreux. )

Author: M, Croiset,

Reference.: Cahiers du Centre Scientifique et Technique du BBtfment, Pub, Trim, 19, Cahier 178, 19530 1lp.- Translator: Do A. Sinclair, Translations Section, N. R. C.

Library,

PREFACE

Although masonry buildings have a long and honourable record i n the h i s t o r y o f building i n Canada, t h e r e have de-

veloped i n recent years some serious problems with regard t o the leakage of some masonry buildings, p a r t i c u l a r l y i n those p a r t s o f

Canada i n which c l i m a t i c conditions a r e severe. The problem o f

the penetration of r a i n i n t o masonry s t r u c t u r e s has therefore been considered within the Division of Building Research almost

since the time of i t s formation.

P r i o r t o t h i s date (1947) many i s o l a t e d s t u d i e s of the problem had been made i n Canada, some of t h e most notable i n the Maritime Provinces, e s p e c i a l l y by Dr. M.R. Foran of the Nova Scotia Technical College,

Based upon t h i s e a r l i e r work, and i n collaboration with o t h e r s i n t e r e s t e d i n the problem such a s Dr. Foran and the s t a f f of t h e Mines Branch of the Department of Mines and Technical Surveys, the Division has been developing i t s own long-tern pro- gram of research. This i s now i n operation i n Ottawa and w i l l

soon be shared with workers a t the new Atlantic Regional S t a t i o n of the Division i n H a l i f a x ~

This work i s n a t u r a l l y based on a thorough survey of the l i t e r a t u r e of the subject, This has revealed m a n y s i g n i l i - cant papers i n languages other than English, one of which i s the subject of t h i s translation, It i s published i n t h i s form a s a general contribution t o Canadian appreciation of t h i s problem,

The Division i s g r a t e f u l t o M r . D.A. S i n c l a i r of the National Research Council's t r a n s l a t i o n s t a f f f o r making the t r a n s l a t i o n .

OTTAWA

RESISTANCE OF POROUS MATERIALS TO RAIN

Report of Artificial Rain Tests Carried out on Walls of Solid Brick* Hollow Concrete Blocks and Limestone

Purpose of the StuQ

Most walls are made either of more or less porous

materials (bricks, concrete blocks, stones) or of materials whose exterior surfaces are practically impermeable (coatings, slabs of concrete, slates, metal),

In the former case, as a rule no attempt is made to pre- vent water from penetrating the wall but merely to stop it from going right through, The solution traditionally employed is to build thick walls

(30

cm. and more; of ten40

cm, for stone;35

and

45

cm for brick); owing to this thickness the water is able to penetrate only part of the wall during the rain, withoutreaching the interior surface; the sun then causes evaporation and the cycle begins again without damaging the masonry, The waterproofing of the material may also be tried,

The second instance (materials with impermeable.surface) does not fall within the scope of the present study, However, the problem of porous joints (mortar) is c o m o n to both cases and will be discussed in connection with brick walls,

The present study is based on artificial rain tests

carried out at the experimental station of the C,S. T.B.* at Champs- sur-Marne, These tests had the dual purpose of determining the possibilities of utilizing certain materials and of studying various waterproofing methods.

- -

Artificial Rain Tests

The impermeability of a porous wall depends, as already stated, on its thickness, the ease with which it absorbs rain water, the effectiveness of any waterproofing process which may

have been applied and finally on the permeability of the joints, From this diversity of factors one can well understand why it is not easy to arrive at dependable conclusions from the

traditional type of laboratory test. One must take into account capillarity, porosity, permeability, shrinkage and adhesion of mortars. We therefore preferred, in common with several other re-

search stations, to proceed with artificial rain tests.

In Cahier

73

of the C.S.T,B, (NO,7

for the firstquarter of 1950), Dr. M a m e describes the methods chosen and the tests carried out by the Netherlands Foundation for the Rational- isation of Construction, He refers to the methods previously employed by the Ehglish and the Americans and explains why he chose his method,

We have adopted the latter method because it appeared simple to apply and was capable of giving quick results. We there- fore thank Dr, Mazure at this point, whose study has undoubtedly saved us much time which would otherwise have had to be devoted to research.

The test apparatus comprises a receiver 1 me wide and 0.20 m. high with a large number of holes

(90

holes0.6

mm. indiameter), providing a uniform spray over an area of 1 sq. m. when the apparatus is placed 0.80 m, from the wall, In order to provide for an adequate guard ring the latter must be at least 1,40 m. x

2 m, high, The rate of flow used is 11 litres per minute (see Fig. 1 and 2).

Comparison Between Tests and Actual Conditions

The r a t e o f 11 l i t r e s p e r minute over an area of 1 sq.

m. i s considerably g r e a t e r than the q u a n t i t y of water f a l l i n g

a g a i n s t a wall during a heavy r a i n , The l a t t e r may reach 0.2

l i t r e per sq. m. per mine (maximum f i g u r e recorded a t Champs-sur-

~ a r n e ) . A t t h e base of a wall 10 m. high t h e t r i c k l i n g r a t e may

n e v e r t h e l e s s reach 2 l i t r e s per min. p e r sq, m.

The t e s t r a t e i s g r e a t e r but, although a porous m a t e r i a l

can only absorb a c e r t a i n l i m i t e d q u a n t i t y of water i n a given time, much l e s s than the amount corresponding t o a heavy r a i n , the t e s t

i s l i m i t e d t o

24

hours, although i n r e a l i t y t h e r e a r e long periodsof r a i n without compensatory evaporation which can be much more

ravaging than a s i n g l e t e s t , Because of t h i s we took i n t o account

i n the i n t e r p r e t a t i o n o f t h e t e s t r e s u l t s not only the time of appearance of the moisture s t a i n s and t r i c k l e s a t t h e back of t h e

t e s t walls, but a l s o the time required f o r the wall t o dry.

From a comparison of a l l the t e s t s we made with t h e phenomena encountered under a c t u a l conditions, we a r r i v e d a t the following s e t of r u l e s :

1. Any wall whose unsprayed face is wet o r i s spouting

water over more than

5%

of i t s s u r f a c e a f t e r 6 hours o f t e s t i n gmay be considered poor and unsuitable f o r construction.

2, Walls which have not been traversed a f t e r 24 hours of a r t i f i c i a l r a i n a r e p r a c t i c a l l y impermeable,

3,

Between these two extremes, the evaluation dependson t h e amount of moisture which t r a v e r s e s t h e wall, t h e presence of running water on t h e unsprayed surface and t h e time taken by

the wall t o dry following t h e t e s t ,

T e s t s Carried Out on S o l i d Brick Walls

The purpose was t o study t h e e f f e c t on the permeability

1, Character of the b r i c k s

We compare: ( i ) ordinary compressed b r i c k s ( a and a t )

a l l the surfaces of which have a s i m i l a r rough appearance;

( i i ) ordinary drawn b r i c k s ( b and b ' ) with smooth f a c i n g surfaces;

( i i i ) drawn and perforated b r i c k s ( c ) with smooth facing surfaces,

Fig, 3 shows the general appearance and d e t a i l s of the surfaces of

these bricks,

Laboratory t e s t s f o r the purpose of c l a s s i f y i n g the b r i c k s produced the r e s u l t s given i n the t a b l e below,

These data were obtained i n the following manner:

Brick

Compressive strength5 The two p a r t s of a b r i c k c u t i n

half a r e joined together by cement mortar so a s t o form a cube of

approximately 11 crn. side. Pressure i s applf ed perpendicularly t o

the joint.

Porosity: Previously d r i e d b r i c k s (weight P,) a r e

immersed i n water f o r 48 hours and then we ghed (weight P , ) ; the

p o r o s i t y i s obtained by the r a t i o (P;

:LO,

where V i s theapparent volume of the brick, Apparent

d e n s i t

3:

k d d m .

C a p i l l a r i t y : The previously d r i e d b r i c k s , (weight Po )

a r e placed i n water t o a depth of 1 mm, The time T, f o r the water

t o r i s e 3 cm, i n the b r i c k i s measured and the weight P, i s

Compression kdcm? a..

.

.

a s . * . b 0 . e . b e e 136 78 153 225 > 300 2.06 1.93 1.80 1.71 Porosf t y c C a p i l l a r i t y by wt, i n $ 13 15.8 16.1 1914

1.80 of the f a c i n g 5.5 x 22 42 60 15.9 14.7 708 by vol, i n $ 33.8 30,5 29 32-5 25e3 of the large surf ace 11 x 22 46 46 21.5 19.514

d e k m i n e d at this instant, This is recommenced at the time T2 = 2T and T, = 4T, The capillarity is obtained as the mean from the three coefficients:

and

where S is the surface in contact with the water; p is measured in grams, S in sq, cm, and T in minutes,

2. Thickness and binding

The study was restricted to the following three types of wall, illustrated in Fig,

4:

22 cm, type 11; 22 cm. type 111;33

cm, type IV.3

.

MortarIn all cases fine river sand was used, This point is important because other tests have shown that mortar made with coarse sand is much more permeable, The disadvantages of quarry sand are equally well known, A more com-plete study would certainly be useful in order to determine under what conditions different

sands can be used, especially marine sands,

The only factor which may have varied was the binder, Either lime XEH

30/60

in quantities of 350 kgm per cu. m, of sand was used, or masonts cement CM 1OO/16O in proportions of 400 kgm.per cu, m,

These tests, therefore, were strictly limited firstly by the small nuniber of walls tested, and secondly by the small number of joints, Neither the proportions nor the grain size varied.

The r e s u l t s a r e i l l u s t r a t e d i n Table I and i n Fig. 5

and 6. The following conclusions may be drawn:

1, The impermeability of the wall seems t o depend f i r s t

and foremost on the kind of brick used,

Walls made with b r i c k s a and a t (simple compressed bricks of high c a p i l l a r i t y and low compressive strength) were decidedly

l e s s r e s i s t a n t to r a i n than those b u i l t with b r i c k s c (drawn and

perforated facing bricks of low c a p i l l a r i t y and high compressive

strength). As f o r ordinary drawn bricks, we obtained good r e s u l t s

with bricks b', but poor ones with bricks b (lower mechanical

atreng t h values). However, t h i s c l a s s i f i c a t i o n does not seem t o

depend on the porosity o r density, but we have made too few t e s t s

so f a r t o be able t o draw any general conclusions from t h i s ,

2, I n the course of the t e s t s i t i s sometimes d i f f i c u l t

t o t e l l whether the water was passing through the bricks or the

joints, The l a t t e r should be subjected t o a more complete investi-

gation.

Although very incomplete, these t e s t s on b r i c k s serve a s a b a s i s of comparison f o r the study of blocks of concrete and

stone,

Tests Carried Out on Hollow Blocks o f Vibrated Concrete

F i r s t hollow blocks of vibrated concrete made w i t h

d i f f e r e n t machines, proportions and moulds were compared with one

another, Fig. 7 shows the shapes and surfaces of the various

materials which were tested, (a, b, c and d were made with ordinary

sand (Marne sand) and f i n e gravel, while e was made with sand only,

The cement employed i n a l l cases was CPB 250/315 f o r three p a r t s of

f i n e sand).

The r e s u l t s obtained a r e summarized i n Table I1 and i l l u s t r a t e d i n Fig, 8,

The following conclusions were drawn from these tests: 1. All these hollow blocks of vibrated concrete are extremely permeable and are unsuitable for constructibn unless protected,

2, The proportion of cement does not appear to affect the permeability between 180 8nd

350

kgm per cu, m,3,

Laboratory tests had shown that the porosity by volume of these materials was less than that of the bricks( 4

to 2% less) and so was their capillarity (less than 10). It is our belief that the permeability of the walls is due much more to the size of the open holes on the exterior (shown by the surface pictures, Fig.7)

than to the capillarity, We have not undertaken any tests on conr pressed materials. We are considering doing so shortly,

Tests of Walls Built of Hollow Blocks of Vibrated Concrete, Waterproofed with Exterior Paints

A number of small walls were built with blocks of type a, i.e,, coarse-grained blocks, Paints were applied to these walls under normal yard conditions,

The artificial rain tests were carried out approximately two months after application of the paints,

< .

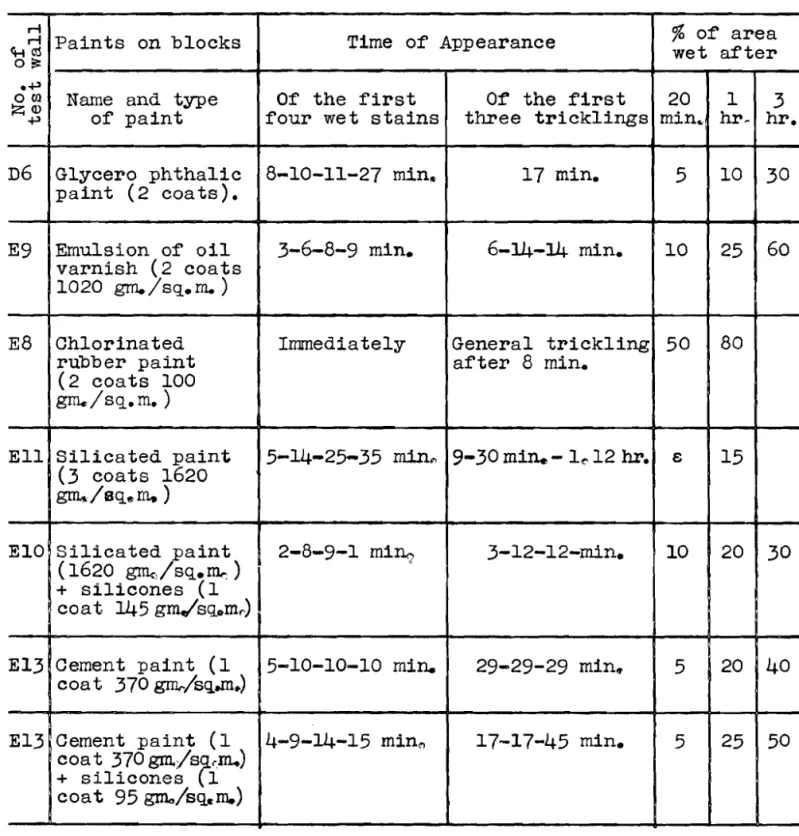

Table I11 and the photographs of Figs,

9

and 10 demon- strate the results, From these we come to the following conclusions:1, None of the paints offered to us was capable, under normal yard application conditions, of waternroofina coarse-grained materials,

2, The application of silicones over the paint on these materials does not appear to improve the impermeability of the wall, This is to be expected, as the water will penetrate through holes which are not plugged by the paint and hence are too large for the anticapillary properties of the silicones to take effect.

Finally,by way of comparison, we may say that a wall of materials which were coated over 1 to 2 cm. with a

1-3

bastard mortar (half lime, half cement), had not been traversed by waterafter

24

hours of artificial rain, This, while applicable over a small surface, may not be true of a large surface which may con- tain cracks,Test on Hollow Blocks of Vibrated Concrete Treated with Waterproofim Comound

Although the use of waterproofing compound is generally restricted to watertight coatings (exterior coats), we wanted to discover their possibilities for waterproofing the vibrated con- crete,

We confined our study to a single product

-

Lithosite, This very old product is defined in "Aidem6moire de llArchitecte et du Constructeurv by Barberot as an oleo-silicate of alumina, It is a liquid which has to be mixed with water.Tests were carried out on blocks (a) and (e), Table IV

shows the results obtained.

The waterproofing effect on (a) blocks (proportions

600-

600-.300) is very mediocre, while that of (e) (proportions 0- 1200-

250)

is excellent, This divergence illustrates both the importance and the complexity of the problem of waterproofing with compounds,At the present time we are unable to reach any final con- clusions on this matter, especially as we do not know how the

waterproofing will behave over a period of time, More complete tests are now being carried out.

Tests Carried Out on Soft Limestone Walls

The problem was a dual one: first to study the perme- ability of a soft limestone wall 20 cm. thick (i,e,, not as thick

as the standard

40

cm.) and in certain cases a30

cm, wall-

and secondly to discover if such a wall can be waterproofed by apply- ing a silicone resin to the surface,This study, carried out at the request of the ~ocidt6 des Carrfsres de laOise et de la Meuse, was restricted to a very definite quality of stone from the Bonneuil quarry belonging to this company ( ~ f g , 11). The characteristics are as follows:

Density

1663

Compression strength for 100 kgrn,/sq, cm, cubes of

7

cm. sidePorosity by volume

27%

Capillari ty 11

These stones, precut at the quarries bnblocks of 20 x

30

x40

were assembled with 1-3

bastard mortar(175

kgr~~/cu, m,of CPB

250/315

+

175

kgm./cu, m, of XEH 30/60 with fine sand), Two months after their construction these small walls were entirely dry and applications were then made in accordance with the following table,The artificial rain tests were carried out not less than

15

days after application of the products indicated,Table V and Fig, 12 show the results obtained, The following conclusions are reached:

1. Without waterproofing these 20 cm, thick walls were traversed with difficulty by the rain (more than 8 hours artificial rain) but they took a very long time to dry (more than one month), whereas a brick wall or one of hollow concrete blocks dries in a week$.

Thus, unless the climate is particularly favourable (in- frequent rains separated by periods of sunshine permitting evapor- ation of the water contained in the stone) it is not possible to modify the rules at present accepted, requiring a minimum thickness

of 30 cm. for walls without interior lining.

On the other hand, there was no trickling of water at the back of the walls even after

24

hours artificial rain, It should be noted, however, that the water absorbed by the wall passes off very slowly and consequently there are obvious effects on the thermal insulation and probably on the aging of the wall, The tests already carried out will be supplemented by a study of their behaviour i n the special physics test room for large units which has already been in operation for a short time at the experi- mental station,2, The silicones reduce the permeability of the stone. If the latter has previously been hardened by a fluoride the sili- cones become very effective. A new test is going to be undertaken using a more concentrated silicone resin solution to see if it is possible to do away with the fluoride,

Unfortunately we do not yet know the effectiveness of the silicones over a period of time as they were introduced on the French market only two years ago,

Conclusion

The t e s t s which we have j u s t described b r i e f l y must,of course, be c a r r i e d f u r t h e r before any technical recommendations

can be derived from them. Even now, however, t h e r e s u l t s a r e

c l e a r enough t o a t t r a c t the a t t e n t i o n of b u i l d e r s t o t h e p r a c t i c a l importance of t h e problems r a i s e d by the penetration of water i n t o walls, e s p e c i a l l y low coat, uncoated walls,

The t e s t s which have now been s t a r t e d r e l a t e t o the following points:

Determination of the b e s t proportions and g r a i n s i z e s f o r obtaining waterproof joints;

Permeability of hollow concrete blocks water- proofed during mixture;

Permeability of hollow blocks of compressed con- c r e t e ;

P o s s i b i l i t i e s of waterproofing varioue m a t e r i a l s by surface a p p l i c a t i o n of s i l i c o n e r e s i n s ,

A l l the wall sectfons b u i l t f o r these t e s t s a r e i n the

open a i r exposed t o bad weather. I n renewing the a r t i f i c i a l r a i n

t e s t s , therefore, we may g e t some i n d i c a t i o n s abollt t h e i r aging ( a p a r t i c u l a r l y important f a c t o r i n connection with waterproof

compounds, p a i n t s and coatings). Since the walls were erected t o

f a c e i n the d i r e c t i o n of the p r e v a i l i n g winds we can a l s o study t h e i r behaviour i n n a t u r a l rain,

Whatever the value of these t e s t s , we b e l i e v e t h a t they a r e a p r a c t i c a l and quick means of developing o r checking new

methods of construction, By varying the doubtful f a c t o r s w e can

e a s i l y recognize t h e i r various e M e c t s and discover how they may

-

14

-

Table

I

Sol id Bricks T e s t T i me of appearance of surFare

"I

U - wet d k e r

OF the Ftrst Four OF the First

,

a h 3 h O h B(hwet s t a i n s three trickles

---

1 0 - 1 0 - 1 0 - l O m n 3 5 m n - 1 . 1 0 - 1 , l O h -----

---

2 0 - 2 0 - 2 0 - 3 0 m n 3 0 - 3 0 m - 1 , l O h -- ------

35-35-35mn-1.50 h 1,SO-1,50- 1,50 h---

1953; a h l , N - l,20- 1,43- 1,48 h 1,11 - 1,48- 1,48 h 0 S 20 80 - . -.-- ! - . . -.,-- - . - - . . - . - - - - . - I 4 - 4 - 6 - 6 m n - --- 10- 1 5 - 1 5 - I s m S 10 15 40/

- - - --- N i l ! I ~ .-- .- -- - - . . 1 - 1 - 1 - 2 h I --1

20mn .~ ~- - - - . . - - - .- i -- . . .- ---- ~ -- - -- I - - - -- I I II

T95Li-Qh

20mn- 1.40- 2.20 - 2.40 hI

: 1951i

I

- - i 1953' 24 h1

~ ~ -- - . / l.,-l_ 19511

8 h I iE . .,... - . - - . . . - .. -. i i I c - -- 10 rnn - 1.40 - 3,30 - 3,35 h , A 3 . c - - 6,25 - 6,25 - 6,26 h 1 ii

1

I /I' i 22 ; 111 ; C M i 1 9 S 1 -- - / -

- - I I i 1953124h A~B&.LP.PI~(~o j!

N i l 1 observation be- I I i I . . , 1 tween8dc24hr)I - 1 I ! - - . -I

--- i .- c 5 1 4 0 . - - -- -- - - ~ - - 3I

2 . 4 5 - 3 - 3 - 3 h N i l i I A? B1C) ~ ~ - . .. - : - -\-- -< n-- - . . ~- . l 9 5 l B h 3 0 3 0 m n - 1 - 1 . 4 5 h 4 . 3 0 - 5 . 2 0 - 6 . 1 5 h I 1.' 33 i IV X E H ~ I951 --'- -- i '1

i

1953 24 h 2,43 - 4.48 - 6.03- 6.05 h 1 6.03 h . . -. . - .. - . . -. .- . . - . .. . - ~ . . ~. . ~ - . - - . ~ . . . . - - - --- -- I I i 1951'?,3 h I ' 5\55 - 6,25 - 6,25 - 6,55 h N i l O l O ' O l c 2 2 ' 11i-

-

a5-

Table I1 T r f ckles Immediately abundant t r i c k l i n g over the e n t i r e surface of the Immediately I m e d i a % e l y abundant t r i c k l i n g a t the base and over the e n t i r eI m e d f a t e l y Immediately abundant

%pickling over the e n t i r e s u r f a c e of the

Table 111 d d

bd

g

a+=' o m =$ D6 a f t e r 8 min, ( 1620 g m /sq,m, )+

s f l f c o n e s ( 1 coat 145 gm./sq,m,) 17-17-45 min, P a i n t s on blocksName and type of p a i n t

Glycero p h t h a l i c p a i n t ( 2 coats).

Time of Appearance

%

wet a f t e r of a r e aO f the f i r s t f o u r wet s t a i n s 8-10-11-27 min. O f the first t h r e e tricklings 17 min, 3 hr. 30 20 rnin,~ 5 1 hr- 10

Table IV

Blocks

+

lithosite Time of appearance $ wet after of area No. of test wall D 7M 7

M8 Of first four wet stains Immediately Immediately 2-3-3-3 min. After 8 hr. nothing, After24

hr. one stain, Block a a+

Litho- site71/&

2

e e+

Litho- site3 -/l/mro 24 hr, e 10 90 25 25 0 Of first tricklings Immediately over the entlre surface of the wall. Immediately at some points. Abundant trick- lings after3

min. at the base of the wall, Very slight trickling at one point after24 hr. min. 30 40 30 0

Table V

the test Observation on Observation on

N.B. No observation made between the interior the exterior

8 hr. and

24

hr, surface after surface after the testall is dry in

after 1 2 days.

M2 Fluoride

+

Silicone,I

The wall remains

dry*

No infiltration. At the end of

the test wall

very slightly

wet.

Wall was dry i~

*

day. No infiltration.Fig, 1

Ar%$ficial ~ a f n test carried out a$ Chms-sw-Mame with the

PPDuteh P P ~ ~ F B ~ U B ~

Pig. 2

Ordbnarr compressed Brdinaw &ram bricks

b ~ f e k e a and a', b

ma

bE,Facing b r i c k s (&am

and perforated e t ) ,

22 ern. type 11. 22 cm. type III

33 em. type IV.

W e t stains on the back of' the wall

Wet

s t a i n s on tihe Back sf the wallafter 2 &, o f artiQBeial rain, after 4 b, sf art%ficfal rain, Big,

5

VJ"da84h 33 c~-ra, thick mde of o g ~ d i n a ~ r ~ 0 m p ~ e s s e 8 b r i c k s ( a B ) ,

We$ stains on the back of the wall We$ s%a%ns ow the back of the wall

Fig. 8

1?Jn6'e$ stsfns and t r i c k l i - ~ s on t h e back 0% w a l l

cement

base

pain%

Wet stains on the back of the Wet a t s i n s sn the back of the

wall a f t e r 3 0 mfn, a ~ t i f i c i a l wall a f t e r 3 k s . artikieial

rain, rain,

Wall of v5brated e o n e ~ e t e b l o c k s $0 which 8 cemen%-ba~e paint has

C e m m t base paAn=b

+

siliconeCement base p a a t

+

sLl%eoa%eWet s t a i n s on the back of the Wet stains on the back of tha

wall after 30 ~ i r t f f i c i a 1 wall a f t e r 93 krs. a r t i f i c f a l

$88%ne r a i n .

Wall of v i b r a t e d concrete b l o c k s to which the following havebeen

applied successively:

1) a cement base paint (by bmshing] 2) a silicone ga2ution (by v e ~ m o ~ e l )

Fig, 11

Surface coaz@gitisn of Bomeu51 limestone,

B a r e w a l l , Wall t r = t e & wii$h Wall hps1"8g=ted Wall t ~ a a $ e d with

f lnorides, with silicones, %luorfdea andthen

f m r e p a t e d with

sf licones, Big, 12