Publisher’s version / Version de l'éditeur:

ASTM Bulletin, 250, pp. 32-33, 1961-02-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Portable adhesion testing device

O'Kelly, B. M.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=72fa10c9-730a-4905-b881-009b05712002

https://publications-cnrc.canada.ca/fra/voir/objet/?id=72fa10c9-730a-4905-b881-009b05712002

TH1

N21r2

no. 121

c. 2

NATIONAL

RESEARCH

COUNCIL

CANADA

DIVISION O F BUILDING R E S E A R C H

PORTABLE ADHESION TESTING DEVICE

MAR 2

125;

N A T I O N A L R i S E A I ! C H C O U N C I L . >9 BYB.

M.

O'KELLY

REPRINTED F R O MAMERICAN SOCIETY FOR TESTING MATERIALS BULLETIN NO. 250,

DECEMBER 1960,

P.

32-

33

PRICE 10 CENTS

RESEARCH PAPER N O . 121 O F T H E

DIVISION O F BUILDING RESEARCH

OTTAWA

This p u b l i c a t i o n i s being d i s t r i b u t e d

by

t h e D i v i s i o n of Building Research of t h e N a t i o n a l

Research Council a s

ncontribrrLion towards b e t t e r

b u i l d i n g i n Canada.

It

should not be reproduced

i n whole o r i n pa*,

without permission

o f t h e o r i -

g i n a l p u b l i s h e r .

The D i v i s i o n would bo glad t o

bo

of

assistance i n ob-tainlng such p r m i s s i o n .

P u b l i c a t i o n s of t h e D i v i s i o n of B u i l d i n g

Research

may be obtained by m a i l i n g

t h e

a p p r o p r i a t e

r e m i t t a n c e ,

( a Bank, E k ~ r e s s , o r Post Off i c e Money

Order o r a cheque nade payable a t p a r i n Ot.tawa,

t o t h e Receiver Gene1v.1 of Canada, c r e d i t N a t i o n a l

R e s e a r c h c o u n c i l ) t o

the

N a t i o c n l Research Council,

Ottawa.

S t a l p s a r o not accsptabl-e.

A

coupon system has been introduced

t o

make payments

f

01-pubZ.Pca'iions

re

l<

-t

i ~ r c l y

sjmple,

Coupons a r e a v a i l a b l e i n dencnlinations

of

5,

25,

and

9

c c n t s ,

and

may be obtained by

making

a

re-

m i t t a n c e as

indicated above,

T h e s e

coupons

may

be

used f o r t h e pwchaso

of

al.1 Na-Lional F c s o a ~ c h

C o u n c i l p u b l i c a t i o n s i n c l u d i n g s p s c i f i c n t i o n s of

t h e Canadian C-overnment S p e c l f i c a t l o n s Board.

Portable Adhesion Testing Device

'. B y B. M. O'KELLYSICVEI~AL

iilquirics con- cerning thc adequacy of a plaster bone1 oil the job motivntecl the clcl-clopmciit of a portable adhesion testing apparatus.It was hopecl t h a t plaster bolid coulcl be testecl in the liclcl nit11 a portable clc\ricc.

Field coilditions coulcl then be coinpnrecl ~ v i t h laboratory findings. Althougli cle- scriptions of clcvices and techniques satisfying t h e above rcquircinents have beell l~ublishecl,~ it was believed t h a t some irnl~rovement in design over thosc published n.as possil)le and desirable.

A t t e m l ~ t s by thc arithor to rcl)rotlucc thc \vork of Pctcr? on the aclhesion of gypsum plaster to V : L ~ ~ O I I S II:LSCS shon-ccl

t h a t this tcclinicluc, involving the cin- bec1dii.g of various shapes in the plastcr apl~lic:ltion, \\-as scl)jrct to gr:Lve short- comirgs. A systcm 1 ~ : ~ s accorcliilgly clevisccl 1vhic.11 did not ii~volve the em- bedding of an): objcct in the ~~ppliecl plaster. Unfortunately, Peter's phi- losophy WLS initially follon~ed t o the es-

tent of using a 11ailel 94 in. square. Such a panel works ~vell ~ v i t h assemblies of high adhesion (for esample, boilcl plaster on concrete), b u t where acl- hcsioil is not high, localized strains lead to premature bond failure. It is be- lieved t h a t there is no hope of success in adhcsion ~ v o r k unless the boncl test is carried out on a specimen of small sur- face area. Accordingly, 2-in. diameter circular disks nere used finally for all adhesion tests.

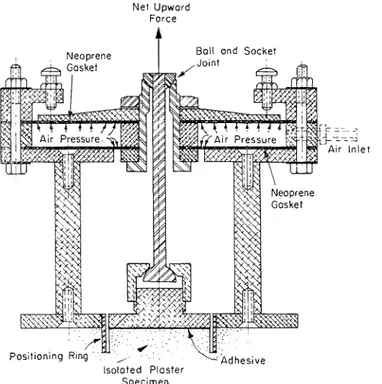

Apparatus

A device using coml)rcssed gas a> a source of polver was cleaigncd, con- structed, and founcl t o operate satis- factorily (Fig. I). The princil~lr of operation is, essentially, application of pressure bet~veen two neoprene gaskets t o produce a net upnnrcl force, since the upper gasket has n larger area tlin~i

NOTE-DISCUSSION 011' TI-IIS I'AI'EK I S I N V I T E D , oitllor for puhlicat,io~i or for thc attention of thc a u l l ~ o r or :~uthora. Acl- dress all conlrnurlicntions to ASTAl tIe:ld quarters. 1916 Race St., Philncli~lphia Y. 1':~.

*

This is a contribution from t h e Divisioil of Building Research, National Research Council, Canada, and is published with t h e approval of t h e Director of the Division.1 J. F. Ryder, methods for Testing the

Adhesion of Plaster to Concrete," Chemistru

and Indtistrz, Aug. 10, 1957, pp. 1090-2.

V. Saretok. P u t s och Putsning" (Plastering and Rendcring), Translated from thc Swed- ish, R I L E M Bulletin

fi.

39, p p 5-79 (1957).2 J. C. P . Peter, Adhesion of Gypsum Piaster to Various Backgrounds," The

American Architect, Vol. 128, Sept. 9, 1926, pp.

227-234.

J Minneapolis-Honeywell No. 356529-1.

the lon.cr. ; l t the same time, no cx- truncous frictional or other restraining iorc~c is introducccl. The compressed gas source is at,t:~chccl to the intake side of :L 111anual-loadi1i g 11ressure regulator."

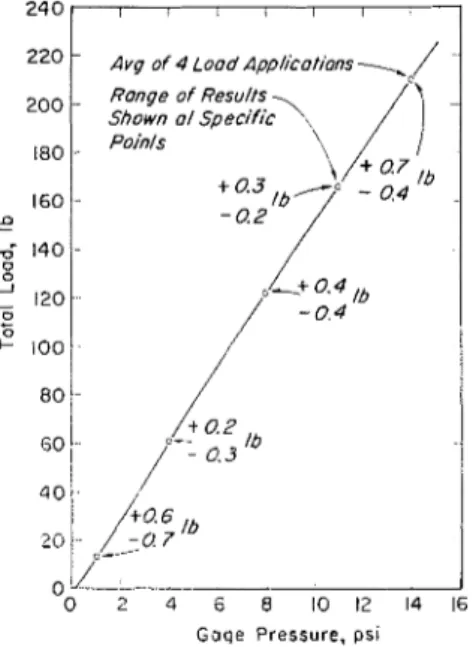

The o t ~ t p u t iron1 t h c regulator is fed t o the clevice nnrl to a sensitive pressure gagc. The clcvicc calibrated b y

Procedure

The technique used in measuring adhe- sive bond is as f o l l o ~ ~ s : A disnlountable brass frame

4

in. eleep is placed on a saml~lc of the backing material. The plaster m i s being testecl is fed into this frame, surplus material is scrcellecl off to give a flat surface t o the plaster. The Net UpwardForce

C

Boll ond Socket

lsoloted Plaster Specimen

Fig. 1-Section through adhesion testing device.

mounting i t in a testing machine and ineasuring the total load (as registered on the testing machi1:c scale) resulting from a give11 air pressure (measured on the pressure gage). Figure 2 shows t h a t the calibration curve is coinpara- tivelp linear.

Figure 3 shows t h c assembled ad- hesion pressure regulator, pressure gage, and testing device. The adhesion test- ing device alone weighs 4 lb 3 oz.

size of t h e brass franlc is :I iiiatter 01

choice nncl convenience. The entire test assembly, aftcr l)reparation, is placccl in :I, humid room overnight, then

removed t o be conditioned t o constant weight, a n d tested.

I n testing n plastered panel, tlisks of plaster 2 in. in diameter a r e isolated from the body of the shect with a suit- able fly-cutting device. Although the design of t h e fly-cutter may vary 11-idely,

B. M. O'KELLY was a member of the Division of Building Research of the National Research Council of Canada from

1952 until 1960. During that time his work was concerned with plastering materials ; he also took an active part in the work of ASTM Committees C-7 on Lime and C-11 on Gyp- sum. Prior to 1952, Mr. O'Kelly was employed for two years as quality control chemist in a gypsum plant in Ireland. In

1960 he left the Division to join the U.S. Gypsum Company in Chicago as a research chemist.

32 (TP 210) A S T M BULLETIN

Authorized Reprint from the Copyrighted ASTM BULLETIN No. 2 5 0 , December, 19G0

i t must be possible t o feed the cutter TABLE I.-RESULTS O F ADHESION TESTS.

slolvly into the plaster, otherwise a n Not Vibrated Vibrated

irregular groove ivill almost certainly result.

Using a suitable contact adhesive," a n aluminum disk carrying a threaded stud is cemented t o the isolated plaster disk. A short thin-walled aluminum

220

1

Avg of 4 Load ApplicafiansI. /

{

Range of Results 200 - Shown a1 specific1, 180 - Poinls 160 - 9 - -* 140 - "0 2 4 6 8 10 12 14 16 G ~ q e P r e s s u r e , p s iFig. 2.-Calibration curve.

positioning ring is inserted into the groove made b y the fly-cutter in the plaster, and the base of the adhesion testing device is fitted around i t (see Fig. I ) . This techniclue insures cen- tering of the testing device over the test specimen. The testing device is screwed t o the threaded stud. Air pressure is then increased until failure occurs.

X

manual-1o:lcling pressure regulator insures t h a t the pressure regis--

'

Minnesota lMining and lManufacturing Co. 31M Adhesive EG524 has been found satisfactory for this purpose.Plaster Base

Gypsum lath, groove cut through lath papera.. . .

Gypsum lath, groove not cut through lath papera..

. .

. . .Corkboard . . . Various brands of bead-tvne

Failure Load, psi Number Failure Load, psi Number of Llislis of Disks Max Min Avg Tested Max Min Avg Tested

foamed polystyrene: '

Brand "A;' first testa.. . . . 13.9 1 0 . 7 11.0 9 . . BrandUA," second test& ... 13.8 12.1 13.2 14 1 4 1 1 1 2 9 15 Brand "B," first testa.. . . . 13.9 10.7 12.1 12 . . . . . . . .

Brand "B," second testb.. . 13.0 11.5 1 2 . 3 14 13.5 12.1 1 2 . 8 1.5 Foamed ~ o l v s t v r e n e , other

than beid-tipe :

One brand*, . . . .. . .

a First plaster batch.

b Second plaster batch.

Fig. 3.-Pressure regulator, pressure gage, and adhesion device.

tered on the pressure gage after failure of the specimen is the pressure a t failure, irrespective of the fact that, on failure, a change in volume occurs in the pressure cell of the testing device.

The results of solnc adhesion tests are given in Table I. Plaster-to-water ratio in all cases was 2 to 1; unaggre- gated hardmall plaster was used throughout. All pauels xere condi- tioned a t 70

F

2nd 100 per cent relative humidity and then dried a t 70F

a n d 50 per cent relative humidity.These results are of interest mainly

to slronl the reproducibility. The inter- ;:~,c%:ltion of thcin is some~vhat more clifficult. particularly in the test on gylwtrn lath since thc breaks \\-ere n o t co1:sistcritly

: ~ t

t l l ~ plaster lath inter- 1':lc.e. 111 the case of t h e polystyrene I m e s the mnjorit'y of failures oecurred1.p scl)ar:ltion of the plaster t o base interfncc, 11ut in a numbcr of cases ::cparntion occurred partly or largely i n the base itself. The true bond strength c ; ~ n never be lcss than b u t may exceed the value shown.

Before testing, soine panels were clamped t o a Gilson sieving machine and vibrated for 15 min. This t e s t procedure has the important advantage t h a t :t large number of adhesion de-

terminations can be made from a con~paratively small t e s t panel. F o r cxaml~le, from a sheet of plaster 95 in.

square i t is possible t o isolate sixteen 2-in. diameter test disks.

A s t u d y involving t h e determination of the bond of plaster applied t o a 12-ft- high ceiling has demonstrated t h a t field testing of plaster bond is practi- cable when using the appa,ratus tliat has been described.