READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Linear expansion due to freezing and other properties of bricks

Davison, J. I.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=2a478264-b511-437f-a340-fd75eb72ce3f https://publications-cnrc.canada.ca/fra/voir/objet/?id=2a478264-b511-437f-a340-fd75eb72ce3f

Ser TH1

N21d

+

National Research Council Canada Conseil national de recherches Canadano. 921

cop. 2

LINEAR EXPANSION DUE TO FREEZING AND

OTHER

PROPERTIES

OF

BRICKS

Reprinted, with permission, from

Proceedings, Second Canadian Masonry Symposium

held in Ottawa 9 11 June 1980

p 13 24

DBR

Paper No. 921B Mvtrion of Building Research

On a cornpar6 la dilatation lineaire B la cong6lation d'Schantillons de briques saturees sous vide partiel avec les propriLtCs des briques d'o3 ils provenaient. L'Ltude a port5 sur des briques d'argile et de schiste, extrud6es et moulees B sec, un beton et une brique de sable-chaux,

un grata et un calcaire.

Les peramktres mesurCs Qtaient: l'absorption aprls immersion

de 24 heuree et Gbullition de 5 heures, le coefficient de saturation, la resistance B la compression, la surface et la distribution de la taille des pores. On a Sgalement effectuE

PROCEEDINGS

SECOND CANADIAN MASONRY SYMPOSIUM

OTTAWA, J U N E 9 - 1 1 ,

1980G.T.

Suter

Symposium Chairman

H.

Keller

Technical Program Chairman

Published

by

LINEAR EXPANSION

DUE TO

FREEZING AND OTHER PROPERTIES

OF BRICKS

J.I.

Davison

Research Officer, Atlantic Regional Station,

Division of Building Research, National Research Council of Canada,

Ottawa. KIA OR6

ABSTRACT

Linear expansions, that occur when vacuum saturated brick samples

13 x

13

x76

mm(4

x3

x 3 in.)are frozen, were measured and compared with

properties of the bricks from which they were taken. Included in the

study were extruded and dry-press clay and shale bricks, a concrete and a

sand-lime brick, a sandstone and a limestone. Most of these were either

manufactured or used in Atlantic Canada and their performance records are

known.

Properties determined were 24-hour immersion and 5-hour boiling

absorption, saturation coefficient, compressive strength, surface area

and pore size distribution. Laboratory freeze-thaw cycling tests were

also conducted.

Four out of nine extruded bricks and two of three dry-press bricks were

considered to have failed during freezing because of cracks or breaks.

The failed samples from extruded bricks had relatively high porosity,

high saturation coefficients and a large percentage of pores in the 0.1

to 1.0

prange. Three of the four did not meet the saturation

coefficient requirement in CSA Specification A82.1, but passed waiver

clause requirements, and three of the four are known to have failed in

field service.

The "failed" dry-press brick samples came from bricks with good

saturation coefficients and pore size distributions and low surface area

values. Their failure may relate to the method of freezing.

Variations in linear change values and freezing patterns of the other

bricks provide interesting comparisons with their various properties.

INTRODUCTION

In general bricks remain the most durable of all building materials, but

there are some that pass the durability requirements in current CSA(1)

and ASTM

(2)Standards and fail in the field after several winters of

freeze-thaw action. Recently Robinson et a1

(3)have studied the

relation between durability and the physical properties of clay bricks

marketed in the United States and, on the basis of a statistical analysis

of data from tests on 5,217 bricks, have concluded that "none of the

properties alone or in combination could determine adequately whether the

brick would fail the 50-cycle freeze-thaw test." Laboratory freeze-thaw

cycling tests have been used to assess durability since the early

1900s

(4).In a recent approach Litvan (5) reports a test method based

on the measurement of surface area, while Ritchie

(6)proposes a test

method based

on"unidirectional" rather than "omidirectional" freezing.

This paper reports data obtained using the test method described

previously

(7).The study was designed to compare linear expansion

values with other brick properties to determine if there is

acorrelation

between freezing expansion, and/or failurenand any other properties.

BRICKS

The study included nine extrudbd and three dry-press clay bricks,

aconcrete and a sand-lime brick, a sandstone and a limestone. Most of

these materials were either manufactured,or are used,in Atlantic Canada.

Four samples (two duplicate sets) of each brick were selected from the

laboratory stockpile

-

one set from the low end and the other from the

high end of the Initial Rate of Absorption (IRA) range. The two bricks

in each set had the same, or as close to the same as possible, IRA

values.

PROPERTIES

The following properties of the bricks were determined by procedures

contained in CSA A82.2

-

Method of Sampling and Testing Bricks: 24-hour

cold water and 5-hour boiling absorption, saturation coefficient,

compressive strength and freeze-thaw cycling. In addition surface area

determinations were carried out using the B.E.T. nitrogen technique

(S),and pore size distributions and total porosity were determined using a

mercury porosimeter.

The 5-hour boiling absorption and saturation coefficient were omitted for

the concrete and sand-lime bricks, and in their place dry densities and

absorption values in lb/cu ft were determined by conventional procedures.

For the limestone the 24-hour cold water absorption value, bulk specific

gravity, unit weight, compressive strength, freeze-thaw cycling, surface

and pore size distribution were determined. The data are compiled in

Table

I.

FREEZING EXPERIMENTS

Test specimens 13

x13

x76

mm ( f x4

x 3in.) were cut from different

locations in the brick, from the length, the width, and where possible,

the height. They were cut from the top, center, bottom, outside surface

and from the inside of the brick. All specimens were marked and

catalogued in order that their origin could be established. Mounting

cups were epoxied on the ends of specimens which were then vacuum

saturated and frozen as described previously

(7).During the experiments the temperature was dropped from about +lS°C to

-2S°C and then returned to the initial value. The temperature drop from

the original level to the freezing point was consistcntly in the 0.7 to

l i n e a r changes were followed by o b s e r v i n g t h e p o s i t i o n o f t h e n e e d l e on t h e d i a l gauge. There was a c o n s i s t e n t p a t t e r n f o r a l l samples. A s t h e temperature dropped t o t h e f r e e z i n g zone t h e t e s t sample c o n t r a c t e d i n l e n g t h . When f r e e z i n g s t a r t e d , a t b a t h temperatures between -2.6 and -10.3"C, t h e p a t t e r n r e v e r s e d and t h e r e was expansion which

continued u n t i l f r e e z i n g was complete, t h e n t h e r e was a resumption o f t h e c o n t r a c t i o n p a t t e r n . When t h e temperature was r a i s e d t h e r e v e r s e p a t t e r n occurred, with expansion u n t i l t h e temperature approached t h e m e l t i n g zone, t h e n c o n t r a c t i o n d u r i n g melting, and f i n a l l y a resumption o f t h e expansion p a t t e r n when m e l t i n g was complete and t h e temperature r o s e t o i t s o r i g i n a l v a l u e . The llexpansion" v a l u e r e p r e s e n t s t h e

d i f f e r e n c e between t h e gauge r e a d i n g a t t h e time f r e e z i n g began and t h e r e a d i n g when f r e e z i n g was complete, while t h e "setf1 v a l u e r e p r e s e n t s t h e d i f f e r e n c e between t h e i n i t i a l r e a d i n g and t h e f i n a l r e a d i n g . Three samples from each o f t h e high and low IRA range s e t s f o r t h e d i f f e r e n t b r i c k s were f r o z e n . The samples t y p i c a l l y represented l e n g t h , width and i n t e r i o r c u t s . R e s u l t s f o r 98 samples a r e compiled i n Table 11. Samples from f o u r of t h e n i n e extruded b r i c k s f a i l e d by breaking o r c r a c k i n g d u r i n g f r e e z i n g . Included were a l l t h r e e o f t h e h i g h IRA samples from b r i c k A l , two o f f i v e samples from b r i c k F , f i v e o f e i g h t samples from H, and s i x samples from b r i c k G. Only one of t h e l a t t e r group f r a c t u r e d , b u t t h e o t h e r f i v e samples a l l had d i s t i ~ c t c r a c k s i n them a f t e r f r e e z i n g .

Two samples from t h e t h r e e d r y - p r e s s b r i c k s f a i l e d , one o f s i x samples from t h e h i g h IRA b r i c k I , and t h e one o f s i x from t h e h i g h IRA

b r i c k J.

Rapid expansion occurred a s soon a s f r e e z i n g s t a r t e d i n 12 o f t h e

18 samples t h a t f a i l e d and t h e expansion exceeded t h e range o f t h e d i a l gauge (440 x 10-5 i n . o r 0.147 p e r c e n t f o r t h e 3 - i n . b a r s ) . S e v e r a l o f t h e b a r s f r a c t u r e d and t h e r e were d i s t i n c t c r a c k s i n t h e o t h e r s . Expansions i n t h e s i x remaining b a r s remained w i t h i n t h e range o f t h e d i a l gauge, b u t t h e y were considered t o have f a i l e d because o f c r a c k s t h a t developed d u r i n g f r e e z i n g .

The sand-lime and c o n c r e t e b r i c k s , t h e sandstone and t h e limestone samples were a b l e t o c o n t a i n t h e expansive f o r c e s without f a i l u r e . The sand-lime b r i c k had t h e h i g h e s t average expansion v a l u e and t h e

c o n c r e t e b r i c k t h e lowest. The h i g h e s t average s e t value was recorded i n one o f t h e d r y - p r e s s b r i c k s , with t h e lowest i n an extruded c l a y b r i c k .

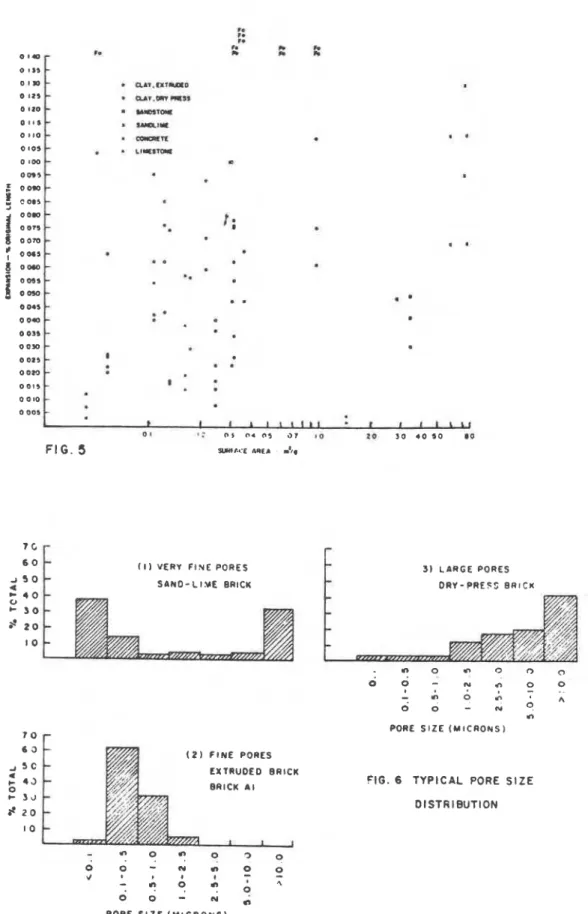

COMPARISON WITH OTHER PROPERTIES

A comparison of expansion v a l u e s f o r f r o z e n samples and t h e p r o p e r t i e s o f t h e "parent" b r i c k s can be seen i n Figures 1 t o 5 . Figure 1 f a i l s t o i n d i c a t e a c o n s i s t e n t p a t t d r n between expansion and 5-hour b o i l i n g a b s o r p t i o n . There i s a l s o a l o t o f s c a t t e r i n Figure 2 which r e l a t e s expansion and s a t u r a t i o n c o e f f i c i e n t v a l u e s , but t h e r e i s a t r e n d toward h i g h e r expansion a s s a t u r a t i o n c o e f f i c i e n t v a l u e s i n c r e a s e . T h i s t r e n d i s a l s o seen i n Figure 3 where expansion v a l u e s i n c r e a s e a s t h e t o t a l p o r o s i t y i n c r e a s e s . Figure 4 i n d i c a t e s c o n s i d e r a b l e s c a t t e r

and no r e l a t i o n s h i p between expansion and compressive s t r e n g t h . In Figure 5 t h e r e i s a p a t t e r n of i n c r e a s i n g expansion v a l u e s f o r c l a y b r i c k s a s s u r f a c e a r e a i n c r e a s e s .

The

p r o p e r t i e s o f b r i c k s from which " f a i l e d " samples were taken follow: S-Hr B o i l i n g S a t u r a t i o n T o t a l Compressive S u r f a c e Brick* Absorption C o e f f i c i e n t P o r o s i t y S t r e n g t h Area(% Dry W t

.

) (%1

( p s i ) (m2/g)*

A t o H-

extruded c l a y b r i c k s I t o J-

d r y - p r e s s c l a y b r i c k sT h i s d a t a i n d i c a t e s a c o r r e l a t i o n between f a i l u r e s and s a t u r a t i o n c o e f f i c i e n t f o r t h e f o u r extruded b r i c k s . The f a i l u r e s r e l a t e t o v a l u e s between 0.853 and 0.975. The 5-hour b o i l i n g a b s o r p t i o n s were

low, but t h e t o t a l p o r o s i t y v a l u e s were r e l a t i v e l y h i g h . High compressive s t r e n g t h v a l u e s (11,000 t o 18,000+ p s i ) d i d not prevent f a i l u r e . S u r f a c e a r e a s ranged from 0.32 t o 0.98 m2/g.

The two d r y - p r e s s b r i c k s a l s o had low 5-hour b o i l i n g a b s o r p t i o n s , low t o t a l p o r o s i t y . v a l u e s and s a t u r a t i o n c o e f f i c i e n t s under 0.80.

Compressive s t r e n g t h s were between 4,200 and 5,300 p s i and s u r f a c e a r e a s between 0.05 and 0.32 m2/g.

A l l t h e b r i c k s i n t h e s t u d y s u r v i v e d 50 c y c l e s o f l a b o r a t o r y f r e e z i n g and thawing with minimal weight l o s s e s ranging from 0 t o 1.84 p e r c e n t . I t should be n o t e d , however, t h a t two of t h e c l a y b r i c k s , extruded b r i c k H and d r y - p r e s s b r i c k J , f a i l e d i n p r e v i o u s freeze-thaw c y c l i n g t e s t s .

PORE SIZE DISTRIBUTION

The pore s i z e d i s t r i b u t i o n s t u d y i n d i c a t e s t h r e e d i s t i n c t groupings c h a r a c t e r i z e d a s f o l l o w s and shown g r a p h i c a l l y i n Figure 6 .

(1) Very Fine Pores

-

l e s s than 0 . 1 p i n diameter. This groupincluded t h e c o n c r e t e , sand-lime and sandstone b r i c k s . A l l t h r e e had 35 t o 40 p e r c e n t of t h e i r p o r e s under 0.1

u ,

while 10 t o 30 p e r c e n t were g r e a t e r t h a n 10 p. The f r e e z i n g p a t t e r n f o r t h e sand-lime and sandstone b r i c k s , and on a l e s s e r s c a l e t h e c o n c r e t e b r i c k , d i f f e r e d from t h e p a t t e r n f o r t h e c l a y b r i c k s i n t h a tf r e e z i n g continued a t much lower t e m p e r a t u r e s , although t h e r a t e o f f r e e z i n g t a p e r e d o f f a t temperatures below - 1 6 ' ~ then continued a t a slower r a t e . D c f i n i t c resumption of t h e c o n t r a c t i o r l p a t t e r n ,

which c h a r a c t e r i s t i c a l l y occurred i n t h e c l a y b r i c k s when f r e e z i n g

was complete, never occurred. Some o f t h e l a r g e s t expansions,

without f a i l u r e , recorded d u r i n g t h e s t u d y occurred i n t h e sand-lime b r i c k s . The presence o f a l l pore s i z e s i n t h i s b r i c k was a p p a r e n t l y b e n e f i c i a l i n accommodating t h e expansive f o r c e s i n

a manner t h a t prevented t h e development o f d i s r u p t i v e s t r e s s e s .

Fine Pores

-

0.1 t o 1.0v.

The extruded c l a y b r i c k s a l l had amajor p o r t i o n o f t h e i r p o r e s i n t h i s range. Samples from f o u r o f t h e n i n e b r i c k s f a i l e d d u r i n g f r e e z i n g , and t h e " f a i l e d " b r i c k s had 81 t o 94 p e r c e n t o f t h e i r p o r e s between 0.1 and 1.0

v ,

with v e r y few p o r e s above 1.0v .

Samples from t h e f i v e b r i c k s , whichsurvived f r e e z i n g , a l s o had a high percentage o f p o r e s i n t h i s range, but t h e remainder were g e n e r a l l y above 1

v.

A l l n i n eb r i c k s had a v e r y small percentage o f p o r e s below 0.1

v.

Freezingi n samples from t h e s e b r i c k s was u s u a l l y complete when t h e temperature reached -10°C.

(3) Large Pores

-

over 5v.

The t h r e e d r y - p r e s s b r i c k s had good pores i t e d i s t r i b u t i o n s with a l l s i z e s r e p r e s e n t e d and 40 p e r c e n t o r

%more above 5

v.

Samples from two o f t h e s e b r i c k s f a i l e d . The t h i r d b r i c k , which accommodated a moderate expansion without d i s r u p t i v e stress, had over 60 p e r c e n t of i t s pores above 5v.

OTHER FACTORS

One o f t h e f a i l e d extruded b r i c k s , G , was coated w i t h a continuous g l a z e on one s u r f a c e . Two o f t h e s i x samples t h a t were frozen had one glazed s u r f a c e . One o f t h e samples f a i l e d by breaking and t h e o t h e r f i v e samples, i n c l u d i n g t h e two with t h e glazed s u r f a c e , developed d i s t i n c t c r a c k s . The samples with t h e glazed s u r f a c e had t h e high (0.076 p e r c e n t ) and low (0.026 p e r c e n t ) expansion v a l u e s f o r t h e group

Pronounced l a m i n a t i o n s were noted when samples were c u t from extruded c l a y b r i c k s A 1 and H. Samples from t h e s e b r i c k s t h a t were s e l e c t e d f o r f r e e z i n g had no obvious l a m i n a t i o n s .

The c o n c r e t e b r i c k , which had t h e lowest expansion v a l u e i n t h e s t u d y

i s known t o c o n t a i n an i n t e g r a l waterproofing m a t e r i a l . FIELD PERFORMANCE

Three o f t h e f o u r extruded c l a y b r i c k s t h a t f a i l e d d u r i n g f r e e z i n g a r e known t o have f a i l e d i n f i e l d s e r v i c e by s p a l l i n g while t h e f o u r t h has

a good s e r v i c e r e c o r d . One o f t h e d r y - p r e s s b r i c k s i s known t o have a good s e r v i c e r e c o r d but t h a t o f t h e o t h e r i s not known.

COMPLIANCE WITH STANDARDS

A l l s i x b r i c k s , samples o f which f a i l e d d u r i n g f r e e z i n g , meet t h e

and 52 satisfy the requirement for individual values for maximum 5-hour boiling absorption (25 per cent) and saturation coefficient (0.90), and

minimum compressive strength (2,200 psi). The other three bricks Al,

G2 and

H,

fail or are borderline with respect to the maximum saturationcoefficient requirement but qualify under the waiver clause accepting compressive strength greater than 8,000 psi in lieu of compliance with the saturation coefficient value. All six bricks qualify under the waiver clause accepting bricks that survive 50 cycles of laboratory freezing and thawing with no breakage and less than 3 per cent weight loss.

DISCUSSION

There is good correlation between failed extruded clay bricks, high saturation coefficient values and concentration of pore size values in

the 0.1 to 1.0 range. There is also good correlation of test

failures and failures in field service for three of four bricks. The fourth brick, known to perform satisfactorily in the field, had a much higher saturation coefficient than the usual value for this brick and is considered an exception, but the results indicate a potential for durability problems. High porosity values, reflecting a large capacity to hold water, must also be considered a contributing cause. There was not good correlation between expansion values (or failures) and surface

area values. Possibly,these shbuld be studied for individual bricks to

be meaningful. Other factors including laminations and the glazed surface on one of the bricks may also have contributed to failure. The combination of test and field failure of the six bricks that meet

durability requirements supports the contention that the current Specification is not a good durability indicator.

Failure of samples from two dry-press bricks cannot be explained on the basis of saturation coefficient and pore size distribution. Their saturation coefficients were below 0.80 and there was good distribution of pore sizes with a predominance of larger sizes in both bricks. The total porosity was considered moderate and there were no laminations or "other factors" that might have contributed to failure. However the compressive strengths of the bricks at 5,297 and 4,595 psi, while well above the Specification requirement of 2,200 psi, were low by.

comparison with the extruded bricks, and the two samples that failed were cut from the interior where the strengths may have been lower than the average value for the bricks. Through the years the frequent

failure of one of these bricks in laboratory freezing tests,

contradicting its satisfactory field performance, has been difficult to

explain. Ritchiels (6) suggestion that laboratory freezing tests

should be unidirectional rather than omnidirectional merits consideration in this area.

CONCLUSIONS

Limited test results indicate that linear expansion caused by freezing in laboratory tests is capable of failing extruded bricks that have a record of failurc in field service. Thc data indicate that many factors contribute to thc durability of bricks and among thcm saturation

is required to study the relationship between saturation coefficient and

pore size distribution. The nature of the pore structure should also be

studied.

The author would like to thank Dr. J. Kung of the Ottawa Laboratories

of the Division of Building Research who carried out the surface area

and pore size distribution determinations. This paper is a contribution

from the Division of Building Research, National Research Council of

Canada, and is published with the approval of the Director of the

Division.

1. C.S.A. Standard A82.1-1977, Burned Clay Brick.

2. A.

S.T.M.

C62-75a Standard Specification for Building Brick (Solid

Masonry Units made from Clay or Shale).

3.

Robinson, Gilbert C.

,

Holman, James R.

,

and Edwards, Joseph F

.

Relation between Physical Properties and Durability of Commercially

Marketed Brick. American Ceramic Society Bulletin, Vol. 56, No.

12,1977,

p.

1071.

4. Jones, J.C.

Effect of Repeated Freezing and Thawing on Brick

Burned to Different Degrees of Hardness. Trans. Am. Ceramic

Society, Vol. 9, 1907, p. 528.

5.

Litvan, G.G. Testing the Frost Susceptibility of Bricks. American

Society for Testing and Materials, STP 589, 1975, p. 123.

6. Ritchie,

T.

Brick Durability Tests and the Method of Freezing.

Presented at the Fifth International Brick Masonry Conference,

Washington, D.C., 1979.

7. Davison,'

J.

I.,

and Sereda, P.

J.Measurement of Linear Expansion in

Bricks Due to Freezing.

J.Testing and Evaluation, Vol.

6, No- 2,IHI 1 4 - ~ r . C . W . h h . 5-Hr. m i l i n g a. 8.turatlnn C ~ r e s s I v . Wight Loma A f t # * Burfa r Atca m t r l Poroslty p / 3 0 sq ina/mlnl - (\ Dry Wt.) (\ 0- we.) C w l f i c l e n t Strsnqth bmi) Y) F/T Cycles 11) (m5/d - 18 v o l w e )

A 3 A 3 Es A S Al* 1 8.9 6.1 6.3 0.975 18.381+ 0.35 17.18 1 9.9 0.950 0'96J 0.17 3 1.3 1 . 5 0 . 4 6 20'ooo1 0.14 8 . 7 7 4 1.3 0 0.17 14-HI. C.W. Abs. (a Dry ut.) Ev. m d u l u a t h l g h t LWm U t o r O u r f s n Aru mt.1 Porosity mptur* h i 1 M I f T CYcloa ( r ) bl/d I n v o l w )

1PA 24-HI. C.W. hbs. 5-Mr. blliq Ab.. S a t u r s t l m Capr*ssivm Waiqht Loss f f t e r 8 u r f a c s Area t o t a l Poroslty J s n / 3 0 s a ins/lin) ( r ayr t . ) (a my wt.1 co*ffIcl.nt Btrsnqth b.1) 50 IfT W c l s s ($1 (m2/p) (t V o l w )

9 l !s *l?n

X I U UI-w. C.W. a s . m ~ s s s i v e w i g h t f f t e r ~ u r t a c s &*a mt.1 i v r o s i t y h l k ~ p c l f i c

*/30 .p indmin) I\ Dry W t . ) Strength (psi) 50 ?/T Clc1.n 181 (m2/9) lt V O ~ U U ) c r s v i t y u n l t Weight (Ibs/cu It] 66.4 11.3 1.286 0.13 0.17 10.118 1.90 118.56

-

A m I inc1.-

extruded olsy bricks +-

n-

s a n d - H r brick**

-

I t o K i n c l .-

dry-prams b r l c l u * - n - msndstons'**

-

L-

concrete bricb +++-

0-

l i u m t o n s8.tru.tlnn 15 Dry Walghtl Al-1 111) 7.6 2 1.)) 6.3 5111 6.3 !sx

L-ll

-

?atrud.d clay tulckmI-ll

-

Dry-Premm Clay briehm L-

Concr-te brlck U-

M n d - l l r brlek u-

sudmbma 0-

-ton* 11)-

wrplo ~t fm Iatqth (w)-

cut fm r l d t h (h)-

-10 cut fm holqhtCut fm Intarlor of th. b r l e t

-

w 'mkIn" 8 l y f 4 nUI othmr . g h m t ~ d a t I-t 1 .mkinm u f a n

r 0.OSO

-

i

A OOIO-

ig

OOTO-

f 8 O M 0-

fg

00.0-

o n 0 9 o m 0.0. 0.3 o w , a s s o s o o a o m o m o w om o w o r loo F I G . 2 Y l U A T l Q C O C W l C I C m l0 1 4 0 - 0 IS5 - OIXJ

-

0 11s-

o 110-

O l l d - 0 110 - 0 1 0 1 - o i w-

0 0 1 1 - = 00- - C0,5-

o o mj

007,-

s

o o m-

0 - 5 - I o m-

a

o w , -b

O m - 0 0 4 1 0 0 4 0-

0 035-

OOXJ - 0 0 1 )-

' .

:

0 0 1 0 - 0 0 0 5 - # I I 1 1 1 1 1 1 1 L I I I l l 1 0 3 ' 0 ) 0 4 0 5 0 7 0 0 SO 1 0 4 0 1 0 * a FIG. 5 W ~ F E nmrr m',. ( I ) V E R Y F I N E P O R E S 3 ) L A R G E P O R E S a 5 0 a S A N D - L I M E BRICK O R I - P R E 5 S B R I C K 7 0 6 0 ( 2 ) F I N E P O R E S a 5 c EXTRUDED B R I C K 4.3 0 B R I C K A l t 3 J 2 ' 2 0 l o - *. o. n. 0 9 0 0?

:

,

Ng

o

- " 3 " d o - 4 9m P O R E S I Z E ( M I C R O N S ) P O R E S l Z E ( M I C R O N S )FIG. 6 TYPICAL PORE S l Z E OlSTfil0UTlON

This publication is being distributed by the Division of Building R e s e a r c h of the National R e s e a r c h Council of Canada. It should not b e reproduced in whole o r in p a r t without p e r m i s s i o n of the original publisher. The Di-

vision would b e glad t o b e of a a e i s t a n c e i n obtaining s u c h permission.

Publications of the Division m a y b e obtained by m a i l - ing the a p p r o p r i a t e r e m i t t a n c e (a Bank, Expresa, o r P o s t Office Money O r d e r , o r a cheque, m a d e payable t o the R e c e i v e r G e n e r a l of Canada, c r e d i t NRC) to t h e National R e s e a r c h Council of Canada, Ottawa. K1A OR6

.

S t a m p s a r e not acceptable.A lis t of a l l publications of the Division is available and m a y b e obtained f r o m the Publications Section, Division of Building R e s e a r c h , National R e s e a r c h Council of Canada, Ottawa. KIA OR 6.