READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Dependence of degree of silica polymerization and intrinsic mechanical

properties of C-S-H on C/S ratio = Influence du rapport C/S sur le degré

de polymérisation de la silice et les propriétés mécaniques

intrinsèques des C-S-H

Beaudoin, J. J.; Feldman, R. F.; Baron, J.; Conjeaud, M.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=035c8f42-b5b3-478b-bfaa-6b69079d6947

https://publications-cnrc.canada.ca/fra/voir/objet/?id=035c8f42-b5b3-478b-bfaa-6b69079d6947

'YHl

Natlonal Research

Conseil natlonal

"la

1

+

1

Coundl Canada

de

recherches

Canada

no.

1510

c .

2

I

BLDG

. :

Institute for

lnstitut de

Research in

recherche en

Construction

construction

Dependence of Degree of Silica

Polymerization and Intrinsic Mechanical

Properties of

C-S-H-

on

C/S

Ratio

by J.J. Beaudoin and R.F. Feldman

Reprinted from

8th International Congress

on the Chemistry of Cement

Rio de Janeiro, Brazil, September 22

-

27,1986

p. 1-6

(IRC Paper No. 1510)

Price $3.00

NRCC 28689

-

& s m

Lics

a o z m

ant&tudi&

Ies

propri&€s

physiques

et mhnigucs

de six

pr@mtions

de

C-S-H

(hydrates de dicate calciquc)

aymtdes

rapporrs

CIS

de

0,68 B

1,48

et desrapports

HIS

de

I.91 & 669.

La

caracthisacion dcs

rnat&nauxm p r e n a i t

les msms

de la densite.

de la

surface et

du

degd

de palym6risauon

de

la

silice.

Us

ant

acquis

une cataine connaissance

des drfftrences

de

nature

enae les

six

pdpmtions

de

C-S-H

partir

de

donn&esobrenues

sur les mdcarions

de

la

masse

er

de la longueur par rapport

I'humiditk rcianvc.Une

certaine d€pendance du de@ de polymkrisatian

s u rle rapport

US

a 6tt etablie.

Des

6chantiIlons comprirnts de p o d

de

C-S-H

out

ttt

atilists pour

mesurer

Its

propridt6s

mkaniques.

La reIation

enmle module

d'€WcitE

IE)ou

la midmtC

(H) etla

pornsit6

a kt6

dCrermin6e. Des

estimations

des

valeurs inainstqucs

(ou

porosite

z h )dc

ces

propriktks

(Eget

Hg)

ont

tt15faites

P

pa&

d'analysts

utilisant divers

modklcs Gel

asticite

pour les corps pareux. L'influcnct du rapport

US

ctdu

degd

de polymCrisation sur les

propriEt&

rnkaniques intrinstques

ctles

a u wp m h c s des mod&les

(factem

"forme",

etc.) a tgalement

6t15dhterminet.

h

s

facteurs "fonnt" associks h

dcuxdes

modtles

dbpendent

du rapport

US.

Le

module

d'dlasticitk intrinstquc

etlcs

v d e m

dela

rnicroduretd

nc dwndcnt pas du

r

a

m

CrS,

Lts

auteursdiscutent

dm

dsultats

entenant

cmptc

dcs ddTQtncesdans la

microshucture

dw mrttkrkuxde

C-S-A.

- - -

- - - - - - -.

_

_

- - .-

-- -

J.J. Henudoin and R.F. Peldman, Oivision of Building &search. National Research Cnl~ncll Canatla; J. baron and M. Gmjeaud, lafarge Coppee Recherche, Prance

DBhl:NI)I~~CG OF I)I<(;KKE 01: SLI.ICA POLYMIXLZATION AND INTRINSIC MECHANICAL PROPERTIES OF C-S-H ON CIS RATIO INPLUSNC~! IW MPPORT C/S SUR LF,

IIKGHE

UE P O L Y ~ ~ H I S A T I O N DE LA SILICE ET LESPRIIPH

.kr?s

MRCAN

[QURS Z N T U I N S ~ ~ U E S U K S C-S-HSUMMARY: Physico-~echanical properties of six C-S-H preparationslhaving C/S ratios of

0.68

to 1.49 and HIS ratios of 1.91 to6.69

were studied. Characterization of materials included density, surface area and silica polymerization measurements. Some insight as to differences in the nature of the six C-S-H preparations was also obtained from weight a~ld length change versus relative humidity data.A

dependence of degree of polymerization on CIS ratio was established. Compacted samples of C-S-H powders vere used for mechanical property measurements. Modulus of elasttcity (E) or microhardness (H) versue porosity relations were determined. Estimates of the intrinsic (or zero porosity) values of these properties (E,, and Ho) were made from analyses using different elastic models for porous bodies. The dependence of the intrinsic mechanical properties And other model parameters (shape factors, etc.) on CIS ratio and degree of polymerization were determined. Shape factors associated with two of the models are dependent on C/S ratio. Intrinsic modulus of elasticity and microhardness values are independent of CIS ratio. Reeults are discussed with respect to possible differences in the microstruct~~re of the C-S-H materials.Foram estudadas as propriedades fisico-quimicas de

6preparacdes de C-S-H tendo rela

cdes de C/S de 0,68 a 1,49, relacdes de Il/S de 1,91 a

6 , 6 9 . Acaracterizacdo doe materiais

incluiu dcnsidadc, Srea de superficie especifica e medic6es de polimerizaclo da silica. Tam

bim se obtcve algum discernimento quanto 5s diferen~as

na natureza das seis preparacdes

de

C-S-H, a partir de mudan~a

de peso e comprimento versus dados de umidade relativa. Foi estg

belecida uma dependencia do grau de polimeriza~do

para corn a relacdo C/S. Foram usadas

smog

tras compactadas de C-S-H para medicdes da propriedade mecbnica. Determinaram-se m6dulos de

elasticidade

(E)ou microdureza (H) versus relacdes de porosidade. Foram feitas estimativas

dos valores intrinsecos (ou porosidade zero) destas propriedades (Eo e Ho) a partir de an514

ses usando diferentes modelos elisticos para corpos porosos. Foram determinados a depend&-

cia das propriedades meclnicas intrinsecas e outros parlmetros-modelo (fatores de

forma,

etc.) sobre a relacgo C/S e grau de polimerizaclo. 0 s fatores de forma associados com dois

dos modelos dependem da relacso

C / S . 0m a u l 0 de elasticidade

eos valores de microdureza

sHo independentes

d arelacdo C/S. 0 s resultados.sdo

discutidos sob o aspect0 de

possiveis

diferen~as

na microestrutura dos materiais de C-S-H.

J.J. Beaudoin and R.F. Peldman, Division uf Building Rerearch, National Rcrearch

Council Canada; J. Baron and M. Conjeaud, Lafarge Qpp6e Becherche, France

INTRODUCTION

Calcium silicate hydrates (C-S-H)* form the principal cementing phases in binders for such building materials as portland cement mortar, concrete, certain typea of .brick and other lime-silica products. The silicate minerals in portland cement (C.S and C2S) hydrate to form C-S-H and calcium hydroxide (CHI. It ie generally held that C-S-H plays an important role in the mechanical behavior of cement systems. Several factors, however, make a quantitative assessment of thia role difficult: (i) Hydrated cement contains several other cement phases (aluminates, ferrites, etc.) including CH; (ii) the role of CH has been investigated but is not fully understood (1);

(iii) the C/S ratio varies over a wide range, from 0.8 to nearly 3.0 depending on waterfeolid ratio,

temperature and time of curing (2); (iv) the

dependence of strength on degree of polymerization of the silicatea is not clearly established; (v) the extent to which mechanical properties of the C-S-H solids contribute to the the porous system

properties cannot be determined directly in hydrated cenents.

Several authors have attributed strength

dif ferencea of cement products to dif ferences in CIS

ratio of the C-S-H present in thoae products. For example, low strength of autoclaved cement products has been attributed to the preeence of aC2SH

(CIS

-

2.0) ( 3 ) .In order to investlgate the contribution of the C-S-H phaee alone, it was decided to syntheeize C-S-H having a wide range of CIS ratioa and to conduct mechanical terte on the material. In addition to mechanical behavior, the importance of the C-S-H phase for volume change and durability ie recognized. There ie, however, a paucity of data on there characteristice for the C-S-8 phaee itself. The objective of this inveetigation wae to determine the dependence of the degree of polymerization, adeorption characterietice and intrinsic mechanical propertiee of C-S-H preparations on CIS ratioe.

EXPERIMENTAL Haterial8 and Preparation

Six C-S-E compoeitionr were produced in aqueous rolutione containing variable proportions of sodium mtarilicate and calcium oxide. They were dried by

WarNng in acetone and ether.

In

order to removethe acetone and ether they were firet expoeed to

a

rtream of dry nitrogen (500 a 3 / d n ) for four daye. Then t h y wmre dried in nitrogen atmasphere at 40%

for 24 hour.. Thir wu the starting condition foz

the experirntal work.

The C/S and H/S ratioe are given in Tnble 1. The C I S ratio vu obtainad w i n g X-ray fluorwcence

and flame ctrophotowtry. The H/S ratio wam

calculated% 1088 on ignition at 1000°C.

I.

spite of the drying t r e a t m t e , the tvo C-S+i preparatiow b v i n g tha highart C/S ratio bad

-at chedrtry notation: C

-

CaQ; S-

Si02;a

-

50.abnormally high ignition loss. The HIS ratioe for these preparations are unexpectedly high when

compared to published values (2). There is no

obvious explanation for thid.

No carbonation was detected in the powdered samples. Calcite and vaterite were found in the

compact with CIS = 1.26. Aragonite and vaterite

were detected in the compact with CIS

-

1.17. Nounreacted C or S wee detected by X-ray diffraction or infrared spectroscopic methods.

Morphology, as revealed by SEM, is broadly divided into two groups according to CIS ratio:

CIS

-

0.99-

1.49 and 0.68-

0.87. C-S-H appears ae50

urn

clusters of 1urn

thin foil subparticlee in thefirst group and is representative of Type I1 cement

paste morphology (4).

In

the eecond group thesubparticlea are much smaller and difficult to resolve'at the 20nm limit of the SEM. At

CIS

-

0.68, the subparti,clea appear as e m 1 1 grains.It could not be determined if the grains were agglomerates of thin foils.

Density value8 were determined ueing mass and solid volume measurements determined by helium

pyknometric techniques (5). Surface area8 of the

C-S-H eamplea were determined ueing nitrogen adsorption techniquee with Numinco-Orr

instrumentation. Density and surface area values

are given in Table 2.

Silica Polymerization Hcaeurements

The molybdate complexing method developed by Parrott and Taylor was used in this inveetigation

(6). The molybdate complexlng reaction curves were

obtained on the following:

1) mono-, di- and polyeilicic acidr. The

aonosilicic acid was obtained by diesolving 83 mg

of anhydrous portland cement in 100 a1 of

methanolic EC1 (0.15 N). The diailicic acid was

prepared with 115 mg of hemimorphite instead of 82 mg of anhydrous cement. The polysilicic acid

was prepared by reacting 317 mg of anhydrour

cerent in 15 ml of ~lethanolic HCl (2.0 8 ) for 20

minutee. ,

2) powdered and coapacted C-S-8 eaapler. The collpactr vere prepared at preesurer rangin# from 510 to 1360 HPa.

ltro eete of meaaurewnte vere conducted on powdered

C-S-H eamples and rilicic acidr. The second set included mearuremnts on compacts.

Weight a d Length Change I r o t h e ~

C-S-8 specireno vere compacted at 510 E(Pa in

the shape of dirce 31.8 diameter and 1.27 a

thick. Weight change isotherma vere determined using a daiccator method after K.n&ro et a1 (7).

Equilibration time. were at least 30 day8 for each

humidity. Two compacts were used for each C-S-kI

preparation. For longtb change wasurerents

specimenr we- mounted on modified 'hckormann

optical extenromterr ( 8 ) . This determined the dimenrional change. to a sensitivity of

4 x 10'~ m/m. The exteneaters were placed in

J.J. Beaudoin and R.F. Feldman, Division of Building Research, National Rese.arch Council Canada; J. Baron and M. Conjeaud, Iafarge Copp6e Recherche, France

Mechanical Properties Sample Preparation

Specimens were prepared by compacting the various C-S-H powders at pressures up to 1020 MPa. A11 specimens were circular discs 31.8 mm diameter and 1.27 mm thick.

Porosity Measurement

Poroaity was calculated uaing the apparent volame of the sample and the aolid volume directly earnure$ using helium pyknometric tqchniquea ( 5 ) .

Porosity wae aleo datermined on ~ o m e compacted sampLes by mercury intrusion e t h o d s at pteeeures up

to 408 MPa.

Modulus of Elasticity Measurement

The method of measurement consists essentially of measuiing the center point deflection of a centrally loaded circular disc supported at three equally spaced edge supports (9). At least three specimens were used for each test condition. All measurements were made in a glove box conditioned at

11% RH. 1

Microhardness Heaeurement

Microhardness was determined on compacted C-S-H samples using a leitz microhardness apparatus with a Vickers indentor (10). The equipment was placed in a conditioned glove box at 11% RH. Up to ten measurements were made on each disc.

RESULTS AND DISCUSSSLON Silica Polymerization

In the molybdate complexing method the analysis of results is based upon the assumption that an individual silicic acid in a mixture of silicic acids is complexed at a rate which is solely dependent upon its degree of condensation, and that the reaction for a silicic acid with a degree of condensation '1' takes the form:

where Y is the proportion of silica complexed, bi is the rate constant and ti the time shift.

The reaction for a mixture of n eilicic acids can be then represented by the equation:

where ai is the proportion of silica with the degree of condensation 'in in the mixture.

In general, the reaction curves (log(1-Y) ve. ti, not shown) for compacts and povdered eamples ~ndice'.o. that compaction led to very little

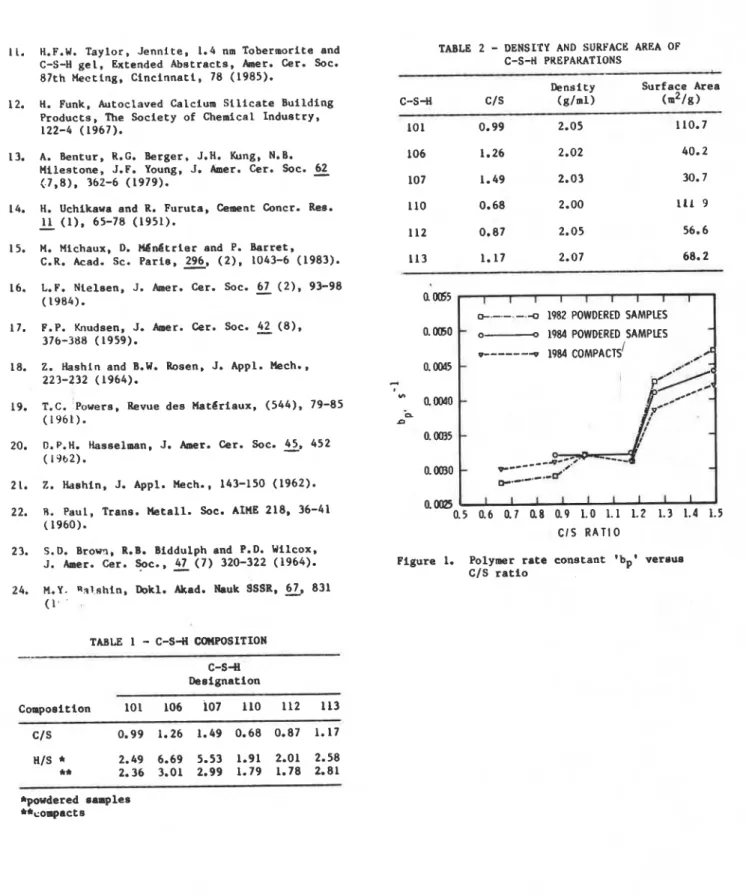

Eerence in the degree of polymerization of the C-S-H, despite large differences in the HIS. The degree of polymerization of the eilicates. meaeured by bp (the elope of the polymer reaction curve.

which increases when degree of polymerization decreasen; the polymer fraction refers to silicate chains longer than dimere), -is plotted against CIS ratio in Figure 1. The curves in the figure are plotted for data obtained two years apart. Thia was intended to assess possible aging effects. The degree of polymerization dxreases non-linearly with an increase in C/S ratio. The term (bp) increases slowly, quickly and slightly for the range of C/S ratios, 0.66-1.17, 1.17-1.26, and 1.26-1.49. The decrease in the degree of polymerization can be explained by both the Taylor and the Feldman models, which postulate the omission of silica tetrahedra in the silicate chain and possible replacement by hydroxyl groups (11,8). Omission of tetrahedra increases the effective CIS ratio of the polymer. Thia is in agreement with results obtained on cement pastes (12,13) and synthetic C-S-H of CIS ratio 0.8 to 1.1 (14). but was not observed on other synthetic C-S-H of C/S ratio 1.14 to 1.55 (15).

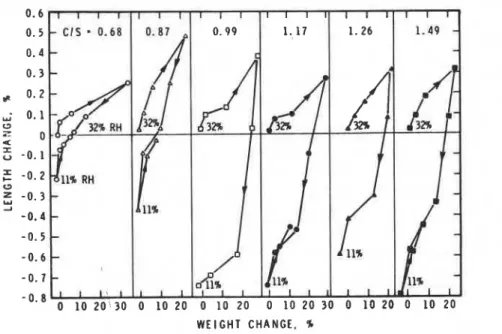

Weight Change and Length Change Isotherms Weight change isotherms are plotted in

Figure 2. All isotherms exhibit primary hysteresis. All isotherms except the one for the C-S-H

preparation having C/S

-

1.26 exhibit secondary hysteresis at lower humidities. Scanning loops start st 11% RH on the desorption branch and rejoin the adsorption branch at 80% RH. Secondaryhysteresis is probably due to intercalation of hydrate water and/or aging effects. The preparation having CIS

-

1.26 (no secondary hysteresis) has thelowest amount of water held at 11X RH (6%) and has a low N2 surface area (40 m2/g). Adsorption on rewetting to 80% RH is reversible. Initiation and completion of intercalation and dissociation

processes associated with hydrate water may occur at low humidities (below 11% RH). Thus,

irreversibility may not be observed. The C-S-H preparation with lowest C/S ratio loses the largest amount of water at high humidities on desorption, e.g., for C/S = 0.68 there is a 23% weight loss at

80% RH compared to a weight loss of 3-52 for the other preparations. This is an indication that the pore structure is much coarser for the C/S

-

0.68 material. These factors will be considered when examining the dependence of mechanical properties on C/S ratio.Length change veraue w i g h t change curves are plotted in Figure 3. The curves are qualitatively similar to the curve for bottle hydrated cement obtained by Peldman (8). The curve for C/S = 0.87

is quantitatively similar, Measurements on drying could not be made below 11% RH as the specimens fractured. The starting condition was 32% RH. The slopes of the length change

-

m i g h t change curvenon deeorption (100

-

BOX RH) for C-S-H in order of increarring C/S ratio are 7.1, 25.3, 123.3, 38.0,110.0 and 55.0 n

lr3,

renpectively. The t r opreparations with the lowast C/S ratio have the l e s t mlopen. Thin may Indicate that they have a coarser pore etructure than the other preparations, if one ignores possible aging factors. 'Ihis is supported by pore m i + & distribution data (not

presented). Pore size maauremente on compacts

(510 MPa) indicate that in the fine pore range (pore

radii 0.0022-0.0015 urn, the lLmiting size of the

poroaiwter) the pcreantqe o f pore voLum war

J.J. Beaudoin and R.F. Feldman, Division of building Research, National Research Guncil Canada; J. Baron and M. Conjeaud, hfarge Copp6e Recherche, France

CIS ratio. The high surface area for the CIS

-

0.68 material may be related to the presence ofmicropores not detected by mercury porosimetry. All the C-S-H samples have large, irreversible shrinkages. Irreversibile shrinkage at 32% RH in order of increasing CIS ratio is as follows: 0.05. 0.11, 0.72, 0.60, 0.42 and 0.58%. The two lowest CIS ratio preparations have the lowest irreversible shrinkages. This may be due to lower amounts of interlayer Ca++ and closer proximity of silicate sheets in the C-S-H structure.

Intrinsic Mechanical Properties

Modulus of elasticity (E) and d.crohardneas (H) values were determined on compacted C-S-H samples prepared at different porosities. Mechanical property

-

porosity data were fitted to several different models, which have been used to describe the dependence of mechanical properties on porosity for a variety of porous system8 (16-23). Estimates of intrinsic values of E and H (i.e.. zero porosity values, Eo and Ho) were obtained by extrapolation methods. All the models fit the data reasonably well with on8 exception. Modulus of elasticity dALa for the Nielsen model have low values of correlation coefficient for four preparations. Ho and Eo, regardless of the model used for their estimation, do not correlate well with CIS ratio. The highest values of correlation coefficient for Ho vs. CIS ratio are 67.4 and 62.7, obtained using the Nielsen and the Knudsen models, respectively. The shapefactors "a" (Nielsen mo~el) and "b" (Knudsen model) do depend on CIS ratio. The shape factor, "a", for example, increases to a maximum at CIS = 1.0 and then decreases. This dependence may, however, be a consequence of the effects of compaction on pore shape.

In another approach the modulus of elasticity data for all C/S ratios were treated collectively. .ne data were fitted to the Balshin model (24) i.e.

B

-

E 1-p)". The regression equation is E-

34 1 181 (l-p)2-.1, which is very similar tothe expression derived from the Powers d e l (19). Suitable regression curves can be obtained using other models (18-23) in a collective treatment of all the data. The application, however, of the Nielsen and Knudsen models (16.17) does not result in a single curve which describes all the data satisfactorily. bnce, for these models, there is a dependence of the shape factors on CIS ratio. The main conclusion arrived at by treating the data in this way is the same as that obtained with separate data aets for each CIS ratio, 1.e. Eo is independent of CIS ratio and degree of polymeriZation. The Nielsen and Knudsen modele do not predict, as do the others, that the relation E = (p) is independent of

CIS ratio.

On the basis of the statistical analysis of the data for all C-S-H preparations, Eo and Ho appear to be independent of C/S ratio. However, examination of the data (all, models) reveals, for example, that Eo is nearly always higheat for CIS

-

1.26. This C-S-H preparation had the highest HIS ratio and reveraible characteristics in the adsorption region of the weight change isotherm. The presence of interlayer water in the region (11-100% RH) may contribute to rigidity of the C-S-H if. the eilicate sheets are held rigidly by this water.Preparations having CIS = 0.68 also have high E

,

, values. This may be due to the absence of interlayer ~ a + + and cloeer proximity of ailicata sheete. It therefore appears that the degrea of polymerization has little effect on EO. The C-S-H preparation having the highest value of H depends on the predictive model used. The largee? value of Ho (1337 UPa) was estimated by the Nielsen model and was for the preparation having CIS

-

1.26.CONCLUSIONS

I

1. Degree of polymerization of C-S-H depends on CIS

ratio. It decreases as CIS ratio increases.

I

2. Synthetic C-S-H materials prepared using sodiummetasilicate solutions are generally layered systems. Irreversible length and weight change characteristics on exposure to water vapor are due to intercalation processes and aging phenomena.

3. Zero porosity values of modulus of elasticity and microhardness for the C-S-H preparations studied appear to be independent of C/S ratio.

As microhardness generally correlates with strength, values for intrinsic strength would appear to be independent of CIS ratio over the range studied.

4. Highest values of modulus of elasticity were obtained for the preparation (CIS = 1.261, which

exhibited reversible sorption characteristics in the low pressure region of the water isotherm. Intercalation processes and their effects on the proximity of silicate sheets may have % greater effect on intrinsic mechanical properties than composition and/or degree of polymerization.

REFERENCES

I

1. J.J. Beaudoin, Cern. Concr. Res.2

(3). 319-324(1983).

2. H.F.W. Taylor, "The Calcium Silicate Hydrates", The Chemistry of Cements, Chapter 5, 167-232 (1964). Academic Press, Ed. H.F.W. Taylor. 3. J.J. Beaudoin and R.F. Feldman, Cem. Concr.

Res.

5

(2). 103-118 (1975).4. S. Diamond, Proc. Conf. Hydraulic Cement Pastes

-

Their Structure and Properties, hiv. Sheffield. UK, 2 (1976).5. R.F. Feldman, Cem. Technol.

2,

3 (1972). 6. L.J. Parrott and M.G. Taylor, Cem. Concr. Ree.9 483-488 (1979).

-'

7. D.L. Kantro, S. Brunauer and C.H. Weire, M.vances in Chemistry, Series 33, 199 (1962).

1

8. R.P. Feldman, Proc. V. Int. Symp. Chem.

am.,

Tokyo, Part 111, Vol. 111, 53-66 (1968). 9. P.J. Sereda, R.F. Feldman and E.G. Swanson,

High. Res. Bd. Spec. Rpt. 90, 58 (1966). 10. P.J. Sereda, Cem. Concr. Res.

2,

717 (1972)..l.J. Beaudoin and R.F. Feldman, D i v i s i o n of B u i l d i n g Research, N a t i o n a l Reeearch C o i ~ n c i l Canada; J. Baron and M. Conjeaud, b f a r g e Gappi5e Becherche, France

H.F.W. T a y l o r , J e n n i t e , 1.4 nm Tobermorite and C-S-H g e l , Extended A b s t r a c t s , h e r . Cer. Soc. 8 7 t h Meeting, C i n c i n n a t i , 78 (1985).

H. Funk, Autoclaved Calcium S i l i c a t e B u i l d i n g P r o d u c t s , The S o c i e t y of Chemical I n d u s t r y , 122-4 (1967).

A. Bentur, R.G. Berger, J.H. Kung, N.B.

Milestone. J.F. Young, J. Amer. Cer. Soc.

2

C7.8). 362-6 (1979).

H. Uchikawa and R. F u r u t a , Cement Concr. Ree. 11 ( I ) , 65-78 (1951).

-

M. Michaux, D. M e d t r i e r and P. B a r r e t , C.R. Acad. Sc. P a r i s ,

296,

( 2 ) . 1043-6 (1983). L.F. Nieleen, J. h e r . Cer. Soc.67

( 2 ) . 93-98 (1984).F.P. Knudsen, J. h e r . Cer. Soc.

62 ( 8 ) .

376-388 ( 1959).

2. Hashin and B.W. Rosen, J. Appl. Mech., 223-232 (1964).

T.C. Powers, Revue d e s Mat€riaux. (544). 79-85 (1961).

O.P.H. Hasselman, J. Amer. Cer. Soc.

2.

452 (19b2).2. Hashin, J. Appl. Mech., 143-150 (1962).

R. P a u l , Trans. Pletall. Soc. AIME 218, 36-41 (1960).

S.D. Brown, R.B. Biddulph and P.D. Wilcox,

J. Amer. Cer. Spc.,

67

( 7 ) 320-322 (1964).M.Y. a a l s h i n , Dokl. Akad. Nauk SSSR,

z,

831( 1 ' ,

TABLE 1

-

C-S-H CONPOSITION C-S-H D e s i g n a t i o nCompoeition 101 106 107 110 112 113

TABLE 2

-

DENSITY AND SURFACE AREA OFC-S-H PKEPAKATIONS Density S u r f a c e Area C-S-H CIS ( g l m l ) (m2/g)

C

0--

.-

. -n 1982 POWDERED SAMPLES 0.0060 -0 1984 POWDERED SAMPLESO

.

m

~

L

J

0.5 0.6 0.7 (18 0.9 1.0 1.1 1.2 1.3 1.4 1.5 CIS RATIO F i g u r e 1. Polymer rate c o n s t a n t 'bpl v e r s u s CIS r a t i o *powdered samples **compactsJ.J. Beaudoin and R.F. Feldman, M v i s i o n of Building Research, National Research Council Canada; J. Baron and M. Conjeaud, Lafarge Copp6e Recherche, Prance

R E L A T I V E H U M I D I T Y , %

Figure 2. Water adsorption isotherms of C-S-H preparations having d i f f e r e n t C I S r a t i o s

W E I G H T C H A N G E . %