Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building Research), 1961-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=b04dc086-b8a9-4dae-8cec-39559b0c35cb https://publications-cnrc.canada.ca/fra/voir/objet/?id=b04dc086-b8a9-4dae-8cec-39559b0c35cb

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20337961

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at Influence of bricklaying method on the strength and moisture penetration properties of brick masonry

NATIONAL RESEARCH COUNCIL

CANADA

DIVISION OF BUILDING RESEARCH

I N F L W C E OF

BRICKLAYING

~ T H O D ON THESTRENGTH AND MOISTURE PENETRATION PROPERTIES OF BRICK MASONRY

by

T.

RitchieInternal Report

No.

200o f the

Division

o f Building ResearohOTTAWA

PREFACE

An extensive program o f l a b o r a t o r y i n v e s t i g a t i o n s i n t o t h e f a c t o r s a f f e c t i n g r a i n p e n e t r a t i o n and bond-strength c h a r a c t e r i s t i c s of b r i c k masonry i s i n progress a t t h e A t l a n t i c Regional S t a t i o n i n Halifax a s w e l l a s i n t h e Ottawa l a b o r a t o r i e s of t h e Division, It h a s been necessary, i n studying t h e e f f e c t s of t h e v a r i o u s f a c t o r s involved, t o develop h i g h l y standard- i z e d techniques f o r making and t e s t i n g t h e small b r i c k and mortar assemblages used. The techniques used i n making and t e s t i n g t h e specimens f o r moisture p e n e t r a t i o n have a l r e a d y been described

i n DBR

Report no, 160. S t u d i e s c a r r i e d out a t Halifax have been described i n Reports No. 161 and 173 and t h e development of a p p a r a t u s and techniques f o r measurement of bond s t r e n g t h a t Ottawa have been described i n Report' No. 175.!be l a b o r a t o r y techniques developed f o r t h e making of t e s t panels were designed t o i n c o r p o r a t e p e r t i n e n t f e a t u r e s of t h e b r i c l s l a y e r l s techniques as

f a r

as t h e s e were understood a t the time. A n opportunity was a f f o r d e d duringt h e c o n s t r u c t i o n of some masonry t e s t p i e r s f o r t h e c o n s t r u c t i o n by t h e b r i c k l a y e r of some t e s t panels f o r d i r e c t comparison

rmith s i m i l a r p a n e l s made i n the l a b o r a t o r y . The r e s u l t s , which suggest t h a t l a b o r a t o r y techniques used t o d a t e do n o t adequately simulate those of t h e b r i c k l a y e r a r e now r e p o r t e d ,

m e a u t h o r of t h i s r e p o r t , a r e s e a r c h o f f i c e r w i t h t h e Building M a t e r i a l s Section,

i s

r e s p o n s i b l e f o r t h e b r i c k masonry s t u d i e s being o a r r i e d out a t Ottawa.Ottawa,

IXTLUmCE OF BRICKLAYING MEICHOL) OPlT

THE

SmENGTHAND

MOIS!lDRE PENETRATION PROPERTIES OF BRICKI ~ S O M Y

T,

R i t c h i eMuch of t h e l a b o r a t o r y work being done

i n

t h e D i v i s i o n of B u i l d i n g Research, N a t i o n a l Research Council, i n connection w i t h moisture p e n e t r a t i o n end s t r e n g t h of bond of b r i c k masonry has made use of small assemblages of b r i c k and m o r t a r c o n s i s t i n g of f i v e b r i c k s l a i d one above t h e o t h e r with mortar j o i n t s between, m e assemblages a r e c o n s t r u c t e d by a method adapted from t h a t of C.C. Fishburn(U.S.

N a t i o n a l Bureau of Standards ) f o r de ternlining t h e t e n s i l e s t r e n g t h of bond between b r i c k and m o r t a r by means of orossed-brickc o u p l e t s .

I n t h e D i v i s i o n ' s work, t h e method of panel c o n s t r u c t i o n c o n s i s t s , i n b r i e f , of mixing a b a t c h of mortar, p l a c i n g it i n a metal mould on a b r i c k and s c r a p i n g off t h e

excess. The mould i s removed, and a f t e r a c e r t a i n time a n o t h e r b r i c k i s s e t on t h e mortar bed and t h e b r i c k i s given a s i n g l e t a p by a hammer dropped on it. The procedure i s r e p e a t e d f o r subsequent mortar j o i n t s ( s e e

D.P.R.

I n t e r n a l ReportlTo. 1 6 0 ) .E a r l i e r t e s t s i n d i c a t e d t h a t t h e s t r e n g t h of bond and t h e r e s i s t a n c e t o moisture p e n e t r a t i o n of p a n e l s

depended on t h e p r o p e r t i e s of t h e b r i c k and mortar used, on t h e l e n g t h of time t h e mortar bed w a s i n c o n t a c t w i t h t h e b r i c k before t h e second b r i c k was placed on

it,

and on t h e t a p p i n g impact g i v e n t o t h e b r i c k a f t e rit

had been placed on t h e mortar. No s t u d i e s had been made up t o t h e p r e s e n t , however, t o determine how t h e p r o p e r t i e s of brickwork made by t h i s l a b o r a t o r y method compared w i t 2 1 t h o s e of brickworkAn o p p o r t u n i t y t o compare t h e methods w a s a f f o r d e d d u r i n g t h e c o n s t r u c t i o n of some brickwork p i e r s f o r e f f l o r e s c e n c e s t u d i e s i n t h e f a l l of 1959. lChe p i e r s were c o n s t r u c t e d on t h e Ottawa exposure s i t e of t h e D i v i s i o n by a b r i c k l a y e r w i t h more t h a n 20 y e a r s ' e x p e r i e n c e i n t h e t r a d e . A t t h e same time t h e b r i c k l a y e r was a s k e d t o b u i l d , i n a d d i t i o n , many f i v e - b r i c k assemblages such a s have been u s e d i n t h e l a b o r a t o r y s t u d i e s , u s i n g however h i s normal t e c h n i q u e of p l a c i n g t h e m o r t a r bed and s e t t i n g t h e b r i c k i n it. B r i c k s and m o r t a r o f t h e same t y p e a s h e used were t a k e n t o t h e l a b o r a t o r y a n d assemblages were c o n s t r u c t e d of them by t h e " l a b o r a t o r y " t e c h n i q u e .

The s m a l l p a n e l s were s u b s e q u e n t l y t e s t e d f o r r e s i s t a n c e t o m o i s t u r e p e n e t r a t i o n (bjr t h e method d e s c r i b e d i n I n t e r n a l Report No. 1 6 0 ) , a n d a f t e r t h e l e a k a g e t e s t were t e s t e d f o r s t r e n g t h of bond i n d i r e c t t e n s i o n (by t h e method d e s c r i b e d i n I n t e r n a l Repor* No. 1 7 5 ) .

BRICKS

Wo t y p e s of b r i c k s mere used: a c l a y a n d s h a l e b r i c k made by t h e e x t r u s i o n method, and a d r y - p r e s s s h a l e briclc. Both t y p e s were r e d - c o l o u r e d and h a d t h r e e c o r e h o l e s . P r o p e r t i e s of t h e b r i c k s a r e shown i n Table I; f i f t e e n b r i c k s of each t y p e were t e s t e d f o r w a t e r a b s o r p t i o n p r o p e r t i e s and f i v e f o r compressive s t r e n g t h . !be maximum a n d minimum v a l u e s o b t a i n e d from e a c h l o t o f b r i c k s a r e shown.

MORTAR

llcvo m o r t a r s were used. One was composed of a masonry cement and sand, i n p r o p o r t i o n s by volume o f one part masonry cement t o t h r e e p a r t s of dry s a n d ; t h e o t h e r w a s

made of p o r t l a n d cement, l i m e and sand, i n p r o p o r t i o n s by volume o f one p a r t cement, one p a r t l i m e and s i x p a r t s of

d r y sand. The l i m e was a d r y h y d r a t e , soaked o v e r n i g h t b e f o r e u s e . The m o r t a r s were mixed i n a m o r t a r t r o u g h on t h e job s i t e by t h e b r i c k l a y e r ' s h e l p e r . Each b a t c h amounted t o approxiniately one c u b i c f o o t , and t h e amount o f w a t e r added was t h a t which produced t h e optimum c o n s i s t e n c y from t h e b r i c k l a y e r t s p o i n t o f view. A s measured by t h e flow t a b l e , t h e m o r t a r b a t c h e s were q u i t e f l u i d , w i t h f l o w i n e x c e s s o f 140 p e r c e n t .

When t h e briclclayer constructed panels on t h e job s i t e , mortar w a s removed from h i s board and taken t o t h e l a b o r a t o r y where a d d i t i o n a l panels were constructed by t h e l a b o r a t o r y technique, using t h e same brick.

In

h i s work on t h e p i e r s , the b r i c k l a y e r v a r i e d t h e ' s p r e a d of t h e mortar bed, depending on t h e type of b r i c k and mortar, up t o a maximum spread f o r f o u r b r i c k s , t h el e n g t h of t h e p i e r . The time i n t e r v a l between placing t h e mortar bed on t h e b r i c k s and s e t t i n g t h e n e x t b r i c k s i n it v a r i e d from about 15 seconds t o 2 minutes, Since previous s t u d i e s i n t h e Division had i n d i c a t e d t h a t t h i s time f a c t o r h a s a very important i n f l u e n c e on t h e p r o p e r t i e s of b r i c k masonry, it was decided t o c o n t r o l it i n t h e b r i c k l a y e r r s technique of panel construction. He was permitted t o l a y t h e mortar bed i n h i s u s u a l manner and t o s e t t h e b r i c k i n place a s he u s u a l l y d i d , b u t was allowed t o s e t t h e b r i c k only a t a c e r t a i n time f o l l o v ~ i n g t h e placing of t h e mortar

I

bed ( e i t h e r 2 o r 1. minute).

H i s method of p l a c i n g t h e mortar bed was t o dump a t r o w e l f u l of mortar on t h e b r i c k , i n v e r t t h e trowel s o that it pointed downvrards a t a n a n g l e , and run i t s p o i n t along t h e c e n t r e of t h e mortar t o form a deep f u r r o w . He then s e t t h e b r i c k on t h e mortar and tapped it quickly f i v e o r s i x times w i t h t h e edge of t h e trowel t o bed it. Although t h e b r i c k was l i g h t l y h e l d i n t h e l e f t hand while being

tapped it seemed t h a t t h e b r i c k l a y e r d i d n o t attempt t o

p r e s s it i n t o t h e mortar. Rather he used t h e trowel t o place it. The heaviness of t h e tapping and t h e number of t a p s

d e l i v e r e d v a r i e d with t h e type OF b r i c k and mortar used. Mortar squeezed from t h e j o i n t was c u t by t h e trowel i n an upward motion, and f o r t h i s study t h e j o i n t s were n o t tooled,

LAB

ORATORY TECHNIQUEThe morta.r, a s r e c e i v e d from t h e b r i c k l a y e r t s board, was placed i n a $-inch deep metal mould on t h e b r i c k and remained i n c o n t a c t w i t h it f o r

&

minute o r 1 minute(corresponding t o t h e time i n t e r v a l used i n t h e b r i c k l a y e r ' s p a n e l s ) u n t i l Yne n e x t b r i c k was placed. The b r i c k was t h e n tapped, ei-bher by a hammer weighing 4 pounds dropped through

1s

inches ("heavy" t a p ) , o r by a hammer of h a l f t h e weight dropped t h e same h e i g h t ( " l i g h t N t a p ) . A l l t h e panels were s t o r e d i n t h e l a b o r a t o r y a t 73OP and50

per c e n t r e l a t i v ehumidity f o r s e v e r a l weeks u n t i l t e s t e d f o r moisture penetration. After t h i s t e s t , they were d r i e d i n t h e same room f o r about

RESULTS

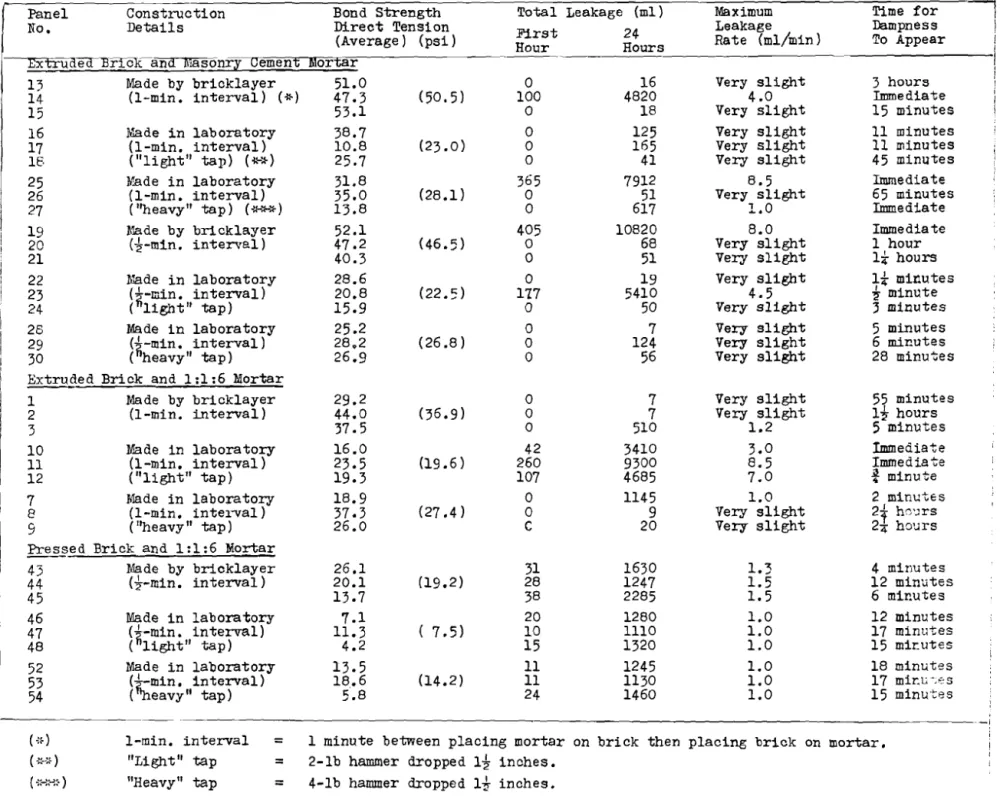

Test r e s u l t s a r e -tabulated i n Table 11, where tihe second column i n d i c a t e s t h e d e t a i l s of c o n s t r u c t i o n of t h e panels. Panels 1 3 , 14 and 1 5 , f o r example, were made

by t h e b r i c k l a y e r of extruded b r i c k and masonry cement m o r t a r ,

w i t h a l-minute time i n t e r v a l between p l a c i n g t h e mortar on t h e b r i c k and t h e n s e t t i n g t h e n e x t b r i c k on i t , Panels

1 6 , 1 7 and 18 were made i n t h e l a b o r a t o r y of t h e same m a t e r i a l s , u s i n g t h e " l i g h t 1 ' hammer t o t a p t h e b r i c k s i n t o t h e m o r t a r ,

while p a n e l s 25, 26 and 27 were c o n s t z u c t e d u s i n g t h e "heavy" hammer. The t h i r d column l i s t s t h e s t r e n g t h of bond between b r i c k and m o r t a r i n d i r e c t t e n s i o n (pounds p e r square i n c h ) , as t h e average of t h e r e s u l t s obtained f o r t h e j o i n t s of each panel. The f i g u r e i n b r a c k e t s i s t h e average bond s t r e n g t h of a l l t h e j o i n t s t e s t e d o f t h e t h r e e p a n e l s i n each se*.

The l a s t f o u r columns of Table I1 r e f e r t o r e s u l t s of moisture p e n e t r a t i o n t e s t s , The amount of w a t e r which passed through t h e panel i n t h e first hour of t e s t i s shorn, a l o n g

w i t h t h a t which p e n e t r a t e d i n 24 h o u r s (measured i n

m l ) .

m e maximum r a t e of l'eakage of moisture through t h e panel ( m l p e r minute) is shown n e x t , and f i n a l l y , t h e time a f t e r t h e s t a r t of t h e t e s t when dampness was first observed on t h e back of t h e panel.Comparing t h e " b r i c k l a y e r " and " l a b o r a t o r y " p a n e l s on t h e b a s i s of bond s t r e n g t h i n d i r e c t t e n s i o n ,

i t

may be seen t h a t i n every case t h e average b o n d d r e n g t h oft h e b r i c k l a y e r - c o n s t r u c t e d p a n e l s exceeded t h a t of t h e l a b o r a t o r y - c o n s t r u c t e d p a n e l s , u s u a l l y by a v e r y wide margin. I n a l l

c a s e s , t o o , t h e average bond s t r e n g t h of t h e p a n e l s c o n s t r u c t - ed u s i n g t h e t a p w a s g r e a t e r t h a n t h a t of t h e p a n e l s tapped by t h e " l i g h t " hammer. The change i n time i n t e r v a l from

4

minute t o 1 minute, which was s t u d i e d only f o r t h e e x t r u d e d b r i c ? and masonry cement mortar, d i d n o t a p p e a r t o have a s i g n i f i c a n t i n f l u e n c e on s t r e n g t h of bond f o r e i t h e r t h e l a b o r a t o r y - c o n s t r u c t e d o r t h e b r i c k l a y e r - c o n s t r u c t e d panels.In

comparing t h e r e s u l t s of t h e leakage t e s t s it can be seen t h a t most of t h e s e t s of t h r e e p a n e l s produced a n anomalous r e s u l t which makes it d i f f i c u l t t o r e l a t ed i f f e r e n c e s i n performance t o d i f f e r e n c e s i n c o n s t r u c t i o n methods. I n one case (panel

25)

it was found on breaking t h e panel t h a t a depression a c r o s s one b r i c k ' s bedding s u r f a c e had prevented b r i c k and mortar from coning i n t o c o n t a c t and provided aIt a p p e a r s from -the t e s t r e s u l t s t h a t moisture penetra-tion i s no-t a s dependent on c o n s t r u c t i o n method a s i s s t r e n g t h of bond. The r e s u l t s f o r -the p a n e l s of p r e s s e d b r i c k w i t h 1:1:6 mortar ind-icated a s l i g h t l y b e t t e r moisture

r e s i s t a n c e f o r t h e l a b o r a t o r y paliels t h a n f o r t h e b r i c k l a y e r - c o n s t r u c t e d p a n e l s , altliough t h e d i f f e r e n c e was s l i g h t . The bond s t r e n g t h of t h e lat-l-er p a n e l s , ho~vever, was s u p e r i o r .

P a n e l s of ex-bruded b r i c k mith 1:1:6 m o r t a r

showed no g r e a t d i f f e r e n c e i n moisture p e n e t r a t i o n p r o p e r t i e s betmeen t h e briclclayer-construc%ed and t h e labora-tory-constructed

( "heavyn t a p ) p a n e l s , altlzou@i t h e r e mere max?.red d i f f e r e n c e s

ill bond s t r e i i g t h . P a n e l s made u s i n g t h e " l i g h t " harmer, however,

were c o n s i s t e n t l y l e a k i e r t h a n t h o s e i n which t h e "heavy'" hammer was employed.

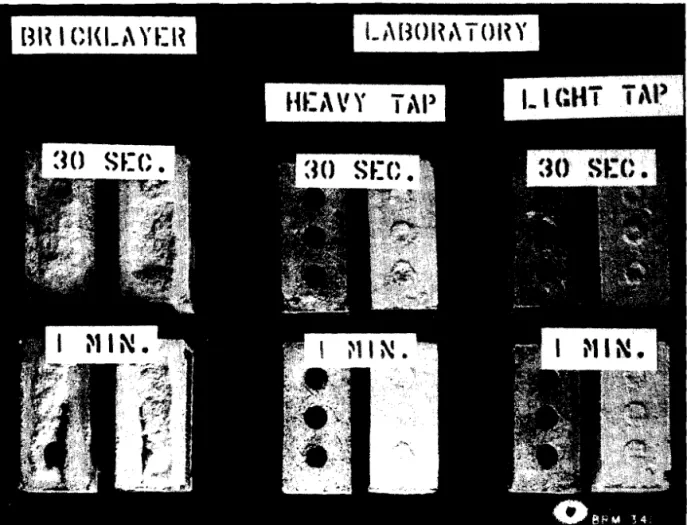

The na-ture of t h e b r e a k s i n t b e m o r t a r j o i n t s was q u i t e d i f f e r e n t b e t ~ ~ e e n t h e b r i c k l a y e r t s p a n e l s and t h e

othe:cs. 'This n a s par-Licularly no-kiceable f o r t h e p a n e l s

of extruded b r i c k and masonry cement mor-tar. For l a b o r a t o r y - c o n s t r u c t e d p a n e l s 1 6 t o 1 3 and 22 t o 3 0 , a l l except t-vo of t h e 48 j o i n t s broke c l e a n l y between t h e bottom of t h e b r i c k and t h e t o p of t h e m o r t a r , wit11 v e r y l i t t l e o r no breakage i n t h e mortar. The corresponding p a n e l s made by -t?ne b r i c k - l a y e r , however, c o n s i s t e n t l y broke i n such a way t h a t l a r g e amounts of mortar adhered t o b o t h s u r f a c e s , much 02 t h e

breakage t a k i n g p l a c e i n t h e m o r t a r i t s e l f a s shov~ii i n Pig. 1; h e r e t y p i c a l mortar-brick bonding c o n d i t i o n s a r e i l l u s t r a t e d f o r t h e two t y p e s of p a n e l s , f o r trvo time i n t e r v a l s , and f o r "light" and t a p s . !he b r i c k s a t lower l e f t sllow t h e v o i d i n t h e mortar caused by furrowing of t h e m o r t a r bed.

B r i c k masonry p a n e l s c o n s t r u c t e d by a method p r e f e r r e d by a b r i c k l a y e r and one used i n t h e Divisiont s l a b o r a t o r y work were cor~~pared on t h e b a s i s of m o i s t u r e pene-bration and bond s t r e n g t h p r o p e r t i e s .

I n -the leakage t e s t s laboratory-made p a n e l s g e n e r a l l y performed i n a s i m i l a r manner t o those made by t h e b r i c k l a y e r , b u t anomalous r e s u l t s prevented a t r u e corn- parison.

I n

bond s t r e n g t h t e s t s , ho~lvzver, t h e b r i c k l a y e r r s p a n e l s were i n a l l c a s e s c o n s i d e r a b l y s t r o n g e r t h a n t h o s e made i n t h e l a b o r a t o r y and Yne n a t u r e of t h e break i n bond tvasThe B r i c k l a y e r ' s method of c o n s t r u c t i o n o f tile p a n e l s appeared t o d i f f e r from t h e l a b o r a t o r y method i n tmo

r e s p e c t s , and may a c c o u n t f o r t h e d i f f e r e n c e s

i n

r e s u l t s , I n t h e f i r s t p l a c e , h e s p r e a d a t h i c l r e r , furrowed m o r t a r bed(3/4

i n c h o r more compared w i t h t h e +-inch bed used i n t h e l a b o r a t o r y method); t h i s probably meant t h a t t h e upper p a r t o f t h e mortar bed l o s t l e s s moisture because of t h e b r i c k ' s s u c t i o n , s o t h a t i n t h e same p e r i o d of c o n t a c t w i t h t h e b r i c k it would be i n a more p l a s t i c s t a t e . I n t h e second p l a c e , t h e b r i c k l a y e r bedded t h e b r i c k i n t h e mortar by g i v i n g it a s e r i e s of s h a r p t a p s w i t h t h e t r o w e l , whereasi n

t h e l a b o r a t o r y method, a s i n g l e t a p w a s given t o t h e b r i c k .Since l a b o r a t o r y - c o n s t r u c t e d rnasonq samples should be s i m i l a r i n t h e i r v a r i o u s p r o p e r t i e s t o f i e l d - c o n s t r u c t e d " masonry, f u r t h e r development work should be undertaken i n t h e method of panel assemblage. T h e use of a t h i c k e r , fbrrowed mortar bed and of a t a p p i n g device t o d e l i v e r

a

s e r i e s of t a p s t o t h e b r i c k should a l s o bei n v e s t i g a t e d and a comparison made of t h e p r o p e r t i e s of b r i c k l a y e r - c o n s - t m c t e d and l a b o r a t o r y - c o n s t r u c t e d p a n e l s ,

FABLE

I

PROPERTIES OF THE BRICKS

Extruded Pressed

b r i c k b r i c k

Suction (grams p e r min p e r maximum 55.4 87.1

30 sq i n . ) minimum 31.1 46.2 Water a b s o r p t i o n (24 h r , p e r maximum 6.9 8

3

c e n t dry w t ) minimum 6.1 6.1 Water a b s o r p t i o n ( 5 h r b o i l , maximum 10.0 10.5 p e r c e n t d r y w t ) minimum7.6

7.3 Sa-taration c o e f f i c i e n t maximum 0.86 0.84 minimum 0.75 0.76Compressive s t r e n g t h ( p s i ) maximum LO, 830 6,150

6,460 3,310

TABLE I1

-

RESULTS OF TESTSBond S t r e n g t h T o t a l Leakage ( m l ) Maximum Time f o r

7

D e t a i l s D i r e c t Tension Leakage Dampness I

24

(Average 1 ( p s i 1 Hour First Rate (ml/min ) l o Appear i

--- Hours

u ZT'BECl-an ' ~ s o n r y cement alortar

1

I 1 3 Made by b r i c k l a y e r 51.0 0 16 Very s l i g h t 3 hours \ 14 (1-min. i n t e r v a l ) (3) 47.3 (50.5) 100 4820 4 .O Immediate

I I

1 5 53.1 0 1 8 Very slight 1 5 minutes I

16 Made i n l a b o n t o r y 38.7 0 125 Very s l i g h t 11 minutes 17 (1-min. i n t e r v a l ) 10.8 (23.0) 0 165 Very s l i g h t 11 minutes ,

1 E, ( " l i g h t " t a p ) 25.7 0 41 Very s l i g h t 45 minutes

25 Vade i n l a b o r a t o r y 31.8 365 7912 8.5 Immediate

26 (1-min. i n t e r v a l ) 35.0 (28.1) 0 5 1 Very s l i g h t 65 minutes

27 ("heavy" t a p ) (**%) 13.8 0 617 1 . 0 Immediate

19 Blade by bricklayer 52.1 405 10820 8.0 Immediate

2 C ($-mln. i n t e n e l ) 47.2 (46.5) 0 68 Very s l i g h t 1 hour

2 1 40.3 0 51 Very s l i g h t 18 hours

22 i%de i n l a b o r a t o r y 28.6 0 1 9 Very s l i g h t

la

minutes23

(i- in.

i n t e r v a l 20.8 (22.5) 177 5410 4.5 3 minute24 ( light" t a p ) 15.9 0 50 Very s l i g h t 3 minutes

26 Made i n l a b o r a t o r y 25.2 0 7 Very s l i g h t 5 minutes 2 9 (4-min. i n t e r v a l 28,2 (26.8) 0 124 Very s l i g h t 6 m i ~ u t e s

30 ( heavy" t a p ) 26.9 0 56 Very s l i g h t 28 minutes

Extruded Brick and 1 :1:6 mortar

1 Made by b r i c k l a y e r 29.2 0 7 Very s l i g h t 55 minutes

2 (1-min. i n t e r v a l ) 44.0 (36.9) 0 7 Very s l i g h t

13

hours3 37.5 o 510 1.2 5 minutes 1 0 Yade i n l a b o r a t o r y 16.0 42 3410 3.0 Immediate I 11 (1-min. i n t e r v a l 23.5 (19.6) 260 9300 8.5 Immediate 12 ( " l i g h t " t a p ) 19.3 107 4685 7.0 $ minu*e 7 Made i n l a b o r a t o r y 18.9 0 114 5 1.0 2 minutes e (1-min. i n t e r v a l ) 37.3 (27.4) 0 9 Very s l i g h t 2$ h,.. c.-rs

5 ( "heavy" t a p ) 26.0 C 2 0 Verg s l i g h t 2r hours Pressed Brick and 1:1:6 Mortar

-

45 Made by b r i c k l a y e r 26.1 31 1630 1.3 4 mir;utes 4 4 (3-ffiin. i n t e r v a l 20.1 (19.2) 28 1247 1.5 1 2 minutes 45 13.7 38 2285 1 . 5 6 m i ~ u t e s 4 6 Wde i n l a b o r a t o r y 7.1 2 0 1280 1 . 0 12 minutes 47 (*-mine i n t e r v a l 11.3 ( 7 . 5 ) 1 0 1110 1 . 0 17 minutes 48 ( l i g h t " t a p ) 4.2 1 5 1320 1 . 0 1 5 mirutes 5 2 Made i n l a b o r a t o r y 13.5 11 1245 1 . 0 1 8 n i n u t s s 5 3 ('-min, i n t e r v a l ) 18.6 (14.2) 11 1130 1 . 0 1 7 m i r . ~ - ) c s 54 (%cavy"

t a p 5.8 24 1460 1 . 0 1 5 minutes -1( G ) 1-rnin. i n t e r v a l = 1 minute between p l a c i n g mortar on b r i c k then p l a c i n g b r i c k on mortar, I ( ::2L ) "Light " t a p = 2-lb harrner dropped 1$ inches.

FIGURE I COhWARISON OF B O D OF