Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

ICOM 2011, [Proceedings], 2011-07-23

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=31f64b4e-7a1c-4598-abc3-35212efc31f7 https://publications-cnrc.canada.ca/fra/voir/objet/?id=31f64b4e-7a1c-4598-abc3-35212efc31f7

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Alternative Materials and Manufacturing Technologies for Fabrication

of Proton Exchange Membranes

Alternative Materials and Manufacturing Technologies for Fabrication of

Proton Exchange Membranes

A. Mokrini, M.F. Champagne, L. Robitaille

Industrial Materials Institute – National Research Council of Canada. 75 de Mortagne, Boucherville (QC) Canada

asmae.mokrini@cnrc-nrc.gc.ca

Ion exchange membranes are extensively used as electrolytes in electrochemical devices such as fuel cells, batteries and electrolyzers, as well as barriers in separation processes such as filtration, gas separation, dialysis etc. This contribution reports on alternative routes to prepare functional proton exchange membranes (PEM) for fuel cell applications. PEM are typically phase-segregated materials where a percolated network of a hydrophilic domain conducts protons while the hydrophobic phase confers mechanical strength as well as dimensional and hydrolytic stability during fuel cell operation. The major challenges in the development of new polymer materials suitable as electrolytes for fuel cell applications are to design materials that combine high ionic conductivity and durability, good mechanical strength, reduced fuel permeability, and low cost for high-volume production.

Melt-processing technologies, such as twin-screw extrusion and melt-blowing, were used to prepare advanced reinforced polymer membranes based on fluoropolymers and hydrocarbon elastomers. In this study, blends of polyvinylidene fluoride (PVDF) as a reinforcing polymer and poly(styrene-ethylene-butylene) block copolymer (SEBS) were examined. The aryl groups of SEBS were sulfonated following membrane melt-processing to confer ionic conductivity to the hydrophilic domain. The properties of these polymer membranes are to a large level determined by the phase morphology and the interfacial properties, both directly related to the processing history. The materials developed in this work exhibit a valuable combination of mechanical, chemical and electrochemical properties while being melt-processable. The use of melt-processable ionomers is also expected to provide a significant cost reduction compared to conventional PEM fabrication technologies and will ease the scale-up toward mass production. Aspects related to interface modification to obtain optimized semi-fluorinated composite membranes were previously addressed [1-2]. Two pilot scale processes were used for membranes prototyping: melt-casting and melt-blowing (Figure 1).

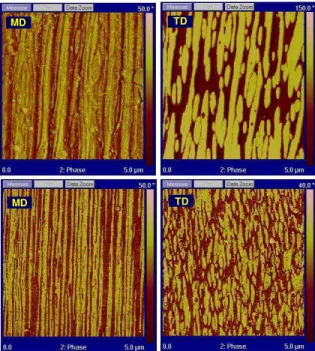

A large range of compositions, processing parameters, thicknesses and functionalization times have been screened, allowing to tailor membrane properties. Results show that the two processing technologies used generate different morphologies (Figure 2), which translate in different properties of the final membranes.

Figure 2. AFM phase micrographs using tapping mode in the machine direction (MD) and transverse direction (TD) of reinforced membranes obtained by melt-blowing (top) and melt-casting (bottom)

Optimized membranes show room temperature conductivity of 8.10-2 S/cm when fully humidified, with a fuel cell performance similar to or higher than Nafion ® benchmark membrane. The mechanical resistance was up to 20 MPa for an elongation at break of 200%. The membranes maintained their mechanical strength after an outstanding 6000 hydration/dehydration cycles.

[1] A.Mokrini, M. A. Huneault. Proton Exchange Membranes Based on PVDF/SEBS Blends. Journal of Power Sources 154 (2006) 51

[2] A. Mokrini, M. A. Huneault, P. Gerard. Partially Fluorinated Proton Exchange Membranes Based on PVDF–SEBS blends Compatibilized with Methyl Methacrylate based Block Copolymers. Journal of Membrane Science. 283 (2006) 74

MD TD