Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Fire Study (National Research Council of Canada. Division of Building Research),

1967-06

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=8cb370cf-88fe-4afb-84ff-38585932f107 https://publications-cnrc.canada.ca/fra/voir/objet/?id=8cb370cf-88fe-4afb-84ff-38585932f107

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001334

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Fire tests on wide-flange steel beams protected with gypsum-sanded

plaster

NATIONAL RESEARCH COUNCIL CANADA

DIVISION O F BUILDING RESEARCH

F I R E T E S T S O N WIDE-FLANGE S T E E L BEAMS P R O T E C T E D WITH GYPSUM-SANDED P L A S T E R W. W. Stanzak F i r e Study No. 16 of the D i v i s i o n of Building R e s e a r c h OTTAWA June 1967

FLRE

TESTS ON WIDE-FLANGE S T E E L BEAMSPROTECTED WITH GYPSUM -SANDED PLASTER

by

W. W. Stanzak*

T h i s r e p o r t d e s c r i b e s a s e r i e s of t h r e e f i r e t e s t s on wide -flange s t e e l b e a m s p r o t e c t e d with gypsum-sanded p l a s t e r . T h e t e s t s w e r e c a r r i e d out i n a c c o r d a n c e with t h e p r o v i s i o n s of ASTM s t a n d a r d E l 19, A l t e r n a t e T e s t of P r o t e c t i o n f o r Solid S t r u c t u r a l S t e e l B e a m s and G i r d e r s ( I ) , which does not r e q u i r e a load t o b e applied during the f i r e t e s t . One of t h e b e a m s w a s loaded for information p u r p o s e s .

In o r d e r t o allow g e n e r a l application of t h e t e s t r e s u l t s , only u n r e s t r a i n e d b e a m s of s m a l l c r o s s -sectional a r e a w e r e tested. A n o n - s t r u c t u r a l top cover having a low h e a t capacity and a high insulating value w a s a l s o employed. A s a r e s u l t t h e b e a m w a s not l a t e r a l l y b r a c e d , a s i t would b e when provided with a n o r m a l floor section. C l e a r l y , n o m o r e s e v e r e condition could occur in p r a c t i c e .

DESCRIPTION O F SPECIMEN

T h e construction d e t a i l s of a typical t e s t s p e c i m e n a r e shown in F i g u r e 1. F i g u r e 2 shows a b e a m before p l a s t e r i n g , and F i g u r e 3 a completed t e s t s p e c i m e n p r i o r t o installation i n t h e furnace. F i g u r e 4 is a view of t h e t e s t s p e c i m e n

installed in t h e f u r n a c e b e f o r e t h e f i r e test. T h e i t e m n u m b e r s below c o r r e s p o n d t o t h e p a r t n u m b e r s in t h e figures.

*

S t e e l I n d u s t r i e s Fellow, Division of Building R e s e a r c h ( F i r s t holder of a n i n d u s t r i a l fellowship established by t h e s t e e l i n d u s t r y of Canada at t h e National R e s e a r c h Council).Wide-flange s t e e l b e a m section, 8 in. by 5 1/4 in. by 17 lb/ft, 16 ft

-

0 in. long, Steel Specification ASTM A36-61T. Box loops, #9SWG(O. 144) annealed s t e e l w i r e , 18 in. on c e n t r e , t a c k welded a t edges of b e a m flanges.F u r r i n g channels, 3/4 in. by 3/8 in. by 18GA(0.0478) supplied in 12 f t

-

0 in. lengths, painted with r e d lead oxide paint, *ire tied t o box loops with t h r e e t u r n s oflBGA(O.048) soft galvanized t i e wire.

2

Diamond m e s h m e t a l lath, 3.0 ~ b / ~ d

,

w i r e tied t o channels6 in. on c e n t r e with 18GA(O. 048) soft galvanized t i e wire. Expanded-wing, galvanized c o r n e r bead, 2 1/2 in. by 2 1/2 in. supplied i n 10-ft lengths.

S c r a t c h coat, 1 p a r t gypsum: 2 p a r t s sand (by weight); a v e r a g e 3

density: 105 lb/ft ; a v e r a g e c o m p r e s s i v e s t r e n g t h of 4 cylinders: 419 psi.

Brown coat, 1 p a r t gypsurn: 3 p a r t s sand (by weight); a v e r a g e 3

density: 105 lb/ft ; a v e r a g e c o m p r e s s i v e s t r e n g t h of 4 cylinders: 473 psi.

F i b r o u s a s b e s t o s cement board, 3/8 in. by 16 in., having a 3

density of 42 lb/ft

.

F i b r o u s a s b e s t o s cement board f u r n a c e c o v e r , 318 in. by 31 i n . , 3

having a density of 42 lb/ft

.

M i n e r a l wool insulating bat, approximately 4 in. thick, having 3

a density of 2.04 lb/ft

.

Stabilizer plate, 5 in. by 24 in. by 3/8 in., welded t o b e a m flush with lower flange.

12. Steel bearing plate,

6

in. b;r 24 in. by 1 in.13. Steel r o l l e r s , 1/4 in. by 8 in. long.

14. R e f r a c t o r y c o n c r e t e furnace l i d s and support b e a m s .

15. R e f r a c t o r y c o n c r e t e f r a m e .

The method u s e d i n applying p l a s t e r t o the specimens i s commonly r e f e r r e d t o a s "three coat work, " although for these t e s t s the usual finish coat was not applied. Nominal p l a s t e r t h i c k n e s s e s w e r e 314, 1, and 1 1/4 in. An attempt was made t o hold the p l a s t e r thickness constant, a s m e a s u r e d f r o m the m e t a l l a t h s u r f a c e , but variations of

*

1/8 in. w e r e not unusual; and variations of a s much a s 1/4 in. below the nominal thickness o c c u r r e d a t a few locations.Lathing and plastering was of o r d i n a r y good workmanship. C a r e was taken to apply the s c r a t c h coat s o a s 'to f o r m a good key behind the metal lath. The brown coat w a s applied a s evenly a s was p r a c t i c a l t o provide the specified p l a s t e r thickness. No c r a c k s developed during the conditioning period. T h i s was done by workmen f r o m a local contracting f i r m ; a l l othe= work

r e f e r r e d t o in this r e p o r t was c a r r i e d out by the staff of the Division of Building Re search.

F i g u r e 5 shows a photograph of a b e a m installed in the furnace immediately p r i o r to the f i r e t e s t . The t e s t s p e c i m e n s w e r e subjected to f i r e t e s t approximately t h r e e months a f t e r the p l a s t e r had been applied.

TEST METHOD

The f i r e t e s t was c a r r i e d out in accordance with the provisions of ASTM specification E-119-61: Alternate T e s t of

P r o t e c t i o n for Solid S t r u c t u r a l Steel B e a m s and G i r d e r s . F u r n a c e t e m p e r a t u r e was m e a s u r e d by nine s y m m e t r i c a l l y

disposed thermocouples enclosed in 13/16-in. OD Inconel tubes

having 0.035-in. wall thickness, the tubes tipped with a carbon s t e e l cap. The hot junction of the thermocouples was placed

1 2 in. below the plane of the b e a m under side. Both individual

t e m p e r a t u r e s a t nine points on the furnace and the a v e r a g e of the nine thermocouples w e r e recorded. The fuel input into the

.

furnace was controlled automatically in such a way that thea v e r a g e t e m p e r a t u r e closely followed the p r e s c r i b e d standard t e m p e r a t u r e / t i m e correlation.

Exposed s u r f a c e t e m p e r a t u r e s w e r e m e a s u r e d a t two points a t the c e n t r e span by m e a n s of unprotected chromel-alumel thermocouples. One was located on the under side of the p l a s t e r on the b e a m flange, the other on the under side of the a s b e s t o s board cover.

S t e e l t e m p e r a t u r e s w e r e m e a s u r e d by 17 chromel-alumel thermocouples peened into the s t e e l b e a m a t locations shown in F i g u r e 6. T e m p e r a t u r e s were m e a s u r e d a t four stations

s y m m e t r i c a l l y located along the length of the beam. T e m p e r a t u r e s on the unexposed s u r f a c e w e r e not m e a s u r e d because the f i r e

endurance of the top section was known t o exceed that of the beams. As was mentioned in the introduction, one of the b e a m s (No. 11, with 1-in. nominal p l a s t e r ) was loaded throughout the f i r e t e s t f o r information purposes. Load was applied by m e a n s of four hydraulic jacks a t two points along the span of the b e a m in

such a way that i t was s t r e s s e d t o i t s allowable limit. Additiopal d e t a i l s and load calculations a r e included in F i g u r e 7.

the beam would be s o proportioned that the t h e o r e t i c a l deflection due to the live load would not exceed 1/360 of the span. T h i s would r e s u l t in a live load e x t r e m e f i b r e s t r e s s of only 16,600 psi. Owing to the unusually light dead load on the b e a m under t e s t , however, i t was decided to apply the full live load p e r m i t t e d by maximum allowable s t r e s s design, generating an e x t r e m e f i b r e live load s t r e s s of 21, 100 p s i . Vertical deflections w e r e m e a s u r e d a t the c e n t r e - and q u a r t e r - p o i n t s of the b e a m by means of t h r e e m e a s u r i n g tapes connected to the b e a m by a mechanical s y s t e m .

The a c c u r a c y of the measurerrlents i s approximately

f

0 . 0 1 in.A detailed d e s c r i p t i o n of the f i r e t e s t facilities of the National R e s e a r c h Council i s available ( 2 ) .

RESULTS

Uniformity of the f u r n a c e t e m p e r a t u r e was v e r y good throughout the f i r e t e s t s ; maximum deviation f r o m the a v e r a g e w a s always well within that p e r m i s s i b l e and no c o r r e c t i o n f a c t o r w a s r e q u i r e d . In the two f i r e t e s t s conducted without a s u p e r - imposed load, no visible d e t e r i o r a t i o n of the p l a s t e r cover could be o b s e r v e d during the t e s t s , but a number of thin c r a c k s w e r e visible when the s p e c i m e n s had cooled.

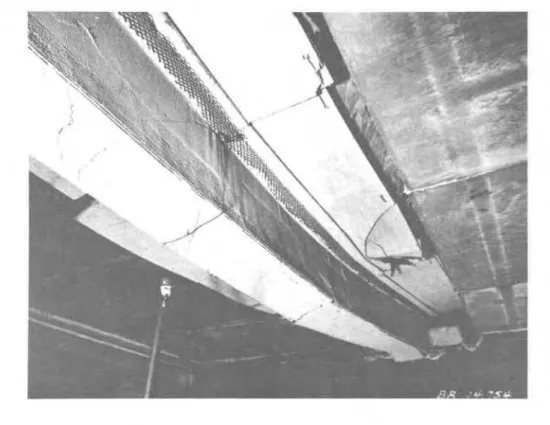

The p l a s t e r on the b e a m with the superimposed load r e m a i n e d intact until the final s t a g e s of the t e s t , and no damage could be o b s e r v e d a t the t i m e the b e a m attained a n a v e r a g e

t e m p e r a t u r e of 1000°F. After 7 7 minutes the b e a m had deflected

downward s e v e r e l y and had buckled and twisted in a l a t e r a l direction. At this t i m e a l a r g e c r a c k w a s visible a c r o s s the width of the p l a s t e r at about the q u a r t e r - p o i n t of the beam. F i g u r e 8 shows the

collapsed beam i n the furnace a f t e r completion of the f i r e test. F i g u r e 9 i s a view of the s a m e b e a m after it had been removed f r o m the furnace.

The r e s u l t s of the three f i r e t e s t s a r e summarized in Table I . Average b e a m t e m p e r a t u r e s a t the hottest measuring station a r e plotted against exposure time in Figure 10. The station number a t which failure o c c u r r e d h a s been marked in brackets after the nominal p l a s t e r thickness.

Figure 11 i s a plot of vertical deflection and r a t e of deflection v e r s u s time for beam No. I I ; Figure 12 shows the deflection

and r a t e of deflection plotted against the average t e m p e r a t u r e of all the thermocouples located on the lower flange of the b e a m (No. 3,

4, 8,

9 ,

21, 13,14,

18, 19).After cooling, beam No. I I was removed f r o m the furnace

and examined. The p l a s t e r was found to have numerous c r a c k s ; that observed during the f i r e t e s t being over in. wide. Vertical deflections of the b e a m a r e shown in Figure 13. In addition to v e r t i c a l deflection, the b e a m was found to have a l a t e r a l deflection of 3; in. a t the c e n t r e and a twist of approximately 30 deg f r o m the original horizontal and v e r t i c a l planes of the flanges and web. COMMENTS

The p l a s t e r on the lower flange of the beam was applied in such a way that only a limited amount could be deposited behind the plane of the metal lath, i t s thickness being approximately the s a m e a s the d i a m e t e r of the w i r e used for box loops. No a i r gap existed between the protective p l a s t e r and the s t e e l of the lower flange. This indicates that heat t r a n s f e r into the beam is p r i m a r i l y through the m a t e r i a l protecting the lower flange. It may thus be expected

that f i r e endurance t i m e will v a r y l i n e a r l y with t h e thickness of p l a s t e r on the lower flange (when the r e s u l t s a r e plotted on s e m i - log paper). A s m a y b e s e e n f r o m F i g u r e 14, w h e r e this h a s been done, t h e t h r e e points do f a l l into a r e l a t i v e l y s t r a i g h t line.

Considering t h e v a r i a t i o n in p l a s t e r thickness ( e s p e c i a l l y behind t h e m e t a l lath), it would b e s u r p r i s i n g i f t h e t e s t points w e r e t o a p p r o x i m a t e

a

s t r a i g h t line m o r e c l o s e l y than they do in F i g u r e 1 4.T h e r e l a t i v e l y l a r g e s l o p e of t h e line indicates t h a t it would be i m p r a c t i c a l t o exceed a f i r e endurance t i m e of 1 1/2 hr with t h e type of p r o t e c t i o n studied. If t h e lath on t h e under s i d e of t h e b e a m w e r e f u r r e d sufficiently f r o m t h e lower flange t o p e r m i t an air gap, however, a significant reduction of p l a s t e r t h i c k n e s s f o r a given f i r e endurance t i m e might b e expected. T h e effect of a m e m b r a n e p l a s t e r protection will be d e s c r i b e d in a f u t u r e F i r e Study.

It is i n t e r e s t i n g t o note t h a t t h e deflection and r a t e of deflection c u r v e s shown in F i g u r e 1 2 begin t o r i s e v e r y steeply once the a v e r a g e t e m p e r a t u r e of t h e lower flange exceeds 1000°F. T o w a r d s t h e ends of t h e s e t e s t s t h e upper flange w a s a t a

t e m p e r a t u r e approximately 100 o r m o r e d e g r e e s below t h a t of t h e lower flange. T h e a v e r a g e of all t h e t e m p e r a t u r e s on t h e b e a m w a s usually not m o r e than 50 F d e g r e e s below that a t t h e

station causing failure.

According t o t h e Robertson-Ryan c r i t e r i a , c o l l a p s e w a s imminent when t h e a v e r a g e t e m p e r a t u r e i n the lower flange w a s 11 53" F, although i t w a s p o s s i b l e t o c a r r y on t h e t e s t until t h e a v e r a g e t e m p e r a t u r e r e a c h e d approximately 1170" F. T h i s is i n c l o s e a g r e e m e n t with other f i r e t e s t s conducted i n t h e DBR l a b o r a t o r y on s t e e l b e a m s with a r e c t a n g u l a r c r o s s -section. T h e s e b e a m s a l s o had a n o n - s t r u c t u r a l top cover having low h e a t capacity and a high insulating value.

P l a s t e r s with sand a g g r e g a t e have a somewhat higher conductivity than p l a s t e r s with light-weight aggregate. The t e s t s d e m o n s t r a t e d , however, that gypsum-sanded p l a s t e r i s a s a t i s - f a c t o r y m a t e r i a l i n that i t d o e s not d e t e r i o r a t e significantly during f i r e exposure. (The cracking and falling off of p l a s t e r on b e a m No.

II

w a s due t o the deflection of the b e a m and not t o the effects of the f i r e on the p l a s t e r . ) It h a s p r e v i o u s l y been thought that with thick p l a s t e r c o v e r s , l a y e r s of the brown coat would s e p a r a t e f r o m the s c r a t c h coat during f i r e exposure.ACKNOWLEDGEMENT

T h e s e t e s t s w e r e c a r r i e d out a s p a r t of a cooperative p r o g r a m of work in the F i r e R e s e a r c h L a b o r a t o r i e s of the Division u n d e r the S t e e l I n d u s t r i e s Fellowship a r r a n g e m e n t with the Canadian s t e e l industry.

REFERENCES

1. F i r e T e s t s o f B u i l d i n g C o n s t r u c t i o n a n d M a t e r i a l s .

A S T M

Designation: E l 19-61. A m e r i c a n Society F o r Testing and

M a t e r i a l s , Philadelphia, P a .

2. S h o r t e r , G. W. and T. Z. Harmathy. F i r e Endurance T e s t F a c i l i t i e s a t the National R e s e a r c h Council. National R e s e a r c h Council, Division of Building R e s e a r c h , F i r e Study No. 1, Ottawa, J u l y 1960, (NRC 5732).

3. Robertson, A. F. and J. V. Ryan. P r o p o s e d C r i t e r i a f o r

Defining Load F a i l u r e of B e a m s , F l o o r s and Roof Construction During F i r e Test. J o u r n a l of R e s e a r c h , National B u r e a u of S t a n d a r d s , 63C, p. 121 -124, Washington, 1959.

TABLE I

RESULTS O F FIRE TESTS

*

P l a s t e r thickness was m e a s u r e d a t 10 points on e a c h f a c e of the T e r m i n a t e d1 1/4 1 1 / 8 71 2 75

beam, spaced s y m m e t r i c a l l y in p a i r s along the length of the beam,

*:$ Load F a i l u r e (min)

-

72 1/2-

one location a t the c e n t r e span.

*

In o r d e r t h a t f i r e t e s t s might be t e r m i n a t e d before, but reasonably c l o s e to, ultimate collapse, Robertson and Ryan ( 3 ) proposed that - -42

the point a t which both 6 2

-

and 6' r-

~2c 150d should be regarded c 800d

a s a n indication of load failure. hit h e s e e x p r e s s i o n s 6 = maximum C

deflection, in.; 6' = r a t e of deflection, in./hr;

R

= c l e a r span ofC

principal s t r u c t u r a l element, in. ; d

=

distance between the upper and lower e x t r e m e f i b r e s of the principal s t r u c t u r a l element, in. The c r i t i c a l values have been m a r k e d by a r r o w s in F i g u r e s (11) and (12) and w e r e taken a s the end point of the t e s t .F I G U R E 1

T Y P I C A L T E S T S P E C I M E N

I - .

--I

F I G U R E 4 B E A M I N S T A L L E D I N F L O O R F U R N A C E B R 3 8 4 0 - 0

( E a s t )

F I G U R E

6

L O C A T I O N O F T H E R M O C O U P L E S O N STEEL C R O S S - S E C T I O N

B R 3 8 4 9 -3S t e e l b e a m : 8 W = 1 7 A = 5 sq i n .

1.

156"-

! I - 5 6 . 4 i n . ' D = 8 i n . I t BMDL , E s t i m a t e d w e i g h t o f g f i n i s h e d b e a m : 5 5 0 BM,, = 5 5 0 x 1 8 6 t 8 B MLL = 1 2 , 8 0 0 i n l l b l2 800 9 1 0 p s i = 1'4.1 P e r m i s s i b l e d e s i g n s t r e s s f o r A 3 6 s t e e l-

= 0 . 6 1 x 3 6 , 0 0 0 2 2 , 0 0 0 p s i .-.QLL = 2 1 , 1 0 0 p s i T h e o r e t i c a l d e f l e c t i o n d u e t o l i v e l o a d 186 0.5211 1 1 3 6 0 s p a n d e f l e c t i o n =-

3 6 0 0 5 2 N o r m a l d e s i g n l i v e l o a d = 5 2 2 0 x - = 4 , 1 0 0 ~ 0 . 6 6 N o r m a l d e s i g n l i v e l o a d s t r e s s = 2 1 . 1 0 0 x 0 ' 5 2 = 1 6 , 6 0 0 p s i F I G U R E 7 B E A M L O A D I N G O R 3 8 4 9 - 4>,. - ,

0 10 20 30 40 50 60 70 80 9 0 T I M E , M I N

F I G U R E 10

A V E R A G E T E M P E R A T U R E O F S T E E L A T H O T T E S T S T A T I O N V S T I M E

N o t e : D e f l e c t i o n d u e t o l i v e l o a d w a s 0 . 6 2 I n .

-

D e f l e c t i o n R a t e o f d e f l e c t i o n 10 20 30 40 50 60 70 80 90 T I M E . M I N F I G U R E 11 C E N T R A L D E F L E C T I O N A N D RATE O F D E F L E C T I O N 8 R 3 8 4 O - 6P C

-

VI 0 w