S(O•rI'.G OF PARpTICLi>S by

ROGER LEE MHcCARTHY

B.A., University of Michigan 1972

B. S . (i, •- .), University of Michi an

1972

3UBMITTED IN PARTIAL FULPILLMEN'T OF iTL .QUIRE'SN-rS

FOR TH4E DEGREE, OF 0ASrEi OF SCCI '2NC2• AXD CH AiiICAL ,GIN:,3EE,

at the

:,ACS AC.HiUS.TS NTSTITUTh OF

TECHN7

CTOLOG

YJune, 1973

Sig•'nature of Author . ... .a -.-.. . . k * * * &

Deoa ment of Mechanical rnwineerinr

May 11, 1973

Certified by ...Thesis uervsor

A Thesis Suoervisor

V / v

-Accepted by ... ...

Chairman, Departmental Committee on Graduate Students

Archives

(JUL 10 1973

-2-DESIGN OF A ,ECTION VORT, X FR. DE-SIITY SO, 0P CTIN OF PARTICL.'ES

by

ROER LEE i!cCA.RTHY

Submitted to the Department of iechanical wnqineerin7 on May 11, 1973, in partial fulfillment of the

require-ments for the deg'ree of MIaster of Science and Mechanical

EnTqineer.

A.B3S i'RtA.C T

This thesis describes the attempts to make a vortex density classifier operational. Specifically an existing: prototype of a device which -Yenerated an air vortex had been built but would not function as desi-. sz- ned . T.he air vortex subjects injected uniform oarticles to a balance of fluid forces which should force the oarticles to travel in circular orbits, the radii bein,; a function only of their density. Comouter investigation revealed that the shaoe of

the classification section was such as to cause thick boundary layers and nonsymmetric airflow.

A. new classification surface, with acceptable

airflow, failed to correct any particle orbiting

oroblems. This oromoted the investigation of transient oarticle behavior in the airflow. This revealed that oarticles failed to orbit because of their interaction with a fluid boundary layer at the lower surface of

the classification section. Furthermore, even with no

boundary layer interaction the time required by an injected narticle to achieve an equilibrium orbit was of the order of 30 seconds, far too long-. However,

transient behavior was found to be a strong function

behavior is proposed. Iransient behavior is quick, hence a larI.ge throughput can be achieved and the dimensions of the classifier kept relatively small.

Thesis 'Suoervisor: David Gordon Wilson

-4-AC •I • WLEmDEM .,. T

I wish to acknowledge the aid, advice, and

most imnortantly, the ercouragement of Profesor

David Gordon Wilsorn, without whose help this

oroject would not have been completed. This project

and my work have been made possible through prant

number EC-00333-2 provided by Solid Waste Research

in the Office of Research and Monitoring, 1National

Environmental Research Center of the Environmental

TABLE O•') CCNTi,•

S

i t le Abstract Acknowled P'ements List of Fiqures ForwardChapter I: General Introduction

Cha

Cha

Section 1-1: Anproach to the refuse treatment problem

Section 1-2: Vortex Classification

Section 1-3: Forces ýroverninp particle

behavior in vortex classifying section

pter 2: Testino: and Modification of the Original Prototype

S•ection 2-1: Abstract

Section 2-2: Problems inherited with the protot y pe

Section 2-3: Testinq and efforts to correct problems

pter 3: Computer Analysis and Photof'raphic

Investigation of Criginal Prototype

Section 3-1: Abstract

Section 3-2: Kathematical model. of vortex flow

Section 3-3: Application of modeling procedure to actual prototype 12 12 16 21 26 26 2/0 2Q 43

43

4352

-6-PAGE

-)ection

3-4: Fhotorraphic investigation ofparticle behavior 60

Chapter 4: Investigation of Transient Particle

Behavior by Computer 69

Section 4-1: Abstract 69

Section 4-2: Yathematical description of

transient behavior 69

Section 4-3: Numerical prediction of transient behavior and awreement with

observed behavior 74

Section 4-4: Verification of numerical orediction o1

Chapter 5: Design Concept for Density

Classifi-cation on the Basis of Transient

Behaývior in a Vortex :Section .6

Section 5-1: Abstract P6

Section 5-2: Transient behavior characteristics

Section 5-3: Selection of the optimum

classification surface 91

Section 5-4: Design of "optimum" classifier 96

Section 5-5: Vortex and ballistic separators 100

Summary of Conclusions 104

Re c omme ndat i ons 107

Appendix I 10

Section Al-I: Drag coefficient versus Re 1for

various three-dimensional shapes 109

Section A1-2: Velocity of airflow versus total pressure in .,age oil height.

;Plot and computer listingp of data. 110

Section A1-3: Airflow data for prototype as

PAfE Section A.1-4: Section A1-5: Section A.1-6: Appendix II Section A.2-1: Section A.2-2: Section A2-3:

Airflow data for prototype after modifications

Airflow data for prototype with increased power

Airflow data for prototype with horizontal surface

Calculated flow parameters for classification surface with angles of three and six degrees

Calculated flow parameters for horizontal classification

surface

Calculation of optimum surface

DCR/DR = -1, Computer data and plot Bibli o,:raphy 117 122 127

130

131 177 1 1 161Q_

IS'T OF FICURES

FIGURE PAGE

1. Mass-flow assumptions for plant design 13

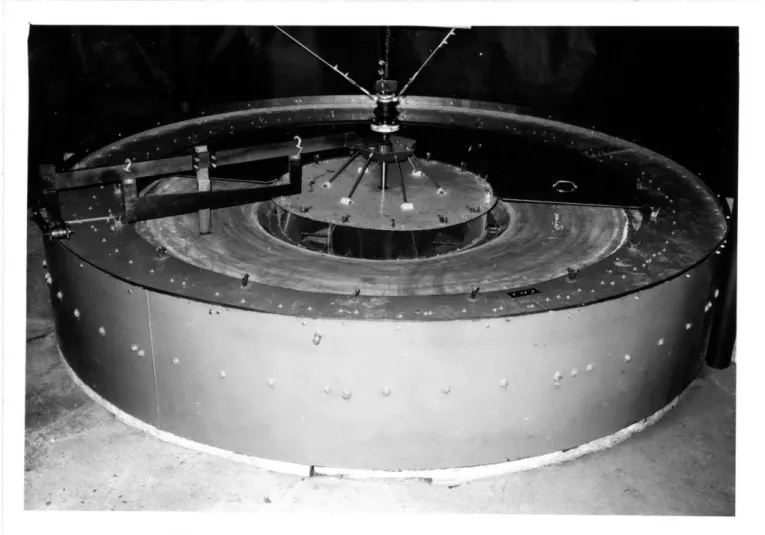

2. Cross-section view of vortex classifier 1)

3. Photograph of original prototype 19

4. Isometric view of classifying section with

flow comoonents 22

5.

Sheet metal cover with liu 296. Yaw meter and pitot tube 31

7. Diairam of the 12 flow measurement positions 32

R. Layout of the diffuser vanes or wedges 34

9. Profile of classification section 35

10. Photo.raph of annulus with zao 37

11. Photograph of annulus with gap filled and

screen installed 30

12. Cross-section of modified classifier 39

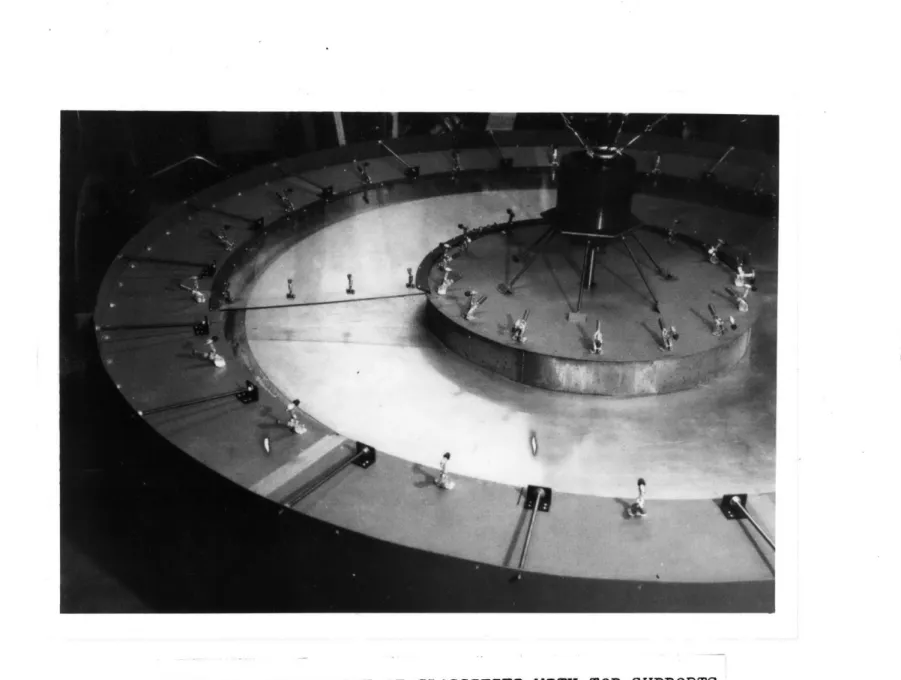

13. Photograph of classifier with top supports 41

14. Flow assumptions for flow model 46

15. Smoke test of classifier section 55

16. Prototype with classification section removed 57

17. Prototyre with radial ribs 59

1i . Prototype with horizontal surface installed 59

PAGE

20.. Photoranhic backroiud of prototyue 63

21. Calibrated oarticle injector 64

22. 3quare block interactin-:: with boundary layer 66

23. Sphere interacting with boundary layer 67

24. Plot for particle inJected at 135 inches/sec 76

25. Path for particle with 100 surface 79 26. Path for particle with 100 surface, 20seconds 90

2?. Phot;ora. h of particle oath 82

22, Predicted poath of 13 lbm/ft3 particle in

actual nrototype 23

29. Path of particle ir prototype with 100 surface,

=10 ilbm/ft 3 !

30. Path of particle in prototyoe with 100 surface,

= 20 Ibm/ft3

-9

31. Path of particle in prototype with 100 surface,

= 30 Ibm/ft3 90

32. Path of 13 Ibm/ft3 particle in prototype with

optimumr surface 93

33. Particle paths in optimum classifier 94

34. Top view of prototype with four classification

sections 99

-10-FOREWORD

Since the beginning of the present decade, a

nationwide consciousness of the state of the

"environ-ment" has appeared. This issue has crept into the

political area (and jargon) as evidenced by the concern

expressed by almost every candidate for public office.

This seems to portend a significant resource allocation

in the future to make man's conduct more compatible

with his environment.

Perhaps the largest single contaminator of the

natural state is man's discarded solid refuse. Present

disposal methods are usually one of two types, landfill (or seafill) or incineration. Landfill has the inherent

disadvantage of being quasistatic at best. Even when

done with some foresight as to environmental effects

(which is not often the case) the landfills will

eventually all be full and the resources in them denied

to future generations. Burning of refuse usually has the

effect of changing pollution from that of land or

water to air. The tougher nationwide air pollution

and land use laws are quickly rendering both these

The ideal solution to this problem would obviously

be to reuse all discarded material in the production of

new products. However, such a solution is not practical

given the present state of the waste-reuse art. The

problem is formidable. Everything now used by man (with

the possible exception of large structures) shows up in

discarded refuse. The difficulty of sorting refuse is

compounded by the fact that most municipalities use a

single pickup method of collecting refuse, for economic

reasons, thus insuring that refuse, when it arrives at

the disposal facility, is a thoroughly mixed collection

of rags, dirt, metals, plastics, glass, garbage, wood,

-12-CHAPTER I

GENERAL INTRODUCTI ON

Section 1-1: Approach to the refuse-treatment problem

The project of which this thesis work has been

part is investigating ways to solve the reclamation

problem. Primarily we are concerned with municipal

refuse. We are attempting to develop a prototype of a

facility that could be used by medium and large-size

municipalities to recycle their refuse. Since past

attempts at getting consumers to separate refuse by

material have proved largely ineffective, our system

proposes to deal with the refuse as it comes from the

single collection truck. We propose to divide the

multi-component stream in the manner shown in Fig. 1.

Research currently being carried on by other members

of the project will refine the percentages of refuse

that actually fall into each category, but these figures

represent our design assumptions.

The paper and plastic film will be removed by a

suction fan as the refuse passes over a vibrating screen.

The vibrating screen will also sort the incoming material

Plastic 1% 4on% n 30/ having reclaim value

Fig. 1: MASS-FLOW ASSUMPTIONS FOR PLANT DESIGN

-14-2" from the larger objects. Ferrous material will be

removed at the vibrating screen by magnetic means. The

small items are ground up. The large items are placed

separately into carts where their infrared and

accelero-meter signatures are examined (infrared signature may

also be used to separate paper from plastic film).

Materials will then be dumped into appropriate bins

depending on whether they were glass, aluminum, plastic,

wood, etc. Some inhomogeneous objects, such as a

transistor radio, would be unclassifiable and hence would

be dumped for grinding. My thesis device is concerned

with the inhomogeneous and the small non-magnetic items, which we expect to compose roughly 50% of the incoming

refuse by weight.

The device I have been working on would sort the

small, non-magnetic items (some of which will be derived

from the large items that were inhomogeneous and were

subsequently comminuted)by density. It would require

that members of both classes of items not of the

appropriate size be ground first. Grinding should reduce

the objects to pieces a higher proportion of which are

homogeneous. This should result in purer reclaimed material.

It is a legitimate question at this point to ask

enough to be recycled. Soft rubber, asphalt, coke,

paper, ebony and boxwood, to mention a few, all have

species with the common density of 69 pounds per cubic

foot (ref. 3 ). But fortunately, waste reclamation has

an economics of its own which gives an affirmative

answer, as follows, to this question.

Certainly 100% accurate sorting would be the most

desirable. But solid refuse carries a disposal cost.

After collection it can cost from $2.00/ton to $20.00/ton

just to bury or burn it. Thus we really need only to

get the refuse in a form that is usable even if it had

no commercial value. Ideally the sorted refuse would

be in a purity that has commercial value so that the

cost of recycling would be borne totally by the sale of

the recycled material. But a municipality would be

ahead to pay an amount per ton equal to the alternative

costs of disposal to sort material into a form with

enough purity that processors of raw materials would be

willing to use if it cost them little or nothing. As

the technology of raw-material processing improves it

can serve only to help the economic feasibility of our

system. Thus it is hoped that materials of a common

density will be in ratios such that one material

pre-dominates. Certainly paper and wood would form the

-16-(

as raw material for paper. However, the real resolution

of this issue will come with the final testing of the

plant with real trash.

Section 1-2: Vortex classification

It was originally planned to do density sorting in

an annular air vortex chamber, which creates an air

whirlpool in which particles get stratified in stable

orbits, the radius of the orbit hopefully being a function

only of the material's density. A machine employing

this concept was constructed for the project last year

by Michael H. Corbin (ref. 1). Before the decision was

made to build a vortex classifier, several other types

of air-classifying schemes were investigated.

Specifially, Ora Smith and Professor David G.

Wilson investigated the Stanford Research Institute

Zig-Zag Air Classifier and some ballistic separators

(ref.9 ). Initial vortex experiments were conducted by

Felix Mascolo (ref.8 ) who employed a radial outward

diffuser. The results were encouraging; however, his

attempt to build a barrel-shaped classifier employing

the principle proved unsuccessful. Michael Corbin took

employed an inward-flowing air vortex. A cross-section

view of this device can be seen in fig. 2, and a

photograph of the actual device is in fig.3.

The operation of this device is fairly simple.

Part 5 is a fan which drives the air in the circular

path indicated by arrows B, B', and D. Part 18 is one of

six radial diffusing vanes which hold up the inner annulus

or "doughnut". The air goes between these vanes in its

outward path, turning the corner at the outside as

indicated by arrow B. The air then travels up and through

the turning vanes shown in part 4: these impart a

tangential component to the radial airflow. The air

then travels over the separation surface, part 9, and

under the cover of the separation annulus, part Y. This

surface was designed so that particles would orbit stably

in orbits that would be greater in radius than point 7, but less than point 6. Part 20 is a screen to filter out

erratic particles and to prevent them from reaching the

fan. The air then returns to the fan shown by arrow D.

The purpose of this recirculating flow was to conserve

the kinetic energy imparted to the flow so that in the

steady state the fan would have to add only enough energy

to compensate for that dissipated by friction. This

r FIGT•Rl 2 : CROSS SECTON VIEW

Part; 4 - hTurninpg vanes Part 18

Part 5 - Fan Part 20

Part 6 - 3Beinning ioint of Part 22

classification surface Part 23

Part 7 - ;'noint n of Part 25

classification surface Part Y Part 17- Dri-ve Shaft

OF VORTEX CLASSIFIER

- Diffuser vanes or "wedges"

- Screen

- Inner annulus or "doughnut"

- Fiberglas corner fillet

- ch chiot

-20-drove the fan through a four-speed automotive transmission.

The device was built as shown and preliminary

testing done with orbiting spheres. The results were

encouraging but inconclusive, the particle behavior being

somewhat erratic. Work was then carried on by Robert R.

Rodgers (ref.

5

) who made some modifications. Referringagain to fig. 2 , the following changes were made. The

separation surface, which originally had been fabricated

from styrofoam and "plasticene" to facilitate forming,

was replaced by an aluminum-sheet surface, which proved

much smoother and more uniform. The original 5-hp

motor was replaced by a 10-hp motor, in the hopes of

achieving greater airflow rates. And finally part Y,

which Michael Corbin had originally constructed out of

aluminum with a viewing window, was replaced with a top

made completely out of Plexiglas, so that particle

behavior could be observed at all points of orbit.

This was essentially the state of the device when I

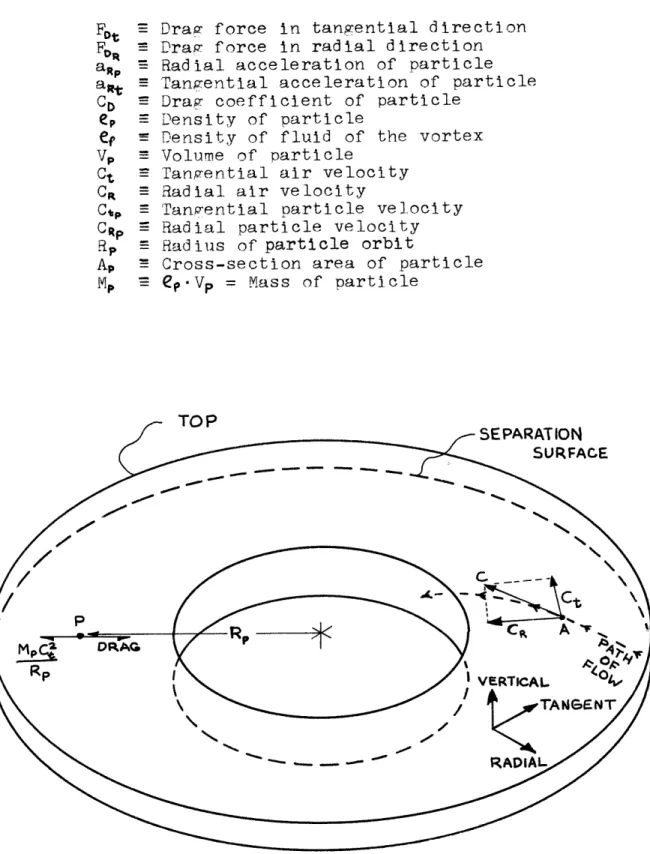

Section 1-3: Forces governing particle behavior in

vortex classifying section

It is desirable at this point to get a thorough

understanding of how the vortex classifier works. A

two-dimensional isometric view of the classifying

sec-tion can be seen in fig. 4, along with the notation

deno-ting relevant parameters. The airflow is depicted by

the labeled arrows. The turning vanes give a tangential

component to air traveling in the inward radial direction.

Thus if we look at the instantaneous velocity vector

of an air particle A traveling on path H we see its

velocity, C, can be resolved into two components; a

tangential velocity C0 , and a radial component CR. Now

if the flow is truly one dimensional at any point with

the same radius as A, by definition the flow should have

the same tangential and radial components at any height

in the chamber. Hence the only variation in the flow

parameters should be in the radial direction. If we now

turn our attention to particle P we can examine how

this air flow affects the particle. Assume particle P

is not in contact with either top or bottom boundary

layer. For the particle to be stable in equilibrium

what forces have to be balanced ? In the tangential

Draw force in tangential direction Drag force in radial direction Radial acceleration of particle Tangential acceleration of particle Drag coefficient of particle

Density of particle

Density of fluid of the vortex Volume of particle

Tangential air velocity Radial air velocity

Tangential particle velocity Radial particle velocity Radius of particle orbit

Cross-section area of particle

ep.Vp = Mass of particle

FIG. 4: ISOMETRIC VIEW OF CLASSIFYING SECTIOUN WITH

FLOW COMPONENTS FDt

FN

aRp aitt CDep

e V, Ct Cao CSp RRp Ap MP "T"/" n"velocity C. If it were slower or faster a drag of

force of magnitude:

F = -*C*A.p ** (C, - C )

would act to speed up or slow down the particle until

it reached velocity Ct , at which time this force would

disappear. (CD is the drag coefficient and is defined

by this equation; it has been found to be a function

principally of particle shape and, to a lesser degree, of the Reynolds number of the relative flow

Re = (Ct - C p).l.e

where 1 is a dimension and }p is the fluid viscosity).

In the radial direction the force balance is more

complicated. For the particle to be in equilibrium in

a circular orbit with orbital velocity Ct it is necessary

for the air flowing inward to impart an acceleration to

the particle of the magnitude:

a

=

a RpRp

To accelerate a mass requires a force which must come

FD =a·C_ D*pA - (C )Z

Since in the steady state the particle stays at a constant

radius it has no radial velocity, only an acceleration.

Thus, for a stable orbit, the acceleration force required

for a circular orbit and the drag force provided by the

air flow balance, or:

Mp = D (CR) But:

a R

P =

Mp

= . VP

aRp - p Therefore:R

2.Vp*

ep*C.

P- CD , A.p•. e CRand since the value of Co, Ct , C, and (Vp /Ap ) are

all fixed for a standard particle, in a vortex of fixed

speed and geometry, the equilibrium radius would then

only be a function of particle density.

The conceot of separation then is to inject

pa.rticles into the air stream of the classifier. They

acting on them. The particles could then be removed, and

the particles at a common radius should have a common

density.

This analysis was made assuming a few important

simplifications. First, the interaction with the top

and bottom boundary layers could be ignored. During the

original design of this device, it was assumed the

parti-cles would never interact with the top of the classifier,

and would never contact the bottom due to the Magnus

effect (rotational lift) that will come from the lower

side of the particle coming in contact with the slower

boundary-layer air, giving the particles "spin" (ref. 4). Also, the possibility of particle interaction was

ignored. I did not see how to consider this problem

analytically, therefore it had to be studied experimentally.

Finally, CC is assumed constant over the range of fluid

velocities of the classifier. This assumption requires

some care be used in actual construction of a classifier,

since this is not true in all velocity regions. In

Appendix I, Section Al-I there is a plot of Cp vs

Reynolds number for some simple shapes.

In summary we see the vortex classifier is designed

to separate particles that are similar in shape but of

differing densities by creating a fluid-force balance

-26-CHAPTER 2

TESTING AND MODIFICATION OF THE ORIGINAL

PROTOTYPE

Section 2-1: Abstract

The first six months of this project were spent

trying to modify the existinw prototype to the point

where it functioned as designed. The changes were aimed

at improving particle behavior. The particles failed

to travel at the tangential velocity of the airflow, and

had very erratic orbits. Unfortunately all improvement

efforts, which were directed primarily at the air flow

patterns, and which are chronicled in the following

sections, proved unsuccessful.

Section 2-2: Problems inherited with the prototype

I began work on this project in September, 1972.

Initially the prototype vortex classifier was operable

only intermittently due to problems with the automotive

drive train, but these problems were quickly solved and

At the conclusion of Michael Corbin's work the

testinv of this device had been confined to balls that

rolled continuously in contact with the bottom surface.

Although the desiqn analysis presumed that particles

would be airborne when solving the fluid-force balance

expressions, denser balls generally took larger orbits

as theory would predict. However, the original

"plas-ticene" (or modeling clay) surface was fairly irregular

and Robert Rodgers placed a sheet-aluminum surface over

the plasticene so the balls would have a more uniform

surface to roll on . Even a uniform surface failed to

make the rolling spheres take stable orbits, where the

orbiting velocity was in equilibrium with the tangential

velocity of the air flow.

Inevitably, the surface and spheres had small

imperfections that were blamed for their poor

perfor-mance. It had also been found that to make the spheres

orbit even erratically it was necessary to inject them

with a tangential velocity component at the point of

inter-jection.

I decided to work initially with materials that

were less dense than the rubber the spheres were cast

from (E= 60 lbm/ft3 ) in the hopes that airborne particles would avoid performance problems due to

-28-separation-surface fabrication. It was necessary to go

to lihter materials because the actual airflow of the

device was less than 1/3 the original design

specifi-cation. Some initial testing: of this type was done by

Robert Rod•rers with some encoura7innw results. Testin'

done with materials with a density of 20-40 lbm/ft

and with a variety of shapes ranping' from spheres to

cubes failed to yield any positive results. Some spheres

would roll in elliptical orbits for as long a desired

but would never assume a constant radius. Particles

that were li'ht enoug7h to become airborne inevitably

tended to fly very unstably until their orbit "decayed"

and they flew inward to be pinned against the filter

screen (part 20, fi'. 2). Because of the poor airborne

particle behavior it was concluded that the particles

must be subject to a radially asymmetric air flow.

Section 2-3: Testinp and efforts to correct oroblems

In order to test the symmetry of the flow, T modified Michael Corbin's ori'inal sheet-metal cover

with an aluminum "lip" around the outside and inside

edges, as shown in fi'. 5, so that the measurino nart, a 15"-diameter hole cut in the cover, could be rotated

-30-constructed the direction- and speed-measuring apparatus

shown in fig. 6, which consisted of a pitot tube and

yaw meter on a cobra head. By also taking a

static-pressure reading- at the same radius as the pitot head,

I was able to determine the speed of the flow, and the

yaw meter, connected to the "U" tube shown in the

photograph, allowed me to read the angle of the flow

from the protractor. The curve of velocity vs. pitot

gage fluid height can be found in Appendix I, Section A.1 -2.

Michael Corbin had performed a series of speed

and angle measurements at one angular position at

different radii and heights within the classifying

section. These showed the flow to be highly variant in

the vertical direction, contrary to design assumption

(ref. 1, p.55-57). The flow angles measured in various

radial positions also showed very poor correlation with analytical prediction. However, since a new surface

had been added, and hence the geometry changed, new

tests were in order. I took readings at 12 angular

positions as shown in fig. 7. The results are tabulated

in Appendix I, Section A.1-3.

One can see wide variations between angle and velocity dependinp on the angular position or height in

This device sits inside the 15" diameter hole in metal cover.

-32-rop view of classification section

B

\ 7I

DRIVE TRAIN1s

04'-4

1

%

I

3 Scale: 1"=14"7DIAGRAM Ok THE 12 FLOW .A;..URE.IN. PO SITIOiS

9

I0A

/I

II-i

FIGURE 7:heights or at a constant height would see constantly

varying flow conditions, and hence would never attain

a stable orbit.

Upon examination, it was noticed that the flow

at a point seemed to be identical with the flow profile

found 1800 opposite. There were eight large diffuser

vanes (part 19, fig. 2) holding up the inner annulus

(part 22, fig. 2). A. top view of the placement of these

vanes can be seen in fig. 8. Because of the large

width of the rear of these "vanes" (which are shaped

more like wedges) it was thought the asymmetry they

introduce into the flow in the bottom of the classifier

was carrying through into the classifying section. The

large notch (point 25, fig. 2) was also thought guilty

of generating an unusually large boundary layer.

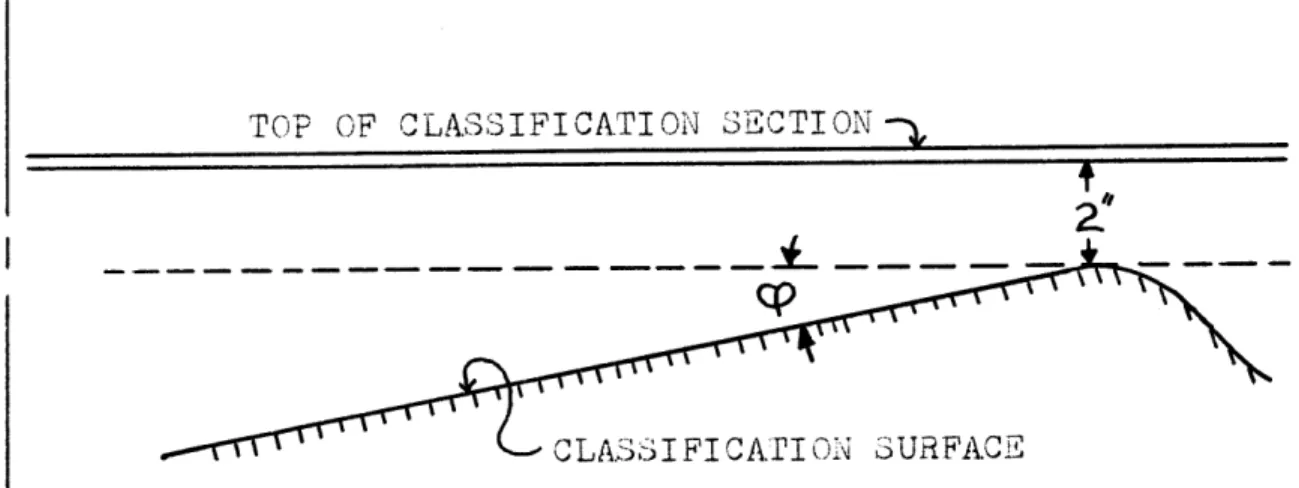

During original calculation of the classifying-section

surface shape it was thought the "wedge" profile

(as seen in fig. 9) would guarantee accelerating flow

which should suppress boundary-layer growth while wivinw

maximum particle stability, so the persistence of a

thick boundary layer in the classifier section was a

mystery at this point, but its existence was attested to

by its velocity measurements.

To solve this flow asymmetry and

FIGUFRE 8: LAYOUT OF THE DIFFUSER VAES] OR "1EDGES"

34TOP OF CLASSIFICATION SECTION

-A

CLASSIFICATION SURFACE

CP = CLASSIFICATION SURFACE ANGLE

-36-classifier from its state in fir.1O to that of fiw.11

Screen with an open area of only 50% was added to create

resistance in the flow that would suppress the apparent

"shadow" of the diffuser vanes that was oersisting. Part

23 (fig. 2 ) was also removed to further agitate the flow,

and the gap at 25 was filled with plaster and plasticene

and made smooth. Part 20, originally mesh with -" holes,

was replaced with resistance screen with 43% open area

to insure that particles would not leave the classifying

section and block the back of the newly added resistance

screen in front of the turning vanes. The classifier now

appeared as in fig.12.

resting began and particle behavior was observed.

Unfortunately, the airspeed was reduced considerably by

the newly added resistance screen. The device was

oriwinally designed to operate with an air flow of

730 ft/sec which required a fan speed of 600 rom (ref. 1

p.15). Unfortunately, without the screen the best

flow that wAs -btainable was 176 ft/sec, due to the fan

operatin. in an aerodynamically stalled condition. The

additional screen reduced this flow to 127 ft/sec. At

this speed only -" cubes or smaller would become airborne

and only if they were of a light material. Spheres of

2 oZ

-40-Testinw with such blocks proved futile, as they behaved

unstably and always decayed, when started in orbit, and

landed a•ainst the inside filter screen.

Another angular air profile was taken and the

results are in Appendix I, Section A1-4. Things seem

to have improved but are hardly cured. The an~ular

divergence and velocity differences are less, but still

bad enough to cause a particle to be very unstable.

Because of the resistance screen the diffusinp vanes were

discounted as the cause of asymmetry. Since the vertical

chamber heights at points 6 and 7 (fig. 12) were not constant at all points around the circumference of the

classifier, it was thought this variation might cause

asymmetric flows. To solve this problem top supports

were added as shown in fig.13 . These were adjusted until the separation chamber was of constant dimension

in all anaular positions. At the same time investigations

were made on how to increase the power to the classifier to increase the airspeed.

Investiqation of our electric power system to the

motor revealed that the motor was drastically underfused,

and underwired. The starter and fuse box had once been

used to power a 2--ho motor, and the wire and "heaters" in the starter had not been changed to accomodate the

-42-was rewired and fan soeeds of 800 rpm were obtained.

With both these chanqes another

angular-air-velocity profile was taken; the data points again are

in Apoendix I, Section A1-5. The velocities have

recovered due to the increased motor hl: however, the

fan apparently remained highly "stalled". With power

input from the motor at 10 hp, the airflow represented

less than 1 hp in its kinetic energy and pressure

com-ponents. A thick boundary layer was found to be present,

because of the reduced velocity and flow angle readings

taken !" off the classification surface (points 6 and

12 being a notable exception to this observation).

Particle behavior did not improve, other than larger

particles would again become airborne.

It was clear at this point that problems in the

performance of this device could no longer be attributed

to fabrication errors. Obviously some aspect of the

theory was misunderstood and our design was in error

accordingly. Hence it was decided to construct a

mathematical model of the device and investigate the

CHAPTER III

COMPUTER ANALYSIS AND PHOTOGRAPHIC INVESTIGATION

OF ORIGINAL PROTOTYPE

Section 3-1: Abstract

This chapter describes the derivation of a

mathematical model of the vortex flow, assuming

incompressibility and conservation of angular momentum.

The results revealed the cause of our boundary layer

to be decelerating flow. The classification surface

was changed to get continually accelerating flow, but

particles still failed to orbit. Photographic

inves-tization revealed the boundary layer or surface slowed

the oarticles when contacted and destroyed their

orbits.

Section 3-2: Mathematical model of vortex flow

Because of the poor results obtained with the

modifications described in the last section, study

was continued on the prototype by digital computer.

anwle inside the classification chamber at every position

was developed. Construction of the model required

assuming the flow incompressible and frictionless. Then

the flow parameters are determinant from conservation of

mass and anQgular momentum.

It was assumed first, as in the original design,

that the flow was symmetric in the anvular direction,

uniform in the vertical direction, and hence varied

with respect to only one parameter: the radius. The

actual flow deviated substantially from this model but

it was assumed for simplicity of programming. Secondly,

the flow was assumed substantially incompressible.

Since the highest static pressure difference in the

device was less than 0.1 inch water column, this seemed

valid. Finally, it was assumed that viscous shear in

the boundary layer did not bring about damoinjr of the angular momentum imparted to the flow by the turning vanes, i.e. the flow was frictionless. With these

assumotions a model_ can be constructed in the followinw

manner.

From actual speed measurements an actual volume

flow rate can be determined or one assumed. The radial

flow rate is then determinant, since the volume through

classification chamber must be equal (see fig. 14). The

tanwential flow velocity can be determined if angular

momentum is conserved, the flow being assumed to have

the angle of the turnina vanes when leaving the turning

vanes*, and the angular momentum beinz constant thereafter.

(See fig. 14). Thus the two components can be added and

the total velocity realized. Additionally, the angle of

flow for every point can be computed from the relation

Flow angle = 1800 - Arctan Tangential Velocity

Radial Velocity

Once the flow velocity and angle are known two

very important parameters for the operation of this

device can be determined. These parameters are, first,

the inward radial acceleration and, secondly, the

stability of a particle in an equilibrium orbit (the

tangential soeed of the air flow being equal to the

orbit velocity).

An acceleration in the radially inward flow is

very desirable for it prevents the flow from separating

from the surface. fig. 12 shows how the classification

surface slants downhill in the direction of the flow.

* while not strictly aerodynamically true, this proves

to be a fair approximation by the reasoninF illustrated in fiw. 14.

-46-)

VIEWS OF PROT

Ct

VOLUMi FLOW THROUGH

-JSURFA.CE A,B, & C, A.RE EQUAL,

CONSrMAT A3lGULA.R

MOMENTU9M MEALS :

IS DEFINED AS VANE AN.iLE. fiHE FLOW I<S ASS'U"~13'ED TO TAKE PHIS ANGLE. THIZS IS A VALID APPCROXIMATI ON BEC AUSE EVE N THOUGH ANGLE & IS GREATER, CIRCULATION WILL CAUSE 2HE FLOW TO ASSUME ROUGHLY ANGLE P.

nEASURhED DATA. VERIFY £THIS ASSUPTiF:I'I( .

FIGURE 14: FTL' ASSUMPTIONS FOR "LOW C` , •MODEL

n O

If the flow is decelerating, the result is similar to

that on. the reverse side of an airplane wing. The flow

experiences a negative pressure gradient, and hence any

perturbation of the flow grows and the boundary layer

becomes turbulent and separates. Hence the velocity

profile would cease to be independent of height, and

the flow would be two dimensional.

The importance of a stable equilibriun is fairly

obvious. If a particle is in an equilibrium orbit

(by equilibrium I mean in equilibrium with the fluid

forces discussed in Chaoter I), what is the effect of

a small perturbation? If the equilibrium is unstable,

the particle leaves the orbit never to return. If

the equilibrium is stable, the net result of the fluid

forces is to restore the particle to its oriqinal

position. This characteristic can be expressed more

quantitatively (see ref. 6).

The inward draq force from the air flow on a

particle was seen in Chapter I to be:

FDR = C A.p ~ (CR )2

This force must impart an inward acceleration, a ,

to the particle. An acceleration requires a force

Mp M c

M aRp P -RP

The particle is in equilibrium when these quantities

are equal. For this equilibrium to be stable, it must

be the case that

d(Net Force) (net Force = FR - Mp* aR )

d (radius)

is always a positive quantity. By using the sign

conventions established for force and radius established

by fig. 4, we interpret this requirement in the following

manner. If the particle is perturbed inward, dR is

negative, hence d(Net Force) must be negative or

M, a:p

>

FD , which means the outward force is greater than the inward drag. Thus the particle would moveoutward and compensate for the perturbance. The

opposite happens when it is p•rtnurbe:1 )utward

-ath matically, the complete expression is:

d(Net Force) d(Fo- Mp-aRg )

d(radius) dR

CD

dR

(

dR

\R

-"• ... .. . ... d Mp g+

in terms of r comes from the expression: Q = 2xrC,-h = constant where r - radius R h E chamber height or -

Qrh

21rh Thus (CR) = h and consequently,d(C,)

dr Q7 d-4-R

dR

Anwular momentum being constant gives us an expression

for Ct in terms of r. If the anzular momentum is always constant then:

H = CR(AT VANES) " sin (angle of turning vanes)-(radius) = constant

Therefore at all ooints in the flow

H

Ct

=

R

Ct

*

= H

-50-where H is the an-,ular momentum. With this expression

d Ct d H _

-dR R, dFR iR)

Substituting all this derivation into our original

expression yields:

d(Net Force) Co DA p ef+ d (1

-d(radius) 4-7tZ d-R Rd2H - R+

For a given classifier geometry, particle mass and size,

and flow rate, the stability as a function of radius

can be computed. The function

h=f (H.)

must be known for the solution of the stability function,

but an approximation of a surface, or discrete point

by measurements of actual classification chamber

heights can be inserted to get a solution.

The last parameters of immediate interest that

can be calculated from a mathematical model of the

classifier is the equilibrium particle density of a

given orbit radius, i.e. what would be the density of

a particle in a given orbit in equilibrium? Referring

to Chapter I, we derived the following expression for

S2 VP ep Ct P

C A.P*~ CR

This expression can be rearranged into the form:

p Co * Ap" e-Sp C *

RP

2

*V

C

Since the model predicts CR and Ct for each point

in the flow, the model will also yield an equilibrium

density for a particle of given volume, area, and

drag coefficient, once a value for the radius is

inserted.

In summary, from simple considerations of

conservation of angular momentum and incompressibility

we are able to construct a mrode' of the classifier

which will yield the flow velocity and angle at

every point. With this information we can compute

the radial acceleration, particle orbit stability,

-52-Section 3-3: Apnlication of modeling procedure to

actual prototype

Employing the procedure outlined in the previous

section I wrote a digital computer program that solved

the equations involved. Parameters such as flow and

surface shape had to be inserted, as well as

turning-vane angle. The program was therefore constructed

to solve for a variety of vane angles and surface

shapes, so that some insight could be gained into how

these parameters affected particle performance. The

results demonstrated the flow over the existing

classification surface was decelerating and therefore

separating.

For parameters that were relatively fixed on

my prototype such as volume flow, the measured value

of 126 ft3/sec was used. Two nested DO loops then

computed stability, CR, Ct, CTOTAL, DCR/DR and

density of orbit for a surface that was tilted 30 less

than the classification surface of the prototype

(relative to horizontal; see fig. 9 for angle

con-vention), roughly 60.

For each of these surfaces, all the quantities

were solved for vane angles varying from 10 to 350

as plots of the data obtained can be seen in Appendix

IISection A2-1.

Inspection of the plots yields some immediate

insight into the problem encountered with the prototype.

First DCR /DR is positive on the outside half of the

classification surface. This means that the flow is

decelerating and hence separating from the surface.

This accounts for the consistently lower velocity

values the flow near the surface appeared to have.

By looking at the radial velocity flow plot of a

classification surface with an angle of 60 we can see

that the deceleration is due to the height of the

chamber increasing too fast for the decreasing radius

to make the flow constantly accelerate. One can also

see that particles of the given density are stable.

An examination of the radial velocity plot of a 30 surface

shows that deceleration is still present at this

lower angle, and more importantly, stability decreases

as flow deceleration decreases. This makes good

physical sense; if the radial flow were faster at larger

radii a particle perturbed outward would meet more

restorinw force. But such a condition would require

the flow to decelerate over the entire surface, which

-54-separation; thus there is an immediate trade off.

To confirm the existence of deceleration and

separation a titanium-tetrachloride smoke-producing

solution was injected into the classifier (fig. 15)

Although it does rot show in the photorraph, a -epara.Lion

bubble was observed in the flow very close to where

the oro ram oredicted flow deceleration.

With this evidence a new surface was concluded to

be necessary. By reducin], the surface angle to 0

the flow would continually accelerate. Hence it was

decided to design a horizontal classification surface.

The computer calculation of narameters can be found

in Appendix II, Section A.2-2, One can see that the

stabi-lity is reduced, as exTected, but the radially inward

flow is continually acceleratin.r

The astute reader might well wonder why a para-bolic surface, that would just impart a very small

acceleration to the flow, and hence would Yive maximum stability, was not considered. It was, and the

com-puted shape of such an optimum surface will be discussed

later. But the fabrication of curved surfaces is ore

difficult than that of stral.ht surfaces and time

restrictions made flat surfaces the only practical

-56-plot it can be seen the densities that would be stable

in the present classifier. It was thus decided to

construct a horizontal surface 3.5" from the

classification-chamber top.

The old surface was removed, fig. 16 shows the

classifier with no classification surface. Wood ribs

were laid radially as shown in fig. 17, and a new

surface laid as shown in fig. 18. Much care was

taken to make the classification chamber exactly 3.5" in

height. This included cutting and planing each radial

support to height independently. The joints on the

surface were carefully made level, in order to avoid

the two sin'ular points, (points 6 and 12, fig. 7)

where the flow seemed to be "turned over", i.e. the

bottom layer having a wreater flow angle than the top.

It was felt this might be due to a discontinuity at

the joints of the aluminum surface.

A velocity profile was taken of the new surface;

data can be found in Appendix I, Section A1-6. rhings

once again are not perfect, the velocity beiny almost

uniform from top to bottom, but flow angle is still

not uniform.

Particle testing proved to be a complete failure.

FIGURE 17: PROTOTYPE WITH RADIAL RIBS

-"--1

I LI OI I

-60-equivalent to 126 cubic feet per second) to cause all

but the very lightest materials to become airborne,

and even airborne particles did not approach any sort

of orbit. Balls would no longer roll in stable orbits.

Since this surface and geometry represented what should

have been an excellent performer according to design

theory, obviously something was wrong. While injecting

particles it was noted that they seemed to fly in

smooth orbits while in free fall from the top of the

classifier, where they were injected, to the bottom.

But once they encountered the bottom of the classifier

their orbits seemed to decay rapidly. Suspecting our

assumntions about borundary- layer interactic~on, ~a .y

"m.nus efflect" lift, to be in error, it was decided to

investigate particle interaction with the boundary

layer with high-speed stroboscopic pictures.

Section 3-4: Photographic investigation of particle

behavior

Photographs of the particle flight while

interacting with the boundary layer demonstrated the

boundary layer slows the particle to an extent that

inward.

To take rood hiph-sneed pictures of the particle

behavior it was necessary to build a stand to isolate

the vibrations of the classifier from the camera.

figure 19 is a picture of the classifier with camera

stand. A. section of the classifier surface was coated

with matt black paoer, and two dotted radial lines

were added for ohotorraohic reference as seen in fir. 20

To make any quantitative studies of particle motion it

is necessary to inject them with a fairly precise

velocity. To do this a torsion-spring injector was

constructed, as shown in fig. 21. The orotractor

was used to calibrate the device, and it was set in the

Plexialas too as shown in fig. 20. Since it was

computed that narticles would have to be 18 lbm/ft3

or less to orbit stably with 300 vane angles, it was

decided to make the study with balsa-wood blocks, with

densities from 7 - 16 lbm/ft3 . Blocks one-half inch on

each side were chosen for testing because of their

ease of cuttinq, handling, and apoearance on photographs.

The blocks were carefully cut to size and the densities

accurately determined.

The ohoto'raohs showed immediately why the

-62-FIGURE 19: PROTOTYPE WITH CAMERA STAND

the effect of the boundary layer on particle travel

(fig. 22). The square block is being forced into a

predicted orbit for the first few flashes; upon hitting

the bottom it immediately loses some angular speed and

starts to soiral inward to the center of the classifier.

All particle orbits eventually decay and the particles come

to rest against the center screen.

Our assumption about the ma8rnus-effect lift would

obviously not apply to blocks, but even spheres, where

this assumption was thought to be valid, proved to have

the same boundary-layer problem. fig. 23 is a picture

of a balsa sphere coming in contact with the surface.

One can see it oath markedly altered.

Investigation into the exact nature of the magnus

effect showed our initial assumptions to be in error.

A plot of lift versus spin for a sphere (see ref. 4)

reveals that in the Reynold numberevime of our device

and at a reasonable spin velocity the lift is negative,

and thus particles would tend to descend into the

boundary layer instead of liftine out of it. Thus the

oarticles lose angular momentum and quickly stop

orbiting.

The conclusions drawn from the photographic

-66-FIGURE 22: SQUARE BLOCK INTERACTING WITH BOUNDARY

LAYER

perform if there was any boundary-layer interaction.

However, if a classifier could be desiwned so that

particles would have reached equilibrium before hitting,

a boundary layer the concept would still be viable.

Since this required a knowledFe of transient behavior,

and there was not sufficient time to build several

different classifiers to experiment with this thesis,

an analytical approach was taken. By transient

behavior I mean the particle behavior from the time

it is injected with a nonequilibrium speed at a

nonequilibrium radius to the time it assumes a stable

CHAPTER 4

INV,.ST I C•ATTIO: OF TRA)NSIENrT PARTICLE BEHAVIOR BY COMPUTER

Section 4-1: Abstract

A comouter oroaram which numerically simulated the transient behavior of a particle in the air

vortex was developed. It revealed that sorting, of

oarticles by waitinri until they obtained an equilibrium

orbit was unfeasible because of the amount of time

the particle took to reach equilibrium. The accuracy

of the transient particle behavior predictions was

tested by actual photow•raohs, and was found to be

p'ood. Thus the conclusions about equilibrium sorting'

are thouvht to be valid.

Section 4-2: Mathematical description of transient

behavior

Newton's third law can be applied to the

-70-and accelerations we can derive two differential

equations, one motion in the tangential direction and

one for motion in the radial direction, which describe

the transient particle behavior.

ITo describe the transient behavior of any particle

seeking• an equilibrium orbit we have to revert to 1Newton's Third Law, force equals mass times acceleration. In

Chapter I we identified a force and a resultinq

acceleration in the radial direction. The force was the

radially inward drav force:

F

=

CD*.Ap.9

*

(CR

)a

and the acceleration was that necessary to make the

particle assume a circular orbit:

aRP Rp

The particle will obviously move inward or outward until

the force just imparts the right acceleration for a

circular orbit. But if a particle is injected with a

tangential velocity differing from the anfular velocity

of the airflow at the point of interjection, then the

vice-versa. Thus we have an additional force in the tanri-ential direction of maq.itude:

FDt = D At -+ tp

as described in Chaoter I. From these basic

considera-tions two sets of differential.. equaconsidera-tions can be derived

to describe 'article motion in the tanv:ential -and rýdiai

directions.

If in the radial direction the force actin, on a.

narticle does not create the ri-ht acceleration; the

narticle will. not assume a circular orbit but will

disolace inward or out. By u.sin•Ž d'Alembert's principle

we postulate a fictitious force equal to the particle's

mass times its acceleration. Then we can write a

force balance in the radial direction. The radius will be

constant if the acceleration in the radial direction

is of the ria'ht rmapnitude,

aRp

.P

as shown previously. Thus when the fictitious and real

-72-MHPC - F = 0

If this subtraction does not equal zero there will be a

net force which will oroduce an acceleration that will

add or subtract from aRp and cause radial displacement.

If we call this force F' then

F = Mp C'1 F

But it is important to note that Fp must be modified

slightly, for if the particle acquires any radial

velocity, it will affect the magnitude of the drag

force. Thus the comolete expression is:

F M.(ct CA *C

'

AP.

P- * (CR -CRp

)The particle must obey Newton's Law so any net force

must impart some radial acceleration to the particle.

But because we have employed d'Alembert's principle, this acceleration we label

a = aR - C

Rp

RP

RP

F' = Mpt aRp

Substituting into the earlier expression we 'et:

M, a - Mp *(C )8 i- A ,C CP

SP. - -(CR - Rp

or

a

(CtP 1- C * ' . (CR - CRp )Rp Rp C) A MP

In differential form this is:

2

dz R a

dtz2

Rpand hence we have a differential equation describing

transient motion in the radial direction; in terms of

known classifier parameters.

In the tanvential direction things are simpler.

The net force has already been defined by the expression:

FO= D Co APe• (Ct - Ct) and

There fore

ap = 2 - = CI Ap

e

(C-where S is the distance travelled measured alone' the

curve of flight.

With these two equations we have a complete

description of the particle motion as a function of

time. However, since both equations are highly

non-linear when reduced to common factors, it is

neces-sary to solve them numerically.

Section 4-3: bNumerical prediction of transient

behavior and ap:reement with observed

behavior

With differential expressions for particle

motion we can obtain numerical solutions. Numerical

solutions of particle behavior in the existing

prototype show there would be no combination of

particle density, injection speed, and injection

r~a·3 •hi.h •Kou. 6 be well behaved.

The t.•. differential ecquatl.-· of the orevious

-74-section can be solved on the Interdata Computer

usinix the M.I.'. written solution routine called DYSYS.

This is essentially a Runqe-Kutta solution alporithm.

A oro!ram was written which incorporated the mathematical

model of flow of the orevious section. Hence the

solution Dredictin nparticle behavior is based on the

model of the flow usinp the measured air-flow rate, and

classifier geometry, denendinq on classification-surface

sha e.

The results of this pro7ram for particles of

13 ibm/ft3 injected at a radius of 31.5 inches, which

is the equilibrium radius, and a speed of 5 inches/sec

greater or less than the 130 inches/sec which is the

equilibrium velocity, resulted in very erratic behavior.

Fi1ure 24 is a plot of particle radius versus distance

travelled. Once can see the particle flies out of the

dimensions of the existing prototype, which has a

maxi-mum radius of 45 inches, and still has not stopped its outward travel.

Even thoufh this particle has a positive stability

function, the particle behaves as on the verge of

instability. By examinin7 the stability function a

little closer we note it will be positive if the

RAeDIUS IN INCWE6~

I 2. 3 4 S.

TIMEi IN SECONDS..

However, this qives no indication of the magnitude of

this force. With the air flow of the actual device these

forces proved to be extremely small, and not strong

enough to restore any significant perturbation from

equilibrium. If the constraint of the exis,,ti.n

clssi-fier size is removed a particle that tends to fly ouitward

will eventually reach a maximum radius, because the

sta-bility function is positive, but this occurs only at

radii orders of magnitude larger than the outer radius

of the actual device. A conclusion that can be quickly

drawn is that our present prototype obviously would not

have worked even if there had been no

boundary-layer-interaction problem. Numerous numerical attempts with

different densities at different radii failed to find

any combination of density, speed of injection, and

radius of injected particle that predicted the particle

would be well behaved.

To see if any classification surface would

perform properly, i.e. have large enough restoring

forces on erratic particles to make them orbit inside

the physical confines of the existing classifier, the

flow conditions of an angled surface of 100 were

inserted into the transient program. This surface was

-?7P

it must be remembered this surface also would have

decelerating flow and therefore would be undesirable in

oractice. The results can be seen in fijj. 25 which is the plot of a 13 lbm/ft3 particle injected at 31.5" radius

with a speed of 135 inches/sec. fhe restorinp forces are

much lar'er, and hence the particle oscillates and

settles down to a smooth oath. However, the equilibriim

radius of a 13 ibm/ft particle in this classifier Qreometry

is about 35.5 inches, yet after 5 seconds and 600 inches of circular travel the oarticle still has descended only

to 37 inches. A longer time period, 20 seconds, shown

in f•i. 26, shows that the oarticle still has not obtained

equilibrium, which it is aporoachnin asymptotically. This

reoresents about 24 comolete revolutions in the existinig

prototyne. ,iin1ce the surface reoresents s tronrer restoring forces than would be practicable because of flow

decele-ration, no actual surface is coing to force the particles

to an equilibrium orbit any faster or even as fast. Any actual surface will not oerform even this well. Bumerous

attempts with other densities and inlection conditions

TIME IN SECONDS