Publisher’s version / Version de l'éditeur:

Durability of Building Materials, 5, 2, pp. 111-124, 1987-10

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Frost-durability study on Canadian clay bricks. II. Thermal gradient and

quality of burnt bricks in kilns

Kung, J. H.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=82834344-1893-488b-aa47-f0f3613ddf20 https://publications-cnrc.canada.ca/fra/voir/objet/?id=82834344-1893-488b-aa47-f0f3613ddf20

National Research Conseil national

1

+

4

Council Canada da recherches CanadaS e r Institute for lnstitut de

TH1 Research in recherche en ~ 2 1 d I Construction construction no.

1498

c. 2 BLDG I - -Frost-Durability Study on

Canadian Clay Bricks.

11. Thermal Gradient and

Quality of Burnt Bricks in Kilns

by J.H. Kung

ANALYZE* Reprinted from

Durability of Building Materials Vol. 5, No. 2, October 1987 p. 111 -124

(IRC Paper No. 1498)

NRC

-

C1-I R C

L I B R A R Y

bMAR

8

ir13bB I B L I O T H ~ Q U E

1 R C

C : d ' C - ICI5T1

-.r.%. --a"--Canad3

78

Y6

758

Price $4.00 NRCC 28550La qualit6 des briques fabriqutes dans diffdrentes usines Wsente des differences importantes : les &hantilIons satisfaisaient h la classe SW selon A S T M C62 dans une proportion variant entre 0 et 100 %I, et on a trouvd des classes de briques SW, MW et N W

diffkrentes dans la plupart des s&ies de production tcudites. On a constat€ que ces differences ktaient dues aux tcarts de temp5rature dans les fours, determints au moyen de la mCthode du remit des d t s Firechek. D1ap&s les estimations, 1'6can de tempCraturc entre la zone la plus h i d e et la zone la plus chaude des neuf fours ttudits varie entre 25 et

90 "C. La diffkrence de degrk de cuisson obtenu sur la surface extkrieure et dans la pame

iaerieure des briques s'est dvtlCe fonction de leur position dans le four, e n particulier par rapport ?l'espace du courant de flammes. i

Durability of Building Materials, 5 (1987) 111-124

Elsevier Science Publishers B.V., Amsterdam - Printed in The Netherlands

Frost-Durability Study on Canadian Clay Bricks.

11.

Thermal Gradient and Quality of Burnt Bricks

in Kilns

I J.H. KUNG*

Institute for Research in Construction, National Research Council Canada, Ottawa, Ontario

I

KIA OR6 (Canada)I

(Received December 1986; accepted March 18,1987)Keywords

Brick Testing and Quality control performance Specification

ABSTRACT

Kung, J.H., 1987. Frost-durability study on Canadian clay bricks. 11. Thermal gradient and quality of burnt bricks in kilns. Durability of Building Materials, 5: 111-124

Significant differences exist in the quality of burnt bricks produced in different plants, ranging from 0 to 100% SW grade according to ASTM C62, and different SW, MW, and NW grades of bricks were found within most production runs studied. These differences were found to be caused by the temperature differences in the kilns, as determined by the firechek-key shrinkage method. The temperature difference between the coldest and the hottest regions within the nine kilns studied is estimated to range from 25 to 90°C. The difference in degree of firing obtained on the exterior surface and in the interior section of a brick was found to be a function of its position in the kiln, especially with respect to the flue space.

1. INTRODUCTION

One of the objectives of a joint research program of the Clay Brick Associa- tion of Canada and the Division of Building Research, National Research Council Canada, was to provide an assessment of the quality of clay brick pro- duced in different kilns. This was to be, from the standpoint of frost durability of the bricks, based on standard test methods. In this program, nine commer- cially marketed clay bricks manufactured by six Canadian plants were studied.

*Present address: Materials Research Laboratories, Industrial Technology Research Institute, Hsinchu, Taiwan.

These six plants produce about 50% of the yearly total clay bricks manufac- tured in Canada. Variations in firing temperature and in raw materials are two important manufacturing variables in the production of clay bricks. The man- ufacturing process of the bricks studied was documented in sufficient detail to examine the relationships between product quality and process variables. The firing procedure was studied in detail; however, as only one production run was studied for each selected product, the effect of variation of raw materials from one production run to another could not be investigated. In this paper the quality of different bricks produced is considered, assessed according to brick standards, and the variation in quality is correlated with the temperature dif- ference within the production kiln.

2. EXPERIMENTAL

Bricks were sampled from various locations in a kiln or on a kiln car prior to the usual sorting and grading. Their absorption properties and saturation coefficient were determined according to procedures specified by ASTM C67 and CSA A82.2, and the results were used to grade the durability of the sampled bricks according to Standards ASTM C62 and CSA A82.1. Firechek keys (Bell Research Inc., Chester, WV, U.S.A.) were used during sampling to measure the heatwork or the degree of firing, which is a measure of the total amount of heat absorbed by bricks in kilns (Newman, 1979). The keys are of ceramic material, which shrinks upon firing. The amount of shrinkage expressed in arbitrary BRI units can be related to the heat work or degree of firing, which is a function of both the peak firing temperature and the soaking time. Thus, by placing the firechek keys in different parts of a periodic kiln or in different positions in a load of bricks on a kiln car, the heat work corresponding to each location could be measured and a profile of difference in heat work or temper- ature in the kiln deduced.

3. RESULTS AND DISCUSSIONS

3.1. Assessment of the quality of bricks

Table 1 shows the grading of the plant-produced samples from all nine prod- ucts studied, according to ASTM C62 and CSA A82.1 standards, based on the individual maximum water absorption by 5 h boiling and the individual max- imum saturation coefficient requirements, without taking into account the waiver based on the compressive strength or the cold absorption.

Significant differences occur between the rating according to ASTM and CSA Standards. Differences were also evident among products obtained from different plants, and within the production of each given product, except for products Nos. 6 and 7. Most of the bricks tested met the MW grade of ASTM

TABLE 1

Percentage of sampled bricks meeting the various grades based on absorption and saturation coefficienta

Product ASTM C62 CSA A82.1

No. SW MW NW Type 1 Type 2 1 13.0 75.4 11.6 88.4 11.6 2 10.0 90.0 - 100.0 - 3 28.6 71.4 - 100.0 - L 4

-

23.7 76.3 23.7 76.3 5-

27.4 72.6 27.4 72.6 6 100.0 - - 100.0-

7 98.6 1.4-

100.0-

55.6 44.4-

100.0 - 3.9 87.4 8.7 91.3 8.7"Requirement of the standard for different grades of brick: Maximum 5-hour boil- Maximum saturation ing absorption ( % ) coefficient

ASTM C62 SW: 20.0 0.80 MW: 25.0 0.90 NW: no limit no limit CSA A82.1 Type 1: 25.0 0.90 Type 2: no limit no limit

C62 and the Type 1 requirement of CSA A82.1, except for products Nos. 4 and 5. But only the products Nos. 6 and 7 and half of the product No. 8 tested met the SW grade of ASTM C62.

3.2. Thermal heat gradient i n kilns

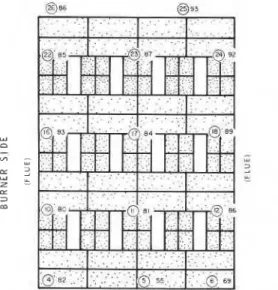

In general, there was a significant variation in the properties of bricks made in a given production run. Examples of heat work measured by firechek keys for a tunnel kiln and a periodic kiln are shown in Figs. 1 and 2, respectively. A thermal gradient exists in all three directions, and is larger in areas farther away from the flue space regardless of the type of kiln. The range of heat work measured and the average heat work of each kiln studied are shown in Fig. 3. Firechek keys corresponding to the coolest region in kiln No. 1 broke. Although no actual measurement was obtained, the corresponding heat works could be deduced from the relationship between properties such as cold absorption and heat work using the data from the laboratory-fired samples as reference (Kung, 1987). The difference in heat work measured for each kiln is plotted as a func-

tion of the average heat work in Fig. 4. The general trend indicates that the difference becomes larger as the kiln is fired to give higher heat work.

The relationship between the heat work measured by firechek keys fired in a laboratory furnace, and soaking temperatures and times is shown in Fig. 5; some data by Newman (1979) are also included. From the firing curve of each production, the soaking time can be calculated. From the soaking time and

measured heat work, the peak temperature reached in each position could be 1

estimated from a graph similar to Fig. 5. Thus, a cross-sectional profile of the

temperature in the kiln can be established. For the tunnel kiln, the soaking I

time at peak temperature was approximately 2 h. In the periodic kiln studied, 1

the soaking time was much longer, about 20 h. The temperature difference in each kiln can be estimated from the difference in the extremes of the heat work measured by using the relationships shown in Fig. 5. The estimated tempera- ture difference is plotted as a function of the difference in heat work measured

for the nine kilns (Fig. 6 ) . The estimated temperature difference in the kilns

ranged approximately from 25 to 90" C, being higher in the periodic kiln than

in the tunnel kilns.

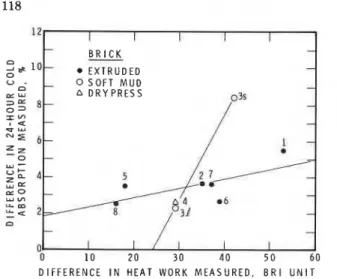

In Fig. 7 the difference between the highest and the lowest 24 h cold absorp- tions measured using samples from each kiln is plotted as a function of the difference in heat work measured in the kiln. Similarly the relationship between the difference in saturation coefficient and the difference in heat work meas- ured for the nine kilns is shown in Fig. 8. In general, the variation in both the cold absorption and saturation coefficient can be related to the heat gradient in the kilns, the correlation coefficient being 0.71 and 0.85, respectively, for

0 3 3 W n - - cn - ", w = 7 3 W r ,.. Z - n 3 m

Fig. 1.Sampling positions (encircled) and thermal gradient in brick tunnel kiln measured by firechek keys expressed in BRI units.

Fig. 2. Vertical sampling positions (lettered) and thermal gradient in periodic kiln measured by firechek keys expressed in BRI units.

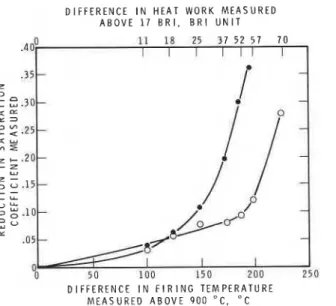

extruded bricks. In both cases, the effect of the manufacturing process is obvious. It was also found that the chemical composition of the raw materials has a greater effect on the scattering in the correlation between the difference in measured cold absorption and the difference in heat work than that of the saturation coefficient. This is to be expected from the results obtained in Part I11 of this series (Kung, 1987), where it is shown that the chemical composi- tion, particularly lime and silica, greatly affects the absorption properties of burnt bricks. In comparison, the better correlation obtained for the saturation coefficient (Fig. 8 ) indicates that the variation in saturation coefficient is due predominantly to the degree of firing. To further illustrate such dependence, I the results of the laboratory-fired samples of the various bricks studied are

!

shown in Figs. 9-11. In these figures, the samples fired at 900°C (17 BRI)serve as the reference, i.e., the reduction in the saturation coefficient from that of the 900" C sample is plotted as a function of the difference in firing temper- ature above 900" C. It can be seen from these figures that in all types of bricks

studied (except No. 6 ) , roughly two linear portions can be distinguished. In the first linear portion (lower degree of firing), reduction of the saturation coefficient is gradual with increased degree of firing. But in the second region (higher degree of firing) the reduction of saturation coefficient becomes great with small increase of temperature or heat work. The two distinct relationships

1

K l L N T Y P EI

K l L N N U M B E R

Fig. 3. The average heat work and the range of heat work measured for brick kilns studied.

-

A V E R A G E H E A T W O R K M E A S U R E D . B R I U N I T

SOAKING TIME 10 rnin l h 0 2 h o 10 h NEWMAN'S DATA (1979) 2 0 h - 0 l85 0 9 0 0 9 5 0 1000 o 1050 1100 1150 o S O A K I N G T E M P E R A T U R E , 'C

Fig. 5. Heat work measured by firechek keys as a function of different soaking temperatures and times.

D I F F E R E N C E I N H E A T W O R K M E A S U R E D , B R I U N I T

Fig. 6. Temperature difference in brick kilns estimated from the difference in heat work measured.

are indicative of two predominant mechanisms: sintering in solid state, and vitrification. Thus, the intercept of the slopes of the two linear relations may indicate the approximate firing temperature and heat work at which substan- tial melting takes place in the brick. Interestingly, at lower firing temperatures

- B R I C K

-

ID- E X T R U D E D - - 0 S O F T M U D - a D R Y P R E S S 8 - - 6 - 1 - - - - - 0 10 20 30 4 0 50 6 0 D I F F E R E N C E I N H E A T W O R K M E A S U R E D , B R I U N l TFig. 7. Difference in cold absorption measured as a function of difference in heat work measured for the nine kilns studied.

D I F F E R E N C E I N H E A T W O R K M E A S U R E D , B R I U N l T

Fig. 8. Difference in saturation coefficient measured as a function of difference in heat work meas- ured for the nine kilns studied.

D I F F E R E N C E I N H E A T W O R K M E A S U R E D A B O V E 17 B R I , B R I U N l T

4 07 11 I 18 I 25 I 37 5 2 5 7 I l l 7 0

D I F F E R E N C E I N F I R I N G T E M P E R o A T U R E M E A S U R E D A B O V E 9 0 0 " C . C

Fig. 9. Reduction of saturation coefficient as a function of the firing condition for brick types NO.

1 (Pennsylvanian shale) and No. 2 (Queenston shale). D I F F E R E N C E I N H E A T W O R K M E A S U R E D A B O V E 17 B R I , B R I U N l T ,40,0 1,l 118 2,5 3,7 ;2 7

,

"0 5 0 100 1 5 0 2 0 0 250 D I F F E R E N C E I N F I R I N G T E M P E R o A T U R E M E A S U R E D A B O V E 9 0 0 " C . CFig. 10. Reduction of saturation coefficient as a function of the firing condition for brick types No. 3-5 (Dundas shales).

soft mud bricks behave like a dry-pressed brick, but a t firing temperatures above 1050°C they are similar to extruded bricks (Fig. 10).

The estimated temperature of melting and heat work (based on Figs. 9-11) are shown in Table 2 for all of the eight raw materials studied. In general, the

transition temperature and heat work can be taken as 1070" C and 55 BRI, i.e. 170" C above 900" C and 38 BRI above 17 BRI. In Fig. 8 two regions can also be distinguished for the extruded bricks at a difference of heat work about 40 BRI. It can also be seen that for the soft mud (No. 3 ) and dry pressed (No. 4 )

bricks, no reduction in saturation coefficient takes place at a low degree of firing (Fig. l o ) , unless the firing temperature is 100°C above 900°C, i.e., 1000°C, or the heat work is about 11 BRI above 17 BRI, i.e., 28 BRI. Extrap- - olating the results of plant samples (Fig. 8) to zero reduction in saturation

.

coefficient for the soft mud and dry pressed bricks, a similar difference of heat work (25 BRI) is obtained. These qualitative and quantitative similarities *D I F F E R E N C E I N H E A T W O R K M E A S U R E D A B O V E 1 7 B R I . B R I U N I T 11 18 25 3 7 5 2 5 7 I I I I i I

I

D I F F E R E N C E I N F I R I N G TEMPE:ATURE M E A S U R E D A B O V E 9 0 0 " C , CFig. 11. Reduction of saturation coefficient as a function of the firing condition for brick types No. 6-8 (Queenston shales).

TABLE 2

Temperature and heat work at which substantial melting takes place in the laboratory-fired brick Brick type T, ( " C ) H, (BRI)

mentioned above between the results of the plant and laboratory samples indi-

cate that the lowest temperature in the production kilns studied was near 900" C.

Figures 9-11 can also be used as a guide in considering the cost effectiveness of increasing the degree of firing to reduce the saturation coefficient of a par- ticular type of brick.

3.3 Differential heating of brick surface and interior

During the sampling s f the soft mud bricks (Type No. 3 ) , an experiment was conducted to evaluate the difference of heat work between the exterior surface and the interior section of bricks. Since the soft mud bricks were solid with a depressed "frog" on one of the bedding planes, it was possible to compare the firechek-key shrinkage data between covered keys placed inside the frog and exposed keys placed on the surface of the same brick at various positions on the kiln car, as partially illustrated in Fig. 12. The experimental measure- ments are presented in Table 3. The results can be summarized as follows. Overall, the firechek keys embedded inside the frogs received slightly more heat work than the corresponding keys placed outside on the surface. The dif- ference is a function of the level of the absolute heat work, as shown in Table

4; the difference being greater as the heat work increases. The difference

between the interior section and the exterior surface is also a function of the position in the kiln, particularly with respect to the flue space, as shown in Table 5. Overall, the surface of bricks placed at flue-space positions obtained

* F L U E P O S I T I O N S

Fig. 12. Some sampling positions and heat work obtained (in BRI units) for the study of soft mud bricks.

TABLE 3

Difference in heat work measured between interior section and exterior surface of soft mud bricks with frog a t various kiln positions

Position Heat Work (BRI Difference between unit interior and exteriora Interior Exterior (frog) (surface) 1 flue 67 74 -7 2 61 58 3 3 flue 65 69 -4 4 66 66 0 5 61 60 1 6 65 60 5 7 flue 76 75 1 8 70 63 7 9 flue 75 76 - 1 10 65 65 0 11 68 62 6 12 73 65 8 13 flue 77 81 -4 14 69 65 4 15 flue 77 78 -1 16 66 70 -4 17 70 64 6 18 67 68 -1 19 flue 77 87 -10 20 75 66 11 21 flue 77 74 3 22 - 78

-

23 74 70 4 24 77 72 5 26 flue 81 84 -3 27 81 80 1 28flue 82 77 5 29 84 80 4 30 80 78 2 3 1 83 76 7"Negative value means the heat work from the exterior surface is larger than that from the interior frog.

more heat work, i.e., 3 BRI, than the interior of the same bricks as a result of more direct and radiative heating, whereas the interior section of bricks placed at non-flue positios obtained more heat work, i.e., 4 BRI, than the exterior surface of the same bricks, perhaps due to the mass effect.

TABLE 4

Difference in heat work between interior section and exterior surface of soft mud bricks as a function of the level of heat work

Range of heat work Average difference between measured (BRI interior and exterior for all unit) positions (BRI unit)

60-70 0.3 f 1.0 70-80 2.4k 1.0 80 or greater 2.7f 1.0

Overall average 1.7f 1.0

TABLE 5

Difference in heat work between interior section and exterior surface of soft mud bricks as a function of kiln position

Position Difference between interior and exterior ( BRI unit ) "

Average Range

Flue -2.9k 1.0 -10to 3

Non-flue 3.7f 1.0 - 4 to 11

"Negative value means that the heat work from the exterior surface is larger than that from the interior section.

4. CONCLUSIONS

Significant differences exist in the assessed quality of burnt bricks produced among the different plants, ranging from 0 to 100% according to ASTM SW grade. There is also significant variation in the properties of bricks made in a given production run. The main cause is the thermal gradient in the kilns. The thermal gradient appears to be a function of the overall degree of firing of the kiln, being greater as the kiln is fired to higher temperature or heat work. The estimated temperature difference within each kiln ranged from 25 to 90°C,

approximately, among the nine kilns investigated. The lowest temperature encountered in these kilns is estimated to be close to 900" C. The difference in heat work obtained on the exterior surface and the interior section of a brick is a function of its position in the kiln, especially with respect to the flue space.

ACKNOWLEDGEMENT

The author wishes to thank G.W. Mould for his assistance in the experi- mental measurements, and plant personnel at Canada Brick Ltd., Domtar Construction Materials, I-XL Industries Ltd., L.E. Shaw Ltd., and Toronto Brick for their cooperation. The author is also grateful to Dr. V.S. Ramachan- dran and Dr. L.W. Gold for their discussions. This study was undertaken by the Clay Brick Association of Canada and the Division of Building Research, National Research Council Canada.

REFERENCES

Kung, J.H., 1987. Frost-durability study on Canadian clay bricks. 111. Characterization of raw materials and burnt bricks. Durability of Building Materials, 5: 125-143

Newman, H.B., 1979. Direct and indirect methods of measuring body maturity. Bull. Amer. Ceram. soc., 58 ( 6 ) : 580-586.

T h i s paper i s being d i s t r i b u t e d i n r e p r i n t form by t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r Research i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i l of C a n a d a , O t t a w a , O n t a r i o , K l A 0R6. Ce document e s t d i s t r i b u C s o u s forme de tit%-3-part p a r 1' I n s t i t u t de r e c h e r c h e en c o n s t r u c t i o n . O n p e u t o b t e n i r une l i s t e d e s p u b l i c a t i o n s de l l I n s t i t u t p o r t a n t s u r l e s t e c h n i q u e s ou l e s r e c h e r c h e s e n m a t i t r e d e b a t i m e n t e n G c r i v a n t