An Application of Value Stream Mapping to Reduce Lead Time and WIP

in a Make-to-Order Manufacturing Line

by

MASSACHUSETTS INSTITUTEOF TECHNOLOGY

Ricolas Wongso

NOV

0

4

2010

B.Eng., Materials Engineering (2009)

LIBRARIES

Nanyang Technological University, Singapore

Submitted to the Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Manufacturing

at the

Massachusetts Institute of Technology

SEPTEMBER 2010

@2010

Massachusetts Institute of Technology

All rights reserved

A

-Signature of Author:

Department of Mechanical Engineering

August 6, 2010

Certified by:

Stephen C. Graves

Abraham

J.

Siegel Professor of Management Science

Department of Mechanical Engineering and Engineering Systems

Thesis Supervisor

Accepted by:

David E. Hardt

Ralph E. and Eloise F. Cross Professor of Mechanical Engineering

Chairman, Department Committee for Graduate Students

AN APPLICATION OF VALUE STREAM MAPPING TO REDUCE LEAD TIME AND WIP IN A MAKE-TO-ORDER MANUFACTURING LINE

by

RICOLAS WONGSO

Submitted to the Department of Mechanical Engineering on August 6, 2010 in partial fulfillment of the requirements for Degree of Master of Engineering in

Manufacturing

ABSTRACT

Significant growth in the sales is expected in the coming years for the product family that is the focus of this research. In order to meet the takt time for the future demand, improvement on the current processes and expansion are needed. In this work, Value Stream Mapping was implemented to identify the bottleneck processes: fit up (oval), full welding, and pressure testing. Assembly cell concept, workload balancing and FIFO lanes were proposed countermeasures or improvements to address the capacity shortfall. A decrease of 27% in manufacturing lead time was projected if these improvements were made. In addition, the capacity analysis suggests that an expansion is required in full welding and heat treatment furnace.

Keywords: Value Stream Map, Lean, Shared resources, Lead time, Work in Process (WIP) inventory,

Make to order, FIFO lane, Capacity expansion, highly customized product

Disclaimer: The content of the thesis is modified to protect the identity of the project company.

Company name and confidential information are omitted or disguised.

Thesis Supervisor: Stephen C. Graves

ACKNOWLEDGEMENT

First and foremost, I would like to express my deepest appreciation to my thesis advisor, Professor Stephen C. Graves, for his guidance and invaluable insights he provided throughout the duration of the thesis. I am really thankful for his strong commitment to keep in touch despite of his busy schedule, and also for all the time spent during the discussion and video conference.

I would also express my appreciation to Dr. Brian W. Anthony who made this group projects possible by

making the arrangement with the Company sponsor. In addition, I would like to thank Ms. Jennifer Craig for her guidance and coaching in improving my writing skills.

I would also like to convey my thanks to the company that sponsored my work for this thesis.

Specifically, I am grateful for my overall corporate supervisor, in providing advice and the necessary resources for me to carry out this study. Many thanks also go to the full time staffs that are involved in the operation of the manufacturing line such as the manufacturing engineers, production planners,

quality engineers, etc. for their support in completing this project.

Above all, I would like to thank God and my family who have supported me throughout the duration of this thesis and allowed me to focus my attention on completing this undertaking. Last but not least, I would like to thank my team-mates for working together and helping each other during the duration of this group projects.

Table of Contents

ACKNOW LEDGEM ENT ... 5

Chapter 1: Introduction ... 10

1.1 Company and Product Description ... 10

1.2 The M anufacturing Process... 11

1.3 Current M anufacturing Issues ... 12

1.4 Thesis Structure ... 13

Chapter 2: Problem Statement and Objective ... 14

2.1 Problem Statement... 14

2.2 Objective and Scope ... 16

Chapter 3: Literature Review ... 17

3 .1 W h at is Lean ? ... 17

3.2 Introduction to Value Stream M apping (VSM )...18

3.3 Application of Lean in Make to Order M anufacturing Environment... 21

3 .4 Le a n G lo ssa ry... 23 Chapter 4: M ethodology... 24 4.1 Project Road M ap ... 24 4 .2 D efin e (D -P hase )... 24 4.3 Measure (M-Phase) ... 25 4.3.1 VSM Data Collection... 25 4.3.2 Current State VSM ... 25 4.4 Analyze (A-Phase) ... 26

4.4.1 Takt time Analysis ... 26

4 .4 .2 W IP A n alysis... 2 7 4.4.3 Capacity Analysis... 28

4 .5 Im p ro ve (I-P hase )... 28

Chapter 5: Results and Discussion... 29

5 .1 P ro d u ct Fa m ily ... 29

5.2 Current State VSM ... 29

5.2.2 Processing Tim e ... 36

5.2.3 W IP and W aiting Tim e... 38

5.2.4 M achine Uptim e ... 40

5.2.5 First Pass Yield... 41

5.2.6 Suppl ier Lead Tim e ... 42

5.3 Takt Tim e Analysis - Current State ... 42

5.4 Future State VSM ... 44

5.4.1 Sizing of FI FO Lanes ... 47

5.4.2 Sum m ary of Future State VSM ... 49

5.5 Capacity Analysis... 50

Chapter 6: Recom m endation ... 52

6.1 Recom m endation on the Current State ... 52

6.1.1 FIFO Lanes Im plementation... 52

6.1.2 Production Scheduling... ... ... 52

6.1.3 Fit Up, Plasm a Cutting and Pocket Fitting Assem bly Cell ... 53

6.1.4 Heat Treatm ent Im provem ent... 53

6.1.5 W orkload Balancing ... 54

6.1.6 Other Im provem ents...54

6.2 Recom m endation on Capacity Expansion ... 55

Chapter 7: Conclusion and Future W ork ... 56

7.1 Conclusion ... 56

7.2 Future W ork... 56

R e fe re n ce s ... 5 7 APPENDIX A - VSM Icons ... 58

APPENDIX B - Product Fam ily Selections ... 59

APPENDIX C - Current State VSM for Round Product Fam ilies ... 61

APPENDIX D - VSM Data... 67

Table of Figures

Figure 1: General process flow chart of oval and round products ... 11

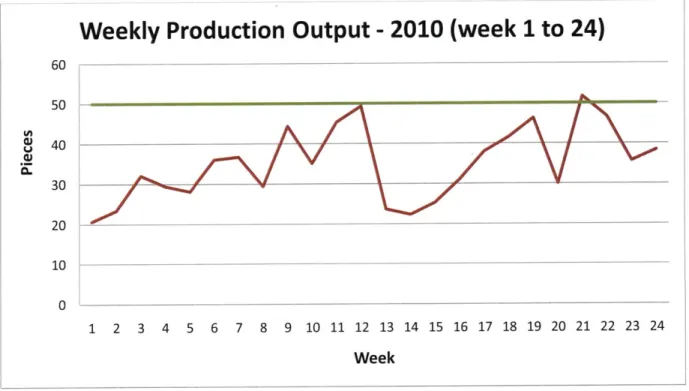

Figure 2: Current weekly production output of the assembly line - 2010 (week 1 to 24)...14

Figure 3: Exam ple of a current-state M ap [7]... 19

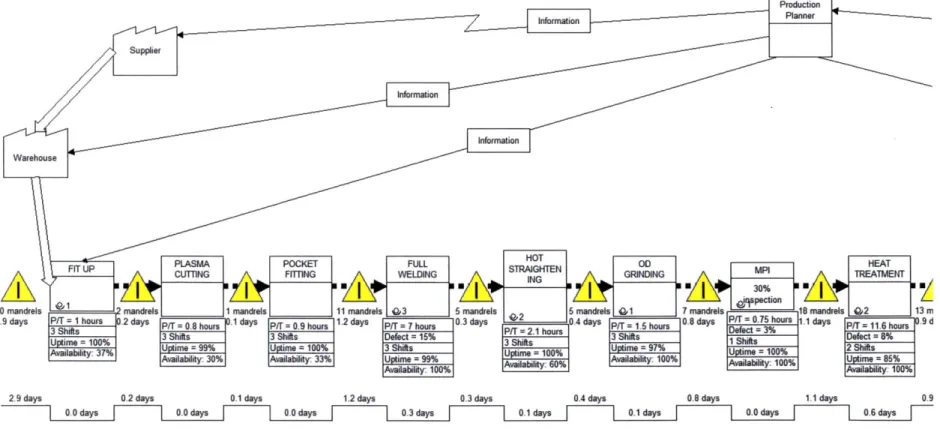

Figure 4: Current state VSM of Oval product family (1/2)... 30

Figure 5: Current state VSM of Oval product family (2/2)... 31

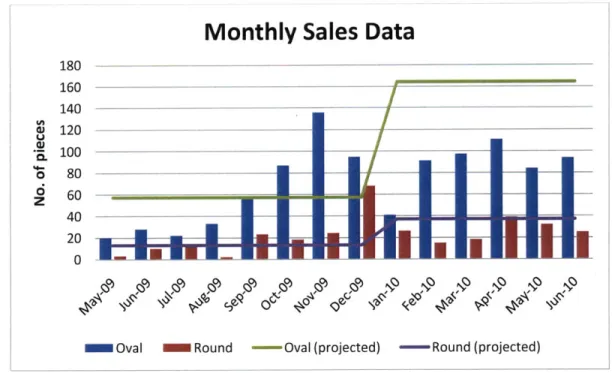

Figure 6: Comparison of actual sales vs. forecasted demand ... 33

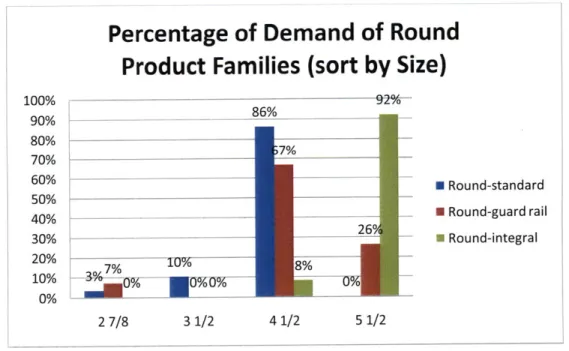

Figure 7: Percentage of demand of round product families ... 34

Figure 8: Percentage of demand of oval product family sorted by size ... 34

Figure 9: Percentage of demand of oval product family sorted by type of materials ... 35

Figure 10: Percentage of demand of round product families sorted by size ... 35

Figure 11: Percentage of demand of round product families sorted by type of materials...36

Figure 12: Takt time and cycle time comparison for both oval and round products - Current state... 44

Figure 13: Future state VSM of Oval product family (1/2) ... 45

Figure 14: Future state VSM of Oval product family (2/2) ... 46

Figure 15: Takt time and cycle time comparison for both oval and round products - Future state ... 49

Figu re 16 : V S M ico ns [7]... ... ... 58

Figure 17: Previous Work of Product Family Selections... 59

Figure 18: Current Product Fam ily Selections... 60

Figure 19: Current state VSM of Round-standard product family (1/2) ... 61

Figure 20: Current state VSM of Round-standard product family (2/2) ... 62

Figure 21: Current state VSM of Round-guardrail product family (1/2) ... 63

Figure 22: Current state VSM of Round-guardrail product family (2/2) ... 64

Figure 23: Current state VSM of Round-integral product family (1/2) ... ... 65

List of Tables

Table 1: Projected number of products to be produced per week (in pieces)... 12

T ab le 2: Project road m ap ... 24

Table 3: Example of processing time calculation for a product family for specific process or station ... 26

Table 4: Sum m ary of current state VSM ... 32

Table 5: Weighted average processing time for every product family (in hours) . ... ... 37

Table 6: Cycle time of processes for different product families (in hours) ... 38

Table 7: W aiting tim e of Oval products product fam ily ... 39

Table 8: Waiting time of Round products product families ... 40

Table 9: M achine downtime of 2009 in hours ... ... ... 41

Table 10: First Pass Yield (FPY) data ... 41

Table 11: VSM data on outsourced process ... 42

Table 12: Takt tim e of processes in the assem bly line ... 43

Table 13: Calculation of size of FIFO lanes ... ... ... 48

Table 14: Summary of future state VSM of Oval product family... 49

Table 15: Maximum weekly output of the assembly line (after improvement)... 50

Table 16: Maximum weekly output vs. forecast weekly demand for 2011, 2012 and 2013 (in pieces) .... 51

Table 17: Processing time of oval products (in hours) ... 67

Table 18: Processing time of round products (in hours) ... 68

Table 19: Number of products queuing before processes (oval products)... 69

Table 20: Number of products queuing before processes (round products)... 70

Chapter 1: Introduction

1.1 Company and Product Description

Company X is a multi-national company that provides technology, information solutions, and integrated project management services to its customers. Company X has their Engineering, Manufacturing and Sustaining facility for their products in Singapore. The plant is equipped with a foundry, machine shops, assembly shops, a heat treatment furnace and a comprehensive set of Quality Control testing facilities. The products are highly customized and have a relatively low demand (high mix - low volume). They are manufactured in different shapes (oval and round), diameters (2 3/8", 2 /8", 3 1/2", 41/2" and 5 1/2"),

lengths, and materials (410SS, 4130, 410-13Cr, Super 13Cr, Inconel 925, etc.), and can be categorized into various product families accordingly. However, significant manufacturing differences only occur between two groups of products; products that have round cross-sections and products that have oval cross-sections.

Round products can be further broken down into two types; standard round products and long round products. Standard round products are made up of six components, while long round products are made up of four components. Oval products, on the other hand, consist of four slightly-different main components.

1.2 The Manufacturing Process

The general manufacturing process flow for oval and round products is shown in Figure 1 below.

ASSEMBLY LINE

Figure 1: General process flow chart of oval and round products

The overall manufacturing process can be separated into the machining and assembly lines. As shown in Figure 1 above, the four components of the oval products are forged by an outsourced supplier and need not go through the in-house machining line. These forged components go directly into the assembly line which starts with the Fit-Up process and ends with Packaging and Shipping.

The four or six components of round products, on the other hand, are first machined in-house from raw bar-stock purchased from an external supplier before proceeding downstream into the assembly line. All assembly workstations that the round and oval products flow through are shared. Both types of products have similar assembly processes and are treated equally.

There are four inspection processes in the assembly line that are highlighted in blue, namely Radiography, Hardness Test, Magnetic Particle Inspection (MPI), and Pressure Test. Processes in italic font in Figure 1 are currently outsourced processes, namely Radiography, Threading, Sand-blasting, and

Painting.

As mentioned in Section 1.1, the products are highly customized in nature and have part numbers as component identifiers. Multiple parts, each with a component part number, are then given a new serial

I . . ...

number when they are assembled together to identify the particular product. The manufacturing process flow might differ from time to time depending on specific customer requirements. Currently there are more than 50 different designs of oval products and more than 40 different designs of round products. Each time a new product design with new features is released, new product part numbers are created. A more detailed process flow about the different products will be covered in Section 5.

1.3 Current Manufacturing Issues

Significant growth in the sales is expected in the coming years. Efforts to increase manufacturing capacity to meet customer demand with competitive lead time, cost, and quality have been put in place. Table 1 below shows the projected number of products that need to be produced per week over the next few years.

Table 1: Projected number of products to be produced per week (in pieces)

Year Oval Round Tta

201 38 9 47

2011

77

14

91

2012 103 19 122

2013 116 23 139

The current manufacturing capacity is able to produce a maximum of 50 pieces per week. Thus, it will be necessary to improve the throughput rate in order to meet the projected demand over the next few years. Also, capacity expansion projects might become a need should the above trend in future demand materialize.

Also, current manufacturing lead times are much longer (ranging from six to nine weeks) than total processing times due to excessive Work-In-Process (WIP). This results in high non-value-adding (waiting) times. It is noted that achieving less WIP will reduce waiting times and consequently reduce the manufacturing lead times. Shorter manufacturing lead times will in turn enable a quicker response to customer orders, ensuring better customer service and on-time delivery.

1.4 Thesis Structure

This thesis is organized into chapters. Chapter 1 is an introduction to the company, the product and the manufacturing process. Chapter 2 describes the problem statement, objectives and scope of the thesis. Chapter 3 reviews work on Lean concepts, Value Stream Mapping (VSM), application of lean in make to order manufacturing environment and Lean glossary. Chapter 4 describes the method that the author used to solve the problem. Chapter 5 describes the current state VSM, takt time analysis, future state VSM, and capacity analysis. Chapter 6 describes the recommendation on the current state and capacity expansion. Chapter 7 is conclusion and future work.

Chapter 2: Problem Statement and Objective

2.1 Problem Statement

As mention in Section 1.3, there are several issues that need to be addressed with regards to the performance of the manufacturing line: they are the rapidly increasing forecasted customer demand, long manufacturing lead time and high amount of WIP. Figure 2 shows the current production output of the assembly line.

Weekly Production Output - 2010 (week 1 to 24)

60 40 30 20 10 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Week

Figure 2: Current weekly production output of the assembly line - 2010 (week 1 to 24)

As can be seen from Figure 2, the current manufacturing line is still capable to support the demand for 2010 which are 47 products per week as shown in Table 1. In order to meet the projected customer demand of 2011, the line capacity needs to be doubled. In order to increase capacity, cycle time of the processes should be reduced so that the products can be produced faster. However, cycle time reduction to increase capacity has its limit. At some point, capacity expansion will be required in order to increase capacity, especially if the customer demand is increasing rapidly. The capacity expansion could be done by buying new machines, tools or equipments, and hiring more workers. The machining line has a relatively small amount of manual work because Computer Numerical Control (CNC) machines

'-w A .... ... .... ... .. .. ... ... . ...

/0000\

\

/ '\

are used. In the contrary, the assembly line has large amount of manual work. In addition, processes such as fit up, welding, hot straightening, cold straightening, etc. require highly skilled workers.

Currently, the company already has a plan on what kind and how many machines need to be acquired, and also how many workers will be needed to increase the capacity. This plan was created based on prior analysis and experience of the manufacturing engineers. From then, a lot of improvement projects have been done to improve the manufacturing line. Hence, it is important to re-access the current performance of the line and to revise the expansion plan, so that necessary budget reallocation could be done to effectively improve the line.

The next issue will be the long manufacturing lead time and high amount of WIP in the manufacturing line. These issues are closely related because manufacturing lead time can be cut by reducing WIP in the system (reduce waiting time) and also by reducing the cycle time of the processes. The current manufacturing lead time of the assembly line for oval and round products is about 5 to 6 weeks. The current WIP in the manufacturing line is estimated to be 180 to 200 pieces combining oval and round products according to the manufacturing engineer. The management feels that there is an opportunity to reduce the manufacturing lead time because most of the lead time is the waiting time between processes. It can be observed that products are waiting to be processed almost before every station. There is an opportunity to address the above issues using Lean manufacturing strategies. However, due to limited resources of time, manpower and money, sometimes it is not feasible to do all improvements simultaneously. Value Stream Mapping (VSM), which originates from Lean manufacturing concepts, is one such tool that can be used to identify and eliminate waste in the manufacturing line. After these areas that need to be improved have been identified, an implementation plan could be developed to make priority to critical areas and quickly solve the problems. This project seeks to improve the performance of the manufacturing line by Lean implementation and also identify areas where capacity expansion is required.

2.2 Objective and Scope

The objectives of the project are as the following:

* Identify and eliminate waste and bottlenecks in the current manufacturing line * Improve the overall process flow, reduce manufacturing lead time and reduce WIP

e Identify critical areas where capacity expansion are needed

The scope of this project is the manufacturing line for both oval and round products, focuses more on the assembly line.

Chapter 3: Literature Review

The following section describes the approaches that are proposed by the author in order to solve the problems. The author will use Lean tools and techniques which are widely used by companies around the world in order to achieve the similar objectives.

3.1 What is Lean?

Lean manufacturing is a set of principles that continuously identifies and eliminates sources of waste in the entire value chain. The core idea is to maximize customer value while minimizing waste [1]. Lean manufacturing was originated from Toyota Production System (TPS) and identified as lean only in the 1990s [2]. There are 8 types of waste identified in lean manufacturing (can be abbreviated as D-O-W-N-T-I-M-E) which are Defects, Over-production, Waiting, Non-engaging employees, Transportation, Inventory, Motion, and Excessive-processing.

Defects are defined as bad parts or out of specification parts that need to be reworked or need to be

scrapped. Over-production is defined as producing product ahead of demand. Waiting is defined as idling time of parts waiting to be processed, for example, waiting for equipments, operator or raw materials). Non-engaging employees could be defined as poor use of human intellect or work force.

Transportation is defined as unnecessary movement of products or materials that is actually not

required for processing. Inventory is defined as raw materials, work-in-process (WIP) inventory and finished product that are not being processed. Keeping inventory requires space and there are costs associated with it. Motion is defined as unnecessary motion in the operations, for example, equipment or operator movement. Excessive-processing could be defined as doing non-value added process to the products.

There are five Lean Principles which are described in the book, 'Lean Thinking', as shown below [3].

1. Specify Value. Value is described as what the customer is willing to pay for. One example could

be processes which transform the product, e.g. machining, assembly, etc. It is defined only by the customer; however sometimes it could be distorted by pre-existing organizations, especially engineers and experts. They add complexity of no interest to the customer.

2. Identify the Value Stream. The Value Stream is all the actions or processes needed to bring a product or deliver value to the customer. The complete value stream flows through the complete supply chain, from raw materials to finished goods

3. Flow. The value-creating steps or processes should be made to flow without delay or

interruption. One should try to eliminate departments that execute a single-task process on large batches.

4. Pull. The production should be make-to-order. The production processes should be activated when the customer wants to receive, not when the supplier wants to provide.

5. Pursue Perfection. There is no end to the process of reducing time, space, cost and mistakes.

One should strive for perfection by continually reducing waste.

Lean principles have several strengths. They provide a structured methodology for diagnosing and executing waste elimination. Lean focuses on workplace organization and preventative techniques. It is also very effective at rapidly reducing operational costs. Typical results that are obtained after Lean implementation in manufacturing systems include shorter lead times, increased productivity and efficiency, less inventory, lower overall production costs which leads to higher profit and return on assets, cleaner work areas, and waste elimination [4]. Some limitations of Lean principles include that it does not bring a process under statistical control [5]. In other words, it is not capable of removing bottlenecks driven by process variability or defects [4]. Lean relies heavily on intuition, or trial-and-error problem-solving, hence it could be a weakness when a problem is caused by interactive factors and makes problem resolution complex [6].

3.2 Introduction to Value Stream Mapping (VSM)

According to the book "Learning to see" published by the Lean Enterprise Institute (LEI), Value Stream Mapping (VSM) is a pencil and paper tool that helps you to see and understand the flow of material and information as a product makes its way through the value stream [7]. The VSM helps the user to visualize multiple processes and see the flow. It is also useful to create a blue print to implement lean concepts because it allows the user to identify the waste and also source of waste in the value stream

[7]. Figure 3 shows an example of a VSM. Information about VSM icons are shown in Figure 16 in Appendix A.

Figure 3: Example of a current-state Map [7]

In order to get started, first the user needs to choose a product family. A product family is defined as a group of products that pass through similar processing steps and over common equipment in your downstream processes [7]. It is very common that a value stream has more than one product family. In that case, one may consider choosing product families which have higher demand because it is not practical to create the VSM of every single products. It is more beneficial for the user to focus on a product family that has significant value to the customers.

The next step would be to visit the plant or the shop floor in order to observe and start mapping the current state of the value stream. It would be helpful to begin with a quick walk along the value stream to get a feel for the flow and sequence of the processes and also interact with operators in the shop floor to learn more about the process. User should pay attention to the material and information flow. User also need to complete the process box data with lean measurement such as process cycle time, changeover time, yield, machine uptime, inventory, etc. Lastly, user would need to draw a timeline and accumulate the process time and inventory waiting time to get the production lead time, value adding time and also non value adding time.

After the current state has been completed, the user should asses the current state value stream in terms of creating flow by waste elimination. Then the user should try to draw the future state VSM which will be the ideal state after lean implementation and waste in the value stream has been eliminated or minimized. Several Lean guidelines that are useful to aid the user in developing the future state VSM are as the following [8]:

1. Produce according to takt time

It is defined as the customer demand rate. Takt time is used to synchronize the pace of production with the pace of sales to avoid over-production or under-production. Takt time is calculated by dividing the effective working time by the total demand for the products.

2. Finished goods strategy

An example of this strategy is the supermarket pull system. Finished goods are being kept as inventory, and then when customers place the orders the finished goods are withdrawn from the supermarket. The upstream processes respond by supplying the supermarket with the same number of goods that were withdrawn (pull system).

3. Develop continuous flow wherever possible

Continuous flow is described as producing one piece at a time with each piece being passed to the next process without waiting.

4. FIFO ("first in, first out") lane

It is often used for highly customized parts, parts that have short shelf life or if the parts if costly. It is also useful to control WIP inventory between processes by setting a maximum size of the lane. If the maximum size is reached, the upstream process should stop producing.

5. Pull system

Customer process withdraws the items it needs from the inventory and the supplying process produces to replenish what was withdrawn from the inventory.

6. Schedule only at one point

The point at which the work is scheduled is called the pacemaker. This pacemaker process will be the one which control how fast the value stream need to operate.

7. Interval

It is defined as the time needed to cycle through all the products in the family. Interval is a measure of batch size and flexibility. Smaller interval provides more flexibility to the manufacturer to build what the customers want, when they want it.

8. Pitch

It refers to the frequency in which the work are released or taken away from the pacemaker. The future state will help the user to create an implementation plan in order to achieve the ideal state. The implementation plan should consist of improvement activities equipped with a timeline to keep track of the progress. After all the activities have been completed, the user could continuously improve the value stream by repeating the cycle of creating the current state VSM, assess, map the future state and implement improvement.

3.3 Application of Lean in Make to Order Manufacturing Environment

Make to order strategy is normally used when a manufacturer needs to produce highly customized product with high mix of different products. The challenges of implementing lean in this manufacturing environment are the difficulties to see the flow because of variations in cycle time of the processes and also because of sharing of equipment or resources. However, some of the basic lean tools such as 5S and visual management could still be applied.

5S stands for Sort, Set in order, Shine, Standardize and Sustain [9]. It is a lean tool which focuses on

workplace organization. Sort means only keep necessary tools or equipments which are needed in a workstation. Set in order refers to arranging these tools or equipments in an orderly manner and labeled

in order to promote efficient workflow. Shine means keeping the workplace tidy and organized. Standardize means that the first 3S should be consistent and standardized so that all workers know their responsibilities. Sustain refers to maintaining and reviewing the first 4S. Examples of visual management in a manufacturing line are production control board, defect rate, production target, etc. They could be in a form of electronic display boards as well as printed posters.

The book "Learning to see" provides some guidelines in implementing Lean in make to order manufacturing environment. First, the scheduling point or the pacemaker process should be further upstream. Second, FIFO lanes could be used to substitute for a supermarket and maintain flow between the downstream processes. For example, supermarket pull system could be used to withdraw the components or raw materials from the warehouse, and then the downstream process are linked by FIFO lanes. In addition, the value stream should keep the interval very small so that it could respond faster to customers demand.

The author also reviewed some of the previous works in Lean implementation in make to order manufacturing environment to learn about Lean tools and implementation that are useful or suitable for this type of environment. Making a High-Mix Make-to-Order Production System Lean is a Master Thesis

by Bo Li [10]. The objective of the thesis was to improve the manufacturing lead time, reduce WIP and

also improve information flow [10]. The method used was to implement CONWIP (Constant Work in Process) system and run a simulation to determine the optimal size for the WIP. CONWIP pull system uses a single global set of cards to control total WIP anywhere in the system [11]. The WIP is not controlled at individual workstation but at a system level, easier to implement and adjust, since only one set of system cards is used to manage system WIP [11]. Kitting is a process in which parts or components needed for manufacturing or assembly of certain products are being collected together into a kit, and issued at the point of use. In addition, the material flow between processes inside the system are maintained and controlled by implementing FIFO lanes.

Head & Base Production Optimization: Setup Time Reduction is a Master Thesis by Haiqing Quo [12]. The

main objective of the thesis was to reduce the setup time of machine without increasing scrap rate and improves output and productivity of the whole machining section [12]. The method used was SMED (Single Minute Exchange of Die) which is a lean tool to reduce the setup time or changeover time when manufacturing different products. There are eight techniques proposed by Shigeo Shingo, leading manufacturing expert of the Toyota Production System, which can be used to achieve this: to separate internal from external setup operations, to convert internal to external setup, to standardize function, to eliminate fasteners, to use intermediate jigs, to adopt parallel operations, to eliminate adjustments, and

3.4 Lean Glossary

The following list provides the definition of terms that will be used extensively throughout the thesis: * Lead time (L/T): the time required for one piece to move all the way through the process or

value stream, from start to finish

e Manufacturing lead time: the time required for one piece to move all the way through the manufacturing process; in this project this consists of the machining line and assembly line.

e Supplier lead time: the time required for the supplier to deliver raw stocks or forged components, from the time the order is placed until it arrives in the company's warehouse.

" Product family: a group of products that pass through similar processing steps and over

common equipment in the downstream processes

e Value added time (V/A): the time taken for the processes that transform the product in a way for which the customer is willing to pay

* Takt time: the customer demand rate

* Processing time: the time a product is actually being worked on by an operator or a machine * Cycle time: how frequently an item or product is completed by a process. For example, a

welding process takes 4 hours to finish a product; if there are 4 welders available in the station, the cycle time of the welding process is 1 hour.

* Bottleneck: a process that cannot meet takt time

Chapter 4: Methodology

In the following section, the author will describe his approach to solve the problems based on the Lean

DMAIC method that is commonly used in the company in any improvement project. DMAIC stands for

Define, Measure, Analyze, Improve and Control. Lean DMAIC consists of five phases and it is structured to help the user to solve the problem systematically.

4.1 Project Road Map

In this project, the author only used four phases of this method which are the DMAI phases. Table 2 shows the list of actions planned by the author that will be carried out in each phase.

Table 2: Project road map

4.2 Define (D-Phase)

In order to understand the operations of the current manufacturing process, the author conducted an informal interview with the people involved in the operations of the manufacturing process, for example the manufacturing engineers, production planners, purchasing, customer service, production manager, supervisor, operators, etc.

DEFINE 0 Understand the current manufacturing process

0 Create a problem definition, objective and scope of the project * Analyze existing or historical data

MEASURE * Collect VSM data on the shop floor

e Map the current state VSM

* Identify bottlenecks in the current manufacturing process ANALYZE Takt time analysis

0 Capacity analysis

0 Map the future state VSM IMPROVE e Identify area for improvement

* Identify area for expansion

In addition, he went to the shop floor and observed how the operators do their work in each process, and also to learn about the information flow and product flow in the manufacturing line. This is very important to gain an initial understanding about the production line and also to get some clues that might be useful in solving the problems. Next, the author defined the problems, the objective or goals that he is trying to achieve, and the scope of his project which were described in Section 2.

4.3 Measure (M-Phase)

4.3.1 VSM Data Collection

The author acquired existing or historical data from the people involved in the manufacturing line to complete the information needed for creating the current state VSM. Examples of such information are historical sales data, forecasted customer demand, general process flow, products routing, manufacturing lead time, first pass yield, WIP and inventory status, cycle time, machine downtime and supplier lead time. These findings are available in Section 5.2.

The author decided to conduct a time study at the shop floor to measure the processing time for all the processes. Data on WIP between processes, availability of operators and number of shifts available are also collected and is reported in Section 5.3.

4.3.2 Current State VSM

To get started, the author grouped the existing products into product families based on their manufacturing process flow which was extracted from the products routing data. Then, the author analyzed the historical sales data in order to determine the demand percentage for these product families; based on this the author decided to focus more on the product families with higher demand. The forecasted customer demand data for 2010 was used to calculate the weekly demand of the product families.

The assumptions that are made for the VSM are as the following:

* Available hours per shift = 8.5 hours - 0.5 hours (lunch) - 2x0.25 (tea-breaks) - 0.5 (toolbox

meeting) = 7 hours

In order to determine the processing time of each product family, the author used weighted average method based on the demand percentage of the products within product family. The demand percentage was obtained from the historical sales data and was sorted based on the product's diameter and type of material. The processing time for each product was obtained from time a study on the shop floor. The calculation method using arbitrary numbers is illustrated in Table 3 below.

Table 3: Example of processing time calculation for a product family for specific process or station

40% 0.4

A2 2 10% 0.2

A3 1.5 25% 0.38

A4 1 35% 0.35

Total 1.33

Finally, after all the data mentioned in Section 4.3.1 have been collected, the author used software named Igrafx [14] to assist him on creating the VSM for four product families. As mentioned in Section

2.2, the author focused more on the assembly line for both oval and round products. On the VSM, the

machining line will be simplified by combining together the process steps from the machining cell into a single stage. The reason behind this simplification is because the machining routings for the round components are not fixed, so the same parts could be machined in different ways.

4.4 Analyze (A-Phase)

From the current state VSM, the current manufacturing lead time, value added time and WIP could be determined. Next, the author did further analysis as described in the following sections to access the current state of the manufacturing line.

4.4.1 Takt time Analysis

The purpose of this analysis is to identify the bottleneck processes in the line and to determine how much improvement is needed so the takt time could be met. Takt time was calculated by dividing the effective working time by the total demand for the products. In practice, factors such as number of shift,

... .. ... .. .. .. .... ... . ... ...... ... .-... . ... . .... . ....

operator availability, first pass yield, and machine uptime need to be considered in calculating takt time of a process. Total demand for the products for a process also depends on whether it is a dedicated resource or a shared resource. The formula to calculate takt time for a process step is shown below.

Takt time = Effective working time

Total demand for the products

no. of days per week x no. of shift x avail. hours per shift x operator availability x machine uptime

weekly demand +

first

pass yieldIn a dedicated resource, the weekly demand is the demand for one single product family. However, in a shared resource, the weekly demand is the accumulated demand for several product families that need to be processed in this shared resource. The demand for each round product family could be determined from the demand percentage of these product families.

Next, the calculated takt time values were compared to the cycle time for each of the processes. If the cycle time is larger than the takt time, it indicates that the process is a bottleneck.

4.4.2 WIP Analysis

The purpose of this analysis is to determine the waiting time of a product between processes. This waiting time (in days) will be displayed in the VSM. The formula to calculate the waiting time is shown

below.

. number of mandrels bef ore process number of mandrels bef ore process

capacity of a process Effective working time per day + cycle time

The number of products before each process will be determined from observation at the shop floor. It will be counted at the start of the morning shift for each day for one week. The number of products waiting before the process will also be displayed in the VSM.

4.4.3 Capacity Analysis

The purpose of this analysis is to identify processes that would need capacity expansion in order to meet the projected demand for 2011 and beyond. It is done by calculating the maximum weekly output of a process (assuming it works for 3 shifts) and comparing it to the forecast weekly demand. If the weekly output of the process is smaller than the forecasted weekly demand, expansion is needed for this process. The formula to calculate the maximum weekly output is shown below.

Available time per week x machine uptime

Maximum weekly out put = cletmofhepcssx yield

cycle time of the process

4.5 Improve (I-Phase)

In this phase, the author mapped the ideal future state of the assembly line after implementing Lean Strategies to the manufacturing line. Examples of the Lean strategies used were FIFO lanes with maximum inventory size and assembly cell concept. Kaizen bursts icons (see Figure 16 in Appendix A) were drawn on the VSM to show the improvement activities that need to be done at a process. Capacity analysis was also done in order to identify areas that need expansion in the future. Finally, recommendations to solve these problems were proposed.

Chapter 5: Results and Discussion

5.1 Product Family

As mentioned in Section 3.2, to get started, the products must be sorted into product families based on their process steps. Although the products are highly customized, generally they can be grouped based on their shape, size and material. Preliminary work had been done by one of the manufacturing engineers who grouped the products into five product families. This work was passed on to the author, who then analyzed the work, verified the process steps and revised it. Details of the product family selection are shown in Figure 17 and 18 in Appendix B. The author combined group B and group E

product families because the process steps are similar for both product families.

The product families that have been identified and analyzed in the next following sections are:

1. Oval

2. Round -standard

3. Round - guard rail

4. Round - integral

5.2 Current State VSM

The current state VSM shows the process flow from the start to the end of the manufacturing line for each product family. In order to simplify the VSMs for round-products product families, the processing time of machining stage in the round-product families is assumed to be 3 to 4 weeks, which is determined from the company's integrated system (MfgPro) that is used to run the operations._The

reason behind this simplification is that the machining cell consists of 5 machines and there are too many different machining routings for the different components.

The current state VSM of Oval product family is shown in Figure 4 and 5. The current state VSMs for the round-products product families are available in Appendix C. The VSMs are separated into two sections (upstream and downstream) for better viewing.

29 days 02 days 0.1 days 1.2 days 0.3 days 0.4 days 0.8 days 1.1 days 0.9

0.0 days | | 0.0 days 0 .0 days || 0.3 days || 0.1 days | | 0.1 days || 0.0 days || 0.6 days

Figure 4: Current state VSM of Oval product family (1/2)

Customer Demand:

38 pieces per Week

(Takt Time 2.76 hours)

0.9 days 0.6 days 0.8 days 3.1 days 1.0 days Manufacturing UT = 26.8 days

0.6 days 0.0 days 0.1 days 0.0 days 0.0 days 12.0 days Total P/T = 13A days

Waiting Time = 13.4 days

From the VSM, the manufacturing lead time, total processing time and waiting time could be calculated. This information is summarized in Table 4 below.

Table 4: Summary of current state VSM

Product Family

Round- Round- Round-standard guardrail integral Manufacturing Lead Time (days) 26.8 55.5 57.6 56.3 Total Processing Time (days) 13.4 42.5 43.7 43.3

Waiting Time (days) 13.4 13 13.9 13

The current state VSMs indicate that the manufacturing line operates as a make-to-order and push system. After customer order is confirmed, the work order is then released to the shop floor. In the assembly line, the product is pushed to the next station one after another. There is space for inventory in between the processes.

More information about the value stream such as processing time, waiting time, number of products between processes, defect, machine uptime, operator availability, and number of shifts are also displayed. The following sections further explain the data and information that were used to construct the VSM. These data and information were extracted from the existing data given from the planners and engineer, and also observed from the shop floor.

5.2.1 Past Sales Data

First, past sales data were used to analyze the accuracy of the projected demand. The comparison between the actual sales and projected demand for year 2009 and 2010 is shown in Figure 6.

Monthly Sales Data

180 160 140 120 100 80 60 40 20 0 _ ,Oval Round - Oval (projected) - Round (projected)

Figure 6: Comparison of actual sales vs. forecasted demand

Figure 6 suggests that for the first half of the year 2009 and 2010, the actual sales seem to fall below the projected demand. However, for the year 2009, the sales were catching up during the second half of the year. Similar trend might happen for 2010, so the manufacturing line should have enough capacity to meet the projected customer demand. The forecasted demand for 2010 is displayed in the current state VSMs as weekly customer demand which will be used in the takt time analysis in Section 5.3.

Second, the author sorts the sales data to get the percentage of demand of the round product families so that the author can focus more on analyzing a product family which has higher demand. The result is shown in Figure 7 below. It indicates that the demand is spread evenly among these three product families so the author decides to include all four product families (including oval product family) in the analysis.

Percentage of Demand of Round

Products (sort by Product Family)

45%

39%

40% 35% 30% 25% 20% 15% 10% 5% 0%Round-standard

Round-guard rail

Round-integral

Figure 7: Percentage of demand of round product families

Then, the author further sorts the data to find the percentage of demand of products within product family based on diameter size and type of materials. Figures 8 and 9 show the percentage of demand of oval product family. Figures 10 and 11 show the percentage of demand of round product families.

Percentage of Demand of Oval

Product Family (sort by Size)

45% 40% 400% 40% 36% 35% 30% 25% 19% 20% 15% 10% 5 5%5 0% 23/8 27/8 31/2 41/2

Figure 8: Percentage of demand of oval product family sorted by size

... ... .. ...

45% 40% 35% 30% 25% 20% 15% 10% 5% 0%

Percentage of Demand of Oval Product

Family (sort by Material)

39%

410-5

410SS HHT 4130 LHT 4130

Figure 9: Percentage of demand of oval product family sorted by type of materials

Percentage of Demand of Round

Product Families (sort by Size)

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 2 7/8 86% . 31/2 41/ 8% 2 5 1/2 * Round-standard " Round-guard rail 1 Round-integral

Figure 10: Percentage of demand of round product families sorted by size

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% n 0Z

Percentage of Demand of Round Product

Families (sort by Material)

_92 69% * Round-standard -_ * Round-guard rail * Round-integral 8% 3 9H8% 0O% = 0% 410-13CR Super 13CR Incornel 925

Figure 11: Percentage of demand of round product families sorted by type of materials

The percentage of demand data shown in Figures 8, 9, 10 and 11 are not displayed in the VSM; however they will be used to determine the cycle time data of a product family using weighted average method. It will be further explained in the next section.

5.2.2 Processing Time

The results of the time study for oval and round products are shown in Tables 17 and 18 in Appendix C. Some of the processing time for products with certain material and size are not available especially for round products. In that case, the demand percentage is adjusted so that the sum of the weighing factor is still 100%. For example, the processing time for round products with size 2 7/8 and 3 1/2 are not available, so when the round-standard processing time is calculated, the weighting factor for different size of products is assumed to be 100% instead of 86%.

Next, the author calculates the weighted average processing time for each product family based on the processing time data on Tables 17 and 18 in Appendix C, and also the percentage of demand data from the previous section. Table 5 shows the results of the weighted average processing time for the product families that will be displayed in the VSM and used in the analysis.

Table 5: Weighted average processing time for every product family (in hours) Process Average Processing Time of Product Family

Oval Round-Standard Round-Guardrail Round-integral

Fit up (Oval) 1 - -Plasma Cutting 0.8 -Pocket Fitting 0.9 - -ID Welding - 2.7 2.6 2.5 Fit up (Round) - 1.8 1.8 1.7 Mill Slots/Flats - - 5.3 10.4 Full Welding 7 8.1 7.9 7.5 Hot Straightening 2.1 1.6 1.6 1.6 OD Grinding 1.5 1.5 1.4 1.7 Heat Treatment 11.6 17.3 18.2 17.1 Cold Straightening 1.2 1.4 1.4 1.6 OD Drift 0.9 1.1 1 1.1 Hardness test 0.5 0.5 0.5 0.5 MPI 0.75 0.75 0.75 0.75 Pressure Test 1 1 1 1

Mill Slots/flats is a machining process, but it is also part of the assembly process. The setup time and run time done in this machine are recorded in MfgPro. Data is extracted from the MfgPro, and then all the setup and run time to mill slots or flats from January 2010 to June 2010 were summed. Next, these values are divided by the quantity of products being machined to get the average processing time. The processing time is the sum of setup and run time.

The processing data is used to calculate the cycle time of the processes by dividing it by the number of stations or batch sizes. The results are shown in Table 6 below. The cycle time data are used in the takt time analysis of the current state VSM.

Table 6: Cycle time of processes for different product families (in hours)

No. of Oval Round-standard Round-guardrail Round-integral

Process stations/ Processing Cycle Processing Cycle Processing Cycle Processing Cycle

batch sizes time time time time time time time time

Fit up (Oval) 1 stations 1.0 1.0 - - -

-Plasma 1 stations 0.8 0.8 - - - -Cutting Pocket 1 stations 0.9 0.9 - - - -Fitting ID Welding 1 stations - - 2.7 2.7 2.6 2.6 2.5 2.5 Fit up 1 stations - - 1.8 1.8 1.8 1.8 1.7 1.7 (Round) Mill Slla 1 stations - - - - 5.3 5.3 10.4 10.4 Slots/Flats

Full Welding 3 stations 7.0 2.3 8.1 2.7 7.9 2.6 7.5 2.5

Hot

2 stations 2.1 1.1 1.6 0.8 1.6 0.8 1.6 0.8

Straightening

OD Grinding 1 stations 1.5 1.5 1.5 1.5 1.4 1.4 1.7 1.7

Heat batch sizes 11.6 0.7 17.3 1.1 18.2 1.1 17.1 1.1

Treatment of 16 Cold 1 stations 1.2 1.2 1.4 1.4 1.4 1.4 1.6 1.6 Straightening OD Drift 1 stations 0.9 0.9 1.1 1.1 1.0 1.0 1.1 1.1 Hardness 1 stations 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 Test MPI 1 stations 0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75

Pressure Test 1 stations 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

5.2.3 WIP and Waiting Time

The number of products waiting to be processed between stations was counted at the start of each morning shift. The challenges faced were that the operators are not dedicated into a particular process and some of the processes were only running in one shift. Hence, the WIP was constantly changing and the long queue was transferred from one process to another.

There are two methods to determine the WIP data to be put in the VSM. First is by taking a snapshot or one time observation at the shop floor. Second is by monitoring the WIP status for a period of time and then take the average. The latter method was chosen because by taking more data samples, the validity of the data over a period of time could be assessed. Five and six days' data were collected and the results are shown in Tables 19 and 20 in Appendix C. The averages of these data samples are taken to determine the WIP between processes to be displayed in the VSM and also to calculate waiting time between processes.

Next, waiting time of products between processes shown in VSM was calculated using the data provided in Tables 6, 19 and 20. For a shared resource, the number of products waiting before the process is the total of oval and round products. The number of products waiting and the calculated waiting time for oval and round product families are shown in Tables 7 and 8 below.

Table 7: Waiting time of Oval products product family

No. of units Effective working Cycle Time Waiting time Process

before process time per day (hour) (hour) (days)

Fit up (Oval) 20 6.9 1.0 2.9 Plasma Cutting 2 6.9 0.8 0.2 Pocket Fitting 1 6.9 0.9 0.1 Full Welding 11 20.8 2.3 1.2 Hot Straightening 5 21.0 1.1 0.3 OD Grinding 5 20.4 1.5 0.4 MPI 7 7.0 0.8 0.8 Heat Treatment 18 11.9 0.7 1.1 Hardness test 13 7.0 0.5 0.9 Cold Straightening 5 9.5 1.2 0.6 OD Drift 8 9.5 0.9 0.8 Pressure Test 22 7.0 1.0 3.1 .... ... . ... ..... ... ...

Table 8: Waiting time of Round products product families

No. of units Effective working Cycle Time Waiting time before process time per day (hour) (hour) (days)

ID Welding 2 6.65 2.6 0.8 Fit up (Round) 0 7 1.8 0.0 Full Welding 11 20.79 2.6 1.4 Hot Straightening 5 21 0.8 0.2 OD Grinding 5 20.37 1.5 0.4 Heat Treatment 18 11.9 1.1 1.7 Hardness test 13 7 0.5 0.9 Cold Straightening 5 9.45 1.5 0.8 OD Drift 8 9.45 1.1 0.9 MPI 7 7 0.8 0.8 Pressure Test 22 7 1.0 3.1 Mill Slots/Flats 0 21 7.9 0.0

The waiting time of the products to be sent to the outsourced processes, such as radiography, threading, sand blasting and painting, is assumed to be 1 day because the products are shipped every 1 or 2 days. Number of products before the station is determined from the supplier data provided in Section 5.2.6.

5.2.4 Machine Uptime

Table 9 shows the total downtime duration of the machine in assembly line in 2009. These data were

obtained from the maintenance system. These values are converted into machine uptime assuming that the available time in a year is 8640 hours (360 days x 24 hours/day). The reason behind this assumption is that the downtime duration of each machine is the actual real time. And so 8640 hours were used as the available hours even though the actual working hours will be much less. The machine uptime will be displayed in the VSM and used in the takt time analysis.

... ... .. .... ... ... .... ... .. ... .. .. .... .... .... .. ... ... .... .... ... ... .... ... ... .. ... .. ... ... ... ... ... ... .... . ...... ... ... . . ...... .... ... ... ... .... ... ... ... .. .. .... ....

Table 9: Machine downtime of 2009 in hours

The machines or equipment in the assembly line are pretty stable, except for the heat treatment furnace. The time to repair is very long. When the furnace is down, the company outsources the heat treatment process to a vendor. This will make sure that the other processes still could run.

5.2.5 First Pass Yield

Table 10 shows the First Pass Yield (FPY) of the inspection processes. For MPI and radiography, if the

product fails the inspection, it will be reworked in the full welding process. For hardness test, it will be reworked in the heat treatment process. The FPY data will be displayed in the VSM and used for takt time, capacity and manpower analysis.

Table 10: First Pass Yield (FPY) data

Month Machining MPI Radiography Hardness test Pressure

FPY % FPY % FPY % FPY % Test FPY %

Jan 2010 90.4% 95.7% 68.1% 90.4% 92.3% Feb 2010 85.5% 94.5% 73.9% 91.6% 97.3% Mar 2010 76.1% 98.0% 65.1% 92.2% 99.1% Apr 2010 62.0% 96.8% 71.2% 93.4% 99.4% May 2010 79.0% 100% 70.6% 91.5% 94% Average 78.6% 97% 70% 91.8% 96.4% 2009 Process U09ptime

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Total

Plasma Puasma 1 13 0 0 2 0 0 24 14 24 0 1 79 99% cutting _____ _______ ID welding 0 12 0 0 0 100 25 296 0 0 0 0 433 95% Full welding 1 4 15 0 3 80 0 2 2 1 0 0 108 99% OD grinding 18 0 104 0 104 0 46 0 8 4 5 1 290 97% Heat 0 9 8 0 0 2 500 359 175 190 6 4 1253 85% treatment Cold 0 0 0 0 0 0 0 7 0 0 1 0 8 100% straightening Kent Milling 1 1 0 0 0 10 17 0 1 6 2 0 38 100% machine .. ... ... .. .... .... .. ... ... ... ... .... ... . ... ... ... ... - - -...

5.2.6 Supplier Lead Time

There are three processes that are outsourced to suppliers which are radiography, threading, and sandblasting and painting. Table 21 in Appendix C shows the lead time quoted by the respective suppliers. The lead times depend on the quantity of products being sent to the suppliers. The products are being shipped out almost every one or two days.

The company monitors when the products are being shipped out and received from suppliers. Data from period January to May 2010 are analyzed to obtain the actual average lead time and average shipment quantity. The results are shown in Table 11.

Table 11: VSM data on outsourced process

Average Supplier Average Shipment Lead Time (days) Quantity (pieces)

Radiography 4 5

Threading 8 7

Sandblasting and Painting 4 10

These data are displayed in the current state VSM as the number of products before the outsourced processes and also the processing time of the outsourced processes. These lead times were assumed to be the processing times of the outsourced processes to simplify the calculation of total manufacturing lead time.

5.3 Takt Time Analysis - Current State

Table 12 show the summary of all the information displayed in the current state VSM and also the

calculated takt time of each of the processes. The takt time calculation of the fit up (oval) process is shown below as an example.

Takt time = Effective working time

Total demand for the products

no. of days per week x no. of shift x avail. hours per shift x operator availability x machine uptime

weekly demand + first pass yield

5 x 3 x 7 x 33% x 100%

38 0.9hours/piece

![Figure 3: Example of a current-state Map [7]](https://thumb-eu.123doks.com/thumbv2/123doknet/14047189.459771/19.918.129.796.134.546/figure-example-of-current-state-map.webp)