HD28 .M414

9/

WORKING

PAPER

ALFRED

P.SLOAN

SCHOOL

OF

MANAGEMENT

Computer Aided

Engineering

and

ProjectPerformance:

Managing

aDouble-Edged

Sword

David

K. MiirotakeThomas

J. AllenAugust

1991WP

# 47-91SSM

# 3343MASSACHUSETTS

INSTITUTE

OF

TECHNOLOGY

50MEMORIAL

DRIVE

CAMBRIDGE,

MASSACHUSETTS

02139The

International

Center

forResearch

on

theManagement

of

Technology

Computer Aided

Engineering

and

ProjectPerformance:

Managing

aDouble-Edged

Sword

David

K.Murotake

Thomas

J. AllenAugust

1991WP

# 47-91SSM

# 3343©

1991 Massachusetts Institute of TechnologySloan School of

Management

Massachusetts Institute of Technology38

Memorial

Drive, E56-390MJ.T. UBBARIF/

NOV 1 5 1991

REtttvt-w

Abstract

Computer aided engineering tools are like a double-edged sword. Properly emploxed.

CAE

tools improve engineering productivity, and help keep technical projects on schedule and

under budget. For some kinds ofwork,

CAE

tools canalso stimulate creativity.However, computer tools can have equally detrimental effects. For less structured engineering tasks, such aspreliminary analysis and problem solving, the use ofinappropriate

or inadequate tools can severely constrain performance. By encouraging the "cloning" of

old solutions, computer tools can also stifle creativity andyield sub-optimal designs through

negative biasing.

Thispaperpresents the results offield research conducted at two U.S. electronics firms, and recommends a strategyfor employing

CAE

tools which maximizes the benefits ofCAE

whileavoiding or minimizing the pitfalls. A triangulation technique consisting of participant observation, interviews, and questionnaires was used to collect datafrom 116 engineers and 32project managers over a two yearperiod.

The "average" engineer's work day spans manydifferent kinds oftechnical and non-technical

tasks, including A certain amount of managerial work. The engineers in the present sample,

on average, spend about 45 percent of the day performing technical tasks traditionally

associated with engineering. Because engineering is a group-oriented activity, about 40

percent ofthe average day is devoted to communicating in somefashion.

Engineers in our work sample also use a wide range ofcomputer tools in their work, ranging

from simple editors and drawing tools, to sophisticated workstations and integrated

application toolkits. Most oftoday's

CAE

tools are specialized "single-fiinction" tools aimedat leveraging personal productivity. Engineers with access to more sophisticated tools in

their immediate work are more likely to use these tools in their work (r = +0.52).

Furthermore, projects whose engineers makegreater useof computer tools are more likely to be under budget (r = -^0.33).

Given their capabilities and limitations, today's

CAE

tools do not always leverage engineering productivity. Use ofcomputer toolsfor less structured work performed early inthe work cycle is correlated (r = -0.30) with less innovative projects. By contrast, use of

computer tools for highly structured work performed late in the work cycle is positively correlated(r = -^-0.35) with moreinnovativeprojects.

INTRODUCTION

Our

research goal, simply stated, is to better understandwhat computer

tools engineers use for different kinds of

work

and

how

this use relates to the engineers' performance.What

kinds of tasksdo

engineersperform?

What

sort ofcomputer

toolsdo

engineers use for these tasks?To

what

extent are they used?

And

how

is the use ofcomputer

tools by engineersrelated to technical performance at the level of the project?

The

Nature

ofEngineering

Work.

A

number

of studies (Ritti, 1971; Allen,Lee

&

Tushman

1980; Marples,1961; Allen, 1966; Frischmuth

&

Allen, 1969)have

examined

the nature ofengineering work,

and have found

it tocomprise

many

types of activity.Engineering

work

is richly multi-disciplinary,spanning

scientificexperimentation, mathematical analysis, design

and

drafting, buildingand

testing of

hardware and

software prototypes, technical writing, marketing,and

projectmanagement

(Ritti, 1971).But

engineeringwork

is notentirely

devoted

to technical problem-solving. Engineersengage

inmany

other activities,

such

as technicalcommunication,

management,

and

administrative work.

Some

studieswould

indicate that engineersspend

aslittle as

20

percent of their timeon

technology related tasks (Miller&

Kelley, 1984).

Engineering

tasks are thus diverse, rangingfrom

technical design,development, and

test (traditionally associated with engineeringwork)

tomanagement,

manufacturing, communications,and

market analysis.Based

on

a preliminary study (Murotake, 1990)we

have

grouped

these tasks into eight categories (Table I): environmental scanning, analysis, design.Table

IThe

Nature

ofEngineering

Work

Environmental Scanning

MarketEvaluation

User RequirementsEvaluation TechnologyEvaluation

Design (Synthesis)

SystemDesign

&

SpecificationMechanicalDesign

&

SpecificationElectrical

&

OectronicDesign&

Specification

Software Design

&

SpecificationMechanical Development

&

PrototypingElectrical

&

ElectronicDevelopment&

Prototyping

SystemIntegration,Testing

&

DebuggingProduction And Maintenance

Manufacturing

&

ProductionEngineeringQualityAssuranceEngineering

Maintenance

&

Troubleshooting CommunicationDiscussions

&

Meetings Writing&

Editing SearchingForInformationReading

Presentations,Demonstrations

&

Briefings

Education

&

TraimngDrafting and Drawing

BriefingPreparation/Presentation

InfcnnationSearchEducationandTraining

Reading

Other; Administrativeactivities,holiday

andvacation,travel, etc.

Production And Maintenance

Manufacturing

&

ProductionEngineeringQualityAssuranceEingineering

Maintenance

&

TroubleshootingComm

urncation Discussions&

Meetings Writing&

Editing SearchingForInformationReading

Presentations,Demonstrations

&

BriefingsEducation

&

TrainingManagement Activities

Project

&

ProposalManagementUnit,Group

&

SectionManagementStrategicPlanning

&

ExecutiveManagement

Software Design

SoftwareCoding

&

Debugging Overall S>stem DesignOverallSystemIntegration ProductionManagement\

Production

&

ProcessEngineeringAdministrative GroupManagementQuality Control

Technical Management

PIaiming

TechmcalCommumcation

OtherCommumcation

WntingandIBditing

Meetings/Seminars(attendance)

Computer

Tools

forEngineers.

Computer

tools are available to addressmost

major

components

of engineering work, including mathematical analysis, engineering designand

development,

desktop

publishing,and

technicalcommunication.

The

integration of diverse tools in a workstation tool kit is

one

of themajor

contributions of

CAE

development:CAE

is an outgrowth ofCAD

and

designautomation...

CAE

brings thecomputer

into thedesign process further upstream -

from

thephysical aspects ofthe design to the design itself.

Using

CAE,

themodem

engineer can conceive,design, simulate, modify,

and

draft at a single workstation. (Swerling, 1982)Engineers at the

two

research sites spend,on

average, several hours perday

performing awide

range of engineeringwork

(Figure 1).About

halfof the engineering use of

computers

supports traditional technical activities such as analysis, design,and

development.About

a fourth of thecomputer

time is spenton

technical documentationand

communication

related work.Making

Engineers

More

Productive with

Computer

Tools

A

report for the National ScienceFoundation

asserts thatCAD

can

significantly reduce the time

and

cost of product design,and

contribute toindustrial competitiveness, especially if

CAD

is used by basic industries(GE/CR&D

et. al., 1976). Increased use of roboticsand

CAM

have been

suggested as a strategy forimproving

a firm's competitive postureon

the international marketplace (Gold, 1982).Automation

technology hasbeen

shown

to be a positive factor in the production function (Nelson&

Winter,An

important factor inimproving

engineering productivityand

the firm'scompetitive posture is the shortened

development

times permittedby

computer

tools(GE/CRD

et al, 1976; Gold, 1982; Johnson, 1984).IBM

reduced their

development

time of theModel

3081

mainframe computer

by over two-thirds usingCAE

(Swerling, 1982). Silicon compilerscan

designcomplex

electronic chips with millions of gates in just afew

hours, a jobwhich

used to take severalmonths

with less sophisticated tools100

i

20.0?

~5.0'

Engineeringschematics

'A"&"B"drawings ;Miller&Kelley,

1984)

4.0:1

IOw'tlP'''"'"Compiler(Wallch, 1984)

'iCmaskdesign(Miley, 1980)

:

_^

J=:iiilMiiil!lliSi3l!lll'3W"''i^^^^^^^^ZO:JiNetlistgeneranon(Rjstine, 1980)

's'^alAutomatedcircuittxsard testing (Tullos 1983)

^:i:JiiSiliilMiiffliiiiiSiiiEteiSsr'; ,

5*0!*' -ifcuitrouting(Rlstlne,1980)

iir>"isiwj«iWiMftwrimii»iraniisi«siia^^

Simple drawings (Chasen, 1980)

'«fflHI!«»)»«Ni«a!ll!»(l«ll(il^^

=ngin©enng drawings(Bowman&Bowman

Assembiydrawings(Chasen, 1980)

3*01 I BM3081 project(Swerling,1982)

=rojectplanning(Miller&Kelley,1984)

Technicaldocumentation(Miller&Kelley,1984) Complexdrawings (Chasen, 1980)

Productivity gains tor various types *'''

of computer aided engineering work

Time

since Implementation

Figure 1 Productivity gains reported in different

CAE

implementation studies.The

lowerportion of the figure

shows

how

productivity gainschange

with time.Note

the initial "learning curve" dip in productivity, followed by productivity gains. In general,productivity gains increase with increasing task complexity

and

repetitiveness (Murotake,(Wallich,1983

),and

which

was

literally impossible without the tools(Miley, 1980).

Automated

circuit board testing permits the exhaustivechecking

of electronic circuits previously considered "untestable"due

to theircomplexity

(TuUos, 1983).Even

basic officeautomation

tools likeword

processorscan

shorten the technicaldocumentation

cycleby

50

percent

(McDermott,

1984; Miller&

Kelley, 1984).An

important factorin

improving

engineering productivityand

the firm's competitive postureis the shortened

development

times permitted bycomputer

tools(GE/CRD

et al, 1976; Gold, 1982; Johnson, 1984).

IBM

reduced theirdevelopment

time of the

Model

3081

mainframe computer

by over two-thirds usingCAE

(Swerling, 1982). Silicon compilers can designcomplex

electronic chips with millions of gates in just afew

hours, a jobwhich

used to take severalmonths

with less sophisticated tools (Wallich,1983),and

which

was

literally impossible without the tools (Miley, 1980).

Automated

circuitboard

testing permits the exhaustivechecking

of electronic circuitspreviously considered "untestable"

due

to their complexity (Tullos, 1983).Even

basic officeautomation

tools likeword

processorscan

shorten the technicaldocumentation

cycle by50

percent(McDermott,

1984; Miller&

Kelley, 1984).Case

studies ofCAD

and

CAE

implementation suggest a learning curve with initial, short-term drops in productivity, followed by gains (Figure 1).In

one

case study ofPC-based

CAE

at a cathode ray tube manufacturer, using thenumber

of engineeringdrawings

per engineeringman-hour

as a productivity measure,an

initial dip of25

percent productivity loss during first threemonths

was

followed by a 2:1improvement

after6

months,and

a 3:1

improvement

after 12months

(Miller&

Kelley, 1984). In anotherstudy involving six

companies and

four strategies forimplementing

CAD,

data

on

perceived

project productivityimprovements

suggested

or

more

design projects, following initial negative productivity losses ofpercent -

25

percentdepending

on

automation

strategy(Gagnon

and

Mantel,1987).

Other

case studiesshowed

long-term productivity gainsranging

from

1.25:1 for highlycomplex

drawings to 4.5:1 for simple logicdrawings, with higher productivity realized for simpler,

more

repetitive tasks(Machover

&

Blauth, 1980).The

Dilemma

-Balancing

Productivity

and

Innovativeness.

There

is a "dark side" tocomputer

tools. Productivityand

innovativenesscompete

for thesame

resources,and

can be at odds. Inan

historical studyof innovation

and

productivity in the automobile industry, simultaneous nurturing of both productivityand

innovativenesswas

described as adilemma:

Stated generally, to achieve gains in productivity, there

must

be attendant losses in innovativecapability; or conversely, the conditions

needed

for rapid innovative

change

aremuch

differentfrom

those that support high levels of productionefficiency. ...Is a policy that envisions a high rate of product innovation consistent with

one

thatseeks

toreduce

costs substantiallythrough

extensive

backward

integration?Would

a firm'saction to restructure its

work

environment

foremployees

so that taskswould

be

more

challenging, require greater skill,

be

lessrepetitive,

and

embody

greater contentbe

compatible

with

a policy thatproposed

toeliminate undesirable direct labor tasks through

extensive process automation?

"No"

is theanswer

prompted

by themodel

toeach

of these questions[which]

suggests a pair of actions that areThis is especially true with

computer

tools,where major

efficiencies aregained

by

"cloning"and

tailoring solutions to previous (and different)problems. Uniformity

and homogeneity

of designscan

result, stiflingcreativity

and

product

performance

through

theacceptance

and

implementation

of suboptimal designs thathappen

to beon

the solutionmenu

(Naisbitt, 1983).Although

productivitymay

improve by

replacing skilledhuman

problem-solvers

with

more

efficient(though

lessimaginative)

machine

counterparts (operated by less skilled operators),design quality

and

innovativeness can suffer (Wallich,1984

;Murotake,

1990).

HYPOTHESES

1

.

Given

equal accessibility, themore

sophisticated thecomputer

tool themore

it will be used by engineers.2.

The

greater the use ofcomputer

tools by a project team, the greater theperformance

of the project, asmeasured

against its planned scheduleand

budget.

3.

The

greater the use ofcomputer

tools by a project team, the greater theperformance

of the project, asmeasured

by ratings of technical qualityand

8

RESEARCH

METHOD

The

researchprogram

used a fully replicated experimental design attwo

U.S. electronic firms.A

triangulation technique,combining

qualitative,ethnographic studies (participant observation

and

personal interviews) withmore

quantitativemethods

(stratifiedrandom

sampling of the engineering population using questionnairesand

statistical analysis),was

used to gatherand

analyze datafrom

thetwo

firms.Measurements were

made

of the type of engineeringwork

performed, the degree towhich computers were

used,and

project performance. Thiswas

done

by administering questionnairesto a

sample

of116

engineersand

their project leaderson 32

projects.Empirical data

on

approximately3500

man-hours

of engineeringwork

were

collected.Company

1 is a defense electronics division of a large technology-based conglomerate. Its fourteenhundred employees

designand manufacture

electronic products for the U.S. defense market.

Company

1 engineershave

shared access to personalcomputers

and

video terminals in theirwork

bays, linked to

networked

minicomputers;

limitednumbers

ofCAD

engineering workstations are available in special

CAD

areas.By

contrast.Company

2 is theR&D

division of acommercial computer

company

About

thesame

size asCompany

1,Company

2 is aCAD/CAM

pioneer with

major market

share in theworld-wide

computer

workstation market,and

has aggressively pursued the goal of a paperless officeand

labenvironment

for its engineers. It has created aComputer

Aided

Engineering

(CAE)

environment

that is amodel

for the industry.Engineers,

managers,

and

secretaries allhave

powerful workstationson

their desks.

The

workstations arenetworked

with high-capacity fileservers, print servers,

and

other computers.High-bandwidth

LocalArea

Networks

(LANs)

bridgenetworks between

buildings, while high-speed telephone data lines linkCompany

2'snetwork

with other networks across the globe.The

Sophistication ofAvailable

Computer

Tools.To

simplify the vast array of availablehardware and

software tools at thetwo

companies, the tools have been classified into four categories:No

tools available:No

computer

hardware

or software tools are available to engineers in the projectteam

in theirimmediate

work

area.Basic

Office

Automation:

The

only toolsimmediately

available toengineers in the project

team

are basic officeautomation

toolssuch

as editors,word

processors, painting/drawing tools, projectmanagement

tools,

and

electronic mail.Hardware

is generally a personalcomputer

orvideo terminal.

Limited

technical capability:Some

computer

tools areimmediately

available to engineers in the project team; these

can

beused

to aid tin technical work. In general, these tools are not integrated,and

include math/statistics packages,programming

tools,and advanced

spreadsheets.Hardware

is generally a personal computer, video terminal or workstation.Advanced

technical capability:Many

powerfulcomputer

tools areimmediately

available to engineers in the project team.These

tools aregenerally integrated (allowing the easy

flow

of outputsfrom

one

application as inputs to another),

and

includecomputer

aided softwareengineering

(CASE)

tools,computer

aided designand

drafting(CADD)

tools,

and advanced

simulation tools in addition to a full suite of officeautomation

tools.Hardware

is generally anetwork

ofadvanced

personalcomputers

or workstations with access tomainframes

or distributed processing.At

bothcompanies,

projectteams have

access tocomputer

tools withadvanced

technical capabilities includingcomputer

aided analysis, design,engineering,

and

drafting.However,

whilemost

(55%)

project engineers atCompany

2have

access toadvanced

tools, only afew (29%)

at10

Company

1have

similar access (Table II).Table II

Sophistication of the

Computer

Tools Available to the Engineers (32 Projects)Company

1Compan

£an^

Sophistication of Available

Tools

Projects Percentageof Projects Percentage of

Projects Projects

11

Use

ofComputer

Tools vs

Company

Company 2

Company 1

m

t^

10 20 30 40 50 60 70 80 90

PercentageofTime ComputersUsedto PerformWork

I

Company1

I

Company2

100

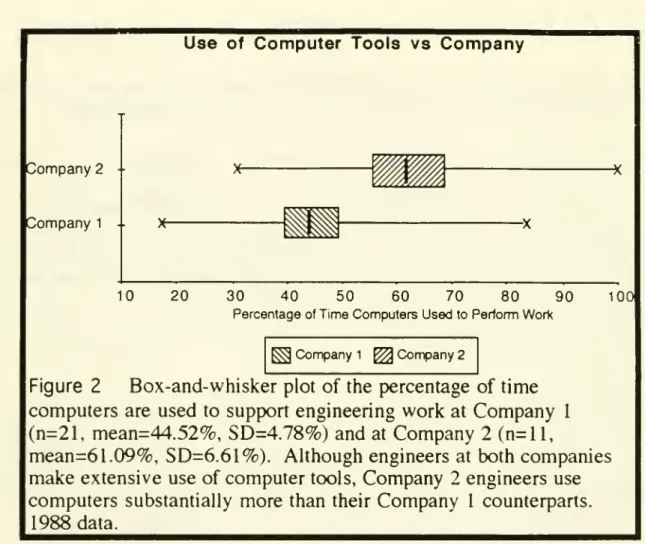

Figure 2

Box-and-whisker

plot of the percentage of timecomputers

are used to support engineeringwork

atCompany

1(n=21,

mean=44.52%,

SD=4.78%)

and

atCompany

2 (n=ll,mean=61.09%, SD=6.6l%).

Although

engineers at bothcompanies

make

extensive use ofcomputer

tools.Company

2 engineers usecomputers

substantiallymore

than theirCompany

1 counterparts.1988

data.Computers

and

Project

Performance.

Projects

whose

engineersmake

greater use ofcomputer

tools are slightlymore

likely to beon

or under the planned budget (r=

-0.33, p<

0.05 ). Thissupports the hypothesis that use of

computer

tools is correlated with higherproject

performance

asmeasured

by beingon

or under budget.The

partial correlations ofcomputer

use with qualityand

innovativeness of thework

providesome

interesting observations (Table IV). Inperforming

the partialswe

control for the sophistication of available tools, since this variedconsiderably across groups.

We

also control for other extraneous variables,such as the level of required technical sophistication in the work, project phase

and

project schedule,which

are substantially correlated with technical12

13

significant.'o

Examining

the data in different phases of the engineering designand

development

process revealssome

very interesting results.The

overalllack of correlation

between computer

useand

projectperformance

resultsfrom two

opposing

relationswhich

nullifyeach

other.

At

thebeginning of the engineering process (idea formulation), increased use of"computers is negatively correlated with innovativeness

(r

=

-0.30), significant at the p<

O.lOi level.However,

at the otherend

of the engineering cycle (development), use ofcomputers by

engineers issubstantially correlated with

more

innovativeness (r=

0.35), significantat the p

<

0.052 level (Figure 4).And,

while use ofcomputer

tools inthe

documentation and communication

area is slightly correlatedwith higher quality (r

=

0.22), it is (not surprisingly) also correlatedwith

less innovativework

(r-

-0.21).Why

thedramatic

difference in the correlation coefficients asone

moves

through the engineering processfrom

idea formulation, through design, to engineeringdevelopment?

We

believe there aretwo

basic

mechanisms

at work.The

first is related to the degree of structureinherent in the work,

and

the "breadth" (orbandwidth)

of thework.

The

second

is related to the "cloning" of solutions usingcomputer

tools.Computer

Tools

and

Work

Structure.As

tasksbecome more

highly structured,computer

toolsbecome

more

capable of leveraging en'^gineering productivity (Figure 3).Most computer

toolsused by

engineers todayhave

sharply focused functionality.Each

tool -

by

design - is

matched

toone

ortwo

kinds ofwork

(word

processors arelA

two-tailed test

isused, since

thisdirection

of relationship

was

not hypothesized.

14

Optimized

for writing;drawing programs

are optimized for drawing;spreadsheets are optimized for calculations, etc.). In fact,

computer

tools

which

supportcomplex

and

highly specialized tasks (e.g. circuitdesign

and

layoutusing

CAD)

usuallysupport

only

one

structured

method,

technique,

or

algorithm.

When

"matched"

to theirintended

role,

computer

toolscan

DevelopmeniDesi'nr

Idea

FormulaUor

iiiiliiiil milIII I

-0.0^ ;^iQ;3C iiiiliiiiliiiiliiiI

l^^\

leverage

an

engmeer

s productivity.When

"forced" toperform

work

outside theirintended

function,computer

toolsmay

hamper

the engineer's efficiency.Also,

while

creative

adaptation

of

acomputer

tool for anew

applicationmay

itself be innovative,

forcing a tool to

do work

forwhich

it is not intended, or requiringengineers to use inadequate

computer

tools,can

alsohave

adverse impactson

project technical performance (Murotake, 1990).Problem

definitionand

problem

solving (analysis)work,

oftenperformed

early in the engineering cycle, is relatively unstructuredand

multi-disciplinary in nature. This kind of

work

often calls formore

innovativeness than

any

other kind of engineering work.The

lack ofI

""

l""

l''

-0^

-0.2 0.2 0.4CorreialioTi CoofficlRnl (rl

Figure 3

For

highly structured tasks, like engineeringdevelopment

work, use ofcomputers

is significantly correlated withmore

innovative work. For loosely structured tasks, such as preliminary analysis

and problem

definition, use ofcomputers

is significantly correlated with less innovative work.15

structure,

and

multi-disciplinary nature precludesany

one

computer

tool

from

supporting the analysis task, while theneed

for creativity defies the use of "existing solutions" for optimal solution.By

contrast,engineering

development

is highly structured("cookbook",

"rack-and-stack",

and

"turn the crank" are terms ofendearment

usedby

engineers to describe this phase of engineering work). Thus,

one

would

expect that engineeringdevelopment

is thecomputer

tool's forte,an

expectation well supported by fact (Murotake, 1990).

CAD

and

CAE

ru!isa

y,mnfl(o^;^A'irri(o)Rin,llliciencJ of

compimT

tools creates zUktX ^uoe"Yhat

ii" designGEHMATIOl

DESIGH

CQmpiMr

tQola eicotr&^e D{solsdou

to old problems, stifling cretfivity.DZYELOPMEH

Figure

4

The

efficiency gained by the use ofcomputer

tools creates slack time which, in turn, can be used to support innovative activity.On

the other hand, the tendency to "crank out"homogenous

solutionsstifles creativity, balancing the efficiency benefits of

computer

tools.Both can

currently be achieved only for structured tasks likeengineering development, for

which computer

tools are well suited.tools are well suited to boost the efficiency of engineers, creating slack

time which, in turn,

can

bemanaged

to yieldmore

time for creativework.

Computer

Tools

and

Homogeneity.

The

desire to "clone" previous16

of previous solutions is a

key

part of the computer's ability toimprove

productivity (Naisbitt, 1983).

The

timeand

effortneeded

to setup

anew

solution foreach

problem

threatens higher productivity.However,

reuse of old solutions

can

lead tohomogeneity

in problem-solvingapproaches

which, by definition, stifles thedevelopment

of innovativesolutions (Figure 6). Further, old solutions

may

represent a "negative biasing set", resulting in suboptimal solutions to theproblem

athand

(Allen&

Marquis, 1963).SUMMARY

AND

CONCLUSIONS.

While

use ofcomputer

tools for preliminary analysisand

problem

solving is correlated with lower innovativeness (r

=

-0.30,N

=

32, p<

0.10)3, the use ofcomputer

tools for engineeringdevelopment

work

issignificantly correlated with

more

innovativeness (r=

-0.35,N

=

32, p<

0.05). Thus, ofcomputer

tools lead to less innovativework

when

used

to support engineering analysisand

problem

solving

butmore

innovative

work

when

used

to supportengineering

development.

The

reasons aretwofold

and

very simple.Computer

toolsmake

engineers very efficient for certain types of tasks, allowing time to be

spent in innovative pursuits.

However

much

of the efficiency isachieved

by

'cloning' old solutions, encouraging homogeneity, stiflingcreativity

and

biasing engineerstoward

convenient butsuboptimal

solutions. In addition,

computer

tend to benarrowly

focused

constraining the 'bandwidth' of the

problem

solving process to fit thecapabilities of the

computer

tool.Recommended

Strategy

A

simple, yet effective, strategy formanaging

the use ofcomputer

tools for engineeringwork

emerges

from

the research:17

1.

Create

and

manage

slack.Computer

tools can be usedto leverage individual

and

group productivity, create in slack inmanpower.

This slack should bemanaged

in away

which

will

produce

both innovation-stimulating tasks for engineersand

increased productivity for the firm.2.

Use

appropriate

tools. Since the nature of engineeringwork

varies considerably, engineers should be provided with acomplete

and

versatile 'toolkit' ofcomputer hardware

and

software tools. Current software technology best supports

structured, repetitive tasks with substantial

amounts

of data ornumerical manipulation.

Use

ofcomputer

tools with anarrow

functional focus to support less focused work, or

work

with high 'cognitive bandwidth', can result in lower performance.Software

capabilities are broadening with time, but for the18

REFERENCES

Abemathy,

W,J,

(1978).The

ProductivityDilemma: Roadblock

to

Innovation

in theAutomobile

Industry. Baltimore:Johns

Hopkins

University Press.Allen, T.J. (1966). Studies of the problem-solving process in

engineering design,

IEEE

Transactions

on

Engineering

Management,

13(2), 72-83.Allen, T.J.,

D.M.S.

Lee and M.L.

Tushman

(1980).R&D

performanceas a function of internal

communication,

projectmanagement

and

the nature ofwork,

IEEE

Transactions

on

Engineering

Management,

27(1), 2-12.Allen, T.J.

and D.G. Marquis

(1963). Positiveand

negative biasing sets:The

effect of previous experienceon

research performance,IEEE

Transactions

on Engineering

Management,

11(4), 158-162. Frischmuth, D.S.and

T.J. Allen (1969).Amodel

for the descriptionand

evaluation of technical problem-solving,IEEE

Transactions

on

Engineering

Management,

16(1), 58-64.Gagnon,

R.J.and

S.J. Mantel, Jr. (1987). Strategiesand performance

improvement

for computed-assisted design,IEEE

Transactions

on

Engineering

Management,

34(4).General Electric/Corporate Research

and Development/Automation and

Control Laboratory, C.S.Draper

Laboratoryand

theMIT

Center for Policy Alternatives (1976).Product Systems

ProductivityResearch:

A

Collaborative

Study, National Science Foundation.Gold, B. (1982). Robotics,

programmable

automation,and

international competitiveness.

IEEE

Transactions

on Engineering

Management

29(4), 135-145.Johnson, L. (1984). Successful application of high tech in technical

design

and

production.IEEE

Engineering

Management

Review

McDermott,

K. (1984).The

utilization of themicrocomputer

word

processor in engineering

management.

IEEE

Engineering

Management

Review

12(1), 45-48.Machover,

C.&

R.E. Blauth (1980).The

CAD/CAM

Handbook.

Bedford

MA:

Computervision.Marples, D.L. (1961).

The

decisions of engineering design,IRE

Transactions

on

Engineering

Management,

8(2), 55-71.Miley, D. (1980). Integrated circuit design. Chapter 5.2 in

Machover

&

Blauth (Eds.),The

CAD/CAM

Handbook.

Bedford

MA:

Computervision.

Miller, J.

&

W.

Kelley (1984). Personal computers,an

engineeringproductivity tool.

RCA

Engineer

(May/June),Murotake,

D.K.

(1990).A

Double-edged

Sword:

RelationshipsBetween

theEngineering

Use

ofComputer

toolsand

Project

Performance.

Doctoral dissertation, Massachusetts Institute ofTechnology,

Sloan School ofManagement.

Naisbitt, J. (1983).

The

outlook:Computer

trends.IEEE

Spectrum

20(11), 110-119.Nelson, R.

&

S.Winter

(1977). In search of a useful theory of innovation.Research

Policy 6, 36-76.Ritti, R. (1971).

The

Engineer

in the IndustrialCorporation,

New

York:Columbia

University Press.Swerling, S. (1982).

Computer-aided

engineering.IEEE

Spectrum

19(11), 37-41.Tullos, R. (1983).

Automated

board testing: coping withcomplex

circuits.

IEEE

Spectrum

20(7), 38-44.Wallich, P. (1983). Automation: Design/ manufacturing,

IEEE

Spectrum,

20(!), 55-58.TJie

International Center

forResearch on

theManagement

ofTechnology

Sloan School of

Management

Massachusetts Institute of Technology

Working

Paper ListNumber

Date Title

1-89 Netgraphs:

A

Graphic Representation of Adjacency Tool for11/89 Matrices as a

Network

Analysis2-90 Strategic Traiisformation

and

the Success ofHigh

Technology8/89

Companies

3-90

Managing

CAD

Systems in Mechanical Design Engineering 1/90Rev. 3/91

4-90

The

Personalityand

Motivations of Technological Entrepreneurs 1/905-90 Current Status

and

Futxrre of Structural Panels in theWood

4/90 Products Industry6-90

Do

Nominated

Boundary

SpannersBecome

Effective6/90 Technological Gatekeepers? Rev. 7/91 7-90 7/90 8-90 8/90 9-90 8/90 10-90 8/90 11-90 8/90 12-90 8/90

The

Treble Ladder Revisited:Why

Do

Engineers Lose Interest in theDual

Ladder asThey

Grow

Older?Technological Discontinuities:

The Emergence

of Fiber OpticsWork

Environment, Organizationail Relationshipsand

Advancement

of Technical Professionals:A

Ten

YearLongitudinal Study in

One

OrganizationPeople

and

Technology TransferExploring the

Dynamics

ofDual

Ladders:A

Longitudinal StudyManaging

the Introduction ofNew

Process Technology:International Differences in a Multi-Plant

Network

Author(s) George Allen Roberts Robertson Allen Roberts

Montrey

Utterback AllenNochur

Allen KatzMcCormack

Utterback Basa Allen Katz Allen KatzTushman

Allen TyreWorking

Paper List (continued)Number

Date Title

13-90 Task Characteristics

and

OrganizationalProblem

Solving in8/90 Technological Process

Change

14-90 8/90

Author(s) Tyre

The

Impact of "Sticky Data" on Innovationand

Problem-Solvingvon

Hippel15-90 Underinvestment

and

Incompetence as Responses to Radical 5/90 Innovation: Evidencefrom

the PhotolithographicAlignment

Equipment

IndustryHenderson

16-90 Patterns of

Commvmication

Among

Marketing, Engineeringand

Griffin7/90 Manufacturing

—

A

Comparison Between

Two

New

ProductTeams

Hauser

17-90 9/90 Rev. 8/91

Age, Education

and

the Technical Ladder AllenKatz

18-90 1/90

A

Model

of Cooperative RiScDAmong

CompetitorsSinha

Cusumano

19-90 Strategy, Structure,and

Performance in Product Development:Cusumano

4/90 Observations

from

theAuto

IndustryNobeoka

20-90 Organizing the Tasks in

Complex

Design Projects 6/90Eppinger

Whitney

Smith

Gebala21-90

The

Emergence

of aNew

Supercomputer

Architecttire7/90

Afuah

Utterback

22-90 Supplier

Management

and

Performance at Japanese, 7/90 Japanese-Transplant,and

U.S.Auto

Plants23-90 Software Complexity

and

Software Maintenance Costs 8/9024-90 Leadership Style

and

Incentives 9/90Cusumano

TakeishiBanker

DatarKemerer

Zweig

Rotemberg

Saloner25-90 Factory Concepts

and

Practices in SoftwareDevelopment

11/90

Cusumano

26-90

Going

PubUc: SeU the Sizzle or the Steak 10/90Working

Paper List (contmued)Number

Date Title

27-90 Evolving

Toward

Productand

Market-Orientation: 11/90The

Early Years of Technology-Based Firms28-90

The

Technological Base of theNew

Enterprise 11/90Author(s) Roberts

Roberts

29-90 Innovation, Competition,

and

Industry Structure 12/90Rev. 6/91

Utterback

Suarez

30-91 Product Strategy

and

Corporate Success 1/9131-91 Cogrutive Complexity

and

CAD

Systems:1/91

Beyond

the Drafting BoardMetaphor

32-91

CAD

SystemUse

and

Engineering Performance1/91 in Mechanical Design

33-91 Investigating the Effectiveness of Technology-Based Alliances: 6/91 Patterns

and

Consequences of Inter-Firm Cooperation34-91

The

High

Centrality ofBoundary

Spanners:A

Source of Natural 5/91 Efficiency in OrganizationalNetworks

Roberts

Meyer

Robertson Ulrich Filerman Robertson Allen George AllenAncona

George Robertson35-91 Impacts of Supervisory Promotion

and

Social Locationon

2/91 Subordinate

Promotion

in anR&D

Setting:An

Investigationof

Dual

LaddersKatz

Tushman

Allen

36-91

Demography

and

Design: Predictors ofNew

Product1/91

Team

PerformanceAncona

Caldwell37-91

The Changing

Role ofTeams

in Organizations: Strategies 2/91 for Survival38-91 Informal Alliances: Information Trading

Between

Firms3/91

Ancona

Schrader

39-91 Supplier Relations

and Management:

A

Survey of Japanese, 3/91 Japanes€-Trar\splant,and

U.S.Auto

Plants40-91 Strategic

Maneuvering and Mass-Market

Dynamics:The

3/91

Triumph

ofVHS

Over

BetaCusumano

TakeishiCusumano

Mylanadis

Rosenbloom

Working

Paper List (continued)Number

Date Title

41-91

The

Softwcire Factory:An

Entry for the Encyclopedia of3/91 Software Engineering

42-91 4/91 Rev. 6/91

Dominant

Designsand

the Survival of FirmsAuthor(s)

Cusumano

Suarez Utterback 43-91 6/91An

Environment

for Entrepreneurs Roberts44-91 Technology Transfer

from

Corporate Research to Operations: EffectsNochur

7/91 of Perceptions

on

TechnologyAdoption

Allen45-91 3/91

When

Speeding Concepts toMarket

Can

Be a Mistake UtterbackMeyer

Tuff

Richardson

46-91 6/91

Paradigm

Shift:From

Mass

Production toMass

Customization Pine47-91

Computer

Aided

Engineeringand

Project Performance:Managing

Murotake

The

International Center for Researchon

theManagement

ofTechnology

Working

PaperOrder

Form

Name:Title:

Company:

Address:

LI Iwould liketo becomeaworkingpapersubscriberand receiveallpapers published duringthecurrent

year. ($125 U.S.,Canada, xVIexico;$150 allothercountries)

l_l I wouldlike to orderworkingpapers individually. Pleasesend

me

the following papers:# # #

Total number papersordered

Additional postage charges (shipmentsoutside USonly)

Subscriptionrate

Within the US: All orders mailed first class.

Outside theUS: Fororders to Canada add$.15perpaper forair delivery. For orderstoothercountries,

add$.25perpaperforsurfacedeliveryor $2.00 perpaperfor airdelivery.

PAYMENT

MUST

ACCOMPANY

THISORDER

Makecheckormoneyorder(inUSfunds) payableto:MTT/ICRMOT

andsendto:

ICRMOT

Working PapersMIT,

Room

E56-390Cambridge,

MA

02142-1347Date

Due

MIT LIBRARIES