Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Student Report (National Research Council of Canada. Institute for Ocean Technology); no. SR-2005-02, 2005

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=356c61ab-ce37-4039-9124-312ad7ec9adb https://publications-cnrc.canada.ca/fra/voir/objet/?id=356c61ab-ce37-4039-9124-312ad7ec9adb

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/8895997

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Industry company profile: Institute for Ocean Technology (IOT) offshore evacuation systems

REPORT NUMBER

SR-2005-02

NRC REPORT NUMBER DATE

April 2005

REPORT SECURITY CLASSIFICATION

Unclassified

DISTRIBUTION

Unlimited

TITLE

INDUSTRY COMPANY PROFILE: INSTITUTE FOR OCEAN TECHNOLOGY (IOT) OFFSHORE EVACUATION SYSTEMS

AUTHOR(S)

Colin Power

CORPORATE AUTHOR(S)/PERFORMING AGENCY(S)

Institute for Ocean Technology, National Research Council, St. John’s, NL

PUBLICATION

SPONSORING AGENCY(S)

Institute for Ocean Technology, National Research Council, St. John’s, NL

IOT PROJECT NUMBER NRC FILE NUMBER

KEY WORDS

Evacuation systems, Conventional Davit Lifeboat Freefall Lifeboat PAGES v, 17, App. A-D FIGS. 11 TABLES SUMMARY

This report composes an Industry Company Profile (ICP), which is an obligation to the faculty of Engineering Co-op office. This report is separated into three sections:

1. Industry Profile on offshore evacuation systems.

2. Company Profile on the Institute for Ocean Technology (IOT). 3. My role as an engineering work term student.

In the Industry Profile I discuss the history of evacuation systems, discussing what type of evacuation systems have been used and are currently being used and the advantages and disadvantages of each.

The Company Profile component of this report focuses on the Institute for Ocean Technology and mainly its first-class facilities. I also discuss the lifeboat performance project, and the life raft operational performance project.

The last section of my profile constitutes my role as an engineering work term student in the company. It deals with my involvement with both the full scale and model scale tests on life rafts in January and April of 2005. It also discusses how I played an active role in the analysis of lifeboat tests in ice.

ADDRESS National Research Council

Institute for Ocean Technology Arctic Avenue, P. O. Box 12093 St. John's, NL A1B 3T5

Institute for Ocean Institut des technologies

Technology océaniques

INDUSTRY COMPANY PROFILE: INSTITUTE FOR OCEAN

TECHNOLOGY (IOT) OFFSHORE EVACUATION SYSTEMS

SR-2005-02

Colin Power

SUMMARY

This report composes an Industry Company Profile (ICP), which is an

obligation to the faculty of Engineering Co-op office. This report is separated into

three sections:

1. Industry Profile on offshore evacuation systems.

2. Company Profile on the Institute for Ocean Technology (IOT).

3. My role as an engineering work term student.

In the Industry Profile I discuss the history of evacuation systems,

discussing what type of evacuation systems have been used and are currently

being used and the advantages and disadvantages of each.

The Company Profile component of this report focuses on the Institute for

Ocean Technology and mainly its first-class facilities. I also discuss the lifeboat

performance project, and the life raft operational performance project.

The last section of my profile constitutes my role as an engineering work

term student in the company. It deals with my involvement with both the full

scale and model scale tests on life rafts in January and April of 2005. It also

discusses how I played an active role in the analysis of lifeboat tests in ice.

TABLE OF CONTENTS Page SUMMARY i TABLE OF CONTENTS ii LIST OF APPENDICES iv LIST OF FIGURES v

1.0 INDUSTRY PROFILE: OFFSHORE EVACUATION SYSTEMS 1

1.1 Evacuation Systems 1

1.2 Primary Evacuation Systems 1

1.2.1 Conventional Davit Released Lifeboat 2

1.2.2 Freefall Lifeboat 3

1.2.3 Madrock Lifeboat 3

1.3 Secondary Evacuation Systems 4

2.0 COMPANY PROFILE: INSTITUTE FOR OCEAN TECHNOLOGY 5

2.1 Facilities 6

2.1.1 Offshore Engineering Basin (OEB) 6

2.1.2 Towing Tank 7

2.1.3 Ice Tank 8

2.2 Projects 9

3.0 STUDENTS ROLE AT IOT 10

3.1 Full-Scale Life raft Testing 10

3.1.1 Engineering Tests 10

3.1.2 Human Factors 11

3.2 Analysis of Lifeboat Tests in Ice 12

3.2.1 Straight Run Analysis 13

3.2.2 Turning Circles Analysis 13

3.2.3 Accelerations 14

3.3 Model-Scale Life raft Testing 14

4.0 CONCLUSIONS 15

5.0 BIBLIOGRAPHY 16

List of Appendices

APPENDIX A IOT’s Major Facilities A1

APPENDIX B Human Factors Preliminary Analysis A2 APPENDIX C Analysis of Lifeboat Tests in Ice A3 APPENDIX D Plotted Tracks and Acceleration Graph A4

List of Figures

Figure 1.1 Conventional Davit Lifeboats Figure 1.2 Freefall Lifeboat

Figure 1.3 Madrock Lifeboat Figure 1.4 Life Raft

Figure 1.5 Chute

Figure 2.1 Offshore Engineering Basin (OEB) Figure 2.2 Towing Tank

Figure 2.3 Ice Tank

Figure 3.1 Engineering Testing (16-person raft) Figure 3.2 Human Factors (16-person raft)

Figure 3.3 Model-Scale Life Raft Testing

2.0 INDUSTRY PROFILE: OFFSHORE EVACUATION SYSTEMS

As offshore petroleum exploration in Canadian waters grows continuously,

the need for improved offshore safety rises also. Companies will stop at nothing

to discover potential oil fields, including exploration in more challenging

environments. The unique weather conditions (wind and waves, cold

temperatures, and ice) of the Canadian coast must be addressed. Until recently,

not much effort has been put forth to investigate ways in which offshore

evacuations systems can be improved.

1.1 Evacuation Systems

The two main categories of evacuation systems are primary evacuation

systems and secondary evacuation systems. Each of these has their own

advantages and disadvantages and one may be more suitable for certain

situations than the others.

1.2 Primary Evacuation Systems

Primary Evacuation Systems includes lifeboats, and more specifically

Totally Enclosed Motor Propelled Survival Crafts (TEMPSC). These lifeboats

include the davit released Convention lifeboat, the gravity induced Freefall

lifeboat, and the Madrock lifeboat. The obvious advantage of these lifeboats is

that, since they are enclosed, they protect occupants from fire, gas, and the

harsh environment of wind, waves, and freezing temperatures.

1.2.1 Conventional Davit Released Lifeboat

The Conventional lifeboat is the most commonly used lifeboat on ships

and offshore structures. It is released by the Davit system (shown in Figure 1.1),

which slowly lowers the lifeboat into the water adjacent to the abandoned vessel.

The risk involved here is the launch. There is the possibility of the hook

mechanism not releasing at all, in which the lifeboat will be at the mercy of the

vessel from which it was launched. There is also a risk of the lifeboat colliding

with the support boat on its way into the water. In addition to this, the round

shape of the conventional design causes it to experience a much greater roll

frequency than the other models, which can result in extreme discomfort of its

passengers.

Figure 1.1 Conventional Davit Lifeboat

1.2.2 Freefall Lifeboat

This lifeboat design gets its name from its ability to be dropped into the

water as opposed to being lowered like the other boats, thus providing a speedy

getaway from the source of danger. In the event of evacuation, this lifeboat is

launched from launch ramp, similar to a slide, on the deck of a boat or structure,

and “dives” into the ocean. Its shape is such that it decelerates at a minimal rate

so that injuries are minimized. This launching method, however, is also the

lifeboats downfall. The decelerations experienced by the occupants at the time

of impact with the water, is often times enough to cause injury. Furthermore, this

launching system is obviously inappropriate for areas where evacuation may take

place near, or in pack ice.

Figure 1.2 Freefall Lifeboat

1.2.3 Madrock Lifeboat

The Madrock Lifeboat is a design of MadRock Marine Solutions Inc. This

company is a part of OTEC (Ocean Technology Enterprise Center). Like the

Conventional lifeboat, this boat also uses the Davit launching systems, and

exhibits all the advantages and disadvantages that are expected from the Davit

system. The Madrock, however, is a more powerful lifeboat, which is thought to

be the primary reason that it handles better then the other two designs in all

types of weathers. Another advantage is that it has a forward canopy with

windows in the sides, front, and back, which provides better view for the

coxswain.

Figure 1.3 Madrock Lifeboat

1.3 Secondary Evacuation Systems

Secondary Evacuation Systems, such as life rafts and chutes, should only

be used in the event that Primary Evacuation Systems are not available. Life

rafts such as the one shown in figure 1.4, are deployed to the water from the

support vessel, and inflate automatically on impact. A chute is then used to get

personnel from vessel to the life raft (figure 1.5). Since these rafts are not motor

propelled, the occupants must use paddles to escape the endangered vessel, as

the raft provides minimal protection from hazards such as fire, or the unforgiving

environment. At certain wave frequencies, the life raft is very susceptible to

capsizing, which greatly increases the risk of occupants becoming exposed to

frigid waters.

Figure 1.4 Life raft

Figure 1.5 Chute

2.0 COMPANY PROFILE: INSTITUTE FOR OCEAN TECHNOLOGY

The Institute for Ocean Technology (IOT) is a branch of the National

Research Council of Canada and is located on Memorial University’s Campus in

St. John’s, Newfoundland. IOT conducts ocean engineering research by

replicating ocean environments, enhancing the performance of oceanic systems,

and developing revolutionary technologies that assist the Canadian offshore

industry. With its combination of knowledge, experience, and outstanding

facilities, IOT has gained both national and international reputation as being a

world-class ocean engineering establishment.

2.1 Facilities

The three major facilities at the IOT are the Offshore Engineering Basin

(OEB), Towing Tank, and Ice Tank (found in Appendix A). The Institute also has

specialized equipment such as a cavitation tunnel, yacht dynamometer, a five

axis-milling machine, and a planar motion mechanism. IOT offers on site shops

for electronics, carpentry, machining, fiber glassing, welding, and painting.

These shops are occupied with experienced experts in these fields, and can be

consulted at any time by the researchers during an ongoing project.

2.1.1 Offshore Engineering Basin (OEB)

The basin is seventy-five meters in length and thirty-two meters in width,

with an adjustable water depth of 0.1 to 3.0 meters. One hundred and sixty-eight

(168) hydraulically activated wavemaker segments produce waves of variable

wave height and wave period. These segments are banked along the south and

west sides of the tank. The facility also has fixed and moveable passive wave

absorbers on opposing sides of the wavemakers which act as a beach. Wind in

the OEB is created by a collection of twelve fans, which have a maximum gusting

capability of twelve meters per second at a distance of ten meters. The

advantages that the OEB has over other basins are its ability to generate oblique

and multi-directional waves as well as generate surface currents. This facility,

along with its instrumentation and data acquisition, is one of the most advanced

engineering basins in the world. The following tests can be performed in the

OEB:

Ship or structure behavior in multi-directional seas Maneuvering and station keeping

Tow out, set down and operation of offshore structures Sea keeping in oblique waves

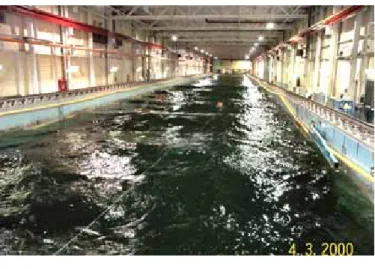

Figure 2.1 Offshore Engineering Basin (OEB)

2.1.2 Towing Tank

The Towing Tank is a rectangular tank 200m in length, 12m in width and

7m in depth. Models are towed the length of the tank in either calm waters or

waves by an 80,000 kg carriage which spans across the width of the tank. The

carriage outputs 746 kW of power, and has a speed range of 0.001 m/s - 10.0

m/s. Banks of digital computer controlled wavemakers along the west side of the

tank generate regular or irregular waves. Wind is created with the exact same

bank of fans as used in the OEB. The following tests may be performed in the

Towing Tank:

Resistance and Propulsion Wave survey

Flow visualization Propeller open water Sea keeping

Floating and moored structures Loads due to wind and current Lift and drag

Dynamics of underwater vehicles Manikins and human subjects

Submarines and underwater vehicles

Figure 2.2 Towing Tank

2.1.3 Ice Tank

The Ice Tank is a rectangular tank 90m in length, 12m in width and 3m in

depth, which makes it the largest ice tank in the world. Models may be towed,

self propelled, or moored a simulated Arctic environment. The 80,000 kg

carriage spans across the width of the tank andoutputs 745 kW of power, and

has a speed range of 0.0002 m/s - 4.0 m/s. Refrigeration is made possible by an

ammonia-based system with 26 evaporators. Temperature is controlled by

computers and ranges from -30°C to +15°C. The typical ice growth rate in the

tank is about 3.0mm/hr at -25°C, and ice can grow up to a thickness of 15 cm.

The following tests can be done in the Ice Tank:

Ship resistance, ship self-propulsion and maneuvering in ice Ice forces on moored and fixed structures

Offshore simulation

Figure 2.3 Ice Tank

2.2 Projects

Two projects that I have been involved with that are currently ongoing at IOT

are the lifeboat performance project, and the life raft operational performance

project. The vision of these projects is to improve the safety of personnel at sea.

The main collaborators of this project are MUN School of Human Kinetics and

Recreation, MUN Engineering, the Marine Institute, and the Offshore Safety and

Survival Center (OSSC). These projects assess the technical performance of

evacuation systems and observe the effects of the environment on them.

Evaluation of human factors and training also takes place. After tests are

performed, inadequacies of current regulations are addressed, and research

findings are applied to improve training of offshore workforce.

3.0 STUDENTS ROLE AT IOT

As a work term student at IOT, I worked under Lawrence Mak, a research

officer, and worked within the Escape, Evacuation, and Rescue (EER) research

team. I was involved with studies on Totally Enclosed Motor Propelled Survival

Crafts (TEMPSC) in ice, as well as tests on 16-person, and 42-person life rafts.

3.1 Full-Scale Life raft Testing

The full-scale life raft testing took place during the month of January 2005

in the Towing Tank. The tests involved towing a 16-person life raft in regular and

irregular types of waves and had two components: human factors, and

engineering.

3.1.1 Engineering Tests

As the raft is being towed down the tank, a program called Qualisys Track

Manager (QTM) continuously plots the rafts X, Y, and Z positions. QTM is a

modern, Windows-based motion capture software that allows the user to perform

two-dimensional as well as three-dimensional motion capture. It does this by

recording the positions of Qualisys markers that have known relative positions on

a body. This motion capture also includes the body’s yaw, pitch, and roll. In

addition to this, load cells were located on the towline, and drogue line, which

recorded the loads at these points. Other data, such as wave height, raft air

pressure, carriage position, accelerations, etc. were also plotted during each run.

My responsibility was to check these channels after each run, using the software

Igor Pro to ensure that all of the data was being collected and looked reasonable.

In the event that a channel looked irrational, I reported it, and ensured that the

problem was fixed before further tests were completed. I was also responsible

for retrieving the drogue after each run as well as deploying it at the beginning.

Figure 3.1 Engineering Testing (16-person raft)

3.1.2 Human Factors

Dr. Scott Mackinnon of Memorial’s faculty of Human Kinetics and

Recreation headed up the Human Factors experiments. For these tests, eight 75

kg manikins were tied to the raft in a seated position. One of the manikins had a

Motionpak located in its chest, which recorded the yaw, pitch, roll, and

translational accelerations that a human would experience. Also for each run;

two human subjects inside the raft performed specific tasks. The tasks included

closing the canopy, movements in the raft, bailing, paddling, and deploying and

retrieving a drogue. Each of the tasks was performed in calm waters as well as

waves, and comparisons were made. I was responsible for checking the

Qualisys data after each run, but it was also very important to verify that the

dummy Motionpak data was being collected. For these tests, there were voltage

signals transmitted when the human subjects began and ended their tasks, which

is how I determined the time it took each subject to complete a task. I also

participated in these studies as a human subject. Preliminary analysis of human

factors tests can be found in Appendix B.

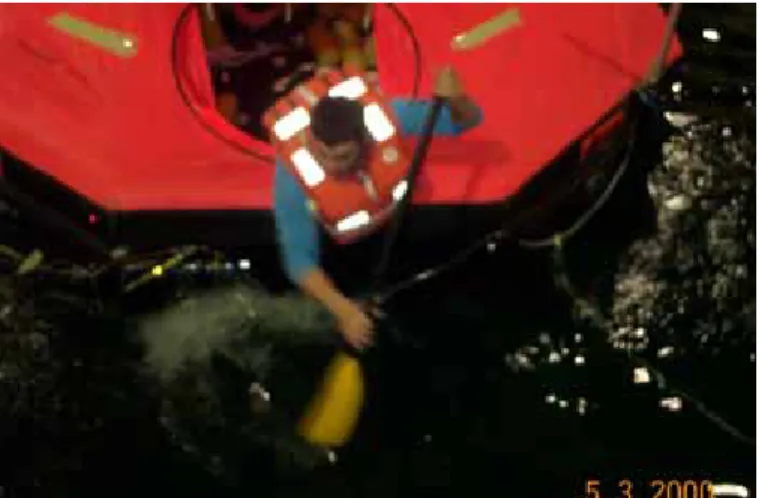

Figure 3.2 Human Factors (16-person raft)

3.2 Analysis of Lifeboat Tests in Ice

For the majority of my work term, I analyzed data from tests that were

done prior to my work term on 1:7 TEMPSC models in ice. In my analysis, I used

a program called Igor Pro. Igor Pro is an integrated program for analyzing,

transforming, and presenting experimental data. The fascinating thing about Igor

Pro is that it has its own built-in programming environment, which allows the user

to display data in such a manner that is simple and most convenient for that

individual. For example, in this test series a procedure was developed to display

up to twenty-six graphs of motions and waveforms that were important to the

experiments with the simple click of a mouse button. My analysis was broken

into straight run analysis, turning circle analysis, and accelerations. Each

examination required a different procedure and special data. Plotted graph that

were used during analysis for the Conventional model can be found in Appendix

C.

3.2.1 Straight Run Analysis

During the straight run tests, the TEMPSC models were required to

maneuver through the ice in a “straight line”. The important data for this analysis

was elapsed time, total distance, and mean speed. I got all of this data from

graphs that were plotted during the test runs. After analyzing the data,

comparisons were made between the Conventional, Freefall, and Madrock

models.

3.2.2 Turning Circles Analysis

The turning circles analysis required the lifeboat models to complete four

or five full circles if possible. Circles were performed turning port and starboard.

The most important data for this was the mean diameter of the circles. I also

determined the roll angles for each run. The Madrock model proved to turn the

best with a much smaller turning diameter than the other two models. The

plotted tracks of the Conventional models straight run and a turning circle are

located in Appendix D.

3.2.3 Accelerations

Before analyzing the accelerations, I had to combine the Y acceleration

and X acceleration in Igor Pro to get the resultant acceleration. Then I analyzed

the most extreme accelerations during each run. This was arguably the most

important analysis, as it would be able to determine whether or not passengers

could be thrown from their seats or experience whiplash.

3.3 Model-Scale Life raft Testing

During the month of April, we performed tests on a 1:7 scale 16-person life

raft, which was manufactured by Newfoundland Marine. I had the same

responsibilities as I did with the full-scale model testing, which included

preliminary checks of the data recorded in each channel. I was also responsible

for any configuration changes that needed to be made to the raft itself, such as

maintaining air pressure, changing batteries, different ballast conditions, etc. The

results of these tests will be compared with the results from the full-scale

engineering tests in the near future. Unfortunately, I will not be here to observe

these outcomes.

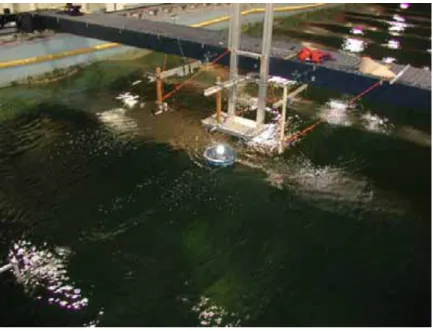

Figure 3.3 Model-Scale Life Raft Testing

4.0 CONCLUSIONS

During my second work term at the IOT under the supervision of

Lawrence Mak, I have learned a great deal about offshore safety, data analysis,

and the overall organization of a project. During my first work term here, I

learned a lot about physical model testing as well as full scale testing in the

institutions world-class facilities. Throughout this work term, I acquired an

abundance of knowledge on the analysis of the data that comes from these

physical tests. My research team was a great source of knowledge, and the IOT

is a superb place to pursue a career.

5.0 BIBLIOGRAPHY

• National Research Council, Institute for Marine Dynamics (2003).

Proposal: Lifeboat Rescue Performance: Survivability and Recovery.

• “Presentation to Management on Marine Safety Program”, [Presentation], (February, 2005).

• “Escape Evacuation and Rescue Survivability Testing”, [Report], Colin Power, (August 2004).

• National Research Council (n.d./2003). IOT-Offshore Engineering Basin [WWW document]. URL http://iot-ito.nrc-cnrc.gc.ca/facilities_oeb.html

• National Research Council (n.d./2003). IOT-Towing Tank [WWW document]. URL http://iot-ito.nrc-cnrc.gc.ca/facilities_tt.html

• National Research Council (n.d./2003). IOT-Ice Tank [WWW document].

URL http://iot-ito.nrc-cnrc.gc.ca/facilities_it.html

• National Research Council (n.d./2003). Facilities [WWW document]. URL

http://iot-ito.nrc-cnrc.gc.ca/facilities.html

• National Research Council (n.d./2003). Research [WWW document]. URL

http://iot-ito.nrc-cnrc.gc.ca/research.html

• “Madrock Marine Solutions Inc.”, Products [WWW document]. URL

http://www.madrock.ca/view.php?sub_cat_id=5

• “Qualisys Track Manager User Manual” (2002). Qualisys Medical AB [WWW document]. URL http://qualisys.se

• WaveMetrics Inc. (2000) “Getting Started, Igor Pro Version 4.0” Volume 1 page 1-2