https://doi.org/10.4224/20378637

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=8d90943e-cd83-4bad-96e4-46fd600c696d https://publications-cnrc.canada.ca/fra/voir/objet/?id=8d90943e-cd83-4bad-96e4-46fd600c696d

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The cost of owning and operating a residential heat pump system in

Canada

NATIONAL RESEARCH COUNCIL OF CANADA

DIVISION OF BUILDING RESEARCH

THE COST OF OWNING AND OPERATING A RESIDENTIAL

HEAT PUMP SYSTEM IN CANADA

R.L.D. Cane

DBR Paper No. 905

of the

Division of Building Research

THE COST OF OWNING AND OPERATING A RESIDENTIAL

HEAT PUMP SYSTEM IN CANADA

by R.L.D. Cane

This paper outlines the operational characteristics of various

i

residential heat pumps and compares the costs of owning and operating

I

such equipment with conventional furnaces. The comparison is made

for nine Canadian cities and for a range of heating energy demands.

I

The data presented will allow the consumer to select a heating system,

for retrofit or replacement of an existing system or for new construction,

on the basis of life-cycle cost.

LES

C O ~ T S

DE POSSESSION ET D'EXPLOITATION DtUNE

POMPE

A CHALEUR R~SIDENTIELLE

AU CANADA

par R.L.D. Cane

R ~ S U M ~

Cet article dBcrit les caracteristiques d'operation de diverses

pompes

3chaleur residentielles et compare les coQts de possession

et d'operation de cet equipement avec les chaudisres traditionelles.

La comparaison est dressee pour neuf villes canadiennes et pour une

g a m e de demandes en Bnergie calorifique. Ltinformation

presentee

permettra au consommateur de choisir

unsystsme de chauffage, pour

ameliorer ou remplacer un systsme existant ou pour une nouvelle con-

struction, sur la base du coQt de la d u d e utile.

PREFACE

Homeowners i n Canada today a r e c o n s i d e r i n g p o s s i b l e a l t e r n a t i v e s t o conventional o i l and gas f u r n a c e s , with t h e r i s i n g p r i c e s of f o s s i l f u e l and t h e p r e d i c t e d s h o r t a g e s of o i l i n t h e n e a r f u t u r e . One h e a t i n g system t h a t has been on t h e market f o r s e v e r a l y e a r s , which i s becoming more a t t r a c t i v e a s f o s s i l f u e l p r i c e s i n c r e a s e , i s t h e e l e c t r i c h e a t

pump. To d a t e , t h e consumer has only had t h e claims of h e a t pump manu-

f a c t u r e r s t o i n d i c a t e p o t e n t i a l savings i n energy and i n h e a t i n g c o s t . This paper was prepared t o provide unbiased information on t h e economic worth o f h e a t pumps compared with conventional b e a t i n g systems.

Recognized methods a r e used t o p r e d i c t t h e performance and energy requirements o f t h e v a r i o u s a l t e r n a t i v e h e a t i n g systems. C a p i t a l and maintenance c o s t s were obtained from i n s t a l l a t i o n c o n t r a c t o r s and a r e considered t o be r e p r e s e n t a t i v e of a c t u a l p r e v a i l i n g c o s t s . For an

economic a n a l y s i s , however, f u t u r e t r e n d s i n t h e f o s s i l f u e l and e l e c t r i - c i t y p r i c e s had t o be assumed. P r i c e s a r e obviously s u b j e c t t o change because of s e v e r a l u n p r e d i c t a b l e f a c t o r s i n c l u d i n g f u t u r e government energy p o l i c i e s .

T h i s paper w i l l a l s o provide t h e consumer with some of t h e informa- t i o n r e q u i r e d f o r t h e r a t i o n a l s e l e c t i o n of a h e a t i n g system, whether it be f o r new c o n s t r u c t i o n o r f o r replacement of an e x i s t i n g furnace. The Division would welcome comments on t h e methods and/or assumptions used i n t h i s a n a l y s i s .

Ottawa A p r i l 1980

C

.

B. CrawfordTHE COST OF OWNING AND OPERATING

A RESIDENTIAL HEAT PUMP SYSTEM IN CANADA

R . L . D . Cane

INTRODUCTION

Most homeowners have had t o d e c i d e whether t o r e p a i r o r r e p l a c e a f u r n a c e . Depending on t h e t y p e o f f u e l b e i n g used, t h e owner might c o n s i d e r changing f u e l and/or t y p e o f h e a t i n g system i f t h i s would save him some money. However, reduced o p e r a t i n g c o s t s must be c o n s i d e r e d i n c o n j u n c t i o n w i t h t h e f i r s t c o s t o f t h e h e a t i n g system c o n v e r s i o n o r up- g r a d i n g ; t h e c r i t e r i o n should be t h e t o t a l l i f e - c y c l e c o s t .

T h i s p a p e r p r e s e n t s a comparison o f t h e t o t a l c o s t o f owning and o p e r a t i n g v a r i o u s a i r - t o - a i r h e a t pump systems and c o n v e n t i o n a l o i l , g a s and e l e c t r i c f u r n a c e s . The comparison i s made f o r a range o f h e a t - i n g l o a d s i n n i n e c i t i e s whose c l i m a t e s a r e r e p r e s e n t a t i v e o f t h e

v a r i o u s r e g i o n s o f Canada. The f a c t o r s o f c l i m a t e , r e g i o n a l f u e l c o s t and a v a i l a b i l i t y have a s t r o n g i n f l u e n c e on t h e b e s t c h o i c e of a new h e a t i n g system.

Although a h e a t pump i s c a p a b l e of p r o v i d i n g c o o l i n g i n summer, t h e e s t i m a t e o f b e n e f i t from a h e a t pump i s based e n t i r e l y on h e a t i n g - energy c o s t s a v i n g s . The r e s u l t s a r e p r e s e n t e d i n a format t h a t w i l l p e r m i t t h e r e a d e r t o determine t h e a d d i t i o n a l v a l u e t h a t must be a s s i g n e d f o r a i r c o n d i t i o n i n g i f t h e h e a t pump i s t o be c o m p e t i t i v e w i t h t h e low- e s t c o s t a l t e r n a t i v e h e a t i n g system.

CALCULATION OF HEATING ENERGY REQUIREMENTS

A number o f f a c t o r s i n f l u e n c e t h e purchased h e a t i n g energy r e q u i r e - ments o f a d w e l l i n g . The t o t a l amount o f purchased energy used t o h e a t a d w e l l i n g depends on t h e h e a t l o s s c h a r a c t e r i s t i c o f t h e house, t h e c l i m a t e o f t h e l o c a l e under c o n s i d e r a t i o n , and t h e amount of h e a t ob- t a i n e d from p e o p l e , a p p l i a n c e s and s o l a r g a i n . The t o t a l h e a t l o s s r a t e

( 9 ~ 0 ~ ) i s d i r e c t l y p r o p o r t i o n a l t o t h e indoor-outdoor t e m p e r a t u r e d i f - f e r e n c e (AT), t h a t is: The p r o p o r t i o n a l i t y c o n s t a n t K i s sometimes r e f e r r e d t o a s t h e t o t a l h e a t l o s s c h a r a c t e r i s t i c o f a d w e l l i n g , having t h e u n i t s w a t t s / " ~ . From E q . (1) i t i s e v i d e n t t h a t f o r a given v a l u e o f K t h e t o t a l h e a t l o s s r a t e i n c r e a s e s l i n e a r l y w i t h i n c r e a s i n g AT.

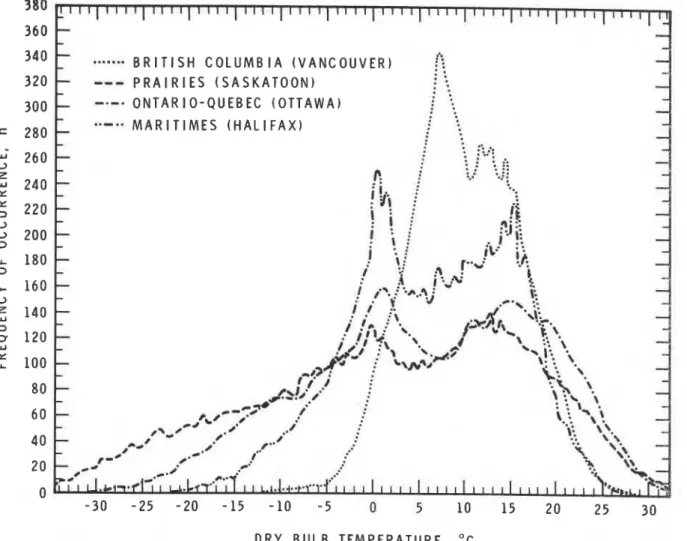

The weather d a t a f o r c a l c u l a t i n g t h e h e a t i n g energy r e q u i r e m e n t s a r e shown i n F i g u r e 1. T h i s p l o t shows frequency d i s t r i b u t i o n s o f o u t - door t e m p e r a t u r e f o r t h e f o u r main r e g i o n s i n Canada; t h e d i s t r i b u t i o n s a r e f o r t h e c i t i e s i n d i c a t e d . T h i s f i g u r e c l e a r l y shows t h a t h e a t i n g

energy requirements vary considcrably from region to region.

The British Columbia region is characterized by few extremes,

with the bulk of the heating hours above 5°C. The average indoor-

outdoor temperature difference is small; of the regions considered,

British Columbia requires the least amount of heating energy for a given

value of K. At the other extreme, the Prairie region is characterized

by a relatively flat distribution over the entire outdoor temperature

range. With a large number of heating hours at low temperature, the

heating energy requirements will be greatest for a given value of

K.

The Maritime distribution resembles in many ways that shown for British

Columbia, but the majority of the heating hours are distributed about

0°C. The Ontario-Quebec distribution is intermediate to that of the

Prairie and Maritime regions, and heating energy requirements reflect

this.

In this study a range of heat loss characteristics was used. A

house of standard frame construction was selected as the model residence

To investigate the effects of varying loads on the heating system, the

levels of insulation in the ceiling and walls were varied. The heat

loss characteristics for the different levels of insulation are summarized

in Table 1. The last 4 columns in the Table are the component heat loss

characteristics for the insulation level shown at the head of the column.

For example, (12-10-7) indicates that R12, R10 and R7 insulation was app-

lied to the ceiling, walls and below-grade walls respectively.

The tabulated values of the total heat loss characteristic, together

with the frequency distribution of outdoor temperature data were used

in a modified "bin" method to calculate the total annual heat loss from

the houses. Allowance was made for both solar and internal heat gains

in arriving at an average heatin load on the equipment. The details of

this method have been published.

f

!

EQUIPMENT PERFORMANCE

Heating systems respond to the heating load in different ways. A

fossil fuel furnace delivers heat to the dwelling at essentially a con-

stant rate while it is operating. The heat output is varied by cycling

the burner on and off in response to a thermostat. An electric resis-

tance furnace, with a number of stages of resistance heaters, operates

on and off in response to a space thermostat. The heating capacity of

conventional furnaces, therefore, can be considered to be independent of

the outdoor and indoor conditions.

On the other hand, the heating capacity of an air-to-air heat pump

largely depends on outdoor condition and to a lesser extent on indoor

conditions. As the indoor-outdoor temperature difference increases, the

heating capacity of the heat pump decreases, mainly because less heat

can be extracted from the outdoor air at lower temperatures (Figure

2).The seasonal utilization efficiency of fossil fuel furnaces, unlike

capacity, is dependent on the load. Over a large portion of the heating

season, the capacity of an oil or gas furnace greatly exceeds the load

on the system. This results in short burner l1onl1

periods and long 'loffff

periods, with attendant heat losses up the chimney during the off cycle.

This chimney action increases the heat loss due to infiltration, which

is reflected in a reduced efficiency value for the furnace under low-

load conditions.

Even at full-load conditions, the combustion efficiency of a furnace

is less than 100%. In fact, bonnet efficiency, defined as heat delivered

to the supply air divided by energy content of fuel burned, rarely ex-

ceeds 80%. To account for part-load inefficiency and off-cycle chimney

heat losses, a part-load correction factor is commonly used. Figure 3

shows the part-load correction factor, CF, to be a function of the fur-

nace oversizing in relation to the design heat loss rate.2 For this

study the high efficiency correction factor was employed. The part-load

correction factor is related to the seasonal utilization efficiency

(S.U.E.) as follows:

IIs.

s

S.U.E.

=-

x 100%

F

S.U.E.

=the seasonal utilization efficiency for a combustion

furnace,

%'Is-

s

=full-load or steady-state bonnet efficiency, assumed equal

to 0.8 for both oil and gas furnaces

CF

=part-load correction factor (Figure

3)The seasonal utilization efficiency of an electric resistance furnace

was assumed equal to loo%, which implies that the purchased energy

equalled the heating energy required.

In the case of a heat pump, the

ratio of heating energy delivered to the house to the amount of energy

that was purchased is referred to as the Coefficient of Performance (COP),

and is usually greater than 1, and in most circumstances approaches 2.

The COP is a

function of outdoor temperature, as shown in Figure 2.

The heat pump is also subject to part-load effects, although not to the

same extent as conventional fossil fuel furnaces. When the capacity of

the heat pump exceeded the heating load (i.e., above the balance point),

a correction factor recommended by Bullock and Reedy of Carrier Corpora-

tion3 was applied. Below the balance point the heat pump runs conti-

nuously and the supplementary heaters provide additional heat as required.

In this case part-load effects are non-existent.

DESCRIPTION OF THE VARIOUS HEAT PUMP SYSTEMS

There are basically two types of residential air-source heat pump

systems on the market today. One is the all-electric heat pump which

employs electric resistance heaters for supplementary heating when the

heating load exceeds the capacity of the heat pump. The other is com-

monly referred to as an "add-onf1

heat pump because it is primarily aimed

at the retrofit market, for application on existing oil and &as furnaces.

This add-on type does not have any supplementary electric resistance

heaters.

A l l - E l e c t r i c I-leat Pump

The system l a y o u t o f an a l l - e l e c t r i c h e a t pump i s i l l u s t r a t e d i n F i g u r e 4. The h e a t pump shown i s r e f e r r e d t o a s a s p l i t system, because t h e u n i t c o n s i s t s o f an outdoor and an i n d o o r s e c t i o n . The outdoor s e c t i o n c o n t a i n s t h e p r i n c i p l e components o f t h e h e a t pump, i n c l u d i n g t h e motor-compressor, outdoor h e a t exchanger, f a n , and r e v e r s i n g v a l v e . The i n d o o r s e c t i o n , which i s r e l a t i v e l y compact compared t o conventional f u r n a c e s , c o n t a i n s t h e i n d o o r h e a t exchanger, a i r c i r c u l a t i n g f a n and e l e c t r i c r e s i s t a n c e h e a t e r s . Both t h e i n d o o r and outdoor h e a t exchangers a r e equipped w i t h expansion v a l v e s , t o c o n t r o l t h e flow o f t h e l i q u i d r e - f r i g e r a n t , one on t h e h e a t i n g c y c l e , t h e o t h e r on t h e c o o l i n g c y c l e . The modes o f o p e r a t i o n a r e shown i n F i g u r e 4.

"Add-On" Heat Pumr,

I n many ways, t h e add-on h e a t pump i s s i m i l a r t o an a l l - e l e c t r i c system (Figure 5 ) . Both have t h e same h e a t pump components; t h e main d i f f e r e n c e s a r e t h e l o c a t i o n o f t h e i n d o o r h e a t exchanger, and t h e o i l f u r n a c e ( i l l u s t r a t e d h e r e ) which s u p p l i e s supplementary h e a t i n g below t h e b a l a n c e p o i n t .

The add-on h e a t exchanger i s l o c a t e d above t h e f u r n a c e i n t h e

supply a i r plenum. With t h i s arrangement, t h e h e a t pump and f u r n a c e can- n o t o p e r a t e s i m u l t a n e o u s l y a s i n t h e a l l - e l e c t r i c system. T h i s i s t o a v o i d abnormally h i g h p r e s s u r e s i n t h e h e a t pump condenser caused by t h e h i g h t e m p e r a t u r e o f t h e a i r l e a v i n g t h e f u r n a c e h e a t exchanger. Two t y p e s o f add-on systems a r e commercially a v a i l a b l e a s d e s c r i b e d i n F i g u r e 5. One a l l o w s h e a t pump o p e r a t i o n below t h e b a l a n c e p o i n t , whereas t h e o t h e r s h u t s o f f and t h e f u r n a c e p r o v i d e s a l l t h e h e a t i n g a t outdoor t e m p e r a t u r e s below t h e b a l a n c e p o i n t . The add-on h e a t pump c o n s i d e r e d i n t h i s s t u d y was of t h e l a t t e r t y p e .

The concept of combining two f u e l t y p e s i n one h e a t i n g system h a s a d v a n t a g e s , p a r t i c u l a r l y i f t h e two f u e l s a r e o i l and e l e c t r i c i t y . In t h e c a s e of a h e a t pump - o i l f u r n a c e combination, t h e e l e c t r i c u t i l i t y l o a d i s reduced c o n s i d e r a b l y d u r i n g t h e c o l d weather compared t o a11 a l l - c l e c t r i c h c a t pump. Thc compressor and f m ~ s J c m i ~ ~ ~ d r c l i l t i v e l y 1 i t t l c

powcr a t low outdoor tcml)cr:lrll rcs, i i S i l l ~ s t r;~tcll i 11 I: i !!~lrc~ 2

Cayac i t y

(I'owcr = -

COP

) 'The supplementary energy i s o b t a i n c d from t h c o i lt a n k , t h e r e b y reducing t h e demand on t h e e l e c t r i c u t i l i t y d u r i n g t h e c o l d e s t weather when t h e t o t a l demand f o r e l e c t r i c i t y i s a t i t s maximum. In f a c t , t h e load f a c t o r on t h e e l e c t r i c power system i s s u b s t a n t i a l l y improved, w i t h t h e r e l a t i v e l y f l a t power demand o v e r t h e e n t i r e outdoor t e m p e r a t u r e range. More i m p o r t a n t l y , however, t h i s combination u s e s l e s s o i l t h a n an o i l f u r n a c e o p e r a t i n g a l o n e . Energy d e r i v e d from hydro, uranium o r c o a l i s used i n p l a c e o f o i l , t h u s c o n t r i b u t i n g t o t h e n a t i o n a l g o a l o f becoming s e l f s u f f i c i e n t i n o i l .

' l H ~ b r i d l l Heat Pumr,

The c u r r e n t "add-on" systems do n o t t a k e f u l l advantage o f t h e h e a t pump. The I1hybridl1 system i l l u s t r a t e d i n F i g u r e 6 u s e s t h e h e a t pump

system t o i t s f u l l e s t e x t e n t . By l o c a t i n g t h e h e a t exchanger on t h e up- stream s i d e of t h e f u r n a c e , t h e h e a t pump can o p e r a t e c o n t i n u o u s l y below t h e b a l a n c e p o i n t . No complicated c o n t r o l s a r e r e q u i r e d t o c y c l e t h e compressor and f u r n a c e on and o f f . The f l h y b r i d l l i s a f u r n a c e - h e a t pump package designed t o o p e r a t e t o g e t h e r . S p e c i a l c o n s i d e r a t i o n s a r e g i v e n t o t h e d i f f e r e n t a i r flow r e q u i r e m e n t s o f t h e h e a t pump and f u r n a c e , and t o p o s s i b l e c o r r o s i o n o f t h e f u r n a c e h e a t exchanger brought on by summer c o o l i n g o p e r a t i o n . Such a h e a t pum f u e l f u r n a c e combination i s c u r - r e n t l y under development i n Canada.

{

-COMPARISON OF HEATING ENERGY COSTS

One of t h e most important f a c t o r s i n t h e c h o i c e of a h e a t i n g system

i s t h e a v a i l a b i l i t y and c o s t o f t h e a l t e r n a t i v e f u e l s . I n Canada, t h e r e a r e c o n s i d e r a b l e d i f f e r e n c e s i n t h e p r i c e s o f e l e c t r i c i t y and n a t u r a l g a s from r e g i o n t o r e g i o n . On t h e o t h e r hand, t h e p r i c e o f h e a t i n g o i l a s p e r c e i v e d by t h e consumer, i s r e l a t i v e l y uniform because of t h e f e d e r a l o i l - p r i c i n g p o l i c y . Table 2 shows t h e energy c o s t s employed i n t h i s s t u d y .

The c o s t o f h e a t i n g energy f o r b o t h h e a t pump and c o n v e n t i o n a l h e a t - i n g systems i s summarized i n F i g u r e s 7 t o 15 f o r t h e v a r i o u s c i t i e s . I n a l l c a s e s , t h e annual energy c o s t i n 1979 i s p l o t t e d a g a i n s t t h e h e a t i n g energy r e q u i r e d by t h e c o n v e n t i o n a l system. I n t h e c a s e o f new cons- t r u c t i o n , one must e s t i m a t e t h e h e a t i n g energy r e q u i r e d b e f o r e t h e s e graphs can be used. For r e t r o f i t o r a d d i t i o n t o an e x i s t i n g system, how- e v e r , t h e owner's p a s t u t i l i t y o r o i l h e a t i n g b i l l s w i l l p r o v i d e t h e i n - f o r m a t i o n r e q u i r e d t o e s t i m a t e t h e s a v i n g s with a p a r t i c u l a r h e a t pump system. I n Edmonton, where h e a t i n g o i l

i s

n o t used, a comparison has n o t been drawn between a h e a t pump system and o i l h e a t i n g . The l i m i t e d u s e o r u n a v a i l a b i l i t y of n a t u r a l gas i n t h e Maritimes has n o t allowed a comparison between t h e add-on o r h y b r i d systems and n a t u r a l g a s h e a t i n g . CAPITAL AND MAINTENANCE COSTSThe remaining components of t h e t o t a l c o s t which must be c o n s i d e r e d a r e t h e c o s t of i n s t a l l i n g t h e equipment and t h e a n t i c i p a t e d maintenance c o s t s . Table 3 summarizes t h e s e c o s t s f o r t h e systems under c o n s i d e r a t i o n Systems 1, 2 and 3 a r e t h e c o n v e n t i o n a l e l e c t r i c , o i l and g a s f u r n a c e s r e s p e c t i v e l y . System 4 i s t h e a l l - e l e c t r i c h e a t pump i l l u s t r a t e d i n Figure 4 . Systems 5a and 5b, t h e add-on h e a t pumps, a r e i l l u s t r a t e d i n Figure 5. System 5a i s an add-on t o an e x i s t i n g o i l f u r n a c e whereas 5b i s an add-on t o an e x i s t i n g e l e c t r i c f u r n a c e . Systems 6 and 7 a r e t h e g a s - and o i l - h y b r i d h e a t pumps i l l u s t r a t e d i n F i g u r e 6 . The l a s t system l i s t e d i n Table 3 i s a c o n v e n t i o n a l c e n t r a l a i r c o n d i t i o n e r . The l a y - o u t o f System 8 i s i d e n t i c a l t o t h a t o f t h e add-on i n F i g u r e 5 b u t i t s o p e r a t i o n i s r e s t r i c t e d t o c o o l i n g d u t y o n l y . The l a s t column o f Table

3 l i s t s t h e P r e s e n t Worth o f t h e C a p i t a l and Maintenance c o s t s ' a s ex- p l a i n e d i n t h e n e x t s e c t i o n . The c o s t s shown h e r e a r e r e p r e s e n t a t i v e of

t h o s e p r e v a i l i n g i n t h e Ottawa a r e a . The i n s t a l l e d c o s t may v a r y from one r e g i o n t o a n o t h e r and should be i n v e s t i g a t e d by t h e p r o s p e c t i v e owner.

The chimney c o s t i s i n c l u d e d f o r t h e g a s f u r n a c e . In t h e c a s e o f t h e o i l f u r n a c e b o t h t h e chimney and o i l t a n k a r e i n c l u d e d . These c o s t s would t h e n o n l y a p p l y i n t h e c a s e o f new c o n s t r u c t i o n .

-

For t h e e l e c t r i c f u r n a c e and t h e a l l - e l e c t r i c h e a t pump t h e i n c r e m e n t a l c o s t o f a 200 As e r v i c e h a s been t a k e n i n t o account f o r new c o n s t r u c t i o n o n l y . The h y b r i d systems, a l t h o u g h n o t commercially a v a i l a b l e a t t h i s t i m e , a r e i n t e n d e d f o r replacement o f e x i s t i n g o i l o r g a s f u r n a c e s , o r f o r new c o n s t r u c t i o n . For t h i s r e a s o n , t h e c a p i t a l c o s t i n c l u d e s t h e c o s t o f h e a t pump and f u r n a c e components ( i n c l u d i n g chimney and/or f u e l t a n k ) a s w e l l a s t h e maintenance c o s t s f o r t h e complete system. The add-on h e a t pump i s i n t e n d e d f o r

a d d i t i o n t o an e x i s t i n g f u r n a c e (both o i l (5a) and e l e c t r i c ( 5 b ) ) , and t h e r e f o r e r e f l e c t s o n l y t h e c o s t o f t h e h e a t pump. With t h e h y b r i d and add-on systems, t h e r e i s no requirement f o r a 200 A e l e c t r i c a l s e r v i c e

( i . e . , no r e s i s t a n c e h e a t e r s ) and t h u s t h e c a p i t a l c o s t i s lower t h a n f o r t h e a l l - e l e c t r i c h e a t pump. A c e n t r a l a i r - c o n d i t i o n e r i s i n c l u d e d f o r t h e c a s e where a combined h e a t i n g - c o o l i n g system i s d e s i r e d by t h e home- owner. In t h i s s i t u a t i o n , t h e c a p i t a l c o s t f o r t h e a i r - c o n d i t i o n e r must be added t o t h e c a p i t a l c o s t o f t h e c o n v e n t i o n a l h e a t i n g system.

TOTAL LIFE-CYCLE HEATING COST

The p r e s e n t worth o r t h e t o t a l l i f e - c y c l e c o s t o f h e a t i n g i s t h e amount o f money t h a t a consumer would have t o i n v e s t t o d a y , a t some i n t e r e s t r a t e , t o pay f o r t h e equipment, maintenance and energy r e q u i r e d by t h e system o v e r t h e s e r v i c e l i f e . T o t a l l i f e - c y c l e c o s t i n 1979 d o l l a r s = PWF (cost o f h e a t i n g energy E i n 1979) + PWFM

-

( c o s t of maintenance i n 1979) + i n s t a l l e d c o s t o f h e a t i n g system where PWFE = p r e s e n t worth f a c t o r f o r energy c o s tPWFM = p r e s e n t worth f a c t o r f o r maintenance c o s t n 1 + e 1 +e where PWF = [(-)

-

111

[(=)- 11

1+1 e = e s c a l a t i o n r a t e on f u e l o r maintenance i = i n t e r e s t r a t eFor t h i s s t u d y , it h a s been assumed t h a t t h e c o s t o f e l e c t r i c i t y and n a t u r a l g a s w i l l e s c a l a t e a t a r a t e o f 2% above i n f l a t i o n on o t h e r goods and s e r v i c e s . I n t h e c a s e o f h e a t i n g o i l , t h e e s c a l a t i o n r a t e h a s been assumed t o be 4% above t h e g e n e r a l r a t e o f i n f l a t i o n . T h i s s c e n a r i o was assumed t o a p p l y o v e r t h e n e x t 1 2 y e a r s , which was assumed a s t h e u s e - f u l s e r v i c e l i f e o f a h e a t pump. A r e a l i n t e r e s t r a t e of 2% was con- s i d e r e d t o be r e p r e s e n t a t i v e o f t h e r a t e o f r e t u r n a v a i l a b l e t o t h e

average consumer (i.e., the cost of residential mortgages) and hence was

employed to calculate the following present worth factors:

PWFoil

=14

PWF

--

PWFelect

=12

gas

PWFM

=10.75

.The total life-cycle costs are summarized in Figure 16 for new

construction and in Figure 17 for the case of retrofit or replacement

of an existing system. In Figure 17 comparison should be made between

competing systems (i.e., 1 and 5b; 2 and 5a;

2and 7).

DISCUSSION OF RESULTS

New Construction

Space heating with natural gas is by far the most economical choice

in Saskatoon and Edmonton, and for this reason these cities have not been

included in Figure 16. In other regions of Canada where natural gas is

generally available (i.e., Vancouver, Windsor, Toronto, Ottawa), it is

the lowest cost choice for space heating today in new construction. For

areas within these regions where natural gas is not available, the

most economical choice would appear to be electric resistance (electric

furnace) or an all-electric heat pump, depending on the amount of annual

purchased energy. The oil hybrid (System 7) is competitive with the

electric heat pump, in spite of its relatively high capital cost.

In Montreal, electric resistance heating offers the lowest cost

in new construction, with the all-electric heat pump competitive at high

levels of purchased energy. Natural gas space heating is not competitive

in this region owing to its high cost compared to that of electricity.

In Fredericton, all systems are competitive (with the exception of

natural gas) over a wide range of purchased energy. The electric furnace

and oil furnace are the economic choices at low consumption levels,

whereas at the other end of the scale, the heat pump systems (4 and 7)

appear to be the best choices.

In Halifax, the high cost of electricity eliminates the electric

heating systems as desirable choices. Ilere an oil furnace offers the

lowest cost to the consumer.

This discussion has dealt with the selection of the most cost ef-

fective heating systems. Where the homeowner wants a combination heating-

cooling system, the cost of a central air-conditioner (System 8)

must be

added to the conventional furnace systems. This would make the electric

heat pump the most cost effective heating-cooling system in Vancouver,

followed closely by the gas hybrid (System 6).

In Windsor, Toronto, and

Ottawa, the gas hybrid would be the most cost effective heating-cooling

system. Where natural gas is not available, an electric heat pump would

be the economic choice.

In Montreal, the electric heat pump would appcar to be the most

cost effective heating-cooling system. In Fredericton, the homeowner

could choose between the oil-hybrid or electric heat pump, because of

the competitive nature of the two systems in this region. If air condi-

tioning were desired in Halifax, the oil hybrid would be the economic

choice followed closely by the combination of an oil furnace and a

central air-conditioner.

REPLACEMENT OR RETROFIT OF

AN

EXISTING HEATING SYSTEM

It was emphasized that natural gas, where available (with the ex-

ception of ~ontreal), was the most cost effective way of providing space

heating in new construction. This situation will probably apply in the

case where an existing oil furnace needs replacement. Here the installed

cost of a new oil furnace must be compared with the installed cost of a

gas furnace and the cost of upgrading the chimney. The installed costs,

together with the energy and maintenance costs are used in a calculation

similar to that presented in the previous section.

One other situation exists where an oil furnace has a number of

years of useful service life remaining. A conversion gas burner can be

fitted with the idea of reducing energy costs. The energy cost saving

must be compared with the cost of the conversion burner and the cost of up-

grading the chimney. Depending on individual circumstances, a gas con-

version may be cost effective.

The following sections will examine the replacement or retrofitting

of existing oil and electric furnaces where natural gas is unavailable.

REPLACEMENT OR RETROFIT OF AN OIL FURNACE

Reu

1

acement

I-lomeowners

faced with the need to replace an oil furnace and who

are unable to obtain natural gas must make a choice between purchasing

a new oil furnace or switching to an electric heating system. Conversion

to an electric furnace requires an increase in the electrical service to

200 A. This involves an expenditure of approximately $700. This in it-

self makes the conversion to an electric furnace or all-electric heat

pump uneconomical on the basis of the assumptions used in the present

analysis.

The homeowner could install an oil hybrid such as System 7, or an

oil furnace together with electric resistance duct heaters up to the

limit of the existing electrical service. In this study only the former

system has been studied. The results are shown in Figure 17.

System 7 is competitive if not decisively more economical than oil

furnace heating in all the cities shown in Figure 17, with the exception

of Halifax. This conclusion is based on heating energy savings alone

and does not involve a capital allowance for air conditioning.

R e t r o f i t

Iiomeowners who have an o i l f u r n a c e w i t h a number of y e a r s of u s e f u l s e r v i c e l i f e remaining ( a t l e a s t 12) might look t o an add-on heat pump t o reduce o p e r a t i n g c o s t s o r provide summer a i r c o n d i t i o n i n g . In t h i s c a s e t h e c o s t of owning and o p e r a t i n g an add-on h e a t pump (System 5a) i s compared with t h e c o s t o f c o n t i n u i n g t o h e a t with o i l over t h e next 12 y e a r s . The r e s u l t s a r e p l o t t e d i n Figure 17 f o r a l l c i t i e s except H a l i f a x . With t h e e x c e p t i o n of Vancouver, t h e r e s u l t s i n d i c a t e t h a t t h e homeowner must be prepared t o p l a c e some v a l u e on having c e n t r a l a i r c o n d i t i o n i n g

i n o r d e r t o j u s t i f y t h e r e t r o f i t t i n g o f an o i l f u r n a c e with an add-on h e a t pump. I t should be emphasized t h a t t h e economics o f an add-on h e a t pump t h a t o p e r a t e s below t h e balance p o i n t would be between t h a t of t h e o i l - h y b r i d and t h e add-on systems c o n s i d e r e d h e r e .

R e t r o f i t o f an E l e c t r i c Furnace

One o t h e r p o s s i b l e r e t r o f i t s i t u a t i o n would be t h e a d d i t i o n o f a h e a t pump (System 5b) t o an e x i s t i n g e l e c t r i c f u r n a c e . The t o t a l c o s t of System 5b i s compared with t h a t of System 1 ( e l e c t r i c f u r n a c e ) i n Figure 17. I t

i s

e v i d e n t t h a t t h e a d d i t i o n o f a h e a t pump t o an e l e c t r i c furnace can be economically j u s t i f i e d i n some c a s e s without making a c a p i t a l allowance f o r a i r c o n d i t i o n i n g . The d e c i s i o n would depend on t h e amount o f energy c u r r e n t l y used by t h e e l e c t r i c f u r n a c e . The "break-even" annual consumption i s seen t o v a r y with l o c a l e . In Vancouver, Windsor, Toronto and F r e d e r i c t o n , circumstances a r e such t h a t an e l e c t r i c h e a t pump could be added t o an e l e c t r i c f u r n a c e and produce s a v i n g s f o r t h e homeowner over t h e s e r v i c e l i f e of t h e h e a t pump. T h i s conversion would not appear t o be a t t r a c t i v e i n Ottawa and Montreal a t t h i s time.In H a l i f a x , r e t r o f i t t i n g o f an e l e c t r i c f u r n a c e with a h e a t pump w i l l almost always r e s u l t i n a s a v i n g t o t h e owner. The p l o t f o r H a l i f a x shows t h e e f f e c t of a 3-ton h e a t pump (System 5b (3T)) on t h e t o t a l l i f e - c y c l e c o s t s . Even though t h e l a r g e r h e a t pump i s more expensive ( - $ b o o ) l e s s r e s i s t a n c e h e a t i n g i s r e q u i r e d and t h e energy s a v i n g s more t h a n o f f s e t t h e a d d i t i o n a l c a p i t a l c o s t . T h i s advantage w i l l o n l y be apparent i n c l i m a t i c r e g i o n s f a v o u r a b l e t o a i r - s o u r c e h e a t pump o p e r a t i o n and where e l e c t r i c i t y c o s t s a r e h i g h . In Ottawa, f o r example, a l a r g e r h e a t pump does not r e s u l t i n a lower t o t a l l i f e - c y c l e c o s t , because t h e incremental energy c o s t saving does not exceed t h e a d d i t i o n a l c a p i t a l c o s t .

IMPACT OF ASSUMPTIONS ON RESULTS

A number of assumptions, such a s f u t u r e energy p r i c e s and s e r v i c e l i f e of h e a t pumps, had t o be made i n o r d e r t o c a r r y o u t an a n a l y s i s o f t h e r e l a t i v e economics o f a i r - t o - a i r h e a t pump systems and conventional h e a t i n g systems. The a c t u a l t r e n d i n energy p r i c e s w i l l obviously have an e f f e c t on t h e r e s u l t s p r e s e n t e d h e r e , a s w i l l t h e e s t a b l i s h m e n t o f a p o l i c y favouring t h e u s e of some energy forms o v e r o t h e r s , such a s t h e use of n a t u r a l gas and e l e c t r i c i t y t o reduce consumption o f o i l .

T h i s assumption i s probably u n r e a l i s t i c a s t h e e s c a l a t i o n r a t e w i l l depend on t h e f u e l used t o g e n e r a t e e l e c t r i c i t y ( i - c . , n u c l e a r , c o a l , hydro o r g a s ) and on o t h e r f a c t o r s .

I f n a t u r a l gas p r i c e s i n c r e a s e a t a r a t e g r e a t e r t h a n t h a t of e l e c t r i c i t y , t h e economics o f e l e c t r i c systems w i l l improve r e l a t i v e t o

t h a t o f t h e g a s f u r n a c e . The o p p o s i t e t r e n d would i n c r e a s e t h e c u r r e n t

c o s t gap between t h e e l e c t r i c and n a t u r a l gas h e a t i n g systems.

A h i g h e r e s c a l a t i o n r a t e f o r e l e c t r i c t y would improve t h e economics

o f t h e a l l - e l e c t r i c h e a t pump compared t o r e s i s t a n c e h e a t i n g , with t h e r e s u l t t h a t t h e e l e c t r i c h e a t pump would become t h e p r e f e r r e d system o f t h e two, without a c a p i t a l allowance f o r a i r c o n d i t i o n i n g .

T h i s s t u d y used t h e performance c h a r a c t e r i s t i c s o f h e a t pumps t h a t

have been on t h e market f o r s e v e r a l y e a r s . Newer, more e f f i c i e n t u n i t s

a r e a p p e a r i n g on t h e market, and depending on t h e a d d i t i o n a l c o s t , i f any, t h e y would i n d i c a t e a lower t o t a l l i f e - c y c l e c o s t f o r t h e h e a t pump systems.

CONCLUSIONS

Based on t h e assumptions made i n t h i s s t u d y , a n a t u r a l g a s f u r n a c e a p p e a r s t o be t h e most economical h e a t i n g system f o r new c o n s t r u c t i o n and f o r replacement o f o i l f u r n a c e s , where n a t u r a l g a s i s a v a i l a b l e .

I f a homeowner wants a combined h e a t i n g - c o o l i n g system, one o f t h e h e a t

pump systems could be t h e b e s t c h o i c e .

Where n a t u r a l g a s i s n o t a v a i l a b l e , a n e l e c t r i c f u r n a c e o r a h e a t

pump system, depending on t h e annual energy consumption, would be p r e - f e r r e d o v e r an o i l f u r n a c e i n new c o n s t r u c t i o n f o r a l l r e g i o n s except H a l i f a x , where t h e most economical h e a t i n g system a p p e a r s t o be t h e o i l f u r n a c e .

In r e g i o n s where n a t u r a l g a s i s u n a v a i l a b l e and an e x i s t i n g o i l f u r n a c e needs replacement, a o i l - h y b r i d h e a t pump can be j u s t i f i e d i n

many i n s t a n c e s without any c a p i t a l allowance f o r a i r c o n d i t i o n i n g . I f

t h e o i l f u r n a c e s t i l l h a s a number o f y e a r s o f s e r v i c e l i f e remaining, an a i r - c o n d i t i o n i n g c a p i t a l allowance i s r e q u i r e d t o j u s t i f y an add-on

h e a t pump of t h e t y p e analyzed f o r a l l c i t i e s e x c e p t Vancouver. I n most

c a s e s , it i s more economical f o r t h e homeowner t o c o n t i n u e u s i n g t h e

o i l f u r a n c e . Add-on h e a t pumps t h a t a l l o w o p e r a t i o n below t h e b a l a n c e

p o i n t were n o t c o n s i d e r e d i n t h i s s t u d y . In many c a s e s t h i s t y p e c o u l d

be an economic r e t r o f i t f o r t h e homeowner, without a c a p i t a l allowance f o r a i r c o n d i t i o n i n g .

I t should be emphasized t h a t t h e c a p i t a l c o s t s employed i n t h i s s t u d y may v a r y c o n s i d e r a b l y w i t h l o c a l e . The homeowner should i n v e s t i - g a t e v a r i a t i o n s i n h i s own a r e a and make a p p r o p r i a t e a d j u s t m e n t s t o t h e t o t a l l i f e - c y c l e c o s t s p r e s e n t e d .

The r e s u l t s p r e s e n t e d should be a p p l i c a b l e t o t h e r e g i o n s i n which

should be representative of heat pump performance in southcrn Ontario;

Ottawa for areas in eastern Ontario; Montreal for southern Quebec;

Fredericton and Halifax for the Maritime region. This of course assumes

that the electrical energy prices are uniform throughout the region.

REFERENCES

1. Cane, R.L.D. A llmodified'l

bin method for estimating annual heating

energy requirements of residential air source heat pumps. ASHRAE

Journal, Vol. 21, No. 9, Sept. 1979, pp 60-63.

2. Borg-Warner Corp., York Division. Seasonal performance factor and

operating cost calculation for heating. Application Data, Form

515.21-AD3-C.

3. Bullock, C.E. and Reedy, W.R. Heat pump cyclic performance and its

influence on seasonal operation. Proceedings of the 3rd Annual Heat

Pump Technology Conference, O.S.U., Stillwater, Oklahoma, April 10-11,

1978.

4.

Development of an innovative hybrid heat pump. DSS Contract No.

OSX78-00058 between Canadian Chromalox Co. Ltd. and the Division of

Building Research, National Research Council of Canada.

; (dux (..r LL~-~J.L.;

,/'

r i l s _ w & O.

-, & 3 L TABLE 1 HEAT L O S S C H A R A C T E R I S T I C S U S E D I N S T U D YI

D E S I G N HEAT L O S S C H A R A C T E R I S T I C , W A T T S I ° C 1 2 3 4 COMPONENT'

(12-10-71' (20-12-81* 3 0 - 1 2 - 1 0 (30-20-101'-

CEILING 1 0 6 5 1 35 25 25 WALL (A. G. ) 1 1 7 6 5 4 8 4 8 3 3WALL AND SLAB (B.G. 2 0 9 1 5 6 5 4 4 7 '36

WINDOW (DOUBLE GLAZED) 2 0 6 2 6 2 6 2 6 2

DOORS 4 9 9 9 9

0.5 7 b

INFILTRATION (0.75 A.C. lh) 453"

*

1 1 4 1 1 4 1 1 4 1 1 4TOTAL HEAT LOSS CHARACTER1 ST1 C, Z" 5

WATTI°C 35 7 3 2 2 305 2 79

Y BRACKETED Q U A N T I T Y REFERS T O N O M I N A L I N S U L A T I O N ( I N BRITISH U N I T S ) A P P L I E D T O C E I L I N G , A B O V E GRADE WALLS A N D BELOW GRADE W A L L S , R E S P E C T I V E L Y . I N CASES 1 ,

2 , A N D 3 B A S E M E N T I N S U L A T I O N A P P L I E D T O T W O FEET BELOW G R A D E ; I N CASE 4 B A S E M E N T .WALL I N S U L A T I O N APPLIED T O F L O O R L E V E L . * * V O L U M E ( m 3 ) I N C L U D I N G B A S E M E N T i> L o ' ,

.

~ b ' -4:'(?

'

TABLE 2 R E S I D E N T I A L FUEL A N D E L E C T R I C I T Y C O S T S ( E M R - J A N . 7 9 ) L O C A T l ON E L E C T R I C I T Y N A T U R A L G A S O I L $ l k ~ . h ( $ I G J ) t l ( S I G J ) ~ * l g a l ~ ( $ I G J ) ~ ~ ~ V A N C O U V E R 2 . 5 0 ( 6 . 9 4 ) 3 0 . 4 ( 2 . 8 8 ) 5 8 . 9 ( 3 . 3 4 ) EDMONTON 2. 3 0 ( 6 . 3 9 ) 2 0 . 2 ( 1 . 9 1 1 ( N . A . - S A S K A T O O N 2 . 5 0 ( 6 . 9 4 ) 2 7 . 4 ( 2 . 6 0 ) 5 8 . 9 ( 3 . 3 4 ) W I N D S O R 2 . 6 0 ( 7 . 2 2 ) 3 6 . 5 ( 3 . 4 6 ) 6 0 . 6 ( 3 . 4 4 ) TORONTO 2 . 6 0 ( 7 . 2 2 ) 3 6 . 5 ( 3 . 4 6 ) 6 0 . 6 ( 3 . 4 4 ) OTTAWA 2 . 5 5 ( 7 . 0 8 ) 3 6 . 5 ( 3 . 4 6 1 62. 2 ( 3 . 5 3 ) M O N T R E A L 1 . 9 0 (5. 2 8 ) 4 3 . 4 ( 4 . 11) 6 0 . 2 ( 3 . 4 2 ) F R E D E R I C T O N 2 . 6 5 ( 7 . 3 6 ) 5 0 . 0 ( 4 . 7 4 ) 6 1 . 2 ( 3 . 4 7 ) H A L l F A X 4. 15 ( 1 1 . 5 3 ) ( N . A.-

6 0 . 8 ( 3 . 4 5 )T A B L E 3 R E P R E S E N T A T I V E S Y S T E M C O S T S , 1 9 7 9 $ P R E S E N T W O R T H ( ' ) M A l N T E N A N C E OF C O S T S ( C A P I T A L C A P I T A L C O S T , A N D M A I N T E N A N C E l , N 0. S Y S T E M C O S T $ / y e a r $ 1 E L E C T R l C F U R N A C E 1 0 0 0 2 0 1 2 2 0

-

2 O I L F U R N A C E ( 2 ) 1 5 0 0 4 5 1 9 8 0 3 G A S F U R N A C E ( 3 ) 1 0 0 0 3 5 1 3 8 0 4 E L E C T R I C H E A T P U M P 2 7 0 0 5 0 3 2 4 0 ( 2 T O N ) 5a, b A D D - O N H E A T P U M P 2 0 0 0 5 0 2 5 4 0 ( 2 T O N ) 6 H Y B R I D ( G A S ) H E A T 2 7 0 0 6 0 3 3 4 0 P U M P ( 2 T O N ) 7 H Y B R I D ( O I L ) H E A T 3 0 0 0 6 0 3 6 4 0 P U M P ( 2 T O N ) 8 C E N T R A L A I R - 1 2 0 0 1 2 0 0 C O N D I T I O N E R ( 2 T O N ) ( 1 ) P W F M A I N T E N A N C E = 1 0 . 7 5 ( 2 ) I N C L U D E S C H I M N E Y A N D T A N K ( 3 ) I N C L U D E S C H I M N E Y1 1 1 , 1 1 1 1

...*

A B R I T I S H C O L U M B I A ( V A N C O U V E R ).

::.

: :-

---

P R A I R I E S ( S A S K A T O O N ) : :-

-.-.

i : O N T A R 1 0 - Q U E B E C ( O T T A W A )-

.

. .

-

.

-

* ...-..

M A R l T l M E S ( H A L I F A X ).

.

.

.

-

.

.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 3 0 - 2 5 - 2 0 - 1 5 - 1 0 - 5 0 5 10 15 20 25 30 D R Y B U L B T E M P E R A T U R E , " CFigure 1. Frequency distribution of dry bulb temperatures in various Canadian regions (based on period 1957-1966)

T E M P E R A T U R E O F A I R E N T E R I N G O U T D O O R U N I T , " C

Figure 2. Perforinance c h a r a c t e r i s t i c s o f 2-ton (7.0

kW)

h e a t pumpFURNACE OUTPUT

-

HEAT LOSS 1 . 1 % OVERFIRING =(

HEAT LOSSO V E R F I R I N G , %

Figure 3. P a r t - l o a d c o r r e c t i o n f a c t o r ,

CF,

f o r f o s s i l f u e l f u r n a c e sI I

AIR ( 35OC )I

-

ICOLDER AIR COLD AIR

1

ELECTRICI+

I

OUT I -5'C 1 IN ( O°C ) RESISTANCE

COMPRESSOR

COOL RETURN

HEAT EXCHANGER AIR (21°C )

I 1 I I I U 1

HEAT PUMP HEAT EXCHANGER

O U T D O O R S E C T I O N I N D O O R S E C T I O N SYSTEM O P E R A T l O N

1 . A B O V E THE B A L A N C E P O I N T THE H E A T PUMP C Y C L E S O N A N D O F F T O S A T I S F Y FIRST S T A G E OF I N D O O R T H E R M O S T A T

2 . I F H E A T PUMP U N A B L E T O S A T I S F Y D E M A N D S E C O N D S T A G E O F T H E R M O S T A T B R I N G S O N ELECTRIC R E S I S T A N C E HEATERS I N S E Q U E N C E U N T I L S E C O N D S T A G E I S S A T I S F I E D ( N O R M A L L Y \ T O 1.5OC D I F F E R E N T I A L BETWEEN FIRST A N D S E C O N D S T A G E )

3 . O U T D O O R T H E R M O S T A T ( S ) M A Y BE USED T O L I M I T A M O U N T OF R E S I S T A N C E H E A T A C T I V A T E D BELOW A N Y P A R T I C U L A R O U T D O O R TEMPERATURE

T w r ~ ~ ~

>

T~~~~~ POINT ADD-ON HEAT PUMPO U T D O O R S E C T I O N I N D O O R S E C T I O N

SYSTEM O P E R A T I O N ( A B O V E B A L A N C E P O I N T )

I . A B O V E THE B A L A N C E P O I N T THE A D D - O N H E A T PUMP C Y C L E S O N A N D O F F T O S A T I S F Y D E M A N D ( I D E N T I C A L T O ELECTRIC H E A T P U M P )

Figure 5. Add-on heat pump T

O U T D O O R S E C T I O N I N D O O R S E C T I O N S Y S T E M OPERA'TION ( B E L O W B A L A N C E POINT)

1 . M O S T A D D - O N H E A T PUMP SYSTEMS E M P L O Y A N O U T D O O R THERMOSTAT W H I C H IS SET T O SHUT THE U N I T D O W N A T THE B A L A N C E P O I N T

2 . OTHER A D D - O N H E A T PUMPS W I L L A L L O W O P E R A T I O N BELOW B A L A N C E P O I N T BY USE OF T W O S T A G E THERMOSTAT A N D OTHER C O N T R O L S . F U R N A C E A N D H E A T PUMP C A N N O T OPERATE S I M U L T A N E O U S L Y A N D H E A T PUMP I S N O R M A L L Y L O C K E D O U T BELOW -12OC T O A V O I D SHORT C Y C L I N G OF COMPRESSOR

WARM

-

- 1 I I7

OUTDOBR > 'MLANCE POINT

COLDER FURNACE BLWER ( ON ) SYSTEM O P E R A T I O N ( A B O V E B A L A N C E P O I N T ) O P E R A T I O N I D E N T I C A L T O A D D - O N H E A T PUMP A N D ELECTRIC H E A T PUMP SUPPLY AIR T T

OUTDOOR 6 BALANCE POINT

COLDER AIR OUT I FURNACE BLrnER ( ON ) SYSTEM O P E R A T I O N (BELOW B A L A N C E P O I N T ) H E A T PUMP OPERATES C O N T I N U O U S L Y , W H I L E F U R N A C E OPERATES U N D E R C O N T R O L O F S E C O N D S T A G E O F THERMOSTAT ( I D E N T I C A L T O O P E R A T I O N OF ELECTRIC H E A T PUMP) F i g u r e 6. Hybrid h e a t pump

O I L F U R N A C E ELECTRIC

/

/

A D D - O N ( 0 1 1 ) HEAT PUMPw*:

,'....'"'

,.:.**wm.

..**.

A L L - E L E C T R I C A N D H Y B R I D ( O I L OR G A S ) HEAT PUMP A C E o!

5 10I

15 2 0I

2 5I

I

I

I

L I I I I I I I I I I I 3 0 1 3 5 40 ( k W . h / 1 0 3 ) I 0 100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0 700 8 0 0 9 0 0 1 0 0 0 1 1 0 0 1 2 0 0 1 3 0 0 ( G A L ) I I I I I I I I 0 25 5 0 7 5 100 125 150 175 2 0 0 ( M C F ) L A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C E0 0 0

-

- 5 0 0 - - 4 0 0-

* 3 0 0 - 1 I I I I I I I I I I I 1 0 100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0 7 0 0 8 0 0 900 1 0 0 0 1 100 1 2 0 0 ( G A L ) I I I I I I 1 I . o 1 2 5 5 0 75 100 125 150 175 2 0 0 ( M C F ) A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C EA N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C E

ELECTRIC C I I D k I A P C

/

L O I L F U R N A C E HEAT PUMP.

- -, 1 1 1 I I I t I 1 1 I 1 I I I I I I 1 0 12.5 25 37.5 50 62.5 75 87.5 100 112.5 125 137.5 150 162.5 175 187.5 200 212.5 225 ( M C F ) A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C E8 0 0

-

-

E L E C T R I C-

9 7 0 0-

0. h 0--

A D D - O N ( O I L ) 4 Z-

6 0 0-

t V)-

0 0...*"

H Y B R I D ( G A S OR >-"

5 0 0-

OIL1 HEAT PUMP@=

-

I- e-

W I 300-

7:I

Z

0'1 0 5 10 15 2 0 , 2 5 I I I I 1 I I I L I I I I I 0 100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0 7 0 0 8 0 0 900 1 0 0 0 1 100 1 Z O O 1 3 0 0 ( G A L ) t I 1 I I I . I . I I 0 2 5 5 0 7 5 100 125 150 175 200 ( M C F ) A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C E. - -

I 1 I I I I , I I I

0 25 5 0 7 5 100 125 156 175 2 0 0 ( M C F )

H Y B R I D ( O I L ) A L L - E L E C T R I C H E A T P U M P

1

0 5 10 1 5 2 0 2 5 3 0 3 5 40 I k W.

h/1031 0 100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0 7 0 0 8 0 0 900 1000 1 1 0 0 1 2 0 0 ( G A L ) 0 25 5 0 7 5 100 125 150 175 2 0 0 ( M C F ) A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S F U R N A C EELECTRIC

/

FURNACE

O I L / FURNACE / A D D -ON H E A T PU A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I L O R G A S ' F U R N A C E/ 8 0 0

-

z

7 0 0 CI. h 0- d'

A D D - O N ( O I L ) Z-

6 0 0 I- V) 0 0$

5 0 0 w W Z w 4 0 0-

-

I- a W I 5 I I I I I I I I I I 1 I I I 0 100 2 0 0 3 0 0 4 0 0 5 0 0 6 0 0 7 0 0 8 0 0 900 1 0 0 0 1 1 0 0 1 2 0 0 1 3 0 0 ( G A L ) I I I 1 I I I 1 0 25 5 0 75 100 125 150 175 2 0 0 ( M C F ) 1 A N N U A L P U R C H A S E D H E A T I N G E N E R G Y ; E L E C T R I C , O I LOF!

G A S F U R N A C E9 I I I 8

-

OTTAWA 7 6 5 4-

7 SYSTEM-

1 - ELECTRIC F U R N A C E 4 - ALL-ELECTRIC HEAT P U M P 2 - O I L F U R N A C E 6 - G A S - H Y B R I D HEAT P U M P 3 - G A S F U R N A C E 7 - O I L - H Y B R I D HEAT P U M P N O T E : N O C A P I T A L A L L O W A N C E FOR C E N T R A L AIR C O N D I T I O N I N G-

1 G J E Q U I V A L E N T T O : 2 7 7 k W . h (ELECTRIC F U R N A C E ) ; 9 G A L ( O I L F U R N A C E ) ; 1 . 5 M C F ( G A S F U R N A C E ) A N N U A L P U R C H A S E D H E A T I N G E N E R G Y , G J l y rVANCOUVER

~ F ' - - - ' l

OTTAWA 6 5 U I I I T 1 T ! , : I w M L l f AX ,:'r5b(211 RETROFIT----

-

REPLACEMENT-

LL-

10 87 d I , Sb(3TI- /, y,:.'

,,, SYSTEM 1 - ELECTRIC F U R N A C E 5 a - A D D - O N HEAT PUMP T O-1 a 9 - ?.;I ,/'

-

2 - O I L F U R N A C E O I L F U R N A C E I- 6 - #; ' ,'-

3 - G A S F U R N A C E 5 b - A D D - O N HEAT PUMP T O ,? /'p'

ELECTRIC F U R N A C E7

-

/

-

4 - ALL-ELECTRIC HEAT PUMP 7 - O I L - H Y B R I D HEAT PUMP6 - I