I +.*

Al IVi~

)

B A M R 0 0 A S A M A T E P I A L

FOR

R E I N F 0 R C I N G C 0 X C R E T E

-o ' 4w

A

'zi ~rw

#-NY: 'S -, , jP R E F A C E

In the Winter of 1912, an order of bamboo was placed with a dealer in Shanghai, China. The

bamboo was purchased for specimens to be used in

test-ing its strength. Its extensive growth, its

abun-dance, and its innumerable uses, coupled with the igno-rance of its properties, demand that such a test be made.

The bamboo arrived in May of the following

year after a journey of thousands of miles on board

trans-Pacific ship and over trans-continental railroads.

The whole batch numbered thirty-five of varying size,

weight and age, of which several were injured, but ninety per cent was sound. They were native of Chikiang Province, China.

Experiments were begun in the fall of 1913, and extended throughout the year while f6llowing the fourth year curriculum of the Coursee of Naval

Archi-tecture in the Massachusetts Institute of Technology, in which these experiments were conducted. The

great tensile strength of Bamboo inspired the author to attempt to use it as a material for reinforcing

been devoted to the discussion of the matter; and it is hoped that further experiments will be made to throw more light upon the subject.

The author desires to acknowledge his indebt-edness to the instructing staff in general of the

De-partment of Theoretical and Applied Mechanics of the Massachusetts Institute of Technology; to Mr. Dean Peabody, Instructor in the Department, whose kind

as-sistance in the making and testing of concrete beams

reinforced with bamboo has been most helpful to the author.

Thanks are also due to all those who have

bestowed their helping hand upon the author.

Massachusetts Institute of Technology, May, 1914.

C ONTENTS

PREFACE

CONCRETE REINFORCED WITH BAMBOO ... ... Preliminary Calculation ... ... ...

Design

of Form- ... ... ... ..Estimate of Material, Bending of Sti Pouring of Concrete ... ... ...

Test of Beams ... ... ... ... ... Notes on the Tests .*.. ... . Analysis of Results ... ... ... ...

Conclusion ... ... s. ... s. . Tests on the Tensile Strength of Bamboo Shearing Strength of Bamboo ... ...

Colurimn Tests on Bamboo ... ... ... Specific Gravity of Split Bamboo ..

Coefficient of Friction of Bamboo... Coefficient of Erpansion of Bamboo

Relation of Number of Toints to Diameter

Miscellaneous ... ... *.. ... *..

Veneering of Bamboo.

Bamboo in Aeroplane Work.

Gluing Quality of Bamboo.

... ... ... ... e ... ...

rrups...

... ... ... ... 5 ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... e ... ... ... ... e&ri

Page iv 1 2 910

11

13 24 26 3133

59

63

67 6971

72

74CONTENTS (continued)

Page Carpenters' Tools on Bamboo.

Bending of Bamboo Strips. Cracks in Bamboo.

Cross-sectioning of Bamboo.

Review of Max Ulrich's Work .... Review of Captain Bond's Work ...

Professor Johnson's Tests on Bamboo

Appendix II *.. ... * * . .o . s.. e. ... ...

78

0 . ... ... *. 89 ... a .. ... ... 97 ... ... ... ... 100 ... ... s.. ... 116 1. V11LIST OF ILLUSTRATIONS.

Bamboo as seen in the

Institute Laboratory ... .. . Drawing of Form - Blueprint... ... ...

Wire Machine, used for testing

Tension of Bamboo ... ... ... ...

Shear Block, used for testing the

Longitu-dinal Shear of Bamboo.

Photo and Drawing -. --. ... ...

Emery Machine, 300,000 pounds capacity Bamboo Coluim Split under compression

Drawing of 5-1/2 inch Extensometer,

used in Column Test ... ... ... ...

Bamboo Cracks at a Joint *.. ... ...

Bamboo Trestles and Bridges... ... . Butt of Bamboo, whole and split

Bamboo Grove in China ... Bamboo Grove in China

another view ... ... ... Page Frontispiece. .0 9 .9.. 9... .9.. .9.. ... 9 ... .0 . After Appendix " "

31

58 62 65 6575

89II

II V V Y111 " II.m

I

Y

V

/

/1

I

--C0000**

CONCRETE REINFORCED WITH BAMBOO.

The high tensile strength of bamboo led the

author to conceive the idea of applying this material to the reinforcing of concrete beams on its tension

side. The abundance of growth of the wood and the

ease with which it can be procured in the land of China

would render it of practical value, should it prove to

contribute to the strength of the member to which the

reinforcement of the bamboo has been applied. There

are several large cement factories in China that

pro-duce first grade cement at comparatively low cost. Although reinforced concrete has been used in China

only to a limited extent, time will come when the wave of concrete construction in the West will spread far and wide in the East.

For structures for which steel reinforcing will be too expensive, and where bamboo can do as well

as steel, bamboo can displace steel. For instance,

bungalows, cottages, watertanks, culvert pipes, foot bridges, etc., can be reinforced with this material.

Preliminary Calculation.

zt

Test specimens of reinforced concrete beams are habitually of the dimensions 40 X 8' X 6' - 8".The beam is to be tested with a six feet span, loaded

by two loads symmetrically placed at one third of the

span from each end. Consequently the calculation

should be made on this assumed beam.

The Joint Committee recommends " The lateral spacing of parallel bars should not be less than two

and one-half diameters, center to center, nor should the distance from the side of the beam to the center

of the nearest bar be less than two diameters."

This practically fixes the design of the section as shown in the following figure.

3

There remains, however, the calculation of maxi-mum loads which may be expected of the beams to bear

with such reinforcement. To do so, the common form-las for reinforced concrete has been used. From the long list of formilas numbering sixteen, the one of immediate application to this case is the. following:

3 r+2n X = 1/6 bd2 Cn

---(r + n) 2

where X = bending moment due to safe loads.

b

=breadth

ofbeam.

d = distance from center of tensile steel area to compression side of beam, or the

effec-tive depth.

C = compressive stress in the concrete.

4

n = ratio of Modulus of Elasticity of steel to

that of concrete.

r = ratio of tensile stress of steel to compres-sive stress of concrete.

In this case,

b

= 4"; d = 7"; C =650concrete); n = 15; r = 15.

(1 : 2 : 4 (The values of C, n and r, are Joint Committee reconzrendations . )

2 3 X 15 + 2 X 15

*M 1/6 X 4 X 7 X 650 X 15

---(15 + 15 )2

=

26,600 inchlbs.

...(1)

The weight of concrete beam is:41/12 X

/12

X 6.66 X 150 (lbs, per cu.ft.) = 220# 22277t. per

foot

=

--- = 33.4666

4//ft.

The maximum bending moments due to safe W

load --- and its own weight is: 2)

W 2

220 X 61 3 Equat ing ( 1 ) and (2 ) we have

W 220 X 6

M

26,600 = --- X 2 X 12 +--- X 122 8

W = 2050#

W being the load which is expected of this beam to --- X 2' + - - - - .. . . . .. (2)

S

s tand without failure. As will be seen later, the maximum load under which the beams fail is many times

the above figure. This shows that in the design a good factor of safety has been used.

There remains, however, the calculation of stirrup near the ends of support, in order that the

beams will not fail by diagonal shear, and the

ten-sion in the reinforcing rods may be fully developed.

The Joint Committee recommends a working -shearing stress of 40 lbs. per sq. in.

V = V b

where V = total shear that the concrete is capable to bear without the help of stirrups.

v

= allowable shear stress = 40#/.'j = vertical distance between points of

appli-cation of horizontal tensile and compres-sive stresses.

3 r + 2 n But = d ---3(r + n) 3 A 15 + 2 X 15 =7 X --- -- 5.83" 3(15 + 15) Therefore V = 40 X 4 X 5.83 933#

There is at the support a shear of 1025#+ 110# = 1135#.

Then 1135 - 933 = 200# must

be

taken upby

stirrups.The proportion

1135 : 200 = 2' : x

will give the distance from support within which rein-forcement by stirrups is necessary. Solving the equa-tion,

x

=

.35'

= 4.2"In the actual beam, the stirrup reinforcement extends as far as 20" from the ends of support to make it

doub-ly sure failure will not occur at sections other than

that of maximum bending moment. For stirrups 1/8"

rods are used.

The calculation for beams reinforced with

bamboo Strips are identical with that for steel in

however

7every respect, with the difference that since bamboo is approximately 2/3 of the tensile strength of steel (from Ulrich's test), the sectional area of bamboo should be 3/2 times as much as that of steel; and the beams reinforced with bamboo are so designed.

The author is aware of the unsoundness of this

assump-tion; but in the absence of better information on this

subject, this assumption is perhaps as good as any other. The ratio of sectional areas for steel and bamboo can be revised should the tests prove that the assumption is incorrect.

The bamboo strips available are of the

sec-tion

.3" X .7"

=.21

. Three strips are usedfor one beam. Hence

3 X

.21

=63

Steel with cross-sectional area of 2/3 of bamboo should

be as strong as the latter according to the assumption

2/3

X

.63 = 42LTwo 1/2" rods are used.

Area = 2 X

.19637

=.3926

.3926

Actual ratio = --- -

.623

.63

The following figure shows the beam in its final form. It should be noted that two small steel rods of 1/8"

8

diameter are put near the top of every beam, the idea

being to prevent possible collapse due to making the top side the tension side when handling.

Design of Form.

The accompanying blueprint shows the forms used for the making of these beams. The sides and

bottom are the same, but end pieces are different for different beams, as indicated, to make provision for the ends of the reinforcing rods to lodge in. As

actually constructed, every joint is a mortise and tenon joint, and with numerous wood screws, every joint is made watertight.

We must note here that by keeping the lower edges of both steel and bamboo pieces at an equal dis-tance from bottom of beams, the value of d for steel in the preliminary calculation is not strictly correct

for bamboo; but the discrepancy is small and can be

neglected. Perhaps the assumption of ratio of cross sectional areas for steel and for bamboo takes care of this discrepancy.

Four beams, two of which reinforced with bamboo, and the remainder with steel, have to be made.

Two extra bottoms are made to make possible the pour-two

ing of concrete two weeks after the first/are

finish-ed, using the same sides and end pieces, inasmuch as

it is unsafe to remove the bottom in such a short pe-riod of time.

/A V7&

43x~

HJ;>-

1 fvf 9 f">P JO 37 7

'a0

/A

OupE

Estimate of Material Required.

4 steel rods: 1/2" dia. 6'-11" each.

Length of one stirrup = 15.5"

4 beams each with 14 stirrups.

Total volume = Cement = 1/7 Sand = 2/7

It

of gravel as

voids in the

sieve.

x

x

Total 27'- 8" " 55'- 4" Total 72.5"1

:2:4 concrete.4x8

8" 8" --- X 6.66) X 4 + 6 XX--x

X--144 12 12 12 7.67 cu. ft.7.67

=1.09

cu. ft. 7.67 = 2.2 cu. ft.is customary to have as many cubic feet

concrete, cement and sand filling up

gravel. Gravel to pass through 1/2"

Bending of Stirrups.

To secure uniform results, a form was made of a thick pine plank 10" X 24" X 1-1/2" into which were driven from behind spike nails about 3" long at carefully marked points where the stirrup stopped or

cornered. This insured the greatest degree of

stirrup was only 1/8" diameter, bending with a pair of pliers was not difficult.

The stirrups were fastened to the steel or

bamboo rods by means of small iron wires. 4 such

fastenings on one stirrup for the steel,.and five for

ba0boo.

Pouring of Concrete.

It was on February 26, 1914, that the first

two beams were made. The outside temperature was

in the neighborhood of 320 F., which was, of course,

objectionable as the concrete was liable to freeze

be-fore setting took place. Fortunately the pouring was executed in a shed adjoining the boiler room of the Instit-ite, which kept the temperature inside the shed always above 320 F. The forms having been previously oiled with cylinder oil to prevent

con-crete adhereing on to the form, the concon-crete was mixed according to the directions given in Baker's "Masonry Construction". It was, of course, all hand mixing.

In this pouring, gravel larger than 1/2" grade was used by mistake; when discovered it was

difficult to pack well under and between the

reinforc-ing rods. This difficulty was more pronounced in

the bamboo beam in which three strips were crowded

in-to the space occupied by two steel rods in the steel

beam.

Three 8" cubes were first poured which of course presented no difficulty. But when the beams

were poured, packing the portion underneath the rods was a trying task.

A maximum and minimum thermometer was put

inside the shed to see if the temperature would fall sufficiently to freeze the concrete within a day or

two. The temperature did not fall below 320 F.

with-in several days after the pourwith-ing of the concrete.

Water was occasionally sprinkled over the top of the beams to prevent sudden drying.

Two weeks after the first pouring, the con-crete had set sufriciently to permit the removal of the sides and ends of the wooden forms, leaving the bottoms intact. Extra bottoms were screwed on to

the sides and ends to make ready for the second pour-ing of the other two beams.

The second pouring was performed on March 12, 1914. The process was identically the same as

the previous; but the difficulty of packing was much less than before, inasmuch as 1/20 gravel was used in place of the larger size.

Test of Beams.

60 days was the age chosen at which these

beams and cubes were to be tested. The test on the first two beams and three cubes was performed on April

17, 1914, in the Beam Machine in the basement of the Applied Mechanics Laboratory of the Institute. The

cubes, previously faced with plaster of Paris to give a good bearing, were tested for compression in the

Emery Machine of 300,000# capacity in the same base-ment. They gave the following results:

Compressive Strength of 8" Cubes.

Concrete 1:2:4; age 60 days; stored gravel l".

in air.

No. of Specimen. Max. Load. Comp.Stress,lbs./sq.in.

1 129,000# 2020

2 132,000# 2060

3

130,0

00#

2030Average 2040

Beams were then tested in the Beam Machine. The beams were placed on jack screws 6' apart from center

to center with an overhang of 4" at each end. Be-tween the beam and jack screws were placed steel

plates to distribute pressure. The load was a sin-gle load concentrated at the middle, and was applied

by raising the jack screws, first one end then the

other, This load was balanced by a weight or

weights through a system of levers. The

deflec-tion was measured by micrometers on both sides of the beam, with reference to two piano wires, one on each

side, stretched taut by weights at each end at the mid-dle height of the beam. Loads increased at 500 lbs. intervals. The following pages show the result of tests on the first two concrete beams.

- Transverse Test

-April 17, 1914.

Specimen: Concrete beam reinforced with steel rods.

Concrete 1:2:4; l11 gravel; age 60 days, storage

in air. Load R D R D D2 - 2 1 1 2 2 2 500 .066 Sum Remarks. .037 1075 .077 .011 .048 .011 2000 .105 .028 .075 .027 2925 -141 .036 .111 .036 4000 .189 .048 .159 .048 .011 .028 .036 .048 .011 .039 .075 e Cra1Lc shown at

.123 this load out-side of

stir-nups.

= reading by micrometer No.

"f " " No. 2.

- difference of readings on micrometer No. 1 if if if if V No. 2.

R R2=

1.

Manner of Loading. Span

D imens ions

Weight of yore

* beam Max. scale reading

IG

Single concentrated load at middle.

6'

25 lbs. 220 lbs. 4400 lbs.

- Transverse Test

-1

April 17, 1914.

Specimen: Concrete beam reinforced with bamboo.

concrete: 1:2:4; gravel 1"; age 60 days; storage

in air. R2 D2 - 2 2 .211 .263 .325

.372

.482 crack cement. Sun Remarks. .052 .061 Small crack .062 .061 .122 4 small cra evenly spa .047 .049 .171 .110 .111 .282at a bad spot patched with neat

cks ced. Load R 600

875

1100 1300 1600 3120 .294 .363 . 423 . 474 .585 .069 .060 .051 .111 Bad18

Manner of Loading: Single concentrated load at middle.

Span 6'

Dimens ions 46I 8*

Weight of yore 25 lbs.

* beam 220 lbs.

Max, scale a"4 reading 3120 lbs.

S5TRES53 3TRAIN

DIAGRAM

re-3T I

The test for the second set of beams and

cubes was performed on May 7, 1914. at the same place. The procedure and operation were practically the same

as in the former tests. The manner of loading the

beams was two concentrated loads dividing the span

in-to three equal parts.

The three cubes gave the following results: Compressive Strength

Concrete 1:2:4; age 60 days;

No.of Specimen. Max. Load

in lbs. 1 142,200 2 141,500

3

118,300

of 8" Cubes. storage gravel 1/2" in air; Comp. stress in Lbs./sq. in. 2220 2210 Average 2220The following pages show the results of

- Transverse Test

2

-May 7, 1914.

specimen: Concrete beam reinforced with steel rods. Concrete: 1:2:4; gravel 1/2"; age 60

D 1+ D 2 DI R2 D2 ~~2--w

.063

.005 .069 .007 -080 .011 .093 .013 .105 .014 .121 .014 .137 .015 -151 .016 .166 .014 .185 .015 .204 .026 .231 .020 .250 .006 .029 .013 .012 .016 .016 .014 .015 .019 .019 .027 .019 .005 .012 .012 .015 .015 .015 *016 -017 .017 .026 .020 Sum .012 .024.039

*

054

.069 .085 -102 .119.145

.165 days; storage in air. Remarks. 2 cracks, one 10 to the right and other 4" to the left of C. L.Manner of Loading: 2 concentrated loads dividing the span into 3 parts.

Span 6'

Dimensions

Wt. of yoke, I-beam, etc.

1" beam

Max. scale reading

Sketch: Load R 500 1000 1500 2000 2500 3000 3500 4000

4500

5000 5500 6100 6500 -015 .020 .027 .038 -051.065

-079

.094 - 110 .124.139

.165 -185 220# 2 20#6900#

- Transverse Test2

May 7, 1914.

Specimen:

Concrete beam reinforced with bamboo.

Concrete: 1:2:4; gravel 1/20; Load R1 D R 2 2 2 2 2

500

1100

1500

2000 25003000

3500

4000

.216 .285.359

.453

.558

.668 -884*069

.074

.094

.105 .110.216

.009

.074

.159 .258 .366 .573 .743.065

.085-099

.108

.207

.070.090

.-102.109

.214age 60 days; storage in air. Sum

.160

.262.371

.585

Remarks. Cracks at pts. of application of loads and at middleManner of loading: 2 concentrated loads equally spaced.

Span

6'

Dimens ions

4H 18'

Wt. of yoke, I-Beam, etc beam

Max. s cale reading Sketc24:

220# 220#

-3TIR

E5

MTIAIN

DlAG C

TE TMAN N E:40F LOfl N G

7.

4

pp

N) CA)

Notes on the Tests.

Beams reinforced with steel did not show cracks at low loads but at high loads, cracks began

to develop. At maximum load, deflection was

con-siderable and beam failed to pick up load. On the

other hand, the beam reinforced with bamboo began to

crack at very low loads; crack continued to develop as the load was added but the beam picked up load readily in spite of the hideous outside appearance of the beam. The explanation of this phenomenon will

be attempted when we come to the "Analysis of Result"

on page .

It was feared thatencased in concrete,

bamboo would rot, from causes for being either too

wet or too dry. Accordingly one of the failed

beams reinforced with bamboo was knocked open, and

strips were taken out and tested. Care was taken

that the hammering did not strain these strips. The result of test showed:

Strips of Bamboo Encased in Concrete 60 days. Previously stressed by testing.

No. Section Breaking Load. Tens. Lbs./sq.in,

1 0.293"X 0.260" 1600 lbs. 21,000

2 0.300"X 0.264" 1600 lbs. 20,200 3 0.273"X 0.225" 1400 lbs. 22,750

Average 21,320

Comment on this result will be found in "Analysis of Results" on page 2r.

The strips showed perfect freshness when

taken out from the concrete. The bonding between

concrete and bamboo seemed to be perfect in every way. Stirrups did their share well as was shown by the

breaks which in every beam occurred outside of the

limit of the stirrup reinforcement.

In the test of the second two beams, it was

observed that beams failed at sections close or under the roller which transmitted half of the total load. If there were any explanation at all, it could be at-tributed to the excessive localized stress due to the

point of contact of the roller and beam. Should

this be the cause, it could be remedied by interposing a narrow steel plate between the roller and the

Analysis of Results.

It is necessary that the results be analyzed,

and conclusion, if there can be any, be drawn as to the actual values of these investigations.

1. The compressive strength of the plain con-crete cutes agrees in remarkable closeness with that

of others tested in the Institute Cement Laboratory.

Thus, in 1905, a series of compression tests was made

on concrete blocks of same mixture, age and storage, giving results of 2070 #/V". On page the

av-erage of three cubes was 2040#43", while on page

202'0#/o" average. Smaller gravel, and therefore

better uniformity of mixture accounts for the increase

of strength of the last three cubes.

Since the working compressive stress was taken at 650#In", we have a factor of safety of

2040 1st. set of tests --- = 3.14 650 2220 2nd. set of tests --- = 3.41 650

which are ample for the compression side under steady

load. The character of cracks showed that the com-pression side was never stressed to its limit.

2. The Mayi.mim Load. (a) The first test. It is to be recalled that in the preliminary

calcula-tion the loading was of two concentrated loads equally spaced, while the actual load in the test was of a sin-gle load concentrated at the middle of the span. It

is, therefore, necessary to make the correction

in

or-der that the. theoretical load and actual load can be

compared. On page

4

we have tie resistingmo-ment of the material:

M = 26,600 in.lbs.

and the bending moment for a load concentrated at mid-dle

W 220 X 6'

= --- X 3'

+---2 8

They should be equal

W 220 X 6 26,600

--- X 3 +- --- =---= 2216

2 8 12

W= 1365 lbos.

The actual maxinua load, however, was:

Steel bean 4400 lbs.

Bamboo " 3120 lbs.

For steel team we have a factor of safety of

4400

--- = 3.2

For bamboo beam we have a

factor of safety of

3120

---

=

2.3

1365

The ratio of maximum loads, steel to bamboo is:

4400

--- = 1.1

3120

That is, the assumption in the preliminary calculation that for the two beams to stand equal loads, the areas of reinforcing rods should be inversely proportional to their fibre stress. For example, if the tensile

strength of bamboo is 2/3 that of steel, the

reinforc-ing area of bamboo should be 3/2 that of steel. Now

if we would increase the area of bamboo to the amount

of

3/2 X 1.41' = 2.12,

we should expect the bamboo beam to stand as much load as did the steel beam.

The discrepancy appeared to arise from the wrong value used of the tensile strength of bamboo.

When the beam was designed, the only available

infor-mation on the strength of bamboo was from the results

of tests made by a German experimenter, Max Ulrich, whose work is reviewed elsewhere in this report, and

the tensile stress was shown to be very nearly 2/3

author showed this stress excessively author's value of tensile strength as erage of eight tests was 18,400 #/t". tensile stress of structural steel to

we have the ratio of

high. The

shown by the

av-Taking the be 60,000#/"

60000

--- =326*

18400

If the bamboo area were proportioned with this ratio,

the bean would have stood as much, if not more, load

as did steel. The soundness of the assumption is sustained.

(b ) The second test.

Expected load ... ... 2050#

Actual load, steel ... 6900#

bamboo

... 4600#Factor of safety, steel... 3.37 " " " tamboo ... 2.25

Max. Load of Steel

---Max. Load of Bamboo

6900

4600

1.5

If the area of bamboo were increased to

3/2

X 1.5 = 2.25we would expect the bamboo beam to stand as much load

30

above, is 3 inasmuch as the tensile strength ratioof steel to bamboo is 3.

The remarkable proximity of results of the two tests can be appreciated in the following table.

Test 1. Test 2. Factor of safety for steel ... 3.2

3.37

" " bamboo ...

2.3

2.3Corrective ratio:

Max. load of steel beam

--- . 1.4 1.5

Max. load of bamboo beam Equal strength area ratio:

Area of bamboo

--- ... ...

2.12

2.25

Area of steel

From plots of the two tests, it can be seen that each additional load produced considerably more deflection on the bamboo beam than on the steel beam.

This can be attributed to the small modulus of

elas-ticity of bamboo. It also explains why cracks in

bamboo beams developed at comparatively low loads. There seemed no way to remedy this except by putting in more reinforcing bamboo strips which is practicable when we remember that the material can be procured in superabundance and at low cost. The author is of

the opinion that if the "equal-strength-area-ratio" be made equal to the strength ratio between steel and

bamboo, the cracks will not develop at such low loads.

Conclusion.

It appears from the tests that bamboo does

contribute to the strength of the beam to which the

reinforcement has been applied, and such reinforcement is practicable both from considerations of durability and strength. The concordance of results of the

tests showed that the bamboo in concrete behaves very

much like steel and can be depended upon to act as we

expect it. There can be no doubt that for small structures bamboo reinforced concrete can be used to advantage.

Much more experimental data is needed to guide the designer. In the absence of any better information, the author recommends the following method of design:

Design the beam as if it were reinforced with steel. Multiply the reinforcing area of steel thus obtained by the ratio of the tensile stress of

product will be the reinforcing area for bamboo.

--- -4~~ ~ 1 -________________ ~~1 I, -z A aib i

4

0 1 4 a 4 1 0 . . 0 .- Tests on the Tensile Strength of Bamboo

-The difficulty of testing the tensile strength of wood in general was so well known that the author

proceeded with every care. The difficulty, of course,

lay in the clamping of ends of specimens such that the specimen should fail by tension and not by shear.

Wood, in general, is strong in tension but very weak

in shear. The fact that bamboo is a species of wood put it on the same ground of suspicion that

ten-sion specimens of bamboo would fail by shear and not

by tension.

A method of preparing the tension specimen such

that the full tension could be developed was proposed

by Mr. Gescher*, under the direction of Professor

Schramb. His specimen consisted of a narrow and

thin strip of hard wood, necked down to about

one-half of the width in the middle for one-one-half of its length, to the ends of which were glued extra strips

of the same kind of wood cross-pieced with wooden

dow-els set in with glue. It did not, however, come out

as expected. Some of them broke by shear at the

neck; others failed through tearing the holes into

.34

which the dowel pins were inserted.

The ease with which bamboo could be bent

naturally suggested a way by which the ends of the

specimen could be secured in the testing machine and tensile strength determined. Accordingly specimens about 8' long were prepared with loops at ends, strap-pei together by wires. The loops were made by steam-ing the ends of the bamboo strips in a steamsteam-ing vessel

of the following construction:

After steaming for an hour, the strips were talcen out and the ends were bent around the outside of

end was finished, the other end was steamed and the process repeated. In this way bends or loops of 4"

diameter could be easily made. The author attempt-ed to bend the ends of strips cold and dry. The smallest diameter obtainable in this way was about 8". Moistened by immersion in water smaller diameters

could be obtained.

The specimen was then put into the Rope Testing Machine of the Institute, the loop ends being held by the pins in the Jaws. The aurvatures of the

loop and pin were so different that extra wooden pieces

conforming to both curvatures had to be interposed

be-tween them. Load was then applied. To our sur-prise, the extension bar clamped on the specimen for a

gauge length of 3' , did not register any elongation as the load was increased. Upon investigation it was found that the wires that strapped the loop ends were giving way under load, and there was considerable

bend-ing at the place where the curve of loop began.

Fur-ther pulling failed the specimen at that place under

light load. It was clearly a case of bending

in-stead of direct tension. It was concluded that this manner of testing should be abandoned.

the jaws of a Wire Testing Machine in the Institute. It met with considerable success. The grip by the

rough cieckered faces of the jaws was so perfect that the specimen broke in two by actual tension.

Encour-aged by this success, a large number of specimens were

made. They were about 4' long, 1/2" wide, necked

down to 1/4" for a length of 3', leaving the gripping ends eaci about 6" long. A gauge length of 30" was

chosen, and elongations measured. In every case the grip was perfect. The jaws of the machine were so designed that the harder the pull the firmer the grip, The ends of the specimen were actually compressed to form a nick which contributed direct resistance to

pull. As will be seen in the following pages, the

in-side fibres, the sap wood, of the specimens in most

cases gave way first, followed by the inner fibres then the outside, the green skin. The tests made by ul-rich showed that the strengths of the t1hree-eeen-, in-side, 4AR44 and outside fibres, varied in the ratio of 1 'r-k4, : 2.25. When the full thickness was tested ,

we naturally expected the inside fibres to give first; and it actually did.

The long gauge length chosen necessarily in-cluded one or two joints. The specimens in almost

all cases failed at one of these joints. The con-Weak

clusion suggested itself that they were the spots in the bamboo.

Tests 1 and 2 were made upon specimens badly

weathered. The curves seemed to have comparatively

more curvature than the others.

Tests 3, 4, 5 were made upon specimens

sea-soned four months. They showed better uniformity of results.

Test 6 was made upon a specimen of short

gauge length such that no joint was included in the length. This was done in order to ascertain

wheth-er or not the joint was a weak spot and responsible

for the failures of the other specimens. The

spec-imen, however, did not show any appreciable increase

in strength.

The seventh test was made upon a specimen

which had for a year been immersed in dirty water in

the pumping well under the floor of the Pierce

Labora-tory of the Institute. The specimen was so soaked

with water that when strained under tension the water

was squeezed out and trickled down the specimen.

The curve presents the same general appearance as

B8 which was in all probability due to a local weakness

near the joint rather than the general decay caused

by the immersion in dirty water.

From these tests it is justifiable in

con-cluding that the weather quality of bamboo is good.

With the exception of one or two, the curves are very flat, and for all practical purposes they can be assumed to be straight. The curvature would be scarcely appreciable, had the scale for the elongation been made half as large. The assumption that the

curves are straight carries with it the inevitable con-clusion that the stress is proportional to strain, and any point on the curve can be used for figuring the modulus of elasticity. In the following table the Modulus of Elasticity is figured by using a point mid-way between the zero load and maximum load.

The caaracteristic points of steel curves, namely, the Elastic Limit, the Apparent Elastic Limit, the Yield Point, are absent in bamboo curve, since the

absence of such points is common to all woods, and

bam-boo is one kind of wood. If we should assume that the Elastic Limit coincides with the breaking point, then the former should be figured on the basis of the latter. The Elastic Limit in the following table is figured in this way.

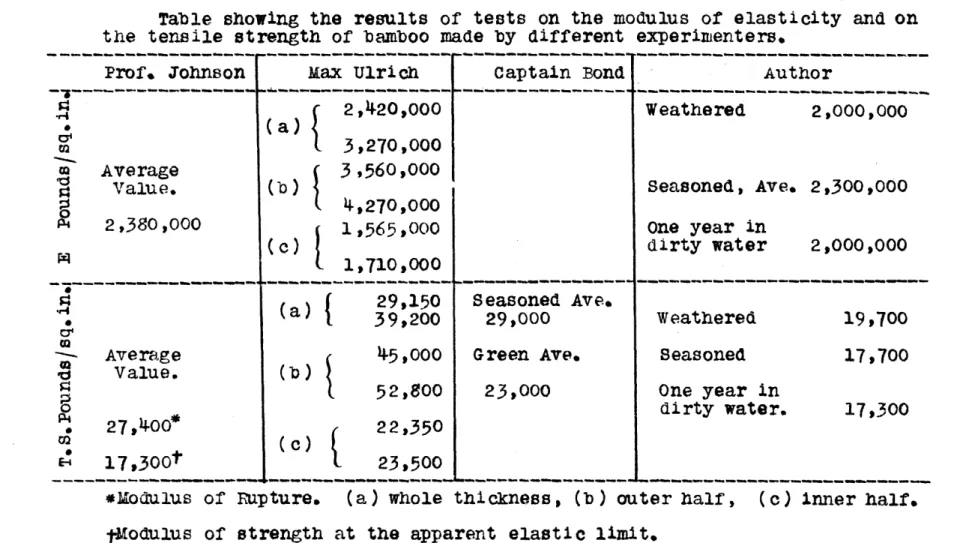

Table showing the results of tests on the modulus of elasticity and on the tensile strength of bamboo made by different experimenters.

Prof. Johnson Max Ulrich Captain Bond Author

---

---f

2,420,000 Weathered 2,000,0000 (a)

3,270,000

m Average 3,560,000

V Value. (b) Seasoned , Ave. 2,300 ,000

4,270,000 2,380,000 1,565,000 one year in (c) 19 ,000 dirty water 2,000,000 --- ---~---

----{

29,150 Seasoned Ave. -r4(a)

( a 39,200 29,000 Weathered 19,700Average 45,000 Green Ave. Seasoned 17,700

Value. (b) 52,800 23,000 One year in 0 dirty water. 17,300 . 27,400* 22,350 (c) 17,300t

-

23,500 - of u . (a---- ---- ne , (----*Modulus of Ruipture, (a) whole thickness, (b) outer half , (c) inner half,

40 From the table it is readily seen that the author's results are lower than those obtained by the other experimenters. The discrepancy seems to arise from the following possible causes:

(a) Difference in the kind of bamboo each

experi-menter used, as there are no less than 200

va-rieties of bamboo.

(b) Difference in the way of preparing the

speci-mens.

Captain Bond's specimens "were

cut

to

shape similar to cement

briquette

---- ", whileMax Ulrich's specimens, as seen from the

pho-tograph, had unusually small reduced sections,

and gauge lengths did not include one or two

joints. Our knowledge of the results of

tests on steel shows us that a briquetted

spec-imen always gives high values. In Ulrich's

specimen, a slight inaccuracy in measuring the cross-section will throw a large error upon

the final result.

The author's tension specimens were about 40" long, having a gauge length of 30" which included one or two joints, and a

uniform reduced cross-section of about

length of the specimen. A larger cross

see-tional area, a longer gauge length and there--fore less uniformity, accounts for the low values the author obtained.

The author claims that his results are

more representative and approach more nearly

the actual working conditions than the rest.

Captain Bond must have been handicapped by

the lack of facility for testing in the field. His results are subject to question. The

ab-sence of joints within the guage length in Max Ulrich's specimen is a serious defect which can not be slighted.

Tension Test No. 1. April 6, Spe cimen: L R 100 .0320 200 .0545 300 .0763 400 .0965 500 1214 600 .1413 700 .1652 800 .1882 900 .2116 1000 .2376 1100 .2602 1200 .2902 1300 .3194 L

=

Load in D *0240 .0225 .0218 .0202 .0249 .0200 .0239 .0230 .0234 .0260 .0226 .0307 .0285 lbs. Bamboo weathered. S Remarks. .0465 .0683 .0885 .1134 .1334.1573

.1803 .2137 .2397 .2623 .2930 .3215 Grip perfect.Broke near joint. Inner fibres gave

way first.

R = Micro-meter Rdgs. D = Diff. of Rdgs. S

=

Sums.Gauge length inches

Dimensions of cross section, inches Max. load on machine, lbs.

Area of cross-section, sq. ins. ...

Elastic Limit, Lbs./sq.in. . . . .

30 .247"X.296 1400 .073 19,200 Modulus of Elasticity ...

1,710,000

47 1914.BAMo 50 1N TE- .) iN

I.- T i5-T

N A NP9I A

GR

\M

6A M CTE- LE N RT H :10,

S AD L-f VE AT HE RE.D

7400

Tension Test To. 2.

April 6, 1914.

Sp e c imen: Bamboo weathered.

Remarks.

Grip perfect. Broke near joint.

Inner fibres gave

way first.

L = Load in lbs.

D = Diff. of Rdgs.

R = Micrometer Rdgs. S = Sums.

Gauge length, inches

Dimensions of cross-section, inches ...

Max. load on machine, pounds

30

.264X.281

1500

Area of cross-section, sq. inches ... Elastic Limit, Lbs./sq.in.

.0742 20,200 Modulus of Elasticity ... 2,190,000 44 R L 100 200 300

400o

500 600 700 800 900 1000 1100 1200 1300 1400 .0250.0435

.0607 .0792 .0983 .1142 .1380 .1578 .1784 * 1990 .2200 .2398 .2600 .2838 S.0357

.0542.0733

.0892 .1120 .1318 .1524 .1730 .1940 .2138 *2340 .2578 .0185 .0172 .0185 .0191 .0159 .0238 .0198 .0206 .0206 *0210 .0198 .0202 .023813A M130 0 1N T E Ni 0 N 60 GA U GE L E- N1 T H 0" DA DLY NEA T H E E D 5004 400 6 00 koo Loo

Tension Test No. 3.

April 9, 1914. Specimen: Bamboo, seasoned 4 months.

Remarks.

Grip perfect.

Broke near joint. Inner ribres gave

way first.

L = Load in lbs. D

=

Diff. of Rdgs.R = Micrometer Rdgs. S

=Sms.

Gauge length, in inches

Dimensions of cross-sections, inches ....

Max. load on machine, lbs. ...

Area of cross-section, sq.in. ...

Elastic Limit, Lbs./sq.in. ...

30

.413*I. 303

1980 .1255 15,800 Modulus ofElasticity

... 2,130,000 R S L 100 200 300 400 500 600 700 800 900 1000 1100 1200 13001400

1500 1600 1700 -. 0015 .0095 .0213 .0328 .0453 .0556 .0701 .0824 .0941 .1052 .1200 .1317 .1430 .1556 -1692 .1807 .1949 .0110 .0118 .0115 .0125 .0103 .0145 .0123 .0117 .0111 .0148 .0117 .0113 .0126 .0136 .0115 .0142 .0228 -0343 .0468 .0571 .0716 .0839 .0956 .1067 .1215 .1332 .1445 .1571 .1707 .1822 .1964-~~~~~ - -. i - - . .

-If . . . . . . . .-- ---

-~~~~~~~~... .... . .- - -- - -- t **

--1 . .. .

48 Tension Test No. 4.

April 9, 1914.

Specimen: Bamboo, seasoned 4 months.

R D S Remarks. .0000 .0111 .0111 .0229 .0118 .0229 .0353 -0124 .0353 .0478 .0125 .0478 .0601 .0123 .0601 .0736 .0135 .0736 .0858 .0122 .0858 .0982 .0124 .0982 .1108 .0126 .1108 .1242 .0134 .1242 .1360 .0118 .1360 Grip perfect.

.1478 .0118 .1478 Broke between joints.

.1608 .0130 .1608 Inner fibres gave

.1741 .0133 .1741 way first. .1874 .0133 .1874 L = Load in lbs. D = Difference of Rdg R = Micrometer Rdgs. 's. S = sums.

Gauge length, inches

Dimension of cross section, inches

Max. load on machine, ts. ...

Area of cross-section, sq.in. ...

Elastic Limit, lbs./sq.in. ...

Modulus of Elasticity ... 30 .376 X .302

1950

.1135 17,100 2,310,000 L 100 200 3004oo

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600TIO 0

Albo

BAM W N TE. 14 5 10 KTK E YU

MAGMA

GA u Gr F- LF- Iq CtT-H m9 00 A '3 N E. D T VI Z oo-': ... . 71 0.0.100

Tension Test No.

50

5.

April 9, 1914.

specimen: Bamboo seasoned 4 months.

D .0118 .0122 .0121 .0125 .0135 .0129 .0129 .0131 .0131 .0125 .0130 .0139 .0126 .0139 .0146 S Remarks. .0230 .0351 .0476 .0611 .0740 .0869 .1000 .1131 .1256 .1386 .1525 .1651 .1790 .1930

Broke near the joint,

L = Load in lbs.

D = Difft. of Rdgs.

R = Micrometer Rdge.

S = Sums.

Gauge lengthinches

Dimensions of cross-sections, inches.. Max. load in lbs.

Area of cross-section, sq. in. ...

30

.381"X.285

1990

.1086 Elastic Limit, lbs./sq.in. ...

Modulus of Elasticity... L 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 R .60000 .0118 .0240 .0361 .0486 .0621 .0750 .0879 .1010 .1141 .1266 .1396

.1535

.1661 .1800 .1946 18,350 2,375,000IA GOONT NO

9

00 U (4E L, N TH o30 NEb 4 MMTRS

Tension Test No. 6. April 27, Specimen: R D .0035 .0041 .0040 .0046 .0043 .0036 .0046 .0034 .0044 .0070 .0056 S .0076 .0116 .0162 -0205 .0241 .0287 .0321 .0365 .0435 .0491 Bamboo Remarks. No joint within gauge length. L = Load in lbs. R = Micrometer Rdgs. D = Mean of diff. of Rdgs. S

=

Sums.Gauge length, inches 8

Dimensions of cross-section, inches

Max. load in lbs.

Area of cross-section, sq. i. ...

Elastic Limit, lbs./sq.in. Modulus of Elasticity .3168 X .2900 .0917 19,600 2,380,000 L 1914. 100 200 300 400 500 600 700 800 900 1000 1200 14.00

loo

i0o

1000

BAMB60 MTEMSIONTRE53-, TMI N D AG R P M

Soo

G.4 44r E L ENC-4TH110JOIJ-41- WITHIN THF- LE-N -TIA

70o Soo -100 Zoo 400 .01 0 -z .04- 0

54

Tension Test No. 7.Spe cinen: Bamboo,1 yr.

May 14, in dirty water. Remarks. L = Load in lbs. D = Diff. of Rdgs. Gauge length, R = Micrometer Rdgs. S = Sums. inches Dimensions of cross-section, 30 inches *

Max. load on machine, lbs.

Area of cross-section, sq.in. ...

Elastic Limit, lbs./sq.in.

Modulus of Elasticity 2... S 1914. L 100 300 500 700 900 1100 1300 R .0265 .0685 .1150 .1690 .2150 .2640 .3150 D .0420 *0465 040 .0490 .0510 .0885 .1425 -1885 .2375 .2885 .236 X .317 1300 .0746 19,300 .. 2,o000,000

A

B 500 IN TE 14 616 11

TRE-3 -5TRAI N DIA( WAM

A lJCjE LF-NCiTH 30"ON E YEAR IN DIRTY WATE R

__Solo

ro

OD

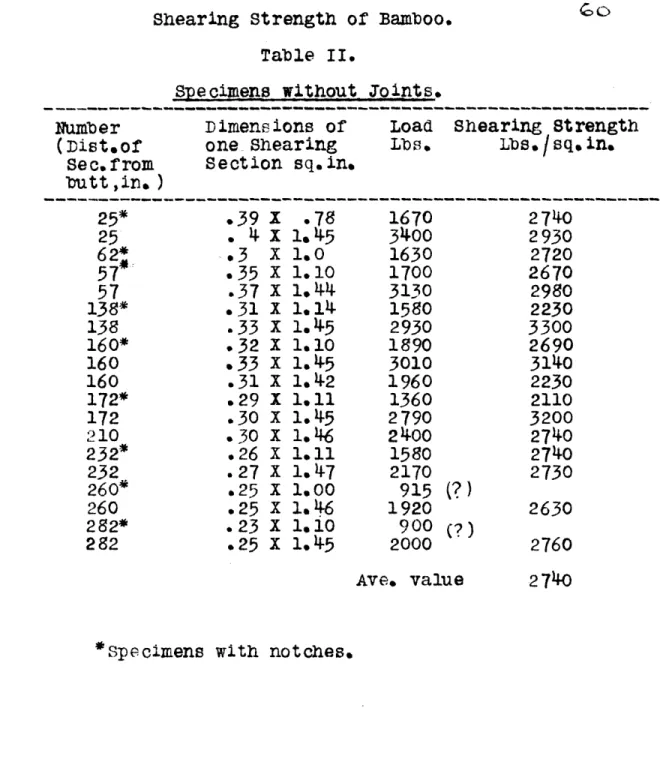

Tests on Shearing Strength of Bamboo.

Wood is as a rule very weak in longitudinal shearing strength, and bamboo, being a species of wood, is no exception to the rule. Many tension specimens

have failed by shear, and yet how surprising it is to

find so little attention has been paid to it. None of the experimenters who made tests on the strength of

bamboo has given the subject its due consideration.

It is the opinion of the author that in practice

ten-sion members on structures made of bamboo will never

fail by tension but will in all probability fail by shear. For this reason it is worth while to look into the subject rather carefully.

A preliminary test was made upon a section of bamboo so shaped that when placed between the heads of the testing machine and compressed, longitudinal sections would slide by each other. This method

works well for testing shears of timbers where large

blocks of wood can be easily gotten and good footing

obtained. But it failed in the case of bainboo for the reason that good footing could not be obtained,

the footing, thus introducing tension into Stress. Various schemes were tried without good success. Finally, a shearing block was designed by the author

as shown in the accompanying illustration. It

con-sisted of two thick, rectangular steel plates bolted together by four bolts passing through four short pieces of piping which acted as distance pieces

be-tween the steel plates. In the center of each

plate was cut a slot, into which a plunger or punch fitfed accurately, taking care, however, that the

close fit did not entail friction. When in use, a

section of bamboo 2" X 1 was placed between the

plates across the bolts, and clamped in place by screw-ing down the four nuts. Then the punch was put

in-to the slot of the upper plate over the specimen, and the whole placed between the heads of the testing

ma-chine. The scheme was attended with such success

that it was employed in the whole series of shear

tests. It is hardly necessary to add that the

clamping of the specimen prevented the spreading of

the footing.

In the following table are shown the results of two series of tests, one on specimen with joint,

SS

and the other without joint. The column headed with

"Number" gives the distance in inches that each

speci-mien was originally situated from the butt of the cane.

For example, the "number 92" specimen was cut from a section 92" from the butt of the pole. This was

done primarily to study the shearing strength at dif-ferent heights of a bamboo pole, as it is to be remem-bered that the thickness of the pole

varies,diminish-ingly. always, from butt to tip.

Specimens marked with an asterisk had notches

at the shearing sections both at top and bottom. The idea was to study the influence of the specimen upon the shearing strength of the material from which such specimen was made.

- Shearing Strength of Bamboo -Table I. Specimens w-tht Joints. Number (Distance from Butt) Ins. Sectional Area of one Shear-ing Section. Sq. in. Load Shearing Strength. In-lbs. Lbs/sq.in. 1900 1150 1570 1260 1330

1650

1150 Av. value5

72 92 113 138 206 255 .40.34

.38

.35

.33

.37

.32

2380 1690 2070 1800 2020 2230 1800 2000Shearing Strength of Bamboo. Table II.

Specimens without Jo ints.

Number (Dist.of Sec.from butt ,in.) Dimensions of one-Shearing Section sq.in.

Load Shearing Strength

Lbs. Lbs./sq.in.

.39

1.

4

x

.3

X

.35 X

.37 X .31 X.33

X .32 X.33

x .31 X .29 X .30 X .30 X .26 X .27 X .25 X .25 X .23 X .25 X .78 1.45 1.0 1.10 1.44 1.141.45

1.10 1.45 1.42 1.11 1.45 1.46 1.11 1.47 1.00 1.46 1.101.4-5

1670 3400 1630 1700 3130 1580 2930 1890 3010 1960 1360 2790 2400 1580 2170 915 1920 900 2000(?)

P)

Ave. value*Specimens with notches.

25* 25 62*

57*

57

138* 138 160* 160 160 172* 172 210 232* 232 260* 260 282* 282 2740 2930 2720 2670 2980 2230 3300 2690 3140 2230 2110 3200 2740 2740 2730 2630 2760 2740It is evident that the joint is a weak spot in

the bamboo inasmuch as the everage for shear for

speci-mens with Joint was 2000#/bW, while without joint

2740#/o. It is also seen that the shearing strengths

of top and bottom pieces from the same cane of bamboo

do not differ in any material way. Notched

speci-mens seem to give lower values than those from plain specimens, by which it is meant that the specimen is

to be out from a section of bamboo in a band saw and

left as it is without being subjected to further

work-irig. The notches in author's specimens were

obtain-ed by cutting the specimen in the band saw, which cut-ting might have injured some of the fibres near the shearing sections and might be responsible for the lower shearing strengths.

In order to appreciate the value of these tests on shear, a simple problem will be solved here. Let

it be required to design a joint in a bamboo structure secured by round hollow iron pins passing through

holes drilled in the members connected, such that a load of 2000# can be transmitted by the joint. The bamboo Is to be of 3-1/2" outside diameter and 1/2"

thick.

(0 z

of bamboo is 8800#/a". Using a factor of safety of

4 we have compressive

strength

= 2200#/fo0. Hence theoutside diameter of the pin

2 (D I 1/2) X 2200 = 2000

D =

.91'

say1".

The inside diameter of the hollow pin may be 3/4.

How we mst determine the length from the pin to the end of the member so as to have sufficient shearing

HLHI

areas to stand the pull or push as the case may be. 500 X 4 X L X 1/'2 2000 L2'

using a factor of safety of 5 for shear of bamboo.

If made shorter than what is required, the shaded por.

Column Tests on Bamboo.

The author at first had an ambitious program for the column tests on Bamboo, but the climate in Boston, where these investigations were conducted delivered a

blow to the whole scheme, for it successfully cracked 80 per cent of twenty to thirty large canes that were

especially ordered from China for these tests. It

was clear that the whole plan must be abandoned. We are glad that Captain Bond and Mr. ilrich made some

column tests, by which the designer can roughly be guided in the absence of better information. The only criticism upon their test is the small size of

specimens used by them. Both of the experimenters made column tests on specimens whose outside diameter

little exceeded one inch, while in actual practice

columns of 4 or 5 inches outside diameter are not un-common. We have reason to believe that results of

tests on small specimens can not apply to large

col-umns. There is need of tests on full size columns.

Some experiments along this line however, were performed before the others cracked. The column had the following dimensions:

Length ..---... '414

Average outside diameter ... 3.34"

Average inside diameter ... 2.76"

Weight . ..---... .