Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Paper (National Research Council of Canada. Division of Building Research); no.

DBR-P-776, 1978

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=5e78cce2-0eca-4a4c-92b1-c59a8aeb001e

https://publications-cnrc.canada.ca/fra/voir/objet/?id=5e78cce2-0eca-4a4c-92b1-c59a8aeb001e

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/40001767

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Experimental study on the effect of ventilation on the burning of piles

of solid fuels

Ser

L G Y ~

THl

N21d

National Research

Conseil national

no.

776

k

Council Canada

de recherches

Canada

c . 2

EXPERIMENTAL STUDY ON

THE EFFECT OF VENTILATION ON

THE BURNING OF PILES OF SOLID FUELS

by

T.Z.

I-JarmathyReprinted, from

Combustion and Flame VoL 31, No. 1, 1978 p. 259

-

264DBR Paper No. 776

Division of Building Research

La vitesse de combustion (pyrolyse) des piliers de bois et des polyuGres synthdtiques filants a dtd 6tudide en fonction de divers niveaux de ventilation forcde. On a constatd que le niveau de ventilation n'influe 2 peu prSs pas sur la combustion des combus- tibles non-carbonisants tandis que la vitesse de combustion des matdriaw carbonisants augmente avec l'accroissement du ddbit de

COMBUSTION AND FLAME 31,259-264 (1 978)

ANALYZED

Experimental Study on the Effect of Ventilation

on the Burning of Piles of Solid Fuels

T. Z. HARMATHY

National Research Council of Canada, Division of Building Research, Ottawa, Canada

The rate of burning (pyrolysis) of cribs of wood and non-dripping synthetic polymers has been studied at various levels of forced ventilation. It has been found that the burning of non-charring fuels is virtually unaffected by the ventilation level, whereas charring materials burn faster up to a maximum as the flow rate of air increases.

INTRODUCTION

It has been customary to assume that the rate of burning1 of piles of solid fuels is determined, as for pools of liquid fuels, largely by energy feed- back from the flame crown2 and, possibly, from the hot environment if burning takes place in a confined space. Yet, there have also been sugges- tions [I-31 that the rate of burning of piles of solid fuels is controlled mainly by the processes developing in the cavities of the pile.

In earlier papers the author [4,5] has suggested

that the analogy between the burning of piles of solids and pools of liquids is misleading. Whereas for pool fires the oxidation reactions are, perforce, restricted to the vicinity of the flame envelope, for

-

In the literature of fire research the rate of loss of mass of the burning solid or liquid fuel is usually re- ferred to as rate of burning. This practice will also be followed in some parts of this paper. The reader must realize, however, that the so-called rate of burning is approximately a measure of the rate of gasification of the fuel (for non-charring materials it is exact); in other words, the rate of formation of volatile pyrolysis pro-

f-

ducts (or vapm& and that has very little to do with the rate of the odxidaLon processes that go on in the gas- eous phase.

"Flame crown" is an expression introduced to refer to the flaming above the fuel pile, as distinct from the flaming that occurs itl the cavities of the pile.

Copyright 01978 by The Combustion Institute Published by Elsevier North-Holland, Inc.

solid fuel fires the pile acts as a primitive air en- training and air-fuel pre-mixing device that may cause substantial gas-phase oxidation within the visible envelope of the flame crown. The author also suggested that the rate of burning (gasifi- cation) of cellulosic materials is controlled by the heat evolved in the oxidation of char, the solid product of decomposition, and to some extent by the burning of the volatile pyrolysis products within the outside boundaries of the pile. If this claim is correct, the rate of burning of a wood pile must, by virtue of the known response of burning carbon t o the flow rate of oxidizer [ 6 ] , exhibit substantial dependence on the ventilation of the pile.

The question naturally arises of how the burning (gasification) of piles of materials that do not yield reactive solid decomposition products (most synthetic polymers) responds to changes in ventilation. This question is not of merely aca- demic interest. The author has shown that the severity of compartment fires can be reduced by increasing ventilation above a threshold value [4], and that forced ventilation can therefore be con- sidered as a convenient tool in fighting fire. There have been some doubts, however, that similar con- siderations are applicable when the fire load con- tains synthetic polymers. To throw some light on this problem area, experimental studies were

T. Z. HARMATHY

Fig. 1. Experimental set-up.

undertaken to measure the rate of loss of mass of burning cribs (cross-piles) of wood and of some synthetic polymers under forced ventilation.

It has always been customary to use cribs in lieu of furniture for experiments concerned with the development of building fires. A great deal of attention has already been paid to the rate of burning of wood in both unconfined atmosphere [2, 3, 7-10] and simulated compartments [ l l , 121. In the latter studies (natural) ventilation of the compartment was treated as a variable, but the question of the possible relation between venti- lation of the cribs and that of the compartment was not discussed.

Although the experiments to be described in this paper were not conducted in a way to permit a rigorous quantitative analysis of the problem, they did offer several conclusions that may be of interest to both fire scientists and fire protection engineers.

APPARATUS AND TEST SPECIMENS

Figure 1 shows the main features of the apparatus used in the experiments. The essential component of the apparatus is a ventilation chamber con- sisting of a five-sided box, 1 (1.22 by 1.22 by 0.61 m), and cover, 2, with an adjustable square opening at the center. The vertical position of the cover is also adjustable. Air enters the ventilation chamber from a 25-mm pipe bent into a circle of 1.01-m diameter, 3, through 8 3 holes of 1.6-mm

diameter on the side of the pipe facing the center. This circular pipe is connected to the air supply line via another pipe, 4, into which various devices are inserted (not shown) for control and measure- ment of air flow.

The specimen, 5, is placed on a wire mesh, 6 , resting on a stainless steel pan, 7, and this in turn rests on a load cell, 8. The rod connecting the pan with the load cell passes through a water trap, 9 , which prevents air leakage from the ventilation chamber. This apparatus permits air flow through the specimens to be made closely analogous to that characteristic of natural ventilation.

Five materials were used in the experiments: white pine, polymethyl methacrylate (PMMA), Polylite, and two kinds of phenolic plastic (acquired from a local retail store), to be referred to as Phenolic-1 and Phenolic-2. The Polylite crib specimens were made up of sticks cast from a resin of approximately 60% unsaturated polyester and 40% cross-linking agent, mainly styrene monomer. After the addition of 1% hardener (60% methyl ethyl ketone and 40% diethyl phthalate) the material was left for a few hours to solidify, then kept in a furnace at 1 0 0 " ~ for 8 hr to promote further cross-linking of the polymer chains. Phenolic-1 apparently contained some textile rein- forcement. Heating of the two Phenolics at 1 0 0 0 " ~ produced less than 1% residue, indicating the virtual absence of inorganic fillers.

As char among the pyrolysis products had been expected to play an important role in the mech- anism of burning (gasification), the four plastics were selected from the point of view of their char- forming characteristics. PMMA is known to decompose almost entirely into its monomers, leaving behind no solid decomposition products, but phenolic plastics are considered to be char- formers. Polylite is essentially a non-char-former, although its pyrolysis produces an insignificant amount of light surface char. The densities of the synthetic polymers were recorded as follows: PMMA 1 180 kg/m3, Polylite 1 190 kg/m3, Phe- nolic-1 1 320 kg/m3, Phenolic-2 1430 kg/m3.

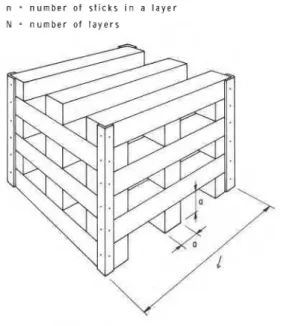

Figure 2 shows a typical crib specimen and illus- trates the meaning of symbol.$ used for the geo-

BURNING OF PILES OF SOLID FUELS 26 1 n = n u m b e r o f s t i c k s i n a l a y e r metric variables. Most cribs were built with stain-

N = n u m b e r o f l a y e r s

less steel reinforcing edges to prevent them from collapsing before the end of the period of interest. To eliminate the difficulties experienced in main- taining the continuous burning of the cribs of Phe- nolics, an extra layer of three sticks of Polylite was placed under them prior to the experiments.

The most important characteristics of the "regular" test specimens are summarized in Table 1. Tests were performed on other specimens not described in the table as supporting evidence.

After placing the crib specimen on the wire mesh, the cover to the ventilation chamber was lowered until it was flush with the upper surface of the crib and its central opening was adjusted t o clear the specimen by 3.2 mm on all sides. To facilitate ignition, 50 g of methanol was poured into the pan and the air supply was held at a lower

Fig. 2. Typical crib specimen. level until the entire specimen was well engulfed in

TABLE 1 Test Specimens Specimen a I MO AO @ No. Material m m n N kg1 m2 m2/kg a W-2-1 pine2 0.030 0.203 4 2 0.559 0.180 0.322 0.409 W-2-2 pine 0.030 0.203 4 3 0.857 0.256 0.299 0.409 W-2-3 pine2 0.030 0.203 4 4 1.217 0.332 0.273 0.409 W-2-4 0.030 0.203 4 5 1.387 0.408 0.294 0.409 W-2-5 pine2 0.030 0.203 4 6 1.626 0.484 0.298 0.409 PM PMM A 0.018 0.155 4 4 1.067 0.158 0.148 0.535 PL Polylite 0.025 0.155 3 3 1.022 0.128 0.125 0.516 Average values.

Kept in a conditioning chamber at 20°C and 50 per cent relative humidity for a few days prior to testing.

Including contributions for an extra layer of Polylite placed under the crib, consisting of three sticks of 25 by 25 by 155 mm dimensions.

Fig. 3. Variation of crib mass with time (typical record).

flames. Change in the mass of the specimen was recorded in all tests. Fig. 3 shows a typical mass versus time curve. The "rate of burning" was inter- preted as the slope of this curve during the period of "quasi-constant-rate" burning (gasification) of the fuel.

TEST RESULTS

The results of all test series involving plastics and of one series involving wood are presented graph- ically in Fig. 4. In spite of the considerable spread, it is clear that the rate of burning (gasification) of cribs composed of the two non-charring materials,

PMMA and Polylite, is not significantly affected by the flow rate of air (at least for the given geo- metric configurations and test conditions). In con- trast, the rate of burning of the cribs of the three char-forming materials, wood and the two Pheno- lics, shows a definite dependence on ventilation.

0 P l n e S p e c N o W I 1

D PMMA

Fig. 4. Effect of ventilation on rate of burning (change of mass) of cribs.

To gain at least qualitative insight into the effect of crib geometry on the rate of burning of char-forming materials some additional experi- ments were performed on wood cribs in the W-1 series (see Table 1). The test results are sum- marized in Fig. 5. After a few trials it appeared that the points could be arranged in logical pat- terns by plotting the rate of burning per unit sur- face area of the cribs RIA, (which is, in fact, equivalent or nearly equivalent t o the intensity of gasification of the fuel) against the flow rate of air

c

OO 0 . 0 5 0. I 0 0.15 0. 20 U ~ I A ~ k g l r n Z r

Fig. 5 . Effect of ventilation on rate of burning (change of mass) of wood cribs in series W-1.

per unit surface area, Ua/Ao. Since the specific surface varies in the W-1 series only in a narrow range between 0.318 and 0.363 (see Table I), it can be dismissed as a variable. It may be concluded that RIAo first increases then slightly decreases with increase of U a / A o , and that RIAo is higher for taller cribs. The maxima for RIAo are reached at values of Ua/Ao somewhere within the interval 0.10 to 0.1 5. (The results for crib W-1-2 seem to be somewhat anomalous.)

As Table 1 shows, the wood cribs used in series W-1-1

,

W-1-4, and W-1-5 had similar dimensions and differed only in the number of layers. It wasBURNING OF PILES OF SOLID FUELS 0.010 a, nor

t

0 C ' l b N O . W-1-1 A c r i b NO. W-1-4 o c r l b NO. W-1-5 o cribs N O S . W - 2 - 1 l o W-2-5Fig. 6 . Effect of crib height on rate of burning (change of mass) of wood cribs at various levels of ventilation.

possible, therefore, to use already available experi- mental points to investigate the effect of in- creasing crib height on the rate of burning at con- stant air flow rate. The dashed-line curves in Fig. 6 show the variation of RIAo with Ua/Ao at selected values of Ua at approximately identical values of the specific surface and porosity. For any constant air flow rate the intensity of gasification of the fuel has a maximum at about the same value of

Ua/Ao ("0.1 I), irrespective of crib height.

Also plotted in the figure are the results of a

,

series of tests performed on cribs W-2-1 to W-2-5.1

These, as Table 1 shows, also had similar dimen-sions and differed only in the number of layers. Obviously, the value of Ua/Ao at which the maxi- mum intensity of gasification occurs is somewhat different for these cribs, which had somewhat lower specific surfaces and higher porosities than

those in series W-1 .

OBSERVATIONS

In most experiments the process of burning appeared to be spatially non-uniform. With the crib configurations used, it proceeded somewhat

more slowly along the four sides, presumably owing to larger heat losses, and near the bottom of the crib where ventilation is usually poor. It is con- ceivable that the pattern of burning is different for larger and denser cribs for which a large portion of the central core may remain underventilated and, lacking combustion-induced heat sources, it may pyrolize more slowly than the peripheral regions. Clearly, the total crib volume must be an essential variable in the description of the burning process. Unfortunately, because of limitations in the maxi- mum air supply, cribs substantially larger than those listed in Table 1 could not be subjected to systematic studies.

In view of the expected spatial non-uniformity of the process and of the reported differences in the kinetics of thermal degradation of various

polymers [13]

,

one may question how realistic itis to take for granted the existence of a period of constant-rate mass loss for any material, crib size, and crib geometry.

The arrows in Fig. 4 indicate air flow rates approximately representing the stoichiometric air requirement for the respective materials. (As the exact composition of the two Phenolics was not known, their stoichiometric air requirement could not be estimated. It seems certain, however, that all experiments involving these materials were con- ducted at large excess air.) It appears that the majority of the experiments were conducted at air flow rates more than sufficient to allow complete combustion of all pyrolysis products without air entrainment into the flame crown. Although in no experiment was the flame crown observed to recede to near the crib, its length decreased with increasing ventilation and at the highest air flow rates employed in the experiments often measured less than one-quarter its length at the lowest ventilation.

CONCLUSIONS

Test results have confirmed the expectation of substantial differences in the way the burning (gasification) of piles of charring and non-charring solid fuels responds to changing ventilation. The rate of burning of non-charring fuels-the majority of synthetic polymers-is ostensibly unaffected by

T

.

Z. HARMATHY rate of air flow. In contrast, the rate of burning ofcharring fuels does exhibit a definite dependence on ventilation; it first increases, reaches a maxi- mum, then decreases as the air flow increases. The taller the crib, the more conspicuous are these changes. Observations clearly indicate the impor- tant role that heat released by the oxidation of char plays in the process of pyrolysis.

The author thanks Messrs. J. W. MacLaurin and N. Rabinovitch for their assistance in the experiments.

This paper is a contribution from the Division of Building Research, National Research Council of Canada and is published with the approval o f the Director of the Division.

NOMENCLATURE

a thickness of fuel sticks,

m

A . free surface area of the fuel, m2

1 length of fuel sticks, m

Mo mass of crib fuel, kg

n number of sticks in row, dimensionless

N number of stick rows in the crib, dimensionless

R rate of change of mass of crib fuel, kg/s

U, mass flow rate of air, kg/s

Greek Letters

E porosity of crib, dimensionless

specific surface of the crib, m2/iig

REFERENCES

1. McCarter, R. J., and Broido, A., Radiative and Convective Energy from Wood Crib Fires, Pyrody- namics, 2,65 (1965).

Smith, P. C., and Thomas, P. H., The Rate of Burn- ing of Wood Cribs, Fire Technology, 6,29 (1970).

Block, J. A., A Theoretical and Experimental Study of Nonpropagating Free-Burning Fires, 13th Symposium (International) on Combustion, The Combustion Institute, 1971, p. 971.

Harmathy, T. Z., A New Look at Compartment Fires, Parts I and 11, Fire Technology, 8, 196, 326 (1972).

Harmathy, T. Z., The Role of Thermal Feedback in Compartment Fires, Fire Technology, 11, 48 (1975).

Spalding, D. B., Some Fundamentals o f Combus- tion, Butterworths Sci. Publ., London, 1955, p. 93, 113.

Gross, D., Experiments o n the Burning of Cross Piles of Wood, J. Res. Natl. Bureau Stds., 66C,

99 (1962).

O'Dogherty, M. J., and Young, R S., Miscel- laneous Experiments on the Burning of Wooden Cribs, JFRO, Fire Research Note No. 548, 1964.

Kanury, A. M., Burning o f Well- Ventilated Wood Cribs, FMRC, Norwood, Mass., Serial No. 19721-1, 1970.

Thomas, P. H., Effects of Fuel Geometry in Fires,

BRE, U . K . , Current Paper No. 29,1974.

Nisson, L., The Effect of Porosity and Air Flow Factor on the Rate of Burning of Fires in Enclosed Spaces, Swedish Natl. Bldg. Res. Znst., Report R.

22, 1971.

Thomas, P. H., The Effect of Crib Porosity in Re- cent CIB Experiments, Dept. Environment, Fire Research Station, Fire Res. Note No. 999, 1974.

Lengelle, G., Thermal Degradation Kinetics and Surface Pyrolysis of Vinyl Polymers, AZAA Journal, 8, 1989 (1970).