Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

CFD 2004, 12th Annual Conference of the Computational Fluid Dynamics Society

of Canada [Proceedings], pp. 1-8, 2004-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=639b1ecb-0319-4e4e-aa93-77199eda81eb https://publications-cnrc.canada.ca/fra/voir/objet/?id=639b1ecb-0319-4e4e-aa93-77199eda81eb

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

CFD simulation of the fire dynamic for a section of a tunnel in the event

of a fire

CFD simulation of the fire dynamic for a section of a tunnel in the

event of fire

Bounagui, A.; Kashef, A.; Bénichou, N.

NRCC-47009

A version of this document is published in / Une version de ce document se trouve dans :

CFD 2004, the 12

thAnnual Conference of the Computational Fluid Dynamics

Society of Canada, Ottawa, May 9, 2004, pp. 1-8

CFD simulation of the fire dynamic for a section of a tunnel

in the event of a fire

A. Bounagui, A. Kashef, and N. Benichou

Institute for Research in Construction, National Research Council Canada Ottawa, ON, K1A 0R6, Canada

Email: Abderrazzaq.bounagui@nrc-cnrc.gc.ca

A

BSTRACTThe objective of this research is to evaluate the in-place emergency ventilation strategies of the L. H. – La Fontaine tunnel. This paper investigates the fire dynamics in one section of the 1.8 km long tunnel. CFD simulations of several fire scenarios were carried out, to gain insight into the effect of several parameters on the fire growth, thermal conditions and species concentrations in the tunnel in the event of fire. A section of the tunnel was simulated to optimize the cost of computations.

In the first part of the study, a sensitivity analysis was performed to determine the effect of the computational grid size and length of the investigated section of the tunnel. The results of this analysis were used to determine the appropriate grid distribution and section length for the parametric study. Results from the sensitivity study showed that the grid size influenced both the computing time and the predictions of the temperature and smoke. Moreover the analysis showed that a 300 m long section of the tunnel was appropriate to investigate the ventilation scenarios.

A parametric study was conducted to investigate the effect of different ventilation configurations on fire-induced flows and thermal conditions in the tunnel section. This study indicated that when the side upper supply vents are open, higher temperatures and CO2 concentrations are observed in the evacuation

path. In the roadway area, a smoke backlayering phenomenon was observed which may delay the removal of combustion gases and heat. It was concluded that the opening of the upper supply vents delayed smoke removal and, consequently, increased hazardous situations in both the traffic and escape paths.

1. INTRODUCTION

The L.-H.-La Fontaine tunnel, located in Montreal, has a mechanical ventilation system (MVS). In the event of a fire, the MVS is used to ensure the safety of the tunnel users and emergency responders. In case of a fire in the tunnel, the operators must activate a smoke management system, which keeps the road upstream of the accident a smoke-free area and prevent backlayering (smoke moving in the opposite direction to the exhaust system). This is done by keeping smoke from moving upstream and either venting it or letting it escape through the downstream portal. When the fire department arrives on the fire scene, the operators must cooperate and modify, as needed, the smoke management system in order to facilitate access to the fire. At present, the standard tunnel emergency ventilation procedures are based on the experience of operators. Recently, the operating instructions were revised and formalized according to the total capacity of the MVS in venting the tunnel. However, a scientific-based validation of these operation instructions is essential.

The tunnel air supply is distributed along the side wall via openings. These openings have adjustable dampers to ensure the uniformity of air distribution. They are at present completely open. It is necessary, within the framework of this study, to validate this state of opening or to propose an adjustment, compatible with the operating instructions, and optimizing the capacities of the MVS.

This paper presents the sensitivity and parametric study that was performed to study the influence of grid size, length of the investigated section of the tunnel as well as the ventilation configurations on the CFD simulated fire-induced flows and conditions in a selected section of the tunnel.

2. CFD FIRE MODEL

The Fire Dynamics Simulator (FDS) is a CFD fire model using large eddy simulation (LES) techniques [1] that was developed by NIST (National Institute of Standards and Technology). FDS has been demonstrated to predict thermal conditions resulting from a fire in an enclosure [1, 2]. The CFD model computes gas density, velocity, temperature, pressure and species concentrations in each control volume based on the conservation laws of mass, momentum, and energy.

Smokeview is a visualization program that was developed to display the results of FDS. Smokeview produces animations or snapshots of FDS results [2].

2.1 FDS Setup and Boundary Conditions

FDS requires as inputs the geometry of the tunnel being modelled, the computational cell size, the location of the ignition source, fuel type, and heat release rate, the material thermal properties of walls, and the boundary conditions.2.2 Geometry

The L.-H.-La Fontaine tunnel, built in 1964, is 1.8 km long and travels underwater gallery in the North-South direction. The public traveller circulates on six laneways inside two concrete tubes, which are separated by a centre section. Two ventilation towers are located at the ends of the tunnel. The North tower contains a control centre that monitors the tunnel operation.

Figures 1 and 2 show the general layout of the tunnel and the emergency ventilation system. A detailed description of the tunnel is provided in reference [3]. The tunnel emergency ventilation system is composed of 8 ceiling exhaust fans (4 fans for each roadway) and 8 fans that supply air through side vents uniformly distributed along one wall for each roadway in two upper and lower rows. The lower and upper side vents are located at heights of 1.0 and 3.9 m respectively above the tunnel floor at intervals of approximately 6 m.

All fans can operate in a reverse mode. Therefore, fresh air may be supplied at either the ceiling using fans VE-151 through VE-254, or by fans VA-101 through VA-204 through the side vents.

For this study, only one section of the North roadway was simulated. A sensitivity, see section 3, study has shown that a 300 m long section of the tunnel is

appropriate to investigate the ventilation configurations [4]. The section is 300 m long, 16.2 m wide and 4.9 high. The roadway is 12.8 m wide. A 0.1 m thick concrete wall separates the roadway area from the escape area. A perspective view of the modelled section is shown in Figure 3.

2.3 Boundary Conditions

Two rows of supply air vents were located in the concrete wall that separates the roadway from the escape area. The typical dimensions of the lower and upper vents are 1.04 m x 0.52 m and 1.4 m x 0.52 m, respectively.

Fresh air was supplied by fan VA-103 through the side vents and combustion products were exhausted by fan VE-153. Both fans were simulated as volumetric airflow introduced or extracted at the end of the section. Therefore, at the end of the roadway area, a volume flow rate Vt of 230 m3/s was

exhausted and, at the end of the escape area, a volume flow rate Ve of 230 m3/s was supplied. The

ambient temperature was 20°C. The other end of the studied tunnel section was modelled as open boundary conditions.

2.4 Fire Specification

For all simulations, a propane pool fire with a heat release rate of 15,000 kW was used to represent a vehicle fire. The fire area was 3 m2, 0.5 m above the tunnel floor and located in the middle of the tunnel section.

2.5 Material Properties

The ceiling, walls, and floor of the tunnel were made of concrete with the following thermal properties: Thermal Conductivity: 1.0 W/m.K

Thermal Diffusivity: 5.7x10-7 m2/s Thickness: 0.1 m

V A - 1 0 1 V A - 1 0 3 V A - 2 0 1 V A - 2 0 3 V A - 1 0 2 V A - 1 0 4 V A - 2 0 2 V A - 2 0 4 V E - 1 5 1 V E - 1 5 2 V E - 1 5 3 V E - 1 5 4 V E - 2 5 1 V E - 2 5 2 V E - 2 5 3 V E - 2 5 4

Figure 1 General Layout of the tunnel

1 0 7 5 ’ ( 3 2 7 . 7 m ) 2 3 0 0 ’ ( 7 0 1 . 0 m ) 1 1 8 6 ’ ( 3 6 1 . 5 m ) G r a d e S lo p e : - 4 .5 % (1 0 5 cf m / l a n e ) + 4 .5 % (1 5 3 .5 c f m /l a n e ) G r a d e S l o p e : + 4 . 5 % ( 1 0 5 cf m ) / l a n e - 4 . 5 % ( 1 0 5 c f m / l a ne ) G r a d e S l o p e : + 0 . 2 5 % ( 1 0 5 c f m / l a n e ) - 0 . 2 5 % ( 1 0 5 c f m / l a n e ) S O U T H N O R T H 4 2 ’ ( 1 2 . 8 m ) 1 1 ’ ( 3 .4 m ) 1 1 ’ ( 3 .4 m ) 4 2 ’ ( 1 2 . 8 m ) 1 6 ’ ( 4 . 9 m ) T u n n e l L . - H . - L A F o n t a i n e

Figure 2 The Tunnel Emergency ventilation system

3. SENSITIVITY STUDY

CFD numerical simulations require hours or even days to run on the latest personal computers. One of the most significant factors influencing the computation time is the size of the computational grid specified by the user. Because it is possible to over-resolve or under-resolve a space by specifying grids that are too fine or too coarse, it is important to determine an appropriate grid size for a given computational domain.

Six grid sizes were used to study the influence of grid size on the prediction of the temperature and the concentration of CO2 in the tunnel section. The

simulations were carried out on an 80 m long tunnel section.

The fire resolution index is defined as the fraction of the ideal stochiometric value of the mixture fraction that is being used in the calculation; i. e. combustion efficiency [2]. It indicates how well resolved the calculation is. When the fire resolution index is close to 1, the calculation is well resolved.

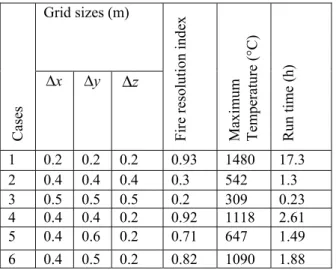

Table 1 shows the different cases along with the grid sizes, the fire resolution index, the maximum temperatures and the computation time.

Grid sizes (m) Cases x ∆ ∆y ∆z Fi re re sol u ti o n i nde x Ma ximum Tempe rature (°C) Ru n time (h ) 1 0.2 0.2 0.2 0.93 1480 17.3 2 0.4 0.4 0.4 0.3 542 1.3 3 0.5 0.5 0.5 0.2 309 0.23 4 0.4 0.4 0.2 0.92 1118 2.61 5 0.4 0.6 0.2 0.71 647 1.49 6 0.4 0.5 0.2 0.82 1090 1.88

Table 1 Grid sizes and maximum temperatures

The simulation results for the six cases are presented in this section to highlight the effect of grid size on the estimations of the temperature. Figure 4 gives the maximum temperature versus the position along the section. It shows the comparison between all the cases. In the vicinity of the fire the maximum temperature is higher when the grid sizes are fine.

0.00 200.00 400.00 600.00 800.00 1000.00 1200.00 1400.00 1600.00 0.00 20.00 40.00 60.00 80.00 100.00 Section position (m) Temperature (°C) Case 1 Case 2 Case 3 Case 4 Case 5 Case 6

Figure 4 Comparisons of the maximum temperature for all cases

Figure 5 shows the computations time for all cases. As anticipated the computation time is higher for the finer grid. 0 5 10 15 20

Case1 Case2 Case3 Case4 Case5 Case6

Cases C o m puta ion tim e (h)

Figure 5 Computation time for all cases The comparison between Cases 1, 2 and 4 indicate that the maximum temperature improves by refining the grid size in the z direction (Figure 6). Since the flow is buoyancy driven,

∆

z

is very influential.0.00 200.00 400.00 600.00 800.00 1000.00 1200.00 1400.00 1600.00 0.00 20.00 40.00 60.00 80.00 100.00 Section position (m) Temperature (°C) Case 1 Case 2 Case 4

Figure 6 Maximum temperatures for different cases

The choice of the grid resolution is important for the prediction of the temperature in the fire area. In this section a comparison between FDS predictions and a well established correlation is presented.

FIERASystem Simple Correlation sub-model [5] was used to calculate the plume centreline temperature and compare it to the CFD predictions. The sub-model uses Heskestad’s correlation to determine the plume centreline temperature and is defined as:

(

)

∞ − ∞ ∞ − + = Q z z T c g T T c p cp 3 5 0 3 2 3 1 2 . . 1 . 9 ρ where: cpT

: plume centreline temperature, K;c

Q

: convective heat release rate, kW;z

: height above top of the fire source, m;0

z

: height of virtual origin relative to the base of fire source, m;∞

ρ

: density at ambient temperature, kg/m3;p

c

: specific heat of gas, kJ/kg.K;∞

T

: ambient temperature, K;g

: acceleration of gravity, m/s2. FDS estimation (°C) Hesk estadCorrelation Case 1 Case 2 Case 3 Case 4 Case 5 Case 6

1721 1480 542 309 1118 647 1090

Table 2 Plume centerline temperature comparisons

Table 2 shows the values of the temperatures obtained from the Heskestad correlation and FDS predictions. The Heskestad correlation provides an estimation that is closer to Cases 1 and 4 of the FDS predictions. The finer grids provide a better prediction. This means a better characterization of the combustion processes and flame behavior (Fire resolution index close to 1 in Table 1). The coarse grids give the worse predictions when compared to Heskestad’s correlation (Fire resolution index quite low, 0.2, in Table 1).

The predictions for Case 4 are close to the correlation and the computational time is reasonable. Thus, we

will adopt the grid cell dimensions used in Case 4 for the rest of the study.

3.1 Section length analysis

Tunnels can be long and to carry out a simulation for the full length of a tunnel would be very time consuming. Assuming that the influence of the fire is diminishing far from the fire, only a portion of the tunnel may need to be modelled. Consequently, the cost of the numerical computation may be reduced. Three tunnel section lengths were investigated. The grid sizes from Case 4 in the previous section were used. The upper and lower vents were open. The results of the three simulations are provided in Table 3. Sectio n Leng th (m) Ma ximum Te mpe rature (°C) Max . T em p er atu re ( °C) a t th e ex it o f th e sectio n Ma x. C O2 co ncen tration (m ol/mol) Ma x. C O2 co ncen tration (mo l/mo l) at the ex it of th e section Case 1 80 1168 116 0.12 0.0065 Case 2 200 1178 84 0.12 0.005 Case 3 300 1237 27 0.12 0.0009

Table 3 Temperatures and CO2 concentrations for

different tunnel section lengths

Figure 7 compares the temperatures estimated for the three simulations. The maximum temperature increases when the length of the tunnel section is increased. In the model, the exhaust is at the end of the tunnel section. As a result, when the length of the tunnel section is increased, the effect of the exhaust on temperature decreases. The temperature at 300 m is close to the ambient temperature as shown in Table 3 and Figure 7.

Figure 8 shows similar results for the maximum concentration of the CO2.

Since the temperature at 300 m is close to ambient temperature and the CO2 concentrations are very low

at the exit of the section, a 300 m long tunnel section was chosen for the parametric study.

0 300 600 900 1200 0 0.5 1 L* Temperature (°C) 1.5 Section 80 m Section 200 m Section 300 m

Figure 7 Maximum temperature for different sections (L*: non-dimensional section length:

distance/section length) 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0 0.5 1 1 L* CO 2 Concentrations (mol/mol) .5 Section 80 m Section 200 m Section 300 m

Figure 8 Maximum CO2 concentrations for

different sections

4. PARAMETRIC STUDY

In case of a fire in a tunnel, the environment is modified greatly inside the tunnel. Several parameters affect the temperature level and smoke behaviour including: the ventilation flow rate, opening conditions of the side vents, fire size and location, and traffic pattern. The following sections will investigate the first two effects.

4.1 Influence of ventilation flow rates

To study the influence of the volumetric flow rate on the thermal distribution and species concentrations, CFD simulations were carried out for different volumetric flow rates (Table 4). The fire was located in the middle of the tunnel and both upper and lower side vents were assumed to be open.Cases Volume flow rate m3/s Vt: volume flow rate in the roadway

Ve: volume flow rate in the escape

area

Case 1 Vt = Ve = 115

Case 2 Vt = Ve = 230

Case 3 Vt = Ve = 345

Table 4 Volume flow rate and maximum temperatures

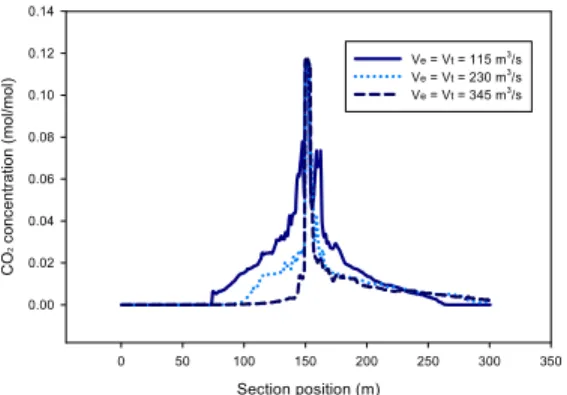

Figure 9 shows the maximum temperatures in the roadway area at different locations and for different volume flow rates. The extension of the area of high temperature decreases when the volume flow rate increases. Figure 10 shows the maximum CO2

concentrations for different sections and for different volumetric flow rates. The length of the high CO2

concentrations zone decreases when the volumetric flowrate increases. With a higher volume flow rate, a better removal of combustion gases was achieved.

Section position (m ) 0 50 100 150 200 250 300 350 T e mp erat u re (°C ) 0 200 400 600 800 1000 1200 1400 Ve = Vt = 115 m 3 /s Ve = Vt = 230 m3/s Ve = Vt = 345 m3 /s

Figure 9 Maximum temperatures for different volumetric flow rate in the roadway

Section position (m) 0 50 100 150 200 250 300 350 CO 2 c onc entr a ti on ( m ol /m ol ) 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 Ve = Vt = 115 m3 /s Ve = Vt = 230 m3 /s Ve = Vt = 345 m3 /s

Figure 10 Maximum CO2 concentration for

Figure 11 and Figure 12 show temperature and CO2

concentration iso-surfaces for Cases 1 and 2. The results indicate that smoke backlayering occurres and that the smoke layer covers a longer area when the flow rate in the roadway is low.

Figure 11 Iso-surface for CO2 concentration at

0.005 mol/mol - Vt=Ve=345 m3/s

Figure 12 Iso-surface for CO2 concentrations at

0.005 mol/mol - Vt=Ve=115 m3/s

4.2 Influence of the upper side wall vents

To study the influence of the upper side wall vents on the estimated temperatures and species concentration, simulations were conducted for different vent scenarios (opened and closed). The values of the volumetric flow rate Ve and Vt are kept constant at230 m3/s. The measurements were taken at a height of 1.5 m. The height of 1.5 m was chosen to indicate the effect on occupants in the roadway and in the escape route.

Figure 13 shows the maximum temperature in the escape path for different positions in the section of the tunnel and different vent scenarios. The maximum temperature decreases for the upper vents closed case by 100 °C. This can be attributed to the

fact that the buoyant hot smoke is restricted to enter the escape route at the upper vents.

Section position (m) 50 100 150 200 250 300 350 Tem p e ra tur e ( oC) 0 20 40 60 80 100 120 140 160 180 200

Upper vents closed Both vents opened

Figure 13 Maximum temperatures for different vents scenarios in the escape path

Figure 14 shows the maximum temperature in the roadway at a height of 1.5 m for two vent scenarios (upper vents closed and opened). The maximum temperature is lower by 200°C for the case when the upper vents are closed than when they are open. This is due to the fact that the flow from the upper vents introduces turbulence into the tunnel traffic area thus, forcing the hot smoke to move down and delaying its removal. Section position (m) 80 100 120 140 160 180 200 220 240 260 Temperatur e ( °C ) 0 200 400 600 800 1000 1200

Upper vents closed Both vents open

Figure 14 Maximum temperatures in the roadway at a height of 1.5 m

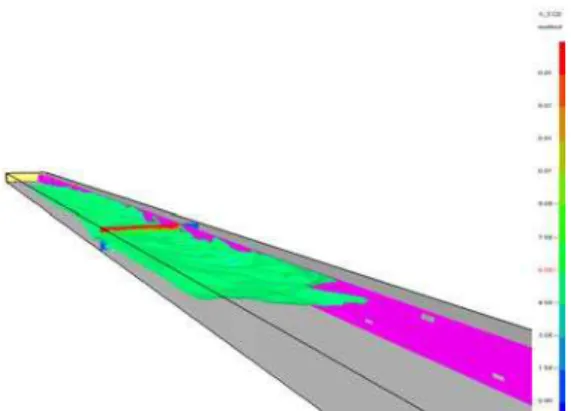

Figure 15 and Figure 16 show the iso-surface for the CO2 concentration for two scenarios. From Figure 15,

there is some effect on CO2 and temperature removal.

However, the better removal of smoke and heat was observed in the case when the upper side vents are closed as can be seen in Figure 16.

Figure 15 Iso-surface CO2 concentrations at 0.006

(mol/mol) both side vents open

For the case when the upper side vents were closed, the hot smoke from the fire spreads symmetrically along the tunnel (Figure 15). In this case the smoke layer covers a long distance in the tunnel.

Figure 16 Iso-surface for CO2 concentrations at

0.006 (mol/mol) upper side vents closed

The backlayering of the smoke was observed over a small distance for the case when the upper side vents were closed and the smoke moves toward the exit (Figure 16). This led to the effective removal of hot gases and smoke

.

With the upper side vents open, the air introduced into the traffic area forced the smoke and hot gases downwards to the tunnel floor (Figure 14) which will delay the extraction of the smoke. Thus, the backlayering of the smoke occurs when the upper side vents are open (Figure 15).CONCLUSION

A CFD model, FDS, was used to perform a sensitivity and parametric study for a section of the L. –H. La Fontaine tunnel.

Results from the sensitivity study showed that the grid size influenced both the computation time and the predictions of temperature and smoke. The numerical model predictions showed that a 300 m long section of the tunnel was appropriate to investigate the ventilation configurations.

Results from the parametric study showed that the area of high temperature decreased in size when the ventilation rate was higher as the heat was rapidly extracted and the smoke spread was controlled. When the upper vents were left open, the smoke and hot gases traversed through the upper vents from the roadway to the escape area causing higher temperature and CO2 concentrations in the escape

route. Moreover in the traffic area, a high temperature was detected at a height of 1.5 m and the smoke backlayering occurred. It was also observed that the air introduced into the roadway from the upper side vents forced the smoke and hot gases downwards to the tunnel floor.

REFERENCES

1. McGrattan, Kevin B., Baum, Howard R., Rehm,

Ronald G., Hamins, Anthony, Forney, Glenn P., (2000), “Fire Dynamics Simulator – Technical

Reference Guide”, National Institute of Standards and Technology, Gaithersburg, MD., NISTIR 6467, January.

2. McGrattan, Kevin B., Forney, Glenn P., (2000),

“Fire Dynamics Simulator – User’s Manual”,

National Institute of Standards and Technology, Gaithersburg, MD., NISTIR 6469, January.

3. A. Kashef, N. Benichou, G. Lougheed and A. Debs. (2003), “Numerical Modelling of Air Movement in Road Tunnels” Proceedings of the

11th Annual Conference of the CFD Society of Canada” p. 23-30.

4.

A. Bounagui, A. Kashef, N. Benichou, (2003), “ Simulation of the dynamics of the fire for a section of the L. H. –La Fontaine Tunnel”Research Report, Institute for Research in Construction, National Research Council Canada,(IRC-RR-140) September 22, 2003.

5.

P. Feng, G. V. Hadjisophocleous and D. A.Torvi, “ Equations and Theory of the Simple Correlation Model of FIERAsystem”, Internal

Report N° 779, Institute for Research in Construction IRC, February 2000.

6.

Heskestad, G., “Fire Plumes”, Chapter2-2, SFPEHandbook of Fire Protection Engineering, Society of Fire Protection Engineers, Quincy, MA, USA, 1995.