Zeitschrift fürPhysikalischeChemie, Bd. 208,S. 107-136(1999) © byR. Oldenbourg Verlag, München 1999

Copper Electrodeposition

on

Alkanethiolate

Covered

Gold Electrodes*

By

O.Cavalleri,

A. M.Bittner**,

H.Kind,

K. KernInstitut de

Physique

Expérimentale,EcolePolytechniqueFédéraledeLausanne, CH-1015 Lausanne,SwitzerlandandT. Greber

Physik-Institut, UniversitätZürich,CH-8057Zürich,Switzerland

(ReceivedDecember 1, 1997;

accepted

December23, 1997)Cyclic voltammetry

IFilmgrowth

IScanning tunnelling

microscopy

(STM)

ISingle crystal

electrode ISurface

structureIThiolsIX-ray photoelectron

spectroscopy

(XPS)

We have investigated the structure and thermal dynamics of alkanethiolate layers on

Au(Hl)with variabletemperaturescanning tunnelling microscopy(STM), X-ray

photo-electronspectroscopy (XPS)and voltammetry.Theresults build the basis fora studyof

electrodeposition of copper on alkanethiolate-covered Au(lll).

Electrodeposition

has been studied as a function ofthe thiolate chainlength, thedepositionpotential

and thetemperature. Time-resolved in situ STM and voltammetry, both at temperatures up to

345K,andXPS of emersedsamplesshowed thatcoppercan

—

depending

onthe

deposi-tion potential

—

eitherformnanometer-sizedislands orlayers, both withoutdestruction ofthe thiolate. We proposeamechanism wherecopperpenetratesthe thiolatelayer. The

slowdeposition rate isdetermined

only by

kineticfactors since Cu/Cu2+ exchangepro-cessescannotoperate.

Finally

wediscuss therole of thiolatesaspreadsorbedsurfactants.1. Thiolate

layers

and the

electrodeposition

of metals

Certain chemical elements or

molecules,

especially

soft bases such asiodide, bromide,

sulphide,

carbon monoxide andcyanide,

areknown tobind withexceptional

strength

tonoble metal surfaces. In electrochemical terms,the substances adsorb

specifically.

Suchadlayers

are oftendensely packed,

hence the atoms or molecules

prefer (quasi)-hexagonal

arrangements

[1—7].

* Presented at the 5. Ulmer Elektrochemische Tage on "Fundamental Aspects of

Electrolytic

MetalDeposition",

June23-24, 1997.**

The

adlayer

geometry is determinedby

theinterplay

ofadsorbate-sub-strate forces that tend to direct the

adsorbing

atoms toplaces

that offer astrong

bond(often

hollowsites)

and interadsorbate forces thatcanbeattrac-tive or

repulsive.

Morecomplex,

but also muchmoreversatile,

are thiolateadsorbates. Alkanethiols

CH3(CH2)„ iSH

('C„

thiols')

formstrongly

adsorb-ed,

ordered thiolatelayers

CH3(CH2)„_,S/substrate [8-10].

Although

theadsorption

process does not differprincipally

from the above-mentionedcases,theterm

'self-assembly'

isemployed

topoint

outthat thiolate interad-sorbate forces are verystrong

—

long adsorption

times are necessary to assemble an ordered structure where the

alkyl

chainsalign

parallel.

Up

tonow,

mainly

theAu(lll)

substrate wasused;

its reconstruction isreadily

lifted

during

theadsorption.

Several studies of vacuum metal

deposition

on thiolate-covered metalsubstrates wereconducted;

Jung

and Czandernacompiled

avaluable review[11].

Theelectrodeposition

ofmetals,

e.g. copper, onthiolatelayers

istech-nically

muchsimpler,

but moredifficulttointerpret

: onehastoconsider the electrodepotential. Especially

the Cu2+/Cuequilibrium

(Nernst)

potential

isimportant.

Positive of thatpoint,

copper canonly deposit

in asingle layer

and

only

on somespecial

substrates(underpotential deposition,

UPD) [12—

17].

Negative

ofit,

normal copper bulkdeposition

takesplace

on anysub-strate

(overpotential

deposition,

OPD).

Electrodeposition

of Cu2+ in the OPD range often results in 3Dgrowth

of copperonmetal substrates ase.g.found with in situ STM

[12a, 18-23].

A similar situation shows up when copper is

deposited

onalkanethiol-ate-covered

Au(lll)

deep

in the OPD range:large

copper nodules with diameters in the 100nm rangedevelop

[24, 25].

In contrast, we worked at moderateoverpotential

which results in acomplex

scenario that can beinvestigated

with in situ STM[26—29].

We found apseudo-layer-by-layer

growth

[27],

i.e. onelayer

is almost finished before the next one starts togrow. Such a behaviour is very rare on bare metalelectrodes

(some

excep-tions of this rule were found with in situ STM

[12a,

19,

30-32]).

On theother

hand,

it is well known that a metal surface coveredby strongly

ad-sorbing

substancescanindeed incite such a2Dgrowth.

Such substances arecalled 'surfactants'; in the

simplest

case, one of the above-mentionedstrongly

adsorbing

atomic ions is asurfactant,

as known for theelec-trodeposition

of silver on iodide-coveredPt(lll) [33].

Usually,

the metalpenetrates

thehalogenide layer;

thetopmost

structure can be addressed as ametal-halogenide

coadsorbate[17, 33-36].

In the presence of alarge

surfactant

molecule,

crystal

violet,

in theelectrolyte,

an STMstudy

indeedproved

the 2Dgrowth

scenario[20,

22].

This situation isalready

close tothe technical

application

where'brighteners'

are added to metalplating

baths to

yield

smoothdeposits.

In the UPD range where island formation on bare metal substrates is a rare

phenomenon (but

see[37]

and[38]),

we were able todeposit

copperCopper ElectrodepositiononAlkanethiolate Covered Gold Electrodes 109 islands with diameters in the nm range on alkanethiolate-covered

Au(lll).

This process is a

relatively simple

method forbuilding

nanometer-sizedmetal structures

[29].

An often

neglected

parameter in electrochemical STM studies is thetemperature

on which we shall concentrate in this paper. As we will showin section

3,

heating

induces severalstages

of disorder inthiolates,

pro-gressing

from the(methyl)

end group towards the substrate.First,

themethyl

rotation is activated atT& 100 Kas revealedby

helium diffractionstudies

[10].

Above 200 K the infraredprobing

oftheméthylènes'

scissors vibrationsuggests

progressive unlocking

of thealkyl

twist(a

rotation around either anS—CoraC-Cbond)

anddevelopment

ofgauche

defects in the otherwise all-transconfigured

chains[39].

Thisbehaviour compareswell with that of self-assembled thiolates on

gold nanoparticles

[40]

andthat of

melting

bulk alkanes[41].

Heating

above 300K as we used for thisstudy

can even affect the Au—S bond: boundaries between different orderedthiolate domains move or

vanish,

masstransport

of the substrate occursandfinally

leads to thehealing

of thetypical

substrate vacancies. Thesevacan-cies are defects

appearing during

theself-assembly [42—45].

A discussion of the

phenomena occurring

uponheating

thiolatelayers

(see

section3.2)

willprovide

a valuable basis forunderstanding

our most recentexperiments

where we followed theelectrodeposition

of copper at elevated temperatures with in situ STM(see

section4).

Electrochemical STMs wereuptonow neveroperated

above 300Kalbeitdeposition

studiesshould be of

greatest

importance

for theunderstanding

of technical metalplating

which ismostly

carried out well above 300K. We will also show that thetemperature

canbe usedas anextraparameter

fortuning

the copperas well as the substrate structure

(see

section4.3).

Encompassing

ourex-periments

at 300K[26,

27,

29]

and therecentresults,

we will focus on thestructure ofthe

deposited

copperin section 4.2 andadditionally analyse

theextremely

slowdeposition

kinetics insection 4.4.Our

experimental

methods are in situ electrochemical STM at 300 up to 345K,

STM innitrogen

at 300 up to 370K,

cyclic voltammetry

andX-ray photoelectron

spectroscopy

(XPS)

of emersedsamples. They

will beexplained

in thefollowing

section.2.

Experimental techniques

The

gold samples

wereprepared by

evaporation

of 120to 150nmgold

on570K hot cleaved mica in a 10~5 mbar vacuum and then annealed for

several hours at —600 K

(2

• 10~6mbar).

Directly

beforestarting

theself-assembly,

thegold

films were flame annealed at very dark redglow

and cooled in ethanol(p.a.,

Fluka).

For theself-assembly,

thesamples

were"beetle" STM

/

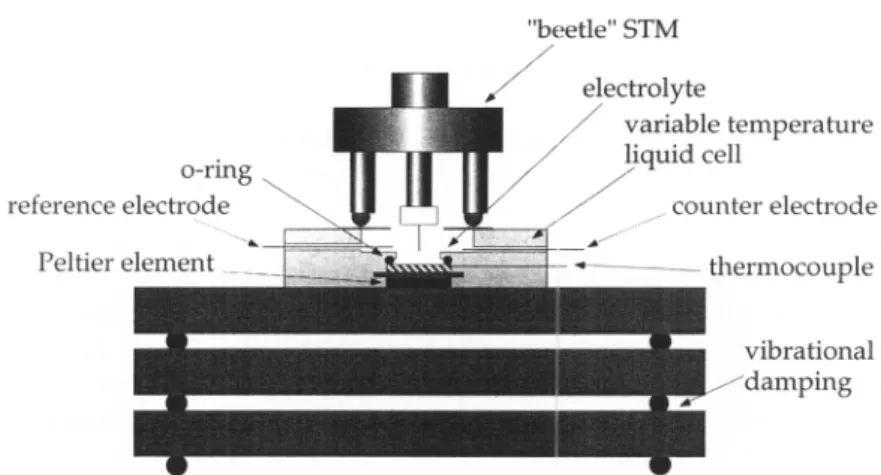

Fig.1. Schematicdrawing of the electrochemicaltemperature-variable STMsetup.

CH3(CH2)„_,SH

with n =6, 8,

10, 12, 14,

16 and 18. Fortheexperiments

carried out under

nitrogen,

thesamples

werekept

at 300 K for at leastone

day.

For the electrochemicalexperiments,

thefollowing self-assembly

programwas used: twohours 300

K,

twodays

ca. 325K,

thereafter several moredays

(or

inrare casesweeks)

300K.Allsamples

wereemersed,

rinsedwith ethanol and

quickly

used. STM measurementswereperformed

asde-scribed in

[29].

As shown inFig.

1,

a new feature is a Peltier element(operated

in theheating configuration)

that wecoupled

with a thin copperspacer to the bare side ofthe mica

sample,

thusattaining

a stablesample

and

electrolyte

temperature

(less

than 1 Kchange

perhour).

Thegold-covered sidewas incontactwith the

electrolyte,

50mMH2S04

(p.a.,

Fluka)

+ 0 or 1 mM

CuS04

(p.a.,

Fluka),

either in water(Millipore®)

or—

for the

high-temperature experiments

—

in 2:1

HOCH2CH2OH

(1,2-ethandiol,

ethylene glycol,

p.a.,Fluka): H20.

Ethylene glycol

veryeffectively

stops

the otherwisequick

evaporation.

The reference was a copperwire,

etchedin

HN03

and rinsed withwatershortly

before use.Thesample

wasmountedin a PCTFE STM cell

equipped

with a Ptcounter electrode. For the XPSsample

preparation

as well as for the redoxpair

measurements,exactly

the sameset-up

wasused. The redoxelectrolytes

containedRu(NH3)6Cl3 (Alfa)

orK3Fe(CN)6 (MicroSelect,

Fluka)

with KC1(p.a.,

Fluka)

and HC1(p.a.,

Fluka)

inethylene

glycol/water,

andanAg/AgCl

referencewasdipped

intothe STM cell. All

potentials

arequoted

withrespect

to the Cu/Cu2+pair

in 1 mM Cu2+(i.e.

0 mV read +250 mV on the standardhydrogen

scale and+50mV on the

Ag/AgCl

(KC1 sat.) scale).

Wealways employed

an EG&GPAR 400

potentiostat.

Thepotential

range above 500mV and below —200 mV wasusually

not accessed in order to avoid oxidation andim-Copper ElectrodepositiononAlkanethiolate Covered Gold Electrodes 111

ages are shown derivatised: steps

descending

from lefttoright

show up asblack

lines,

ascending

ones as white lines. TheX-ray photoelectron

spectrahave been

performed

in a VG ESCALAB 220. After removal from theliquid

we mounted thesamples

with electrical contactand introduced them via a fastentry

lock into the vacuumsystem.

In order to minimizeX-ray

tube induceddamage

thespectrometer

transmission was maximized withlowest

angular

resolution andanoverall energyresolution of 1.4 eVFWHM onthe Au4f7/2

peak

at84.0eVbinding

energy. TheX-ray

twin anode thatprovides

non-monochromatizedMg

Ka(1253.6 eV)

radiationwas retractedand run with 140W

input

power. Withrespect

to the maximum flux thesesettings

lower theresulting

electron flux from an aluminumsample by

afactor of0.3 to 15 nA/cm2. The emission

angle

was 0°(normal emission)

and 80°

(grazing

emission).

Fromthecomparison

ofthetwoemission direc-tions the vertical structure of the chemicalcomposition

of the(Cu)/

CH3(CH2)„_,S/Au(lll)

system

canbe inferred.3.

Alkanethiolate

layers

onAu(lll)

Inorderto

develop

abasis forunderstanding

thecomplex

copperdeposition

process we shall herepresent

studies of alkanethiolatelayers

onAu(lll)

under vacuum, in

nitrogen,

air and immersed inelectrolyte,

all in absenceof copper.

3.1 Structure and

morphology

Let us first focus on the chemical

composition

of alkanethiolatelayers

onAu(lll)

which can be detected with XPS. InFig.

2 the overview spectrumof

CH3(CH2),7S/Au(lll)

(sample

A)

is shown for normal emission. Thespectrum is dominated

by

the strongemission from thegold

substrate and the C Ispeak.

It can be seen that thesamples

remain almost oxygen freealthough they

have beenexposed

to air formore than 100s. In alldetails,

such a

spectrum

istypical

of thethiolate/gold

system[46, 47].

In

Fig.

3 the Au4f,

CIs,

O Is(and

forcomparison

Cu2p3/2)

XP spectraare shown for

sample

A. The Au4f7/2

peak

is set to 84.0eVbinding

energy. TheC Ispeak

is foundat 285.0 eV andcorresponds

tothat ofpolyethylene

chains[48].

We show aswell thespectra

fromgrazing

(80°)

emission(data

for carbon and oxygen are not shown since the

sample

holder contributesto the oxygen and some of the carbon

emission).

As theintensity

fromsulphur

(not shown),

theintensity

of thegold signal

isstrongly suppressed

;this is observed in presence

(as

inFig.

3)

and absence(not

shown)

of copper. The attenuationby

more than one order ofmagnitude

canonly

beexplained by

alayer

model in which the thiolate covers thegold

and binds-1-1-1-1-Au 4) SampleA Au4d Au4f Au4p Cu2p 01s , CuLMM

-~U,

1000 800 600 400 200 0ElectronBindingEnergy (eV)

Fig.2. Normal emission XPS ofaC18thiolatelayeron Au(lll); X-ray source Mg Ka.

Sample Acorresponds to an untreatedsample, while on sample B copper was

electro-chemicallydeposited.

In

Fig.

4 thegrazing

emissionintensity

of the CIs,

the Au 4fand the Cu2p3/2

levelareshownas afunction of exposure timetotheX-rays.

While the carbon emission remains constant, thegold

and the copper emission increase with the exposure time. Forsamples

without copperdeposit

we doobservethesame

aging

kinetics(not shown).

This variationclearly

indicates achange

ofthesample.

Theoverlayer

appears to become moretransparent

tothe emission from the substrate. The

gold

andcopperintensitiesperfectly

fitafirstorder kinetics ansatz I «(1

—

ße~"T)

where

ß

> 1 isasensitivity

factor and where x is the time constant. Within the

uncertainty

of thedata,

the

sensitivity

ß

and the time constant x areindependent

whether copperhas been

deposited

on thesample

or not. Thesensitivity

ß

is 0.45 ±0.07 for copper andgold,

x isinversely proportional

to thesecondary

electron flux from thesample.

From the value of x of 2•

104s and the

secondary

electron emission flux we find that the

secondary

electron currentdensity

from an aluminum

sample

times the time constants is in the order of 2• 1015 e"/cm2. This indiates that the thiolate films arevery

susceptible

toionizing

radiation as alsoreported by

Jäger

etal.[49]

(other

groups foundmuch

larger

timeconstants[50]).

Turning

the attention towards the interfacial structureprobed by

STM,

let us first note that thetunnelling

currentsemployed

(some

tenths ofnA)

are

essentially

sensitive tothesulphur

atom—

the

tip easily

penetrates

the thiolate chains which cannot offer local electronic states in the properCopper ElectrodepositiononAlkanethiolate Covered Gold Electrodes 113

(Fig.

5),

can thus be ascribed tothesulphur

atoms,yielding

a coverage of0.33. Note that thesamestructurewas found fora

sulphide

adlayer

adsorbed on anAu(lll)

electrode and forS/Au(lll)

in vacuum[7].

However,

we detected'super-superstructures',

e.g. the well-known centered(4X2)

distri-O) 'c 3, c O)

J:

0 0 10 20 30 40X-ray

exposure-t¡me(103

s)

Fig.

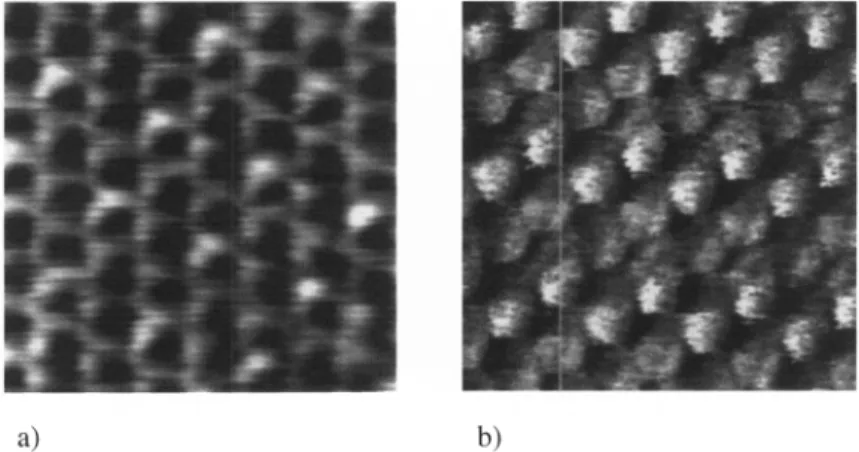

4. Grazing photoelectron emission intensities ofC Is, Au 4f and Cu 2p3/2 (C18 thiolate)as afunctionofexposuretotheMgKoX-raysource.The solid lines in the data of copper andgoldarefitsto first order kinetics.a)

b)

Fig.5.Molecular resolution STM

images

takeninnitrogenshowing

thec(4X2)pinwheel

(a)and thec(4X2)zig-zag

(b) superstructureson aC,0thiolatesample. Tunneling

param-eters: (a) I = 1.0nA, V = 1000mV; (b) I = 0.6nA, V = 1000mV Image size:

3.5 nmX3.5nm.

bution

(Fig.

5)

of the(73

X73)R30°

elements(in

proper notation(3X273))

[10, 52-55].

At lower coverage(attainable

by

vapourphase

dosing

of thiols[56]

orby

heating

above 370K[57, 58])

and for shorti i i

i-C1s

CopperElectrodepositiononAlkanethiolate Covered GoldElectrodes 115

Fig. 6. STMimageofaC10thiolate-covered Au(Hl)surface in air. The dark linesare

thiolate domain boundaries which are pinned by the substrate vacancies (dark spots). Tunnelingparameters: I = 0.3nA,V = 900 mV. Image size: 320nmX320nm.

chain thiolates we detected

striped

structures[58]

(see

also[56,

57, 59,

60]).

Allthese structurescanexist in different domainsseparated by

domainwalls. These walls show up as dark grooves of

roughly

half amonolayer

depth

and 1 to 3nm width. InFig.

6 the walls often extend betweenneigh-bouring

substrate vacancies(large

darkspots),

butthey

can also terminateat other walls or at

steps.

During heating

innitrogen,

the number of grooves in an STMimage

diminuishes,

i.e. the average domain size in-creases[61].

Further

healing

processes that can be followed involve Ostwaldripen-ing,

coalescence and annihilation(at

steps)

ofthe vacancies[43, 45].

The latter are ascribed toetching

processes[62, 63]

and thelifting

of theAu(lll)

reconstruction and concomitant surface diffusionduring

theself-assembly

process[64, 65];

their surface is coveredby

thiolate as are allotherterraces

[58,

66,

67].

Our latest

experiments

show that the(73

X73)R30°

lattice,

domain walls and vacancies arefoundalso when thesamples

areimmersed inelec-trolyte

andkept

underpotential

control(in

situSTM).

When we use themodified

electrolyte

basedon anethylene

glycol/water

mixture,

we can nowadditionally

scanthe surface at elevatedtemperature

[28].

As visualized in theimage

series ofFig.

7,

depicting

a vacancy that israpidly

filled withmaterial from a

nearby

step, we foundhighly

mobile surfacesalready

at 335 K. The surfaceappeared

to be moremobile than innitrogen, probably

a result of the electrochemicalpolarization.

Some further

properties, especially

theability

to transfer electronsthrough

athiolatelayer,

canbeprobed

withcyclic

voltammetry.

Aselectro-lytes

weroutinely

usedsulphuric

acid either inwater orinethylene glycol/

water. In

passing

we note thatweproved

thatethylene glycol

does neitheraffect the

electrochemistry

ofthiolate/Au(l 11)

nor that of the copperre-ductionat

thiolate/Au(l 11)

and bareAu(lll) [28].

Thevoltammograms

aretypical

for nonreactive surfaces since the doublelayer

current is smaller than forabare metal surface. Ingeneral,

the currentfor short chain thiolatesis

larger

than forlong

chain thiolates. Athigher

temperatures

the current risesconsiderably.

Thus electrons canbe transferredacrossthe thiolateeas-ier when the chain is short and the temperature

high.

However,

one shouldkeep

in mind thatthe doublelayer

could have a structure andthuscapacity

differing

from thaton baregold.

Hence we also

probed

the surfaces with a redoxpair, Fe(CN)s/4".

Thevoltammogram

inFig.

8 reveals thetypical

current waves that result fromkinetic and diffusional

limitations,

but with lesspeak

current than on bareAu(lll).

Wefound the samebehaviourasfor the doublelayer

currentmen-tioned above: the redox waves' current rose at

high

temperatures

and for short chainlengths.

Note that thetemperature

behaviourcan be morecom-plex

[68].

Experiments

withRu(NH3)i/2+

normally

showed a muchhigher

current ;

however,

thesamedependence

onthe thiolate chainlength

is found(Fig.

9).

To assess thefindings

we note that the diffusional limitation mustbe the same at bare and thiolated

Au(lll).

The rate of the slowest(rate

determining)

processresponsible

for the thiolates'blocking

behaviour canbe the

charge

transfer across the thiolate orpossibly

apenetration

of thecomplexes

into the thiolate.In the

following,

we shallinterpret

the structure andmorphology

of alkanethiolate-coveredAu(lll)

at 300K. We will progress from asingle

molecule

(sub-nm)

to themesoscopic

scale(pm).

First,

ourXPS datacon-firm the

accepted

structure model of agold

surface coveredby

sulphur-bound thiolates. The small oxygen contamination is

likely

due toairexpo-sure. It may consist of adsorbed oxygenatoms

(e.g.

atthiolate-freedefects)

and/orwater(difficult

toremovecompletely

invacuumchambers).

However,

oxygen isaminor

species

on athiolatesurface,

evenafter exposuretoair.Fig.7.In situelectrochemical STM imagesequence(time separationca. 1 min)

showing

the temperature induced

mobility

ofaC6thiolate/Au(lll) interfaceat335 K.Electrodepotential:

300 mV vs. Cu/Cu2+, i.e.positive

from the UPD range, thus the surface iscopper-free. Electrolyte:

50mM H2S04 + 1 mM CuS04 with the solventbeing

a 2:1mixture ofHOCH2CH2OH:H20.Tunnelingparameters:I =0.5nA,V = 120 mV.Image

CopperElectrodepositiononAlkanethiolate Covered Gold Electrodes 117

a) 100 -, 50

"s

< ° 3. '" -50 -100 b) 1 0 CM B -1 U < -2 3. - -3 -4 -5 O 200 400 E(mVvs.Cu/Cu2+)Fig.8.Cyclic voltammograms foranAu(lH)electrodeat 300K(a),foraC16

thiolate-coveredAu(lll)electrodeat300 K(b,dashedline)andat335 K(b,solidline).

Electro-lyte: 1000mMKC1+ 1 mMK,Fe(CN)6with the solventbeinga2:1 mixture of HOCH,

CH2OH:H20. Scanrate: 50 mV/s. Potentials weremeasured vs.the

Ag/AgCl

electrodeand are reported vs. a hypothetical Cu/Cu2+ (1 mM) reference electrode for an easier

comparison

with thepreviously

shown voltammograms.Extending

the view from asingle

moleculetoneighbouring

molecules,

we notethat the coverage ofsulphur

atoms(and

thusof thealkanethiolates)

is in most cases

1/3;

thesulphur

atoms occopy a(73

X73)R30°

lattice(see

above).

Exceptions

are encountered for the short-chain thiolates(e.g.

n = 6 where this lattice and astriped

structurecoexist)

or for the lowcoverages attainable either for

samples

annealed above 370 K orby

vacuumdeposition

of thiols. As wealready pointed

out in section1,

the(73

X73)R30°

geometry

is also found for theS/Au(lll)

system.

This and other(quasi)hexagonal

structures(e.g.

found when soft bases are adsorbedat noble metal surfaces; evenwhen the substrate structureis not

hexagonal

[1, 2])

aretypical

for abalance betweenadsorbate-substrate andadsorbate-adsorbateinteractions.

Clearly,

this balance has to beadditionally

affected whenalkyl

chains interact with each other. It is well known that this results in the all-transCopperElectrodepositiononAlkanethiolate Covered Gold Electrodes 119

_I_I_I_L

-300 -200 -100 0

E(mVvs.Cu/Cu2+)

Fig. 9.Cyclic

voltammograms

for a C10thiolate (solid line) and a C,4thiolate-covered(dashed line) Au(lll) electrode at 300K. Electrolyte: 50 mM H2S04 + 1 mM Ru(NH3)6Cl3. Scanrate: 50 mV/s. Potentials were measured vs. the Ag/AgCl electrode

and are reported vs. a

hypothetical

Cu/Cu2+ (1 mM) reference electrode for an easiercomparisonwith the

previously

shown voltammograms.| Au OS • C

Fig. 10. Models ofthe CH3(CH2)9S/Au(lll) interface: (a)

alkyl

chains in the all-transconformation,(b) alkyl chainspartially ingaucheconformation.

configured alkyl

chainsbeing

tilted away from thesurfacenormalby

about 30°(see

Fig. 10(a)).

The azimuthal tilt direction lies betweenthe directions of the next and nearest nextsulphur neighbours.

The above-mentionedc(4

X2)

lattice appearstobe basedon anordereddistributionofalkyl

chaintwist

angles (presumably

a twist around the S—Caxes);

structures basedonordered distributions of

alkyl

twistangles

exist also in bulk alkanes[4].

60%

o < 3 -60 -120 -180We can conclude that the thiolate structure is based on the strong Au—S

bond;

the maximum coverage isgoverned by

S —S and interchain interac-tions—

each one exhibits an energy

minimum,

and theirinterdependence

yields

an overall minimum with theoptimum

geometry

described above.The

densely spaced alkyl

chains form an effective spacerlayer

that blockselectron transferas evidenced

by

the voltammetric data.On the

length

scale of 10nm,we find the groovesthatform thebound-aries between

differently

oriented molecular domains.Unfortunately,

it isimpossible

todeducea structural model for them:firstly,

the mechanism oftunnelling

on thiolates is still underdebate,

hence thedepth

is difficult tointerpret; secondly,

molecular resolution of the grooves is very difficult. Thesimplest

idea is anantiphase boundary

where the S —S interdomaindistance is

larger

thanthe intradomain distance of7?

atomicgold

distances,

but also

missing

rowsof thiolate molecules have beensuggested

[55].

Finally

let usshortly

focus on themesoscopic

scale(pm):

this is thetypical

length

ofgold

substratesteps.

Very

long

andstraight

steps

arepre-sumably

due to thehealing

of volume defectsduring

thegold

flamean-nealing (gliding along

internal(111)

planes);

hencethey

can cross eachother. Shorter and more round

steps

shoulddevelop

viatransport

processesduring

gold

flameannealing

andquenching.

3.2 Thermal

dynamics

Substantial

changes

of the surfacemorphology

manifest themselves instep

movements whichcanbe ascribedtothe diffusion ofgold

adatomsorsingle

atom vacancies. Indeed we use the

smoothening

effect ofsurface diffusionin both the vacuum

heating

and flameannealing processing

of ourgold

samples.

Naturally,

such processes arethermally

activated. Onthiolate-covered

Au(lll),

theirrate is muchhigher

than on bareAu(lll)

since theAu—Au interaction is weakened

by

thestrong

Au—S bond. Substrate atom diffusion was also recorded forsimilarly

strongly

boundhalogen

atoms onAu(100) [69a], Au(lll) [69b], Au(110] [70]

andPt(110) [71, 72].

High

temperature

dosing

ofhalogènes

can evenproduce virtually

defect-freesur-faces

[2, 73]

as canprolonged annealing

of thiolate-coveredAu(lll)

[42].

For this

annealing procedure,

the vacancies andstep

edges

moveby

dif-fusion of

single

substrate atom vacancies[26, 45].

This leads to Ostwaldripening

before the vacancies reach each other(vacancy

coalescence)

andfinally

othersteps

(vacancy annihilation).

We can group all such events under theheading 'strongly

activated': thethermodynamic driving

forceshave to be so

large

thatthey

result indesorption

of moreweakly

boundadsorbates. An

example

for adriving

force is thetemperature

that shouldbe above ca. 800 K for

gold

flameannealing

(acting

to desorbimpurities

andresulting

inlarge

scalestep

movements)

oraboveca. 340 K for vacancyCopper ElectrodepositiononAlkanethiolate Covered Gold Electrodes 121

Another

example

for'strong

activation' is the electrodepotential;

changing

it to either morepositive

or morenegative

values can result indesorption

of adsorbed substances and surface diffusion. In most cases, anelectron is transferred from orto the adsórbate

during

thedesorption. E.g.

only

below -1100 mV thiolates desorb fromAu(lll) [74, 75],

demon-strating

thatthey

bindstrongly;

below—

500 mV

sulphide

desorbs fromAu(lll) [7];

below —300 mV iodide desorbs fromPt(110),

causing

surfacemass

transport

of the substrate[72]

; —200mV sufficetodesorb the weakerbonded

sulphate

ionfromplatinum

surfaces[76]).

In thepositive potential

range, the situation can be muchmorecomplex;

often an adsórbate is firstoxidized and the

product

candesorb,

e.g. alkanethiolates are oxidized toalkanesulphonic

acids. In any cases,changing

thepotential

willsupply

theCH3(CH2)„_,S/Au(lll)

interface with additional electrons(or

draw elec-trons fromit)

andthereby

weaken the Au—Au and Au—S interactions. The firstcaseleadstosubstratemobility,

the lattertoadsórbate surface diffusionor

desorption.

However,

theanalogy

tohalogenide

orsulphide

adlayers

reaches itslimits when we consider that in the course of surface diffusion not

only

Au—Au,

Au—S and S —Sinteractions,

but also interchain forces come intoplay. Clearly,

forlonger

alkyl

chainsthey

arelarger

and present anad-ditional

barrier;

hence the mobilities will be lowered(as

observed[43]).

Whether thiolate molecules remain bound to amoving

gold

adatom ornot,during

a diffusion event interchain van-der-Waals bonds are broken andreestablished. Thus the thiolate has toreorient which canentrain formation ordestruction of the all-trans conformation and

change

of azimuth and twistangle.

At

temperatures

above ca. 330K,

alarge

part

of the thiolate moleculesmay exist in an

energetically (slightly)

disfavoured state such as distorted twistangles

orgauche

conformations; thesulphur

atoms remain in a fixedposition.

Let us name such a situation'moderately

activated'.Locally

theeffective thickness will be

lowered,

i.e.'spots'

appear in the otherwise dense 'forest' ofalkyl

chains(see

Fig.

10(b)).

Such'spots'

are not to be confused withmissing

molecules(which

are rare iftheself-assembly

wasgiven

sufficienttime).

Here an ion in theelectrolyte

canapproach

thegold

surface much more

closely.

It canthereby

at leastpartially

penetrate

thethiolate,

facilitating

anelectron transfertoorfrom thegold

surface. For this reason we detecthigher

doublelayer charging

or redox currents when weincrease the

temperature.

The currents also increase when we use shorteralkyl

chains—

in thiscase,the molecular spacer

layer

becomesthinner,

andanioncan

(even

withoutpenetration) approach

thegold

surfacemoreclose-ly

than in the case oflong

chains(see

Fig.

9).

We note that'moderately

activated' processes cannot bebrought

aboutby potential changes

—

this

-100 0 100 200 300 400 E(mVvs.

Cu/Cu2+)

Fig.11.Cyclic voltammogramsforCl()thiolate-coveredAu(l 11)at300K(a) and 335 K

(b)

showing

the temperaturedependent

blocking behaviour towards copperdeposition.

Electrolyte:

50mM H2S04 + 1 mM CuS04 with the solvent being a 2:1 mixture ofHOCH2CH2OH:H20. Scanrate: 10mV/s.

500 mV and -200

mV)

without noticeablechanges

of surfaceproperties.

In otherwords,

in this range theCH3(CH2)„_,S/Au(lll)

system

isideally

polarizable.

4.

Copper electrodeposition

on

alkanethiolate-covered

Au(lll)

4.1 From UPD islands to OPDlayers

We

begin

thepresentation

of the copperdeposition

studies with the voltam-metricexperiments.

Herevoltammetry

is notsimply

ananalytic

tool,

butalso the methodtoachieve

potential

control of thesystem

(for

the STM and XPSexperiments,

we started at apotential

of 400 mV where copperde-posits

neither on bare nor on thiolatedgold,

then lowered thepotential

insteps

of20,

50 or 100mV).

The

voltammograms

of thiolate-coveredAu(lll)

samples

in contact with Cu2+ inelectrolytes

basedonwateraswell as onethylene glycol/water

areusually

featureless with low doublelayer charging

currents(see

Fig.

11).

CopperElectrodepositiononAlkanethiolate Covered Gold Electrodes 123

In the UPD

regime,

i.e. above the Cu/Cu2+equilibrium potential

of0mV,

no features were found

either,

albeit in some cases very shallowpeaks

as-signed

tocopperUPD showed up. This behaviour reflects acertainsample-to-sample variability

of thiolatelayers

as alsoreported by

other groups[24, 77].

Below 0mV the currentdrops slightly, pointing

towards copperdeposition

at amuch reducedratecompared

to a baregold

substrate wherecurrents

drop

toseveral tenpA/cm2

(compare

e.g. thecurrenttransients for copperdeposition

onAu(lll) [78, 79]).

Rising

thetemperature

increasesthe double

layer

current and reveals small UPDpeaks

for allsamples

(see

Fig.

11).

A reasonableexplanation

is thehigh

temperature

defect structure of the thiolate(see

section3.2)

that should accelerate the reduction of Cu2+. Faradaic andcharging

currents also increase withdecreasing

thiolate chainlength.

Thesefindings

compare well with the behaviour incopper-free

elec-trolytes

(see

section3.1):

higher

temperatures

and shorteralkyl

chainsgen-erally

increase the current, whether it is due tocharging

or Faradaiccur-rents

—

in both cases electrons have tobe transferred

through

the thiolate to theadjacent electrolyte phase.

After

regulating

thetemperature

andsetting

thepotential

to a fixedvalue,

the surface structure can be followed time resolvedby

insitu STM.We now have to consider three

parameters

influencing

themorphology:

temperature,

potential

and thiolate chainlength.

In a certain range of theparameters

(UPD

for all thiolate chainlengths

andtemperatures; OPDonly

forn > 12 at lowertemperatures,

seeTable1)

thesystem

showed asurpris-ing

topography:

monolayer

high1

islands with an average diameter of2nm cover10to 15%of the surface(Fig.

12).

They

arerandomly

distributedandalso found in the substrate

vacancies;

they

are notpinned

atsteps

or at domain boundaries. The initial nucleation of these islands couldnotbe fol-lowed. Furthergrowth proceeded

eithernot orextremely slowly

atless than 0.7 nm in two hours.Apart

fromthe fact that island formation in the UPD range is a rarephenomenon

(but

see[37]

and[38]),

the observed islandshave the

unique

property ofchanging

neither size norshape

forhours,

i.e.they

cantruly

be addressed as stable or at least metastable nanostructures.At all other conditions

(OPD

forn < 12and OPD for all n at 345K)

apseudo-layer-by-layer growth

was found(Fig.

13):

islands grow untilthey

coalesce.

Only

islandsalready

nucleated in theUPDregime

grow,nofurtherislands nucleate. In electrochemical terms, the nucleation is

instantaneous,

not

progressive,

in contrast to copperdeposition

on bareAu(lll) [79].

When a

monolayer

is almostfilled,

the nextlayer

nucleates ontop.

How-ever, the

growth speed depends strongly

on thetemperature

and the chainlength.

At 300K,

even the shortest chain(n

=6)

system

exhibits a veryslow

growth

(at

least onehour perlayer).

Athigh

temperatures,

all thiolatelayers

allow arapid growth

in the range of minutes perlayer.

1

The

monolayer heights

of Au(lll) (0.236nm) and Cu(lll) (0.208nm) are too similartobedistinguishedinourSTM setup.Table 1.Copper growthscenarioasfunction of alkanethiolate chainlengthn,temperature

and

deposition

potential range(OPD: <0mV,UPD: >0mV).room temperature elevated temperature short chain UPD 2D islands OPD layer-by-layer UPD 2D islands OPD layer-by-layer

long

chain UPD 2D islands OPD 2Dislands UPD 2D islands OPD layer-by-layerFig.

12.In situ STMimage showing

the 2D copper island formation ona C,8thiolate-coveredAu(lll)surface in theUPDrange. Electrolyte:50 mMH2S04 + 1 mMCuS04.

Electrodepotential:30mVvs.Cu/Cu2+.Tunnelingparameters:I=0.3nA,V= 200 mV.

Image size: 220nm + 220nm.

For a

special

set of theparameters

(short

chainthiolates,

300K,

OPD)

we observed a fractal

shape

of thegrowing

andcoalescing

islands asvisualized in

Fig.

14: each islanddevelops

three 'arms' which canagain

sym-Copper Electrodepositionon Alkanethiolate Covered GoldElectrodes 125

Fig.

13. In situ STMpicture exemplifying

the OPD copperlayer-by-layer

growthon aC,othiolate-covered Au(lll) electrode at 300 K. Electrode potential: -90mV vs. Cu/

Cu2+. Electrolyte: 50 mM H2S04 + 1 mM CuS04. Tunneling parameters: I = 0.4nA,

V = 110mV. Image size: 220nmX220nm.

metry

of theunderlying gold

surface and/ortothesymmetry

of thesulphur

adlattice. Suchgrowth shapes

areusually

associated with akinetically

hin-dered

growth

[80].

To obtain information onthe chemical

composition

of theinterface,

weemersed

C18

thiolatesamples

on which copper had beendeposited

for 3 hat50or20mVat300

K,

i.e.samples

coveredby

copper islands.They

wereinvestigated

with XPS. The overviewspectra

(see

Fig.

2,

sample

B)

show the same featuresas in absence of copper, butadditionally

a Cu2pV2

emis-sion is

present

(correspondingly

thegold

emissiondecreases).

Intensity

curves

(Fig.

4)

indicate arapid

destruction withX-ray

exposure. Theoxy-gen contamination is

slightly higher

than for thecopper-free samples,

but stillcorresponds only

to a minorportion

compared

to that of copper. From theintensity

ratio,

thephotoemission

cross sections and thebinding

energyof Cu

2p3/2

(932.1 eV)

weconclude that thedeposited

copper didnotoxidizealthough

thesamples

had to endure more than one minute of contact withlaboratory

air which should suffice forcomplete

oxidation ofa coppersur-face. Hence the copper is

protected against

oxidation. In addition to theFig. 14. In situ electrochemical STM image of fractal islandsthat nucleated during the

growthof thefirstcopperlayeron aC6thiolate-coveredAu(lll)electrodeat300 K. The

imagewasobtained after80min of OPDpolarizationat —110mVvs.Cu/Cu2+.

Electro-lyte:

50mMH2S04 + 1 mMCuS04.Tunneling

parameters: I = 0.5 nA, V = 120mV.Image size: 175 nmX175nm.

grazing

emission(see

Fig.

3).

Thisemphasizes

that the copperpenetrated

the thiolatelayer

during

thedeposition.

4.2 Structure of

electrodeposited

copperThe formal electrode

potential

(measured

here with the Cu/Cu2+ referenceelectrode)

wequoteisnottheoneofthethiolate/electrolyte

interface. Hencetheoretically

one cannotexpect

a copper bulkdeposition

at 0 mV(even

athighest

Cu2+concentrations).

However,

thepotential

drop

in the thiolatelayers

should not exceed 100 mV since theoverpotential

for copper bulkdeposition

of about 150 mV is the same as on bareAu(lll)

andAu(100)

[18].

The reduction of Cu2+ in acidic mediaproduces

copper metal. In our case it grows inislands,

and the firstquestion

wehave toposeconcerns thecopper islands' distance from the

gold

surface. Wealready

disproved

the idea of copperresiding

inthiolate-free surface areas[29]

since such areaswould result in clear

Cu/Au(lll)

UPDpeaks

for allsamples.

Fig.

15 illustrates the two furtherprincipal possibilities

that arise:first,

the copper islands could be located between thiolate andgold

(CH3(CH2)„_1S/Cu/Au(lll)),

second,

they

could be ontop

of the thiolatelayer

(Cu/CH3(CH2)„-iS/Au(lll)).

We here discard other models becauseun-Copper ElectrodepositiononAlkanethiolate Covered Gold Electrodes 127

H

Au B Cu os • cFig.15. Schematicrepresentationof the

possible

structures oftheCu/thiolate/gold inter-face: copperelectrocrystallized below(a) and above(b)the thiolate layer.likely (e.g.

alloying

into thegold

surface that isonly

known for the(110)

face

[81]).

The second model wouldpostulate

isolated copper islandscon-nectedtothe

methyl

end groups(see

Fig.

15(b)).

Aswealready pointed

out[27],

onemight

think that the necessary electron transfer to thetop

of the chains shouldnicely explain

theslow formation(but

seesection 4.4!).

How-ever, several

arguments

speak against

the model: ifone observesUPD,

thegrowing

metal should have astronger

interaction with the substrate thanwith itself. Forcopperontopof the thiolate

layer,

thisisimpossible

becausethe Cu-H

(or Cu-CH3)

interaction is very weak. The islands evenwith-stand

rinsing

with water, i.e.they

arestrongly

bound.Also,

heating

involv-ing

the formation ofalkyl gauche

defects should shortensome(but

not all!)

of the thiolate chains below an island. Then the island that behaves as a

rigid

copperlayer

'disk'(compared

to the thiolatelayer)

would remain attachedonly

to the intactthiolates,

but the distance to thegold

surface would be the same as at lowtemperature

(when

all molecules areintact).

Hence the electron transfer

probability

would be the same at low andhigh

temperatures,

and copper shoulddeposit

at the same rate; this is not ob-served.Furthermore,

let us assumean island thatadditionally

has somecontacttothe substrate

(i.e.

a copper columnthrough

thethiolate).

Such an islandof copper atoms

should,

in absence ofstrongly

bound coadsorbates(S02~

does not

qualify!),

continueto grow 3D[22]

asCu/Au(lll),

in contrastto the observations.Clearly,

if the thiolatelayer

isdamaged by large negative

Copper placed

below the thiolate(Fig.

15(a))

is in accordance with thefollowing

facts:firstly,

the XPS data show anangular dependence

of theCu

2p

emission whichmustbe due toconsiderable amountsofmaterial,

i.e. thiolatemolecules,

ontop

of the copper.Secondly,

theresulting

Cu—S bond isstrong

andcaneasily explain

thepassivation

ofcopper[29]

:it isimpossi-ble to rinse off the

islands,

they

withstand verypositive potentials,

copper doesnotreactwith air which wouldproduce higher

Ols XPSsignals.

Note that suchathiolate/copper

structurecan be called acoadsorption

structure,and

examples

likeI/Ag/Pt(lll),

detected afterelectrodeposition

of silveronI/Pt(lll) (not

adsorption

of iodide onAg/Pt(lll)!)

are well documented[33, 34, 73].

Thequestion

we haveto address is whether copperatoms canpenetrate

a thiolatelayer;

in section 4.4 we will show that this is indeedpossible.

Here we mention that silverevaporated

onthiolate/Au(l 11)

in vacuum has indeed been observed topenetrate

thelayer

[11, 82].

Let usalso mention that thiolates

readily

adsorb onCu(lOO) [83]

and that evenmultilayer

copper thiolates can form[84].

All thesearguments

lead us to propose aCH3(CH2)„_,S/Cu/Au(lll)

structure.Further structural details are much more difficultto observe. This con-cernsthe lattice of the copperatoms which could be

(1

X1)

asinacomplete

UPD

layer

[15, 85, 86],

ahoneycomb (73

X73)R30°

lattice as in theincomplete

Cu +SOJ"

coadsorption

UPDlayer

onAu(lll) [14, 86-88]

or a normal(73

X73)R30°

structure. All three would offer reasonableadsorption places (e.g.

hollowsites)

for thesulphur

atoms. A more intricatefeature is the structureof the islands' rims. Hereone could

probably

find atopography

that isdistinctly

different from that in the island—

thusonemay

explain

thesurprising

stop

ofgrowth

and hence the instantaneous instead ofprogressive

nucleation. Since this isonly

the case forlong

thiolate chains and lowtemperatures,

we canspeculate

thatespecially

thealkyl

chainsadjust

themselves inaspecial

structure.However,

STM observations(which

for the currents we

employed probe

thesulphur

atoms rather than thechains)

didnotyield

anyclues.4.3 Thermal behaviour

For an

interpretation

oftemperature

phenomena

we have to consider thechanges

thatdevelop

in the thiolatelayer during annealing.

Thegradual

development

of thiolate defect structures such asgauche

conformations,

newtwistangles

orpossibly

azimuthal disorder(see

section3.2)

willagain

allow for

increasing penetration

ofions2,

this timeincluding

Cu2+. As forFe(CN)6~,

a reduction will occur much faster.Doubtlessly,

thecomplete

penetration

is now even more facile.However,

we also have toexplain

aqualitative change:

islands grown on thiolates of all chainlengths

canco-2

On the fate ofthe

hydration

shellwecanonly speculate.This iseventrueinabsence of thiolate [89]!Copper Electrodeposition onAlkanethiolate Covered Gold Electrodes 129

alesce at

high

temperatures.

This means that the unknown barrieragainst

further

growth (presumably

atthe islandrim)

is overcomeby

thermalacti-vation. The

pseudo-layer-by-layer growth

is duetothepresenceofthe thiol-atewhichalways

staysontop; otherwisethegrowth

(on

purecopper)

would carry on much faster and 3D nodules would result. This is the classicalpicture

ofa surfactantthathinders thegrowth

in the directionnormaltothesurface as also observed whencopper was

deposited

ongold

in presence ofcrystal

violet[20].

However,

our surfactant is adsorbed in awell-charac-terized

geometry

and will neither desorb nor readsorbduring deposition.

Thusweexcludeoneof the many processes that

complicate

theunderstand-ing

of surfactant action inelectrodeposition.

At

high

temperatures

substratesteps

becomemobile('strong

activation',

see section

3.2).

Whenweaccept

that copper is boundtothe substrate(see

section

4.2),

copper island rims — copperstep

edges

—should be at least

as mobile as the substrate

steps.

This isequivalent

to an incrased islandperimeter mobility,

i.e. the fractal islandshapes

transform tocompact

shapes.

Obviously,

the barrieragainst

furthergrowth

thatprevails

at lowtemperature

is overcome, and furthergrowth

and coalescence can occur.This

arguments

are in line with thetheory

of surface diffusion limitedaggregation

that hassuccessfully

beenapplied

toexplain

ramified metal islands grown in vacuum.However,

the fact thattemperature

alsoenhances copper

penetration

and thusdeposition

rate makes aquantitative

theoretical

modelling

verydifficult,

sincetwointerdependent

barriers(thiol-ate

penetration

and the barrier at the islandrim)

are overcome at the sametime.

4.4 Potential

dynamics

—copper

deposition

ratesWe shall start the discussion with a look at the

permittable

limits of thepotential.

At thepositive

end,

we dissolve the copper islands atpotentials

several hundred mV

positive

of the Cu/Cu2+equilibrium

value. Note thatwe haveto wait several hours at 400mV

(300

K),

and some islands resistdissolutionevenat1000mV

[29]

whichimpressively

demonstrates thepas-sivation. As one

expects,

the dissolution is much faster when thetempera-ture is raised.

Inthe cathodic

regime, only

wellbelow —200 mV thelayer growth

canchange

to 3Ddeposition

of nodules with diameters above 100nm. Sincevoltammograms

show copper UPDpeaks

after suchnegative

excursions,

some bare substrate

spots

appear to exist which wouldclearly

cause theobserved

growth

oflarge

nodules.Forthe UPD processes, nocurrent flow is found since the

growth

is soslow that the

resulting

peaks

would be far too shallow(sub-nA

range).

In the OPD range, the detectedcurrentsusually

predict

adeposition

ofamono-layer

of copperduring

several minutes which is

-at 300 K

than observed

by

STM. Thediscrepancy

canbeexplained by

the destructionof the

sample

close to the vitonring

where weoccasionally

found visiblecopper

deposits;

this means that copper had heredeposited

at least 100 times thicker than elsewhere. Thus theglobal

current is unreliable at least when its value is small. Therefore we estimate thedeposition

rate from STM measurements:typical

rates are 10% ofamonolayer

in one to twohours

(UPD),

onelayer

in twohours for copperlayer growth

on short andmedium chain thiolates

(OPD)

and onelayer

per minute athigh

tempera-tures

(OPD)3.

Assuming

a Cu(1

X1)

geometry

onAu(lll)

with amono-layer charge

of 440pC/cm2,

thisgives

rates of 0.01pA/cm2,

0.06pA/cm2

and 7pA/cm2,

respectively.

We can setlimitstotheexperimental

rates:0.005

pA/cm2

< r< 10pA/cm2.

(1)

In order toexclude or

verify possible

mechanisms,

it is instructive tocom-pare those rates to rates calculated under

typical

conditions. Let us first assume that bulk diffusion of Cu2+ is therate-limiting

(slowest)

process.Thenthe Cotrell

equation

wouldapply

[12]:

r, = 2

Fc0

JUhti

•[1

-exp

(2

FAE/RT)]

(2)

where F = 96485

C/mol,

D is the diffusionconstantof Cu2+ inelectrolyte

(5.7

• 10~6 cm2/s[90]),

c0 the Cu2+ concentration(1 mM),

t thetime,

R = 8.314

J/(mol

K),

AE thepotential

stepcausing

thedeposition

(e.g.

-100mV)

and T thetemperature.

Weshould then findr, « 260

pA/cm2

•JV(tIsj

(2a)

(comparison:

440pA/cm2

accounts fora Cu(1

X1)

monolayer

onAu(lll)

deposited

in onesecond)

which isabout 100 timeslarger

than the transient we observedduring

the first minute ofpolarisation.

This means that thediffusion isnot the

limiting

factor.This could leave the electron transferasthe slowest process. First let us

concentrate onthecase of copper

deposition

oncopper, e.g. copper islands.Then the slowest

possible

rateis thatat zerooverpotential

where dissolutionand

deposition

currents cancel each other. Theirvalue,

theexchange

currentdensity,

is[91]

r2« 500

pA/cm2

(3)

3

Theestimatesare rough, hence the copperatom