Publisher’s version / Version de l'éditeur:

Durability of Building Materials, 3, 3, pp. 213-223, 1986-04

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Mineral granules: optimal grading for maximum protection of roofing

Dutt, O.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=add6ac56-c5ac-4c50-b5d4-c7b6eda87562 https://publications-cnrc.canada.ca/fra/voir/objet/?id=add6ac56-c5ac-4c50-b5d4-c7b6eda87562Ser

,

TH1National

ResearchConseil

national

N21a

C

coumw

crua

de

nckuehr

Crud.no.

1410

c. 2 Institute for lnstitut de

BLDG

Research in recherche en\ -

Construction

constructionMlneml Granules: Optlmal

Grading

for Maxlmum

Protection

of

Roofing

by

0.

DuttAMALYZED

Reprinted from

Durability of Buildin Materials Vol. 3, No. 3, April 1 86

p. 21 3

-

2238

(IRC Paper No. 1410)Price $2.00 NRCC 26428

NRC

-

CISTIBLDG.

RES.

L I B R A R Y

On a dtudi6 le classement granulom6trique et la densite des granules provenant de divers echantillons de couverture. Leurs arrangements geom6triques ont 6t6 analyses B l'aide de spheres

de dimensions specifiques qui couvriraient entisrement une surface plane theorique. Apres avoir compar6 les tailles des spheres avec celles des granules tires des echantillons de couverture, on a constate qu'il Etait possible de modifier le classement granulom6trique afin d'accroftre la protection des toits. L'effet produit par l'enlevement successif de spheres de plus en plus petites de la surface thdorique a 6t6 compare B

celui resultant de l'enlevement de granules d'une membrane de couverture r6elle.

Durability o f Building Materials, 3 (1986) 2 13-223

Elsevier Science Publishers B.V. Amsterdam -Printed in The Netherlands

MINERAL GRANULES: OPTIMAL GRADING FOR MAXIMUM PROTECTION OF ROOFING

0. DUTT

Division of Building Research, National Research Council o f Canada, Ottawa, Ontario KIA OR6 (Canada)

(Received May 7 , 1 9 8 5 ; accepted September 1 4 , 1 9 8 5 ) Keywords

Roofing, Aggregate, Properties Physical Models Bituminous

products

ABSTRACT

Dutt, O., 1986. Mineral granules: optimal grading for maximum protection of roofing.

Durability of Building Materials, 3 : 2 1 3-223.

Granules from various roofing samples were studied for their size grading and densities. Geometric arrangements were analyzed, using specific sizes of spheres that would provide total coverage of a theoretical plane surface. The sphere sizes, when compared with the sizes of granules obtained from the roofing samples, indicate that there is a scope for modifying the grading of granules t o increase protection of the roofing surfaces. The effect of removing spheres of successively smaller sizes from the theoretical surface was compared with that of removing granules from an actual roofing membrane.

INTRODUCTION

Bituminous roof surfaces are damaged by solar radiation and other natural elements of weather. Ultraviolet (UV) radiation, heat and atmospheric oxygen accelerate the photochemical oxidation of bitumen. Rainwater dissolves oxidized bituminous compounds, exposing fresh bitumen. This deterioration continues as a cyclic process (Cheetham and Banfill, 1983). Mineral granules embedded in the bituminous surfaces provide protection against solar radiation and reduce surface temperature, thereby increasing the durability of the roofing material.

The granules may consist of crushed stone, slate, blast-furnace slag or any other natural or synthetic aggregate particles. They range in size, generally, from 500 pm to 6 mm in diameter (Griffin, 1982). Some roffing material standards (CSA Standard A123.1-M1979, ASTM D225, ASTM D3462) specify different size ranges between 150 pm and 3.36 mm, but each manu- facturer of granules sets his own standard for their sizing and grading within

that range. A typical grain-size distribution used by manufacturers is given in Table 1 , which also lists the computed average of size range and particle count for each size of granules. The graph of sieve analysis values for granule samples obtained from different shingles (Fig. 1 ) shows the variation in grain-size distribution within the normal range. In this figure, the granules retained on a sieve are assumed t o be the same size as that of the sieve rather than the average of the 'passing' and 'retaining' sieve sizes.

The minimum amount of granules that must be applied t o a bituminous surface is specified in standards applicable t o particular products. However,

TABLE 1

Distribution of grain-size and numbers in a typical sample of granules (computed from information supplied by a manufacturer)

Sieve Granules

No. Opening (or size) Size Size Average Average

range range mass no.

(in.) (mm) (mm) average on sieve count

(mm) (%) (%I 8 0.0930 2.362 2.362-3.326 2.844 0 0 1 0 0.0650 1.651 1.651-2.361 2.006 7 1.5 1 4 0.0460 1.168 1.168-1.650 1.409 37 16.3 20 0.0328 0.833 0.833-1.167 1 .O 3 1 27.1 28 0.0232 0.589 0 . 5 8 9 4 . 8 3 2 0.711 1 9 32.8 3 5 0.0164 0.417 0.417-0.588 0.503 5 17.3 pan 0.0164 0.417 0.417 0.417 1 5.0 0 0. 5 1. 0 1 . 5 2 . 0 S I Z E O F G R A N U L E S , m m

Fig. 1 . Variation in grain size distribution of granules as obtained from six different commercial samples of shingles.

each roofing producer generally uses more than the minimum required to ensure maximum protection of the bitumen. Experimental determination of the mass of granules and the granular coverage of various samples using the linear traverse method (Dutt, 1985), given in Table 2, shows that the maxi- mum coverage obtained for the samples tested so far has been 89.4%.

TABLE 2

Granule coverage of some bituminous surfaces Sample Coverage Mass of granules description

(%I

From For 100% specimens coveragea (g1m2 ) (91m2) ( 1 ) ( 2 ) ( 3 ) GU - Cap sheet 84.7 1289 1522 (modified bitumen) XS - Single-ply 89.4 1186 1327 (modified bitumen) SI - Shingle 87.7 1497 1707 Density Observation of granules (kg/m3) 2674 Large portion of smaller sizes 2891 a Theoretical coverage = ( 2 ) + ( 1 ) X 100.The granules must be sized, graded and counted so as to ensure proper nesting, which is vital to the continuity of surface protection. Oversized granules will add to the weight, and thus to the cost, of roofing membranes and, because of greater leverage, will increase the probability of granule erosion by wind, flowing water, traffic, and handling of materials. Excessive fines in the undersized granules will tend to submerge into the hot bitumen coating during manufacture and may not perform their protective function. A mathematical study of granule sizing for maximum coverage was under- taken to investigate the effect of particle-size distribution. It was expected that a theoretical coverage would enable tangible coii~parison with a real granular surface. The objectives of the present study are thus as follows: (1) To develop a mathematical model of closely packed spheres to deter-

mine the sizes that will completely cover a surface;

(2) To determine the grading and quantity of spheres needed for total coverage;

(3) To investigate the increase in exposure of a bituminous surface after gradual erosion or loss of successively smaller spheres from a theoretical surface, and to compare the results with those for a granule-covered roofing surface.

GEOMETRIC ARRANGEMENT OF SPHERES

A geometric arrangement of spheres of different sizes is considered that would provide maximum coverage of the plane supporting the spheres. The

problem, prima facie, is similar to the close-packing configurations of identi- cal spheres in space that have been studied for many years by specialists in mathematics, crystallography, porosity of materials and many physical systems (Sloane, 1984).

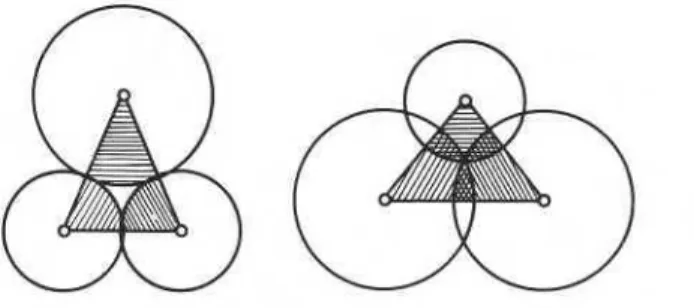

Toth (1964) has discussed systematology and genetics of regular figures, including spheres and circles. In the case of non-overlapping circles, he presents a lower bound for the density of packings of the Euclidean plane using circles, the ratio of whose radii lies in a definite finite interval. Simi- larly, in overlapping circles, an upper bound for the density of coverings is given (Fig. 2). However, in the case of spheres, the subject matter does not cover the overlapping of spheres of different sizes, a situation that occurs in granular surfaces where the magnitude of overlap between each pair of spheres is limited by their sizes.

Fig. 2. Density of packing and covering of Euclidean plane (Toth, 1964).

The so-called 'kissing number' and covering problems related to sphere- packing (Sloane, 1984) are reduced to specific conditions in the present study of granular surfacing, in which granules are replaced by spheres. This problem is partly three-dimensional and partly two-dimensional. These conditions are as follows.

(1) Spheres can be any number of different sizes.

(2) Each sphere must touch the surrounding spheres such that it is not loosely placed.

(3) All spheres must be in contact with the supporting plane. (4) The spheres must be arranged so as to cover 100% of the plane.

In random placement on a plane surface, the spheres can take up many configurations. Two configurations are discussed here: (1) the top layer of spheres is arranged in a triangular fashion, called the hexagonal lattice packing, L2, and

(2)

the top layer is arranged in a square packing, D2.TRIANGULAR PACKING

Initially three spheres were considered, each of radius

R

and mutally touching each other and the supporting plane. In plan, they formed three circles with their centres at the vertices of an equilateral triangle, giving acover density of 90.69%. In the depression, or deep hole, between these spheres, a fourth sphere of maximum radius was packed underneath such that it touched the plane and the three original spheres. Using principles of solid geometry, the radius of this underlying sphere, labelled as a second-size

TABLE 3

Packing of spheres for complete coverage of a plane

Packing Spheres Area configuration coverage

Size Mass Number (cumulative) ratio

(%I

count(%I

Triangular 1 0.333 0.250 Square 1 0.50 0.268 0.172 0.104 P L A N-

-

P L A N S E C T I O N A - A S E C T I O N A - AFig. 3(a). Close packing of spheres of three different sizes resulting in 100% coverage. Diameters are in the ratio 1 2 :4 :3.

Fig. 3(b). Close packing of spheres of five different sizes resulting in 100% coverage. Diameters are in the ratio 12:6:3.2:2.1:1.2.

sphere, was computed to be

4

R. The covering density, excluding the over- lapping areas, was found to be 99.15%. The procedure was repeated for a third set of spheres which could be packed in the underlying interstitial spaces. These spheres, with a radius that was found to be$

R, increased the covering density to 100%. Further investigation of the hexagonal configu- ration was not considered necessary. Sizes, quantities and numbers of spheres required to cover a unit area were computed and are given in Table 3.The arrangement of the spheres is shown in Fig. 3 (a). SQUARE PACKING

In this configuration, four spheres, each of radius R, are packed so that their centres lie on the corners of a square of side 2 R. This gives a cover density of 78.54%. A smaller sphere of radius

4

R, which fits in the under- lying space and touches the surrounding spheres and the base, increases the coverage to 95.48%. Another set of still-smaller spheres increases it to 99.93%. Two further sets of successively smaller spheres filling the under- lying spaces increase the cover density to 100%. The details of spheres required for 100% coverage in the square-packing configuration are given in Table 3; their arrangement is shown in Fig. 3(b).OPTIMAL GRADING

It is expected that, when a large number of spheres are dumped on a sticky surface, such as granules on hot asphalt in a roofing plant, the spheres will take any form of arrangement. The number of configurations and the number of times that each possible configuration may occur on the surface can be assessed statistically. Each configuration requires a set of specific sizes and numbers of spheres for maximum coverage. The sizing of spheres and the coverage for two basic forms, triangular and square, were analyzed; the results are presented in Table 3.

When various patterns are combined for maximum coverage, the proba- bility of spheres settling in a triangular form is very high compared with other forms for two reasons. Firstly, spheres in bulk are generally packed in the densest form of triangular pyramid, known as face-centred-cubic packing (Sloane, 1984); secondly, in the process of settling, the spheres push against each other and tend to lie on the plane in the densest form of packing, which is a triangular form.

In order to demonstrate the method of combining the two configurations discussed above, a model was designed to determine a mix of different sizes of spheres that would cover one square area and fifty-six different-sized triangular areas. The largest average size of spheres, 2.006 mm diameter, was identical to the largest size of granules given in Table 1. The sizes of the smaller spheres were based on the ratios given in Table 3, but were adjusted t o fit the nearest size of Tyler sieves (Lambe, 1951). The hypothetical

surface was considered to be fully covered when all triangular areas occupied

84% of the surface and the square area occupied 16% of the surface. The calculations were done for the total mass, volume and number count of the various sizes of spheres. For convenience, an approximate density of 2500 kg/m2 was assumed for computing the mass of spheres per unit area on the theoretical surface. The assumption was based on the densities of some samples of granules (Table 2) that were experimentally determined using a mercury intrusion porosimeter. The results and some calculations are given in Table 4.

TABLE 4

Model of a graded mix of spheres Sieve Spheres

No. Opening Size Required for following Total Mass Number

range areas (%) count

average Nos. Volume

(a)

(mm dia.) 1 8 1 6 32 (mm3 SQa A1 AZ A!

Total 1 8 24 48 96 19.74 100.0 100.0

a SQ = square area.

A1, A,, A3 = triangular areas.

Area covered by 1 square

+

8 Al+

1 6 A+

32 A3 = 1 ( 4 ~ ' ) + 8(&R2+

1 6 ( & ~ ! ) + 32($~:)=

6

(4(2.0062'+

8$(1.409)'+

16&(1.0) 32&(0.711)') = 24.84 mm.

Mass of spheres = 19.74 X mm3 volume X 2.5 g/cc assumed density = 49.350

x

g.Mass per unit area = 1987 g/m2.

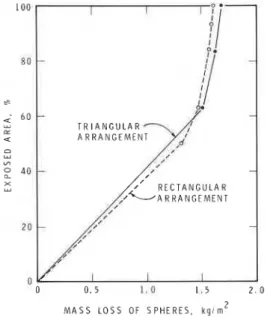

EROSION OF THE GRANULAR SURFACE

A bituminous surface is exposed as the granules are removed by loosening through degradation and loss of adhesion, and by the scouring effect of wind, water and traffic. In this weathering process, the large granules, having greater leverage, are usually removed first, followed by the smaller ones. This phenomenon of exposure resulting in the loss of granules was studied with

reference to a theoretical plane covered with spheres densely packed in either a triangular or a square pattern.

Starting with a fully covered surface in each case, the largest-size spheres

M A S S L O S S O F S P H E R E S , k g i m 2

Fig. 4. Surface area exposed by removing successively smaller spheres from a plane covered with closely packed spheres.

TABLE 5

Theoretical exposure due t o removal of the successively smaller spheres of two configu- rations of closely packed spheres

Packing Spheres Cumulative effect

configuration

Sizea Removed LOSS of massb Exposed area

(mm dia.) (kg/m2

(%I

Triangular All 1.o

0.333 0.250 Square All 1.o

0.50 0.268 0.172 0.104 None3

Nonea Assumed largest size = 1 mm.

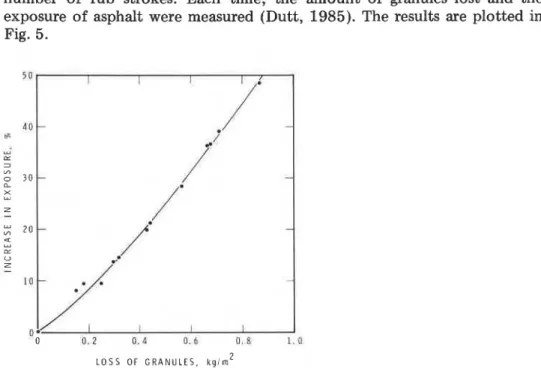

were removed first, as would happen if a granular surface were subjected to the standard granule embedment test (UL55B, 1983). The area thus exposed was calculated, then the spheres next in size were removed and the new exposed area was computed. The process was continued until all spheres were removed. The values of the increasing loss of mass of granules and of the increasing exposed area are calculated and plotted for both patterns of packing, and are given in Table 5 and Fig. 4, respectively. In order to corre- late this theoretical model with the results of abrading a roofing sample in a granule embedment tester, a roofing specimen was subjected to an increasing number of rub strokes. Each time, the amount of granules lost and the exposure of asphalt were measured (Dutt, 1985). The results are plotted in Fig. 5.

L O S S O F G R A N U L E S , k g / r n 2

Fig. 5 . Increase in the exposed area of bitumen as the granules are removed from a sample

of roofing membrane (initial exposure was 10.4%).

I

DISCUSSIONThe mathematical model for the close packing of spheres shows that 100% protection of a bituminous surface is possible with specific sizes and numbers of granules. The results given in Table 3 show that one can achieve over 99% coverage even by excluding the smallest size of granules in a triangular arrangement and the two smallest sizes in a square arrangement. In

t

practice, one could remove the finer particles that tend to get submerged in hot asphalt, while maintaining almost complete coverage. The ratio of sizes given in Table 3 can also be applied to the grading of gravel to increase protection of built-up roofing. The same principle could be extended to any other situation that requires grading particles for covering a surface.

Table 4 shows that the choice of packing configurations can be varied and mixed in order to obtain a suitable grading for maximum protection. The largest-size spheres, which are only 0.5% of the total number but account for 21.4% of the total mass, can be sized down with small loss in coverage. One could evaluate the effect of down-sizing the larger spheres in a pilot project by experimenting with various size combinations based on the present study. The increasing exposure of surfaces that results when spheres of suc- cessively smaller sizes are removed is seen in the ascending curves shown in Fig. 4. Removing the smaller spheres exposes a comparatively larger area for the same mass removed. A similar trend is seen in the results of an experi- ment in which granules from a commercial roofing sample were rubbed off, exposing the bitumen (Fig. 5). The small curvature of the curve in Fig. 5 is attributed t o the fact that, during manufacture, the rollers press the granules into the bituminous surface to different depths. The abrasion test conse- quently removes granules of various sizes at any stroke, resulting in a small curvature compared with the theoretical curves of Fig. 4. In fact, the cwve is almost linear.

CONCLUSIONS

(1) The mathematical model of closely packed spheres shows that granules can be graded and placed so as t o provide 100% coverage of bituminous roof surfaces. The ratio of sizes thus determined can also be applied to the grading of gravel used on built-up roofs for improved protection, as well as to any other situation where particle-sizing is required for cover- ing a surface. It can also be used as a basis for optimal grading in a granule manufacturing plant. However, the probability that the bulk of graded spheres, deposited on a sticky surface like that of hot bitumen, will settle in geometric patterns needs further experimental work.

(2) Loss of smaller-size granules causes exposure of a comparatively large area. In the standard granule embedment test, granules of various sizes are removed simultaneously, thereby making the mass loss of granules almost proportional to the increase in exposure.

ACKNOWLEDGEMENT

The author acknowledges with thanks the assistance of G.A. O'Doherty in conducting the laboratory tests. This paper is a contribution from the Division of Building Research, National Research Council of Canada.

REFERENCES

ASTM D 225, 1 9 8 0 . Standard Specifications for Asphalt Shingles (Organic Felt) Surfaces with Mineral Granules. ASTM, Philadelphia, PA, U.S.A., Vol. 04.04.

ASTM D 3462, 1983. Standard Specifications for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules. ASTM, Philadelphia, PA, U.S.A., Vol. 04.04.

223 Cheetham, D.W. and Banfill, P.F.G., 1983. The uses of poly(viny1)chloride and bitumens in building with special reference t o their possible interactions. The Chartered Inst. of Building, U.K., Constr. Papers, 2 (2): 91-103.

CSA Standard A123.1-M1979, 1979. Asphalt Shingles Surfaced with Mineral Granules. Canadian Standards Assoc., Rexdale, Ont., Canada.

Dutt, O., 1985. Granule coverage of bituminous roof surfaces. Submitted t o ASTM J. Test. Eval.

Griffin, C.W., 1982. Manual of built-up Roof Systems. McGraw-Hill, New York, NY, U.S.A., p. 461.

Lambe, T. William, 1951. Soil Testing for Engineers. John Wiley & Sons, Inc., New York, NY, U.S.A., pp. 29-35.

Sloane, N.J.A., 1984. The packing of spheres. Sci. Am., 250 (January): 116-125. Toth, Fejes L., 1964. Regular Figures. MacMillan, New York, NY, U.S.A., pp. 204-209,

238-254.

UL 55B, 1983. Standard for Class C Asphalt Organic-Felt Sheet Roofing and Shingles. Underwriters Laboratories Inc., Northbrook, IL, U.S.A., pp. 6, 13-15.

I

I

T h i s paper i s b e i n g d i s t r i b u t e d i n r e p r i n t form by t h e I n s t i t u t e f o r Research i n C o n s t r u c t i o n . A l i s t of b u i l d i n g p r a c t i c e and r e s e a r c h p u b l i c a t i o n s a v a i l a b l e from t h e I n s t i t u t e may be o b t a i n e d by w r i t i n g t o t h e P u b l i c a t i o n s S e c t i o n , I n s t i t u t e f o r R e s e a r c h i n C o n s t r u c t i o n , N a t i o n a l Research C o u n c i l of C a n a d a , O t t a w a , O n t a r i o , KIA OR6. Ce document e s t d i s t r i b u 6 s o u s forme de t i r 6 - 3 - p a r t p a r 1' I n s t i t u t de r e c h e r c h e e n c o n s t r u c t i o n . On p e u t o b t e n i r une l i s t e d e s p u b l i c a t i o n s de 1 ' I n s t i t u t p o r t a n t s u r

les t e c h n i q u e s ou les r e c h e r c h e s e n

matisre

d e b t t i m e n t e n 6 c r i v a n t 3 l a S e c t i o n d e s p u b l i c a t i o n s , I n s t i t u t de r e c h e r c h e en c o n s t r u c t i o n , C o n s e i l n a t i o n a l d e r e c h e r c h e s du Canada, Ottawa ( O n t a r i o ) ,