Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Research Report (National Research Council of Canada. Institute for Research in

Construction), 2003-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=776a0693-0bd4-44af-8075-911ceba8c0d9 https://publications-cnrc.canada.ca/fra/voir/objet/?id=776a0693-0bd4-44af-8075-911ceba8c0d9

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20378767

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Cigarette Ignition Propensity Testing - First Series

Cigarette Ignition Propensity Testing – First Series

Su, J.Z.; Leroux, P.; Latour, J.C.

IRC-RR-142

November 2003

CIGARETTE IGNITION PROPENSITY TESTING – First Series

By

Joseph Z. Su, Patrice Leroux, John C. Latour Fire Risk Management Program Institute for Research in Construction National Research Council of Canada

ABSTRACT

The ignition strength of 10 brands of Canadian cigarettes was determined in accordance with the ASTM E2187-02b standard test method. Full-length burning of these 10 brands of cigarettes was observed in 95 to 100% of the determinations on 15 layers of filter paper. These high percentages of full-length burns suggest that these cigarettes have a relatively high

propensity to ignite upholstered furniture if lit and dropped on soft furnishings, demonstrating the need to make these cigarettes less probable to cause a fire.

TABLE OF CONTENTS

1.0 INTRODUCTION... 1

2.0 EXPERIMENTS ... 1

2.1 Test Facility ... 1

2.2 Test Method ... 3

2.3 Quality Assurance and Conditioning of Filter Papers... 4

2.4 Storage and Conditioning of Cigarettes ... 4

2.5 Test Procedure and Parameter Randomization ... 4

3.0 RESULTS AND DISCUSSION... 7

3.1 Results of Calibration Tests with “Standard” Cigarettes ... 7

3.2 Results of 10 Brands of Canadian Cigarettes ... 7

4.0 SUMMARY... 7

5.0 ACKNOWLEDGEMENTS ... 8

6.0 REFERENCE ... 8

LIST OF TABLES Table 1 Ten Brands of Canadian Cigarettes ... 4

Table 2 Test Sequence for 10 Brands of Canadian Cigarettes ... 6

Table 3 Results of ASTM E2187-02b Tests for 10 Brands of Canadian Cigarettes... 7

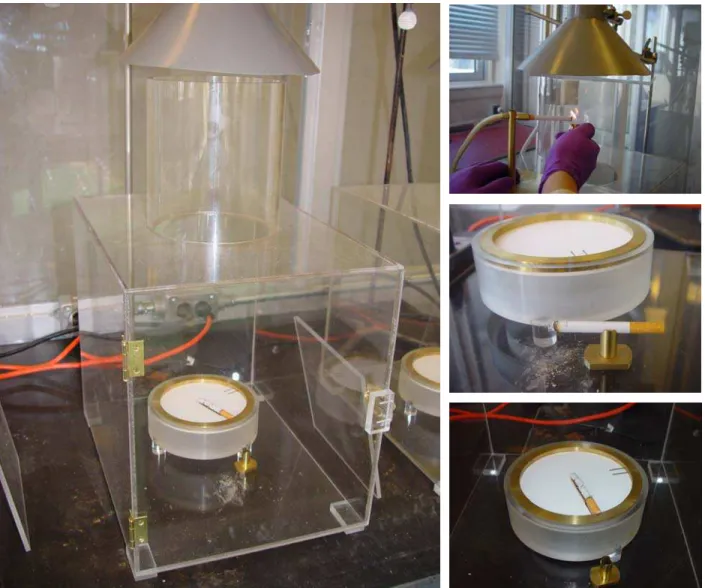

LIST OF FIGURES Figure 1 The conditioned test room and 4 test chambers built for the experiments ... 2

Figure 2 Test chamber, filter paper holder with metal rim, cigarette holder and ignition system ... 3

CIGARETTE IGNITION PROPENSITY TESTING – First Series

Joseph Z. Su, Patrice Leroux, John C. Latour

Fire Risk Management Program, Institute for Research in Construction National Research Council of Canada

1.0 INTRODUCTION

A common initiating event for fatal fires is the dropping of a lit cigarette onto a bed or a piece of upholstered furniture. According to a recent consultation paper by Health Canada [1], fires started by the careless use of smokers’ materials are the leading known cause of

fire-related death in Canada, on average killing more than 70 people per year. On a per fire basis, fires ignited by smokers’ materials result in more fatalities and property damage than fires ignited by other sources. Reducing cigarette-ignited fires and developing less fire-prone

cigarettes have proved to be a long struggle in North America [2].

In recent years, there has been extensive research by the National Institute of Standards and Technology (NIST), among others, to investigate the parameters that affect the ignitability of upholstered furniture by cigarettes. One outcome of this research was the development of a test method to measure the ignition strength of cigarettes. The test method is being

standardized by ASTM International [3].

Health Canada is proposing to regulate the ignition propensity of cigarettes in order to reduce the ignitability of upholstered furniture by lit cigarettes. As part of its background research, Health Canada requires information on the ignition strength of at least 36 brands of Canadian cigarettes.

In response to this need, the National Research Council (NRC)'s Fire Risk Management Program built a test facility and completed an experimental series to study the ignition strength of an initial 10 brands of Canadian cigarettes in accordance with the ASTM E2187-02b standard test method [3]. This report documents the results of this experimental study.

2.0 EXPERIMENTS

This section describes the test facility that were constructed and the cigarette tests conducted at NRC. NRC staff visited the NIST laboratory and received training in conducting the ASTM standard test before building the test facility and conducting the tests at NRC.

2.1 Test Facility

The test facility includes a conditioned test room, 4 test chambers and equipment for controlling and measuring temperature, humidity and ventilation in the room. Figure 1 shows a conditioned room and 4 test chambers with pipes to an exhaust hood. This test room is

approximately 8 m2 (3 m long, 2.5 m wide and 3 m high), built with an aluminium-alloy frame and transparent Plexiglas panels. Figure 2 shows the test chamber, filter paper holder with metal rim, cigarette holder and ignition system. Other equipment includes a hygrothermograph recorder for monitoring the temperature and humidity, a psychometer for measuring dry/wet bulb humidity, heaters and humidifiers for conditioning the room, and a fan for air circulation.

Figure 2. Test chamber, filter paper holder with metal rim, cigarette holder and ignition system.

The facility and equipment were set up and calibrated in accordance with the requirements of the ASTM test method. The condition of the test room was monitored for stability for more than a week before starting the experimental series. Both the temperature and humidity were stabilized within required condition — a relative humidity of 55% ± 5% and a temperature of 23°C ± 3°C. The exhaust and room ventilation was controlled and maintained at the level that air movement in the test chambers rose steadily with no turbulence.

2.2 Test Method

The methodology is fully described in the ASTM standard [3]. In brief, this test method uses a set number of layers of filter paper as standard substrates to determine the propensity of a cigarette to ignite upholstered furnishings. A lit cigarette is placed on the substrate supported by the filter paper holder inside the test chamber. The filter paper substrate acts as a heat sink, absorbing heat from the lit cigarette. Depending on the strength of a cigarette as a heat source and the number of layers of the filter paper, the lit cigarette may or may not produce a full-length

burn. A substrate assembly of 15 layers of filter paper needs a cigarette with stronger heat strength to produce a full-length burn, compared with using 10 or 3 layers of filter paper. Relative ignition strength of a type of cigarettes is determined by testing 40 cigarettes (of the same type) on a set number of layers of filter paper and observing the percentage of the cigarettes that produce full length burning.

2.3 Quality Assurance and Conditioning of Filter Papers

Whatman #2 filter paper was used to assemble the standard substrates. Quality assurance of the filter papers was conducted according to the ASTM Standard (Clauses 9.3.1 and 9.3.2) before placing a large order (450 boxes, 100 sheets per box). The top-removed boxes of the filter paper were conditioned in the test room (at a relative humidity of 55% ± 5% and a temperature of 23°C ± 3°C) for more than a week prior to cigarette testing.

2.4 Storage and Conditioning of Cigarettes

NIST provided 300 "standard" cigarettes for calibration tests. Health Canada provided samples of 10 brands of Canadian cigarettes (75 cigarettes each brand), as shown in Table 1. All cigarettes were stored at -4 to 0°C to minimize the risk of contamination. The cigarettes were conditioned at a relative humidity of 55% ± 5% and a temperature of 23°C ± 3°C for 48 hours prior to testing.

TABLE 1

Ten Brands of Canadian Cigarettes

Symbol Type Size

m1 Export "A" (full flavour) Regular Size

m2 Rothmans Special Mild King Size

m3 Export "A" Medium Regular Size

m4 Craven Menthol King Size

m5 Player's Light King Size

m6 Player's Light Regular Length

m7 Craven A Light Regular

m8 du Maurier (parent) King Size

m9 Benson and Hedges Special Regular

m0 Rothmans King Size

2.5 Test Procedure and Parameter Randomization

The procedure specified in the ASTM standard method (Clause 11) was followed in conducting the ignition strength determination of the NIST “standard” cigarettes and Canadian cigarettes. Calibration tests for 200 “standard” cigarettes were conducted to check and verify whether the NRC facility and operation would produce results consistent with that from NIST and other laboratories. Five repeat rounds were conducted, each round using 40 “standard” cigarettes and substrate assemblies of 10 layers of filter paper.

The procedure was then conducted for 10 brands of Canadian cigarettes listed in Table 1. A total of 400 Canadian cigarettes were tested on the substrate assemblies of 15 layers of filter paper. Experimental variables, such as cigarette types, test chambers and test samples were randomized for the experiment sequence in order to eliminate systematic errors. The experiments were divided into 10 test cycles, each cycle involving all 10 types of the

cigarettes and all 4 chambers. Table 2 shows the experiment sequence used in this test series, resulted from the randomization of the experimental variables.

TABLE 2 – Test Sequence for 10 Brands of Canadian Cigarettes

Cycle 1

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 5 37 17 1 13 33 9 25 21 29 19 11 30 34 23 6 3 15 27 39 12 24 40 20 8 36 16 32 2 26 4 14 28 18 22 35 38 10 7 31

Cycle 2

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 24 32 37 35 27 20 5 1 16 9 12 29 39 4 36 15 19 23 25 8 2 38 22 7 17 28 31 14 10 33 21 3 26 34 40 11 18 13 6 30

Cycle 3

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 9 13 36 21 38 5 25 17 1 31 16 3 8 19 12 39 35 32 28 24 18 15 26 22 33 40 6 29 11 2 10 30 37 4 23 34 27 7 20 14

Cycle 4

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 32 39 10 24 35 19 5 15 28 1 31 4 36 12 40 27 8 16 20 23 9 29 2 37 13 25 17 33 22 6 34 7 11 3 14 30 38 18 26 21

Cycle 5

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 16 6 30 1 19 36 26 21 40 11 25 13 33 5 17 9 3 38 29 23 14 27 10 8 35 4 32 22 39 18 12 24 2 37 15 34 7 20 28 31

Cycle 6

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 34 17 29 6 25 38 21 13 9 2 27 31 15 23 37 19 7 10 35 4 40 26 14 22 18 8 3 11 30 33 16 5 36 32 24 39 1 20 12 28

Cycle 7

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 37 22 33 11 8 3 29 14 25 18 6 12 40 20 16 1 36 30 24 27 17 9 21 38 5 34 2 13 31 26 39 28 32 15 4 35 7 23 19 10

Cycle 8

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 14 18 26 9 37 29 33 22 3 6 4 28 24 39 16 32 36 12 20 8 34 19 15 31 5 23 2 27 38 11 21 40 10 7 17 30 1 13 35 25

Cycle 9

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 19 31 38 10 14 35 2 6 27 23 25 21 13 11 33 17 7 40 3 29 32 36 12 8 24 4 20 39 28 16 5 18 34 30 26 37 15 22 1 9

Cycle 10

Chamber 1 Chamber 2 Chamber 3 Chamber 4

m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 m1 m2 m3 m4 m5 m6 m7 m8 m9 m0 13 9 17 21 30 6 34 39 25 2 22 10 37 7 29 19 4 26 14 33 1 31 15 28 18 23 36 5 11 38 8 40 32 16 27 12 24 35 20 3

3.0 RESULTS AND DISCUSSION

3.1 Results of Calibration Tests with “Standard” Cigarettes

The determination of ignition strength for the “standard” cigarette was conducted with 10 layers of the filter paper as the substrate assembly. Five repeat tests were conducted, each test consisting of 40 determinations. A total of 200 calibration cigarettes were used.

The number of the cigarettes that produced full-length burning was 7, 9, 12, 10, and 13 for the five repeat tests, which represented 18, 22, 30, 25 and 32% full-length burns,

respectively. The full-length burns were well distributed among the 4 test chambers. These results are well within the expected inter-laboratory reproducibility range [3, 4].

3.2 Results of 10 Brands of Canadian Cigarettes

The ignition strength for the Canadian cigarette was determined in tests using 15 layers of the filter paper as the substrate assembly. A total of 400 cigarettes were used. Out of the 400 cigarettes tested, only 3 cigarettes did not burn to the full length (1 of the 40 Export "A" Medium cigarettes and 2 of the 40 Craven Menthol cigarettes), as shown in Table 3.

TABLE 3 – Results of ASTM E2187-02b Tests for 10 Brands of Canadian Cigarettes (on 15 layers of filter paper)

Symbol Type Size Full Length Burns

(40 determinations)

Percentage

full length burns m1 Export "A" (full flavour) Regular Size 40 100%

m2 Rothmans Special Mild King Size 40 100%

m3 Export "A" Medium Regular Size 39 97.5%

m4 Craven Menthol King Size 38 95%

m5 Player's Light King Size 40 100%

m6 Player's Light Regular Length 40 100%

m7 Craven A Light Regular 40 100%

m8 du Maurier (parent) King Size 40 100%

m9 Benson and Hedges Special Regular 40 100%

m0 Rothmans King Size 40 100%

4.0 SUMMARY

A long-term facility with a controlled test environment for determination of cigarette ignition strength was set up at NRC. Calibrated in accordance with the ASTM E2187-02b standard test method, this facility produced results consistent with that from NIST and other laboratories for the "standard" cigarettes. This facility has been used to determine the ignition strength of 10 brands of the Canadian cigarettes and will continue to be used to generate technical data to support Health Canada's efforts in regulating ignition strength and reducing fire risks from cigarettes.

The ignition strength for the 10 brands of Canadian cigarette was determined with 15 layers of filter paper as the substrate assembly. Full-length burning of these 10 brands of cigarettes was observed in 95 to 100% of the determinations. These high percentages of full-length burns suggest that these cigarettes have a relatively high propensity to ignite upholstered furniture if lit and dropped on soft furnishings, demonstrating the need to make these cigarettes less probable to cause a fire.

5.0 ACKNOWLEDGEMENTS

NRC acknowledges assistance from Victoria Tunstall and Julie Fillion of Health Canada during this project. NRC also acknowledges supports from Dr. Richard Gann and Mr. Jack Lee of NIST for technical training and guidance. The authors also wish to thank Jocelyn Henrie for his contribution in constructing the test facility.

6.0 REFERENCE

1. Health Canada, Tobacco Control Programme, "Regulatory Proposal for Reducing Fire Risks from Cigarettes, A Consultation Paper," Health Canada, Ottawa, ON, December 2002. 2. Markey, E., "Slow Burn: Fire-Safe Cigarettes," NFPA Journal, November/December 2002,

pp. 42-45.

3. ASTM E2187-02b, "Standard Test Method for Measuring the Ignition Strength of Cigarettes," ASTM International, West Conshohocken, PA, 2002.

4. Gann, R. G., Personal communication, National Institute of Standards and Technology, Gaithersburg, MD, January and February 2003.