Publisher’s version / Version de l'éditeur:

Concrete International: Design and Construction, 18, 3, pp. 34-38, 1996

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Durability of repair materials

Cusson, D.; Mailvaganam, N. P.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=b0ba5366-fc29-481b-be55-04eb7695746b https://publications-cnrc.canada.ca/fra/voir/objet/?id=b0ba5366-fc29-481b-be55-04eb7695746b

http://www.nrc-cnrc.gc.ca/irc

Dura bilit y of re pa ir m a t e ria ls

N R C C - 3 8 8 1 7

C u s s o n , D . ; M a i l v a g a n a m , N . P .

J a n u a r y 1 9 9 6

A version of this document is published in / Une version de ce document se trouve dans:

Concrete International: Design and Construction, 18, (3), pp. 34-38, 1996

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d'auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d'identifier la source de l'information et, dans certains cas, d'interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

OveNiew of material and structural characteristics...

Durability of Repair Materials

by Daniel Cusson and Noel Mailvaganam

Repair

Substrate

(e) Longitudinal Crack attheBond Interface

ments, thus further contributing to the problem of premature deterioration.

This article presents an overview of

material and structural characteristics

and other factors that should be consid-ered in the design of the repair process and the selection of patching materials.

Types of failure in

patching systems

Lack of durability in repaired struc-tures manifests itself in spalling, crack-ing, scalcrack-ing, and loss of strength. Three major modes of failure can be

ob-served:

• Tensile cracking through the thick-ness ofthe patch, This type of cracking

causes moisture and salt ingress (Fig.

Ia) and is likely to occur when the

ten-sile strength of the patch is lower tban the strength of both the bond at the in-terface and the substrate concrete. The patch will remain bonded to the

sub-strate concrete until freeze-thaw

cy-cling or dynamic loading cause

delamination.

• Shearing of the substrate concrete be/ow the interface, When this occurs,

failure is manifested as delamination of the patch with a layer of the base con-crete bonded to its underside (Fig. Ib).

Repair

Substrate

(b) Longitudinal Crack in

the Substrate Concrete

Concrete Slab on Grade

lal Transverseernct<

in the Repair Malerial

Fig. 1 - Types of failure in patching systems.

membranes. Patching is done prior to waterproofing in order to level surface irregularities and fill cavities produced by surface degradation or to replace

concrete that had to be removed

be-cause of chloride contamination. Often, readily available proprietary patching materials and specially designed con-crete mixes are used without proper consideration of load-bearing

require-UveLoad

•

p,tc,·,r,,

1:., (bI

Structural lal Non·Stnrctural Compressive ::; .:::: :::; . ...-->--> -<-D

espite the widespread andex-panding need for concrete re-pair, the lack of comprehensive data and suitable guidelines

leaves designerswith some uncertaintyas

to how toprooeedwith the design and

ex-ecution of durable repairs. The extreme climatic conditions in North America make it even more difficult.

To achieve a lasting repair,it is

es-sential that the properties of the repair material and the substrate be properly matched. This helps ensure that the

re-pair material can withstand the stresses

resulting from the volume changes and

load, for a specified environment over a

designated period of time, without ex-periencing distress and deterioration.'

One of the most widely used methods of repair is the patch and waterproof

procedure involving cementitious or

polymeric patches and elastomeric

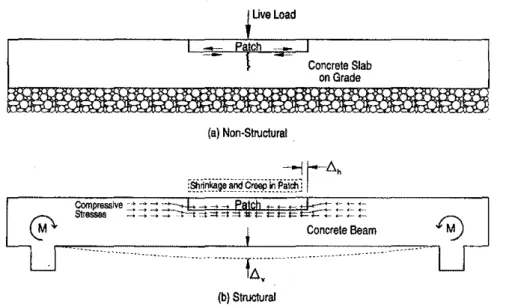

Fig. 2 - Typical nonstructural and structural repairs.

Cementitious Monan Cementitious MortarsPolymerwModified Resinous Mortars

Portland cement (PC) Styrene-butadiene rubber Epoxy

High alumina cement(HAC) Vinyl。」・エ。セ Polyester

PCIHAC mixtur

es

Magnesium phosphate AcrylicExpansion producinggrouts Acrylic Polyurethane

1 j

This is the predominant failure mode when the shear strength of the substrate

concrete is lower than the bond

strength at the interface and the tensile strength of the patch.

• Failure of the bond between the

re-pair material and the base concrete.

This takes place when the bond

strength at the interface is lower than the strength of both the base concrete and the repair material (Fig. Ie).

structural repairs, this phenomenon

can cause a loss of load-bearing ca-pacity. Clearly, the large number of

commercially available repair materi-als with wide variation in mechanical

properties makes proper selection of suitable repair materials a daunting

task - especially for harsh

environ-mental and loading conditions. The major criteria that should be con-sidered in the selection of patching

ma-terials for a given environment include in-service exposure conditions, logistic

considerations, patch installation

pa-rameters, and material characteristics.

In-service exposure

conditions

Some of the in-service exposure

condi-tions that should be considered in a re-pair program are listed below:

• Humidity and temperature

varia-tions. Temperature changes and cycles

of wetting and drying cause

dimension-al expansion and contraction. These conditions may generate tensile stress-es in excstress-ess of the repair materials

ten-sile capacity and thus cause cracking and debonding of the repair material.

• Freeze-thaw cycles. When saturated

and hardened concrete is exposed to low temperatures, the water held in the

Cementirious Polymer-Modified

Mortars Cementitious Resinous Mortars

Mortars 20'50 30-60 50-100 2-5 5-10 10-15 20-30 15-25 10-20 10 10-20 25-30 5-15 0.1-0.5 1-2 >300 tOO-300 40-80 35 Mechanical

PrUI!X'[lies

suring that the repair material is

com-patible with the substrate concrete is crucial, as the repaired member must behave monolithically and carryall stresses in the region of the repair

with-out distress or deterioration.

Selection of a compatible

and durable patching

material

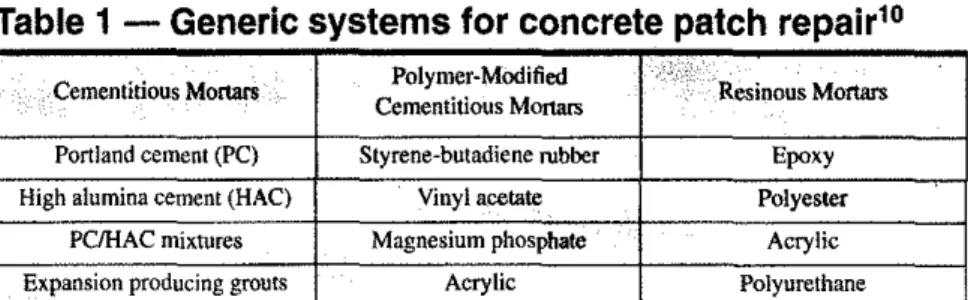

A wide variety of repair materials is now available to the design engineer.' These materials can be categorized into

three groups: cementitious mortars,

polymer-modified cementitious

mor-tars, and resinous mortars. As shown in

Table I, these groups can be further subdivided into generic types of repair products.

Table 2 shows typical values for some important properties for the three groups of repair materials. For a given mechanical property, a large difference in the values for the three different groups of repair materials can be observed. Such differences in the mechanical properties of two bonded materials can give rise to the development of initial tensile stresses as well as the formation of cracks at or near the interface, leading to the de-bonding of the repair material. In

Table 2 - Typical mechanical properties of repair materials

14March 1996

Types of repair: structural

and nonstructural

Although patching is widely used in the rehabilitation of structures, there is little differentiation shown between the types of materials used in

non-structural or non-structural repairs.

Con-crete patching materials are used in two different ways:

• nonstructural repairs, which

im-prove surface appearance, reduce

per-meability, protect reinforcement, or

improve abrasion resistance (Fig. 2a), and

• structural repairs, which restore the design load-bearing capacity of a dam-aged member, or improve the load-bearing capacity of an under-designed member (Fig. 2b).

Significant, or even excessive, stresses can develop in nonstructural

repairs just as easily as in structural

re-pairs. A proper repair design requires the correct combination of properties and dimensions of the bonded

materi-als in order to ensure that for

nonstruc-tural repairs, the interface bond

strength is not exceeded by stresses at the interface, and for structural re-pairs, the repair can carry its design load and allow for any volume chang-es which may take place over time in

service conditions.2

During the repair process and subse-quent curing period, failure to provide support to some of the external dead and live loads by jacking and shoring the memher undergoing repair may

re-sult in some of the internal stresses Compressiveウエイ・ョァセエィ⦅Hセmp⦅。セI

-1----,-,--+--:-:-:,--4--==--1

(which were transferred to the sur- Tensile strength (MPa)rounding substrate concrete when the Elastic modulusin

」ッNZNュMーイ・NNNNZNウMZウゥッMョセiMMM]]LMMKMMZMZMZZMZMMTMM]]MMQ

damaged concrete was removed) re- (GPa)

maining permanently in the substrate セ GGG[|エセFヲNGGッエエィ・エjiャ。ャ・クー。ョウゥッョ

concrete. In such a case, the・ヲヲ・」エゥカ・セ (oC-1 x10-6

ness in bearing and transmitting the .2.-

1--_-,-,__+_-:--:-0-_4__--:'-';:-__

stresses of the structural repair would Water absorption

be diminished or compromised. (percentby we..:ig:..h:..t)_ _

+__

=:-__I--_==::-_+-_-:=::-__

repaired beams of indeterminate

struc-tures cause redistribution of the

mo-ment (generated by the shrinkage force in the repair material) resulting in greater shrinkage than is found in

de-tenninate structures.4Therefore, where

shrinkage is likely to be restrained, a repair material with low shrinkage po-tential is required.

Material characteristics

Some of the most important properties to consider in the selection of a durable and compatible repair material are list-ed in Table 3 and discusslist-ed below. The reqnired relationship between the prop-erty of the repair material (R) and that of the substrate concrete (C) is identi-fied in parentheses for each property.• Shrinkage strain (R<C). In cement-based materials, most of the shrinkage occurs when the cement paste dries out after setting and hardening. In resin-based materials, shrinkage is a result of cooling following the exothermic reac-tion, particularly for patches with a thickness exceeding 15 rum (0.59 in.). When shrinkage is restrained (Fig. 2b),

permanent tensile stresses develop in the repair material and may cause

ten-Table 3 -

General

requirements of patch

repair materials for

compatibilit

y

lO(b)Extem.1 Load Parallel to the Inlenace

member depends, for the most part, on the strain capacity of the repair materi-al, while the performance of large structural patches depends on both the

strain and stress capacities of the repair

material over the service life of the structure.' For both large and small patches, high stresses can concentrate at edges and at changes in section, and may result in cracking at the bond inter-face and in the patch itself. Thus, a re-pair material with adequate tensile strength should be selected.

• Presence of reinforcement in the

re-pair. The effect of reinforcement on patch repairs is to reduce both the shear slress along the interface between the patch and the substrate as well as the

tensile stress in the substrate concrete.

,

,

,

Low Modulu.

,

,

HighModulu.,

HighModulu. Material

,

,

Mate,lal Matenal,

,

,

jJ,

jJ,

,

,

,

Moderate trans er e strass : Low load-bearing High axial stress :

concentration at inle ace I

,

effectiveness concentration IjJ,

:

,

Low Modulus Material

,

, ) Polenli.1セ

:,

tIe a). :

,,

(a) Extemalload Perpendicular 10 the Interface

Fig. 3 - Effects of mismatching elastic moduli.

capillary pores freezes and expansion occurs. Repeated freeze-thaw cycles have a cumulative effect, causing rapid degradation of the repair material.

• Impact, sustained, or cyclic loads.

Impact loads can cause the concrete to spall because of the different

wave-transmission rates of the material's

several constituents. Sustained loads

can induce additional strains in the

re-pair material because of the differential creep between Ihis material and the substrate concrete. Furthermore, cyclic loads can exceed the fatigue capacity of the repair material and cause its failure.

Logistic considerations

In many instances, the area to be paired may be inaccessible and mayre-quire the use of a self-leveling material Itcanalso provide a strong mechanical Relationship,of,

that flows easily. The repair may also anchorage for the repair material, re- .•• i"S;;,·.· •..•· •..··

..

セB

'itil/lf"

have to be done while the facility re- duce the distortion of the transverse in- ⦅GLUイュ[[ヲLセセwGQHB\GZ[LェセNBLセ[⦅_

mains openl necessitating the use of terface, and

eliminate concentrated

ii.","'·c'}:"·

.

tbconcretesubsttatefast products. These logistic stress zones near the interface.

Howev-(C)

cunng

considerations often dominate others in er, reinforcing bars can introduce new sbrir¢age-,s,ltwn R<C

the selection of repair materials. The problems: restraints imposed on move- Creep coefficient (for R<G

··;;·V"

growing trend for performance rather ment and increased pressure as the re- t:CpairsincOJnP!e§si()n)

than prescription specifications and life suit of corrosion can create large Creepcoefficient R>C

cycle costing may also dictate the use stresses which concentrate around the (for repairs.U:tension)

,'C:>

of low-maintenance repair systems, bars. For these reasons, it is important Thennal eXpansion R=C

to select a repair material that bonds coefficient

Patch installation

sile strength and low permeability.well to steel and that has adequate ten- Modulus of elasticity R=Cparameters

•

Effect ofsection stiffness. Additional Poisson's ratio R=CThe following parameters should be shrinkage stress can be generated in the Tensile strength R>C

considered dUring the design of the re- repair material of a stiff beam because f。エゥァオ・セイエZHIヲエャQスゥjQセセセ R>C

pair program. of the restriction of movement imposed

• Size and geometry of repair patches.

"Adhesibti

.'.'\

9.3·"·,

R>C

by the relatively small amount of

cur-The performance of small patches in- vature of this type of beam. Moreover, pッイッウNゥセ[セ[セェウLエゥカゥエケ R=C

traduced to restore durability to the differences in section stiffness along ChemlC'Ol'mtotNl.tYi R<C •..

Repair Material Subetrate Concrete

(b)later stages·high corrosionsctMtydueto uneven distribution of oxygen and chloride Ions

Fig. 4 - Effects of mismatching porosities.

CI-

cr

0, Substrate Concrete (highporosity) 0, 0, 0,I

I

I

Depletion of oxygen セ セ.+

al the interface OW OW OW セGMMMMセGMMMMGLセ- - _

..⦅MセMMMMMセcr cr

0,,

i Rapidciffusion of oxygen to the rebar and chloride

1ionsto the intenace due to higher permeability

0,

cr cr

(allnWaIstage·,qualCOfIC8Illralion ofoxygen,n<! chlorld'

lon, intllerepair materlal,ndsubstrateoonorete

R,palr Matarlal (low porosity)

Consumption of OWwillcause

thepH of concrete to decrease Fe(OH),

t t t

Fe++ Fe++ Fe++

t t t

Accumulation of positive charges

?

Aebarstress concentration and failure of the • Poisson's ratio (R=C).Poisson's

ra-high modulus materiaL' When the ex- tio controls the magnitude of the

trans-temal load is applied perpendicular to verse strain in relation to the strain in

the bond line (Fig. 3a), the difference in the direction of the applied uniaxial

stiffness between both materials is less loading. The effect of Poisson's ratio is

problematic if the eXlemalload is com- greatest when the bond interface is

per-pressive. However, if the perpendicu- pendicular to the direction of loading

larly-applied external load is tensile, and negligible when the load is parallel

mismatching elastic moduli is likely to to the interface,1O Bonded materials

cause adhesion failure. with mismatched Poisson's ratios can

The higher modulus material impos- generate differential transverse strains

es a severe constraint on the transverse at the bond line if the interface is

per-contraction of the lower modulus mate- pendicular to loading, causing cracking

riaL High concentrated stresses can at the interface. For this reason, it is

im-then locate in the lower modulus mate- P0rlant that both the substrate concrete

rial very close to the interface and ini- and the repair material have similar

tiate failure.9Therefore, when selecting Poisson's ratios.

a repair material, designers should en- • Tensile strength (R>C), A tensile

sure that both substrate concrete and force can be generated in a repair

mate-the repair material possess similar elas- rial by a combination of external

load-tic moduli. ing Hゥュー。」セ sustained and cyclic),

セMMイM

_ _----r_ _

37_1

sile cracking in the material itself, ordelamination at the interface of the

re-pair material and the substrate,5Since

most repair materials are appliedtoan

older substrate concrete tbat has negligible shrinkage, the repair material -which will begin to shrink soon after

casting - must have very low

shrink-age potential.'

• Creep coefficient (R<C or R>Cj,

Creep is the continuous deformation of a member subjected to a sustained

ap-plied load,It can result in reduced

load-bearing effectiveness in the repair ma-terial and also result in load transfer from the repair material to the substrate

concrete, or to a nonstructural element.

In the case of structural repairs loaded in compression (Fig, 2b), the

repairma-terial must possess very low creep

po-tentiaL On the other hand, in the case of repair patches loaded in tension, creep can be beneficial, as it can reduce or cancel the adverse effect of shrinkage

in the repair materiaL7

• Thermal expansion coefficient

(R=C), The coefficient of thermal

ex-pansion is a measure of the change of length in a material when it is subjected

to a change in temperature. When two

materials of different coefficients of thermal expansion are joined together and subjected to significant

tempera-ture changes, stresses are generated in

the composite material. These stresses may cause failure at the interface or in the lower strength material. This is par-ticularly evident in meat processing plants where floors are coated with ep-oxy toppings, Steam cleaning of the floors causes the topping (which has a higher thermal expansion coefficient) to shear off at the interface, Unless the temperature change is expected to be very small, the repair material should possess a thermal expansion coefficient similar to that of the substrate concrete,

• Modulus of elasticity (R=C), The

elastic modulus is a measure of rigidi-ty; low modulus materials deform more than those of high modulus under a giv-en load, Whgiv-en the external load (com-pressive or tensile) is applied parallel to the bond lin" (Fig, 3b), materials with different elastic moduli will transfer stresses from the low modulus material (lower load-bearing effectiveness) to the high modulus material, leading to

March 1996 e '1

,-a s ,I "Selected for reader interest by the editors. volume changes (shrinkage, creep, and

temperature and humidity variations) and mismatches in the properties of the repair material and the substrate con-crete, When any of these forces pro-duce a tensile stress in excess of the repair material's tensile capacity, fail-ure of the material can be expected in the form of tensile cracks, spalling or debonding, Thus, tensile strength -perhaps even more than compressi ve

strength - is an important property to

consider when selecting an appropriate material for a repair project.

• Fatigue peiformance (R>C), Be-cause cyclic loading Be-causes progressive

development and propagation of

cracks, the fatigue strengthofa materi-al is less than its static strength. The number of loading cycles a repair mate-rial can withstand decreases rapidly as the level of stress increases. Unless the repair material is expected to experi-ence only a negligible level of stress, it must have properties that can provide sufficient fatigue performance.

• Adhesion (R>C). Provided that an

adequate match of the bonded materi-als exists, any improvement of the bond will increase the performance of the composite system. Repairs with bond

lines in direct tension have a greater

de-pendency on bonding than do repairs with bond lines in shear, which benefit from the aggregate interlock mecha-nism. The bond strength at the interface can be influenced by the properties of the substrate concrete and its surface

(roughness, cleanness, and curing

state), by the properties of the repair material, including absorption and its ability to adhere to the substrate, and by environmental conditions.I I

• Porosity and resistivity (R=C). The

porosity and resistivity of the patching material may also affect the durability of the patch (Fig. 4). When materials that are dense, impermeable, highly re-sistive. or nonconductive are used, there is a tendency for the repaired area to become isolated from adjacent un-damaged areas. Consequently, there is a large porosity or chloride content dif-ferential between the patched area and the rest of the concrete which, in turn, causes lhe current from the resultant corrosion to become concentrated in a restricted area. The rate of steel corro-sion may then be accelerated, causing premature failure in either the patch or the adjoining concrete." Therefore,

38

when selecting a repair, it is important to ensure that both the substrate con-crete and the repair material possess similar porosities or densities.

• Chemical reactivity (R<C). The

re-activity of the patching material with steel reinforcement and other embed-ded metals, with the aggregate in the concrete, or with specific sealers or protective coatings applied over the patch must also be considered. Patch-ing materials with low to moderate pH provide little protection to concrete while highly alkaline material may at-tack potentially reactive aggregates in the concrete. Therefore, the reactivity of patching materials with both the sub-strate and the surface protection

prod-uct should be checked.3

•!3

Summary

The lack of comprehensive data on the performance of repair products and on the potential incompatibility between repair materials and substrate concrete is at least partly responsible for the large number of premature repair fail-ures in North American concrete struc-tures. Effective and durable repairs can be realized only when a detailed diag-nosis of the causes of deterioration has been made and given full consider-ation in the selection of materials that are both suitable for the particular en-vironment and service conditions, and compatible with the intended

sub-strates. It is the responsibility of the

design engineer to ensure that the se-lected repair material has these quali-ties so that it will last for the intended life of the repair.

References

1. Emmons, P.R and Vaysburd, A.M, "Factors Affecting the Durability of Concrete Repair: The Contractors Viewpoint," Construction and

Build-ing Materials, 80),1994,pp.5-16.

2. Plum, D.R., "The Behavior of Polymer Ma-terials in Concrete Repair, and Factors Influenc-ing Selection," The Structural Engineer, 68(17), 1990. pp. 337-345.

3. Mailvaganam, N.P., Repair and Protection

of Concrete SmKtures,eRePress, Boca Raton, 1992, pp. 47J.

4. Yuan, Y-S. and Marosszeky, M., "Re· strained Shrinkage in Repaired Reinforced Con-crele Elements," Materials and Structures, 27, 1994, pp. 375·382.

5. Yuan, Y.-S. and Marosszeky. M., "Major Factors Influencing the Perfonnance of

Structur-。! Repair," ACI Special Publication SP-J28·50, 2.1991, pp. 819-837.

6. Brill, L., KomIos, K., and Majzlan, B.. "Ear-ly Shrinkage of Cement Paste. Mortars and

Con-crete," Materials and Structures, 13(73), 1980. pp.41-45.

7. Saucier, E, Detriche. c.H.. and Pigeon. M .• "Tensile Relaxation Capacity of a Repair Con-crete," Materials and Structures, 25, 1992. pp. 335-346 (in French),

8. Hewlett, P.c. and Hurley, S.A., The

Conse-quences of Polymer-Concrete Mismatch, Design Life of Buildings, Thomas Telford, London,

1985, pp. 179·196.

9. Good, R. 1., Locus of Failure and its

Impli-cations for Adhesion Measurements, Adhesion Measurement ofThin Films, Thick Films, and Bulk Coatings, ASTM STP 640, K.L. Minai, Ed.•

American Society for Testing and Materials, 78, 1978. pp. 18-29.

10. Emberson, N.K. and Mays, G.C., "Signifi-cance of Property Mismatch in the Patch Repair of Structural Concrete - Part I: Properties of Re-pair Systems," Magazine of Concrete Research, 42(152),1990. pp. 147-160.

II. Saucier,F. and Pigeon, M., Durability of

New-to-Old Concrete Bondings, ACI Special

Publication SP-l2843, I, 1991, pp. 689"705. 12. Gu, P., Fu, Y.• Xie, P.• and Beaudoin, J.J.• "Effect of Uneven Porosity Distribution in Ce" ment Paste and Mortar on Reinforcing Steel Corw

rosion," Cement and Concrete Research,24(6),

1994, pp. 1055-t064.

13. Mailvaganam, N.P., "Studies Aim at Un-derstanding Why Concrete Patches Fail," MaJew

rial News, Material Laboratories, Institute for

Research in Construction, National Research Council Canada, spring1994,p.4.

14.Mays, G. and Wilkinson, W., Polymerr・セ

pairs to Concrete: their Influence on Structural Performance, ACI Special Publication SP-l()()..

22.1,1987. pp. 35t-375.

Daniel Cusson is .a research afllllXli-""

ate with the Re- C

pair Technologies and Strategies. ,,",' lq;roup atlhe Na- ','

tional Research Council's Institute

nstruction

ftom the Univer

ャセᆪNゥ[ヲ

Canada and completed a post-dOC-toral fellowship In Paris on the con-finement of high-strength concretll cohimhs, ,:.

",;K'\c?%k';i.'

Noel Mallvagan-am is a senior re-search officer with the Repair Tech-nologies and Strategies Group at the National Research

Coun-cil'siョゥゥエャiオエャゥセGャGi・ウャャャAセ iセ

Con-struction (NRC/IRC).

Hills

active inCSA, ACl;and

AILEM

committeeson repairs and.isthe author of books

on。、ャャIャNis|NセセャAAセエイウL