Publisher’s version / Version de l'éditeur:

Journal of the American Concrete Institute, 80, 4, pp. 326-331, 1983-07

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Air entrainment in the presence of superplasticizers

Litvan, G. G.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=fee92c28-c060-4c17-a748-7e84c0472f67 https://publications-cnrc.canada.ca/fra/voir/objet/?id=fee92c28-c060-4c17-a748-7e84c0472f67

National Research

Conseil national

"'*

1

$

Council Canada

de recherches Canada

c . 2

I

I

I

1 I

.

AIR ENTRAINMENT I N THE PRESENCE OF SUPERPLASTICIZERSby G.G. Litvan

Reprinted from

ACI Journal, JulyIAugust, 1983

ANALYZED

p. 326

-

331DBR Paper No. 1139

Des g c h a n t i l l o n s de m o r t i e r ( r a p p o r t ciment/s a b l e = 1 :3, r a p p o r t eaulciment = 0.65), 3 a i r o c c l u s e t o r d i n a i r e , o n t &ti3 prspar'es avec, comme a d j u v a n t , un p o l y d r e s u l f on'e modifi'e, un condensat n a p h t a l h e - f ormald'ehyde ou un f ormald'ehyde-mdlamine s u l f on'e 3 deux c o n c e n t r a t i o n s d i f f'erentes. Le s y s t b e de b u l l e s d ' a i r , dgtermin'e p a r l a mgthode d e s l i g n e s t r a n s v e r s a l e s (Rosiwahl), l a d i s t r i b u t i o n d e l a t a i l l e d e s p o r e s obtenue p a r p o r o s i m g t r i e p a r i n j e c t i o n d e mercure, e t l a r h i s t a n c e a u g e l mesur'ee p a r l a mgthode de g e l e t d d g e l s u c c e s s i f s o n t d t 6 compargs aux caract'eristiques de mglanges de rsf'erence ne c o n t e n a n t p a s de s u p e r p l a s t i f i a n t . La m e i l l e u r e r k i s t a n c e a u g e l d e l a p a t e p u r e e s t attribu'ee 3 un grand volume d e s p o r e s de - 0 , 3

a

2 pm e n p r s s e n c e d'un a d j u v a n t e n t r a h e u r d ' a i r . Les s u p e r p l a s t i f i a n t s g l i m i n e n t l e s g r o s s e s b u l l e s d ' a i r v i s i b l e s a u microscope, mais i l s o n t peu d ' e f f e t s u r l e r a l e d e s a g e n t s e n t r a f n e u r s d ' a i r dans l a f o r m a t i o n d e s p e t i t s pores.Title no. 80-33

Air Entrainment in the Presence of Superplasticizers

by

G.G.

Litvan

Authorized Reprint From

American Concrete I n s t i t u t e

Title no. 80-33

Air Entrainment in the Presence

of Superplasticizers

by

G.G. Litvan

Air-entrained and plain mortar specimens (cement-sand ratio = 1:3. water-cement ratio = 0.65) were prepared using a moditled sulfon- ated polymer, o naphthalene-formaldehyde condensate, or a sulfon- ated melomine formaldehyde admixture at two levels of concentra- tion. The air-void system determined by the linear traverse method, the pore size distribution obtained by mercury intrusion porosimetry, and frost resistance messed by alternate freezing and thawing were compared with those of control mires containing no superplasticizer. A large pore volume (-0.3 to 2 pm) in the presence of an air-en- training admixture is assumed lo be responsible for the improved frost resistance of cement paste. Superplasticizers eliminate large air voids visible under the microscope but do not significantly interfere with the oction of air-entraining admixlures in the formation of small pores.

KcyworQ: airatraining agents; Ilr nld-l; I-haw d o d U t y ; mor-

tars (maferial; p h I h m s ; pordty; void& water-reducing agents.

The freeze-thaw resistance of concrete containing a superplasticizer (high-range water-reducing admixture) has been a controversial topic for some Con- cern is based on the fact that in air-entrained, super- plasticized concrete the conventional air-entraining ad- mixtures fail t o achieve air content of six percent with a void spacing of 0.2 mm which are considered essen- tial for good freeze-thaw resistance. The performance of concrete 'containing superplasticizer and air-entrain- ing admixtures has been found, however, to be supe- rior to that expected on the basis of air content and spacing factor values. This is most surprising because air content and, particularly, void spacing are known to be excellent indicators of freeze-thaw resistance, and a unique relationship is believed t o exist between frost resistance and the two parameters.

Apart from the theoretical interest, these observa- tions are of great practical importance. Firstly, air-en- trained concrete containing a superplasticizer admix- ture cannot be used with complete confidence in a freezing environment until the cause of the anomalous behavior is identified. Secondly, prediction of perfor- mance of plain concrete in a freezing environment is made more uncertain by the discovery that under cer- tain conditions the relationship between the void spac- ing factor and frost resistance is ambiguous. The pres-

ent study was undertaken to gain a better understand- ing of the effect of air-entraining admixtures in the presence or absence of high-range water reducers.

TEST SPECIMENS

Mortar used in the fabrication of the specimens was made of CSA Type 10, ASTM Type I portland cement, and ungraded sand. The high-range water-reducing ad- mixtures were as follows: a) a modified sulfonated polymer, manufactured in Montreal, Canada; b) a naphthalene-formaldehyde condensate manufactured in the U.S.; and c) a sulfonated melamine formaldehyde of German origin. The air-entraining admixture was the triethanolarnine salt of a sulfonated hydrocarbon.

The mixes were prepared in a laboratory type mixing machine (Hobart, Model N-50) in batches containing

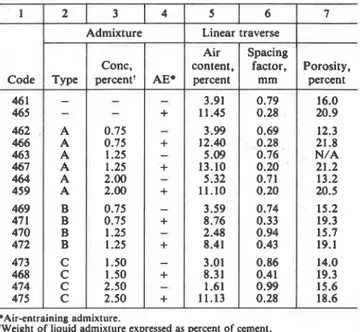

200 g cement in accordance with ASTM C 192 standard method. The water-cement ratio was 0.65 and the ce- ment-sand ratio (by weight) 1:3. The air-entraining agent was added with the water, while the superplasti- cizer was mixed in two minutes before the termination of stirring. Table 1 lists the mixes together with admix- ture concentrations, the lower values being the dosages recommended by the manufacturers.

Prisms 25 by 25 by 150 mm, outfitted with stainless steel studs for length change measurements, were pre- pared by casting. Upon removal from the molds (after 1 day), the specimens were cured in a fog room for 28 days.

EXPERIMENTAL METHODS

The air void content and spacing factor was deter- mined according to the ASTM standard recommended practice, C 457-71." An instrument capable of produc- ing 41.34 MPa (60,000 psi) was used for pore size dis- tribution analysis by the mercury intrusion method.

Received Aug. 29, 1982, and reviewed under lnatitute publication policies.

Copyright 0 1983, American Concrete Inaitute. All rights reserved, including

the making of copies unless permission is obtained from the copyright propri- etors. Pertinent d h s s i o n will be published in the May-June 1984 ACI JOUR-

NAL if received by Feb. 1. 1984.

Y

A C I member G. G. Litvan is senior research officer of the Division of Build- ing Research, National Research Council Canada. Dr. Litvan's research deals with surface chemical problems of concrete durability. H e is a corresponding member of A C I Commiltee 201. Durability of Concrete, and ~echnical com- millees of CSA and R I L E M . H e is past presidenr of the Eastern Ontario and Quebec A C I Chapler.

Resistance to rapid freezing and thawing was assessed on duplicate specimens according t o ASTM standard test method C 666,14 Procedure B, involving freezing in air and thawing in water.

RESULTS

Air contents and spacing factor determined by a mi- croscopical method are shown in Table l , Columns 5 and 6, respectively. The apparently high air content values result from the absence of coarse aggregate in the samples. It has to be remembered that in concrete the air content is expressed as percentage of total vol- ume, or six times larger than that of the cement paste (the cement-sand-aggregate weight ratio being 1:2.25:2.75). In mortar with a cement-sand ratio of 1:3 the reference volume is only four times larger than the volume of the cement paste. The following observa- tions can be made:

1. Superplasticizer A increases the air content (Col- umn 5) of non-air-entrained plain mortar (461) and this effect is proportional to the concentration of Admix- ture A. Superplasticizers B and C decrease the air con- tent, C more than B, and this effect is concentration- dependent (469, 470 and 473,474, Column 5).

2. The air-entraining action of Superplasticizer A is apparent also in air-entrained specimens. Here the air content is even higher than in the plain air-entrained specimens (466, 467, and 459) at constant dose of the air-entraining agent, and in Specimen 467 it is the high- est in the set (13.10 percent).

3. In specimens containing either B or C plus an air- entraining admixture the air content is considerably greater than in the companion non-air-entrained mor- tars (471, 472, 468, 475 versus 469, 470, 473, 474, re- spectively), but it is less than that of Specimen 465, which contains air-entraining agent but no superplasti- cizer

.

4. Spacing factor (Column 6) of non-air-entrained mortar containing Admixture A (462, 463, 464) does not show the significant difference, with respect to ref- erence specimen 461, comparable to the increase in air content (Column 5).

5. In the presence of Superplasticizer A the addition of the air-entraining agent achieves or approaches the required spacing factor of less than 0.2 mm (466, 467, 459).

6. Air-entrainment in the presence of admixture, either B or C, produces spacing factor values (Column 6) that are greater than the required 0.2 mm (471, 472, 468, and 475).

7. In non-air-entrained mixes total porosity is less in the presence than the absence of superplasticizers (461 versus 462, 464, 469, 470, 473, and 474).

ACI JOURNAL I July-August 1983

Table 1

-

Admixture concentration, air content,spacing factor, and total porosity of specimens

I 2 1 3

1

4 5 6 7Admixture Linear traverse

Air Spacing

Conc, content, factor, Porosity,

Code Type percentt AE* percent mm percent

461

-

-

-

3.91 0.79 16.0 465-

-

+

11.45 0.28 20.9 462 A 0.75-

3.99 0.69 12.3 466 A 0.75+

12.40 0.28 21.8 463 A 1.25-

5.09 0.76 N/A 467 A 1.25+

13.10 0.20 21.2 464 A 2.00-

5.32 0.71 13.2 459 A 2.00+

11.10 0.20 20.5 469 B 0.75-

3.59 0.74 15.2 471 B 0.75+

8.76 0.33 19.3 470 B 1.25-

2.48 0.94 15.7 472 B 1.25 + 8.41 0.43 19.1 473 C 1.50-

3.01 0.86 14.0 468 C 1.50+

8.31 0.41 19.3 474 C 2.50-

1.61 0.99 15.6 475 C 2.50+

11.13 0.28 18.6 *Air-entraining admixture.'Weight of liquid admixture expressed as percent of cement.

8. Total porosity (Column 7) of air-entrained mortar appears to be little affected by Superplasticizer A (466, 467, 459 versus 465).

9. Total porosity (Column 7) of air-entrained mortar is somewhat reduced by either Admixture B or C (471, 472, 468, and 475 versus 465). Pore size distribution curves of the specimens are shown in Fig. 1.

10. In general, due to air entrainment there is signif- icant difference in pore size distribution, mainly in the region of 1 t o 0.1 pm pore diameter, regardless of the type of superplasticizer (465 versus 461; 466, 467, 459 versus 464, 462; 471, 472 versus 470, 469; 468, 475 ver- sus 474, 473).

11. In air-entrained mortars, the volume of pores with 1 t o 0.1 pm diameter appears in the presence of Admixture A (466, 467, 459) to be similar to the vol- ume of pores in the air-entrained mortar without su- perplasticizer (465); in the presence of Admixtures B and C (471, 472, 468, 475) the pore volume appears to be smaller.

Table 2 shows the volume of pores of selected sizes expressed as percentage of apparent volume. The effect of the air-entraining admixture is measured by the in- crease of the pore volume in terms of the volume of the non-air-entrained mortar of the same class.

12. Of the four pore size ranges, c0.088, >0.088, 2

-

0.035, and 2-

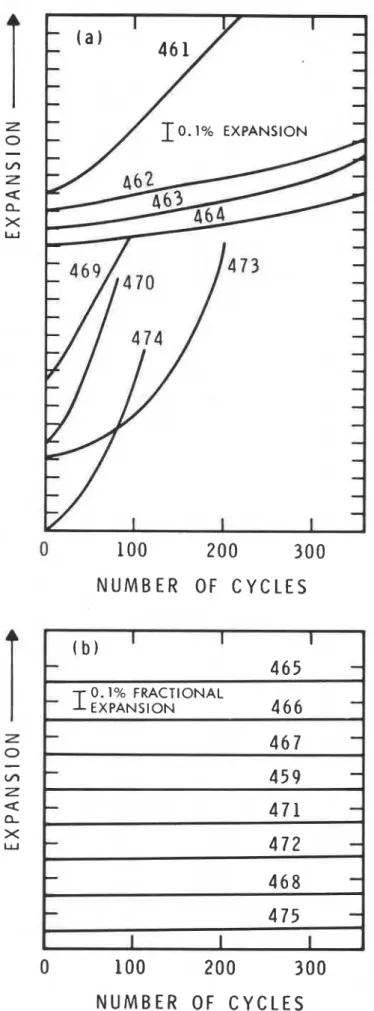

0.35 pm, the volume of pores be- longing t o the last group increases most as a result of air entrainment, whether superplasticizer is present or not.Fig. 2(a a n d b), which shows the dimensional changes of the specimens effected by alternate freezing and thawing, leads to observations 13 to 15. Because the curves obtained from duplicate specimens are simi- lar there is only one curve for each set. Table 3 gives the number of cycles producing 0.1 and 0.2 percent ex- pansion.

13. All air-entrained specimens, with and without superplasticizer, show good freeze-thaw resistance as

k be detrimental in this respect (473, 474). These indica- tions must be treated with caution until further experi- mental evidence can be obtained.

DISCUSSION

The results give clear indication that even if the spac- ing factor is larger than 0.2 mm, good frost resistance is provided by an air-entraining admixture in the pres- ence of superplasticizer. This is in agreement with the findings of previous workers. Behavior deviating from that expected on the basis of the spacing factor was ob- served earlier. Mielenz15 found no general correlation between spacing and durability factors. Rather, each

I combination of admixtures seems to produce its own * _

relation between the two parameters.

The significant, and unique, increase of pore volume in the range of 0.35 t o 2 pm diameter found in this study strongly suggests that pores of this size may be responsible for the increased frost resistance of air-en- trained cement paste. This hypothesis is contradictory to the present view of the mechanism of protection by air entrainment. The success of air entrainment, how- ever, has never been proved t o rest on the incorpora- tion of air voids. Two facts are indisputable: Addition

I

of air-entraining agents is beneficial, and in entrained paste large voids are detectable.

Although Walker and Hsieh16 found that the volume of pores in the

+

8 micron range correlate best with freeze-thaw durability of various aggregates, Koh and Kamada17 reported a good relation between frost resis- tance and the volume of pores in the 0.15 to 1.5 pm range, increasing greatly with the addition of air-en- training agent to the mix. Lange and Modry18 investi-12 gated the frost resistance of limestone aggregates and

10 observed good performance if pore size distribution in-

dicated a large number of pores in the 2 t o 0.2 pm 8 range. This is corroborated by the present work. Re- sults obtained by CebeciI9 also indicate that the pore

b size distribution of air-entrained cement paste differs

4 from that of the corresponding air-free paste, mainly in

the region of 2 to 0.1 pm pore diameter.

2 Furthermore, in a n attempt to provide freeze-thaw

0 durability for cement paste by incorporating particu-

10 1 0 . 1 0 . 0 1 0 . 0 0 1 late matter containing pores it was found" that large

pores in the over 2 pm range of agglomerated and sin-

P O R E D I A M E T E R , prn tered fly ash were, surprisingly, not effective at all. The presence of smaller pores between 0.3 and 2 pm in fired

Fig. I

-

Pore size distribution of specimens deter- clay and diatomaceous earth imparted excellent frostmined by mercury intrusion porosimetry resistance.

Kaneuji, Winslow, and Dolch21 established a correla- evidenced by the low values of expansion. tion between the freeze-thaw durability of coarse ag- 14. Admixture A, without air entrainment, provides gregates and their pore structure. Frost susceptibility limited degree of frost resistance (462, 463, 464 com- was found to be associated with large total pore vol- pared with 461) that increases with increasing admix- ume and small median diameter in the range extending

ture concentration. from 1 pm t o larger sizes.

15. Admixtures B and C provide no protection with- The role of the 0.35 to 2 pm diameter pores has es- out air entrainment (469, 470, 473, 474). The number caped attention up to now because in plain concrete the o f cycles t o produce 0.1 t o 0.2 percent expansion is large-air-void: small-pore ratio is probably constant; larger in the plain mix (461) than in the presence of measuring one provides information about the other. In Admixture B. Increased concentration of C appears to the presence of superplasticizer, however, not only is

328

ACI JOURNAL I July-August 19830

100

200

300

NUMBER OF

C Y C L E S

( b )

I I1

4 6 5

-

I

0.1% FRACTIONAL EXPANSION4 6 6

-

4 6 7

-

459

-

-

4 7 1

-

4 7 2

-

4 6 8

-

4 7 5

-

1

1

I

NUMBER

O F C Y C L E S

not only more successful in predicting frost resistance but also simplified. The linear traverse method requires lengthy preparation, including grinding of the surface

330

Fig. 2

-

Residual expansion mortar prisms as a func- tion of alternate freezing a n d thawing. a) Non-air-en- trained mixes: 461 reference, 462-464 Admixture A; 469-470 Admixture B; a n d 473-474 Admixture C. b) Air-entrained mixes: 465 reference, 466-467, 459, Ad- mixture A; 471-472 Admixture B; and 468 and 475 Ad- mixture Cfor microscopical observation, and the procedure itself is time consuming, demanding, and subject to operator judgement. It cannot be easily automated using an im- age analyzer. In contrast, mercury porosimetry can be performed easily and quickly in the laboratory and is reproducible. It is possible that a relatively simple test could be developed for field test. Obviously, appropri- ate sampling procedure will have to be devised to as- sure representativeness in concrete.

Klieger foundz2 that the strength reduction due to air entrainment depends on cement content, aggregate size, and amount of air-entraining agent. The representative value at 6 percent air, 290 kg/m3 cement content, 50 to 75 mm slump and 19 mm aggregate size results in a loss of 2.7 percent in flexural strength and, for compressive strength, 3.9 percent per each percent of air. This sub- stantial loss in mechanical strength is unnecessary and can be avoided without loss of durability. Good frost resistance appears to be possible by increasing the vol- ume of small pores, thus avoiding the reduction of me- chanical strength.

CONCLUSIONS

The present studies lead t o the following conclu- sions:

1. The improved freeze-thaw resistance of air-en- trained mortar is due mainly to the increased number of pores with diameters in the range of 0.3 to 2 pm.

2. Superplasticizers eliminate large air voids, but the I pore volume of the critical size is still greatly and suf-

ficiently increased by air-entraining admixtures. This conclusion is put forward as an explanation for the good frost resistance of superplasticized concrete de- spite its high spacing factor.

3. For the assessment of freeze-thaw resistance a test based on measurement of the air-void content in the 0.3 to 2 pm diameter range could be developed; not only would it be more reliable but it would be simpler t o perform than the present ASTM C 457 test.

ACKNOWLEDGMENT

The competent technical help of H. Schultz in carrying out the ex- perimental work is gratefully acknowledged. This paper is a contri- bution from the Division of Building Research, National Research Council Canada, and is published with the approval of the Director of the Division.

REFERENCES

1 . Tynes, William O., "lnvestigation of Proprietary Admixtures, Final Report," Technical Report No. C-77-1, U . S. Army Engineer Waterways Experiment Station, Vicksburg, Apr. 1977, 39 pp.

2. Sprinkel, M. M.. "Super Water Reduced Concrete Pavements and Bridge Deck Overlays," Preprints, International Symposium on Superplasticizers in Concrete, Canada Centre for Mineral and En- ergy Technology, Ottawa, 1978, pp. 215-247.

3 . Perenchio, W. F.; Whiting, D. A.; and Kantro, D. L., "Water

Reduction, Slump Loss, and Entrained Air-Void Sysiems as Influ- enced by Superplasticizers," Superplasticizers in Concrete, SP-62, American Concrete Institute, Detroit, 1979, pp. 137-155.

4. Mather, Bryant. "Tests of High-Range Water-Reducing Ad- mixtures," Superplasticizers in Concrete, SP-62, American Concrete Institute, Detroit, 1979, pp. 157-166.

5. Mielenz, Richard C.. and Sprouse, James H., "High-Range, Water-Reducing Admixtures: Effect on the Air-Void System in Air- Entrained and Non-Air-Entrained Concrete," Superplasticizers in Concrete, SP-62, American Concrete Institute, Detroit, 1979, pp. 167-192.

6. Mukherjee, P.K., and Chojnacki, B., "Laboratory Evaluation of a Concrete Superplasticizing Admixture," Superplasticizers in Concrete, SP-62, American Concrete Institute, Detroit, 1979, pp. 245-261.

7. Malhotra, V. M., and Malanka, D., "Performance of Super- plasticizers in Concrete: Laboratory Investigation-Part I," Super- plasticizers in Concrete, SP-62, American Concrete Institute, De- troit, 1979, pp. 209-243.

8. Malhotra, V. M., "Superplasticizers: Their Effect on Fresh and Hardened Concrete," Report No. 79-31, CANMET, Energy, Mines and Resources Canada, Ottawa, 1979, 21 pp.

9. Roberts, L. R., and Scheiner, P., "Air Void System and Frost Resistance of Concrete Containing Superplasticizers," Developments in the Use of Superplasticizers, SP-68, American Concrete Institute, Detroit. 1981. pp. 189-213.

10. Okada, E.; Hisaka, M.; Kazama, Y.; and Hattori, K., "Freeze- Thaw Resistance of Superplasticized Concretes," Developments in the Use of Superplasticizers, SP-68, American Concrete Institute, De- troit, 1981, pp. 215-231.

11. Kobayashi, M.; Nakakuro, E.; Kodama, K; and Negami, S., "Frost Resistance of Superplasticized Concrete," Developments in the Use of Superplasticizers, SP-68, American Concrete Institute, Detroit, 1981, pp. 269-282.

12. Malhotra, V. M., "Mechanical Properties and Freezing and Thawing Resistance of Non-Air-Entrained, Air-Entrained and Su- perplasticized Concrete Using ASTM Standard C 666-Procedures A and B," Report No. MRP/MSL 81-53 (J), CANMET, Energy, Mines and Resources Canada. Ottawa, 1981, 51 pp.

13. "Standard Recommended Practice for Microscopial Determi-

ACI JOURNAL I July-August 1983

nation of Air-Void Content and Parameters of the Air-Void System in Hardened Concrete," (ASTM C 457-71), 1979 Annual Book of A S T M Standards, Part 14, American Society for Testing afid Mate- rials, Philadelphia, pp. 269-284.

14. "Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing," (ASTM C 666-77), 1979 Annual Book of A S T M Standards. Part 14, American Society for Testing and Mate- rials, Philadelphia, pp. 383-388.

15. Mielenz, R. C., "Use of Surface-Active Agents in Concrete,"

Proceedings, 5th International Symposium on the Chemistry of Ce- ment (Tokyo, 1968), Cement Association of Japan, Tokyo, 1969, V.

IV, pp. 1-29.

16. Walker, Richard D., and Hsieh, Tai-Chou, "Relationship Be- tween Aggregate Pore Characteristics and the Durability of Concrete Exposed to Freezing and Thawing," Highway Research Record No. 226, Highway Research Board, 1968, pp. 41-49.

17. Koh, Y., and Kamada, E., "The Influence of Pore Structure of Concrete Made with Absorptive Aggregates on the Frost Durabil- ity of Concrete," Proceedings, RILEM/IUPAC International Sym- posium on Pore Structure and Properties of Materials (Prague, Sept. 1973), ARTIA, Prague, 1973, V. 11, pp. F-45 to F-62.

18. Lange, H., and Modry, S., "Determination of the Frost Resis- tance of Limestone Aggregates in the Light of Porosity Investiga- tion," Proceedings, RILEM Symposium on Durability of Concrete (Prague, Sept. 1969), Building Research Institute, Prague, 1969, pp. B-129 to B-138.

19. Cebeci, Omer Z., "Pore Structure of Air-Entrained Hardened Cement Paste." Cement and Concrete Research, V . 11, No. 2, Mar. 1981, pp. 257-265.

20. Litvan, G. G., and Sereda, P. J., "Particulate Admixture for Enhanced Freeze-Thaw Resistance of Concrete," Cement and Con- crete Research, V. 8, No. 1, Jan. 1978, pp. 53-60.

21. Kaneuji, M.; Winslow, D. N.; and Dolch, W. L., "The Rela- tionship Between a n Aggregate's Pore Size Distribution and Its Freeze-Thaw Durability in Concrete," Cement and Concrete Re- search, V. 10, No. 3, May 1980, pp. 433-441.

22. Klieger, Paul, "Studies of the Effect of Entrained Air on the Strength and Durability of Concrete Made with Various Maximum Sizes of Aggregate," Bulletin No. 40, Portland Cement Association, Skokie, 1952, 25 pp.

T h i s p u b l i c a t i o n i a being d i s t r i b u t e d by the Division of Building P.esearch of t h e N a t i o n a l R e s e a r c h C o u n c i l of C a n a d a . I t s h o u l d not b e r e p r o d u c e d i n whole o r i n p a r t without p e r m i s s i o n of t h e o r i g i n a l p u b l i s h e r . The Di- v i s i o n would b e g l a d t o b e of a s s i s t a n c e i n obtaining s u c h p e r m i a s i o n . P u b l i c a t i o n s of t h e Division m a y be o b t a i n e d by m a i l - ing t h e a p p r o p r i a t e r e m i t t a n c e (a Bank. E x p r e s s , o r P o s t O f f i c e M o n e y O r d e r , o r a cheque, m a d e p a y a b l e t o t h e R e c e i v e r G e n e r a l of Canada, c r e d i t N R C ) t o t h e N a t i o n a l R e s e a r c h C o u n c i l of Canada, Ottawa. K I A OR6. S t a m p s a r e n o t a c c e p t a b l e .

A l i s t of a l l p u b l i c a t i o n s of t h e Division i s a v a i l a b l e a n d m a y b e obtained f r o m t h e P u b l i c a t i o n s Section. Division of Building R e s e a r c h , N a t i o n a l R e s c a r c h C o u n c i l of C a n a d a , Ottawa. K I A OR 6.