Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Internal Report (National Research Council of Canada. Division of Building

Research), 1963-05-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=98d8ad97-8bcd-4379-b9ad-611af666c7f2 https://publications-cnrc.canada.ca/fra/voir/objet/?id=98d8ad97-8bcd-4379-b9ad-611af666c7f2

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338021

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Properties of clay bricks manufactured in the Atlantic Provinces

NATIONAL RESEARCH COUNCIL CANADA

DIVISION OF BUILDLNG RESEARCH

PROPERTIES OF CLAY BRICKS MANUFACTURED LN

THE ATLANTIC PROVI NCES by

J. I. Davison

Internal Report No.

266

of the

Division of Building R e s e a r c h

OTTAWA May 1963

P R E F A C E

T h e l a b o r a t o r y r e s e a r c h a c t i v i t i e s of t h e Atlantic Regional Station of t h e Division a t H a l i f a x

a r e d i r e c t e d m a i n l y t o s t u d i e s of m a s o n r y p e r f o r m a n c e . Such s t u d i e s a r e c l o s e l y r e l a t e d t o t h e field p r o b l e m s encountered in providing t h e a s s o c i a t e d i n f o r m a t i o n s e r v i c e t o t h e c o n s t r u c t i o n industry. It h a s been p o s s i b l e a s p a r t of t h i s p r o g r a m t o a s s e s s the p h y s i c a l p r o p e r t i e s of c l a y b r i c k s m a n u f a c t u r e d in t h e Atlantic P r o v i n c e s . T h i s i n t e r e s t i n g and useful i n f o r m a t i o n is now r e p o r t e d . T h e a u t h o r , a c h e m i s t and a r e s e a r c h officer on t h e staff of t h e Atlantic Regional Station of t h e Division in H a l i f a x is engaged in l a b o r a t o r y and field studies of m a s o n r y and m a s o n r y m a t e r i a l s .

Ottawa May

1963

N. B. Hutcheon A s s i s t a n t D i r e c t o r

PROPERTLES O F CLAY BRICKS MANUFACTURED IN THE ATLANTIC PROVINCES

b y

J. I. Davison

T h e study of r a i n p e n e t r a t i o n in m a s o n r y walls a t t h e Atlantic Regional Station of t h e Division of Building R e s e a r c h h a s included, a s an e s s e n t i a l p a r t , a continuing r e v i e w of t h e p r o p e r t i e s of m a t e r i a l s u s e d in m a s o n r y c o n s t r u c t i o n in t h e a r e a . Information of t h i s n a t u r e is e s s e n t i a l in a p p r a i s i n g p r o b l e m s that o c c u r in t h e field. T h i s r e p o r t r e c o r d s d a t a on p r o p e r t i e s of c l a y b r i c k s m a n u f a c t u r e d and used in t h e a r e a . GENERAL F o r the p u r p o s e s of t h i s r e p o r t a b r i c k m a y b e defined as a s t r u c t u r a l unit, usually r e c t a n g u l a r i n shape, m a d e of c l a y o r s h a l e , d r i e d and burned o r f i r e d at t e m p e r a t u r e s up t o 2 0 0 0 ° F . T h e p r o p e r t i e s of b r i c k s , t h e r e f o r e , depend on t h e p r o p e r t i e s of t h e r a w m a t e r i a l s u s e d and on t h e conditions of m a n u f a c t u r e , i n p a r t i c u l a r t h e method of shaping t h e u n i t s and t h e t e m p e r a t u r e a t which t h e y a r e f i r e d . Clay and s h a l e b r i c k s a r e c u r r e n t l y m a n u f a c t u r e d b y one of t h r e e m e t h o d s , (a) soft -mud p r o c e s s , ( b ) stiff -mud p r o c e s s and ( c ) d r y - p r e s s p r o c e s s . Details on t h e m e t h o d s of m a n u f a c t u r e have been d i s c u s s e d b y ~ l u r n m e r ( ' ) .

In r e c e n t y e a r s b r i c k s u s e d i n m a s o n r y c o n s t r u c t i o n i n t h e Atlantic a r e a have been p r e d o m i n a n t l y c l a y and s h a l e m a n u f a c t u r e d b y t h e stiff-mud p r o c e s s ; although t h e r e a r e s o m e d r y - p r e s s b r i c k s u s e d , and during t h e y e a r Dunbrik h a s a p p e a r e d in c e r t a i n a r e a s . Sand-lime b r i c k s a r e not used, but s m a l l n u m b e r s of c o n c r e t e b r i c k s h a v e been u s e d t h r o u g h t h e y e a r s , m a i n l y as back-up units. C u r r e n t widespread u s e of the stiff -mud b r i c k i n t h e a r e a c a n

undoubtedly b e a t t r i b u t e d t o i t s g r e a t e r durability, which h a s enabled i t t o withstand t h e s e v e r e weather of t h e c o a s t a l r e g i o n s without d e t e r i o r a t i o n .

T h e b r i c k s used in t h i s study w e r e obtained f r o m the four manufacturing p l a n t s in the a r e a . T h r e e , which p r o d u c e four of t h e f i v e b r i c k s studied, u s e t h e w i r e - c u t stiff-mud e x t r u s i o n p r o c e s s .

T h e fifth b r i c k i s manufactured by a s e m i

-

d r y p r e s s p r o c e s s . T h e stiff -mud b r i c k s a r e commonly manufactured inmodular s i z e s , but other s i z e s and s h a p e s including Norman, Roman, and SCR units a r e a l s o available. Two of the four stiff -mud b r i c k s a r e r e d in colour, one i s buff, and one is brown. T h e r e a r e a

v a r i e t y of s u r f a c e t e x t u r e s with both solid and c o r e d units. T h e d r y - p r e s s b r i c k is manufactured a s a n 8- by 32- by 2i-in. solid unit, r e d in colour, with a smooth s u r f a c e texture.

R e s u l t s included in this r e p o r t a r e considered r e p r e s e n t a t i v e of t h e different b r i c k s . They have been collected over a period of

four y e a r s , and during t h i s t i m e v a r i a t i o n s in the p r o p e r t i e s of the b r i c k s have been encountered, probably due t o different m i x t u r e s of r a w m a t e r i a l s and t o variations in the d e g r e e of firing t o which the units have been subjected. In p r e s e n t i n g t h e data an attempt h a s been m a d e t o give over -all l i m i t s for p r o p e r t i e s of each b r i c k .

It should be noted that although the p r o p e r t i e s listed a r e considered to b e r e p r e s e n t a t i v e of t h e v a r i o u s b r i c k s , t e s t s w e r e conducted on r e l a t i v e l y s m a l l n u m b e r s .

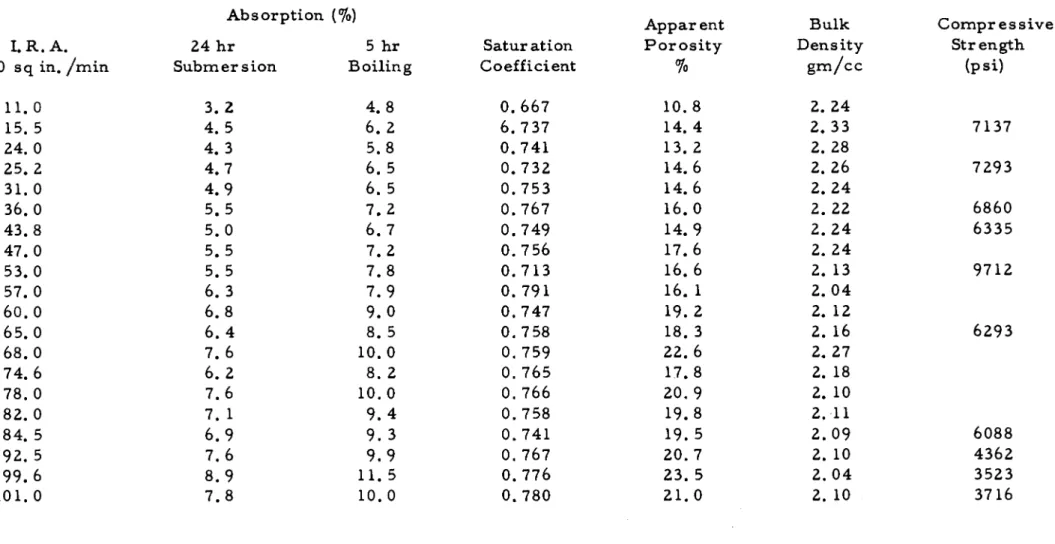

BRICK A

Initial r a t e s of absorption w e r e determined for a l l units i n a shipment of 471 d r y - p r e s s b r i c k s . Values ranged f r o m 11.0 t o

101.0 gm/min/30 s q in. T h e I. R. A. distribution i s shown graphically in F i g u r e 1, w h e r e i t can be s e e n that approximately 42 p e r cent w e r e in the 30 t o 50 gm/min/30 s q in. r a n g e and about 82 p e r cent w e r e within t h e 20 t o 70 gm/min/30 s q in. range. T a b l e I contains a r e c o r d of the p r o p e r t i e s of 20 b r i c k s s e l e c t e d a s r e p r e s e n t a t i v e of t h e over -all suction range. C o m p r e s s i v e s t r e n g t h values a r e l i s t e d for ten b r i c k s and a r e considered sufficient t o give a r e p r e s e n t a t i v e picture. Values in T a b l e I indicate t h a t t h e s e b r i c k s qualify a s Grade SW according t o CSA Specification A82. 7-1954 for facing brick. L a b o r a t o r y t e s t s , however, have r e s u l t e d i n consistent f a i l u r e during e a r l y s t a g e s of f r e e z e -thaw cycling t e s t s . T h i s i s c o n t r a r y t o r e p o r t s f r o m the field, w h e r e t h e r e h a s been no evidence of f a i l u r e b e c a u s e of l a c k of durability i n a r e a s experiencing s e v e r e weather conditions. It should b e r e c o r d e d t h a t b r i c k s s i m i l a r t o t h o s e t e s t e d in the l a b o r a t o r y h a v e been i n s e r v i c e i n the field for a r e l a t i v e l y s h o r t period, following changes i n r a w m a t e r i a l s and manufacturing p r o c e d u r e s . F i g u r e 2

gives a graphical p i c t u r e of t h e r e l a t i o n s h i p between the v a r i o u s

absorption p r o p e r t i e s and suction (initial r a t e of absorption). In general, absorption and p o r o s i t y values i n c r e a s e with i n c r e a s i n g suction and

BRICK B

I. R. A. v a l u e s for a shipment of 180 extruded b r i c k s a r e shown g r a p h i c a l l y in F i g u r e 3. T h e r a n g e is v e r y n a r r o w

-

2 t o 8 gm/min/30 s q i n . , with m o r e than 80 p e r c e n t of t h e shipment having v a l u e s between 3 and 6 gm/min/30 s q in. Absorptionp r o p e r t i e s f o r 22 of t h e b r i c k s , r e p r e s e n t a t i v e of t h e o v e r - a l l suction r a n g e , a r e l i s t e d in T a b l e I I , which a l s o includes c o m p r e s s i v e

s t r e n g t h values f o r t e n b r i c k s . T h e s e low absorption, high c o m p r e s s i v e s t r e n g t h b r i c k s , f a v o u r i t e s in t h e a r e a w h e r e t h e y have a good r e c o r d of field s e r v i c e , h a v e s u c c e s s f u l l y s u r v i v e d the p r e s c r i b e d 50 f r e e z e - thaw c y c l e s in t h e l a b o r a t o r y on m a n y occasions. Absorption p r o p e r t i e s f o r t h e s e b r i c k s a r e c o m p a r e d g r a p h i c a l l y with suction values in

F i g u r e 4. T h e r e l a t i o n s h i p s a r e quite s i m i l a r t o t h o s e noted f o r B r i c k A except t h a t t h e s a t u r a t i o n coefficient shows a pronounced i n c r e a s e with i n c r e a s i n g suction.

BRICK C

A second extruded b r i c k m a n u f a c t u r e d in a different plant, had even lower suction v a l u e s , a s indicated by t h e I. R. A. d i s t r i b u t i o n f o r a lot of 197 b r i c k s ( F i g u r e 5). Suction values w e r e a l l under

6 gm/min/30 s q i n . , with 90 p e r c e n t of t h e shipment l e s s t h a n 3 gm. O c c a s i o n a l l y b r i c k s of t h i s t y p e h a v e been found with suction values up t o 10 gm/min/30 s q in.

,

but t h e biggest p e r c e n t a g e is always under5 gm. P r o p e r t i e s of 16 s a m p l e s r e p r e s e n t a t i v e of a 1 t o 10 g m / m i n / 3 ~ s q in. suction r a n g e a r e l i s t e d in T a b l e I 11, which a l s o i n c l u d e s c o m p r e s s i v e

s t r e n g t h values for ten b r i c k s . Again t h i s b r i c k h a s s u r v i v e d c o u n t l e s s l a b o r a t o r y f r e e z e -thaw t e s t s without f a i l u r e s . A g r a p h i c a l c o m p a r i s o n of a b s o r p t i o n p r o p e r t i e s and suction v a l u e s i s shown i n F i g u r e

6,

w h e r e t h e r e l a t i o n s h i p s a r e s i m i l a r t o t h o s e f o r B r i c k B.

BRICK D

A t h i r d extruded b r i c k had a higher suction r a n g e , a s

indicated by t h e d i s t r i b u t i o n f o r a lot containing 194 b r i c k s ( F i g u r e 7). T h e I. R. A. r a n g e w a s 17 t o 34 gm/min/30 s q in. Various shipments examined during t h e ~ e r i o d of t h e study, however, r e v e a l e d d i f f e r e n t suction l e v e l s

-

m a n y lower than t h a t shown in F i g u r e 7. T h e l a t t e rr e p r e s e n t s r e s u l t s for a r e c e n t s h i p m e n t and is c o n s i d e r e d r e p r e s e n t a t i v e . Outside suction l i m i t s for t h i s b r i c k would b e 3 t o 35 gm/min/30 s q in. Only a s m a l l p e r centage in any given shipment would b e above

30 gm/min/30 s q in. P r o p e r t i e s f o r a r e p r e s e n t a t i v e group of 20 b r i c k s f r o m the lot shown in F i g u r e 7 a r e l i s t e d in T a b l e I V , which a l s o

includes c o m p r e s s i v e s t r e n g t h v a l u e s for nine of t h e b r i c k s .

T h e r e h a v e been no c a s e s of f a i l u r e in m a n y l a b o r a t o r y f r e e z e - t h a w t e s t s . F i g u r e 8 i n d i c a t e s t h e s a m e g e n e r a l r e l a t i o n s h i p s p r e v i o u s l y noted between a b s o r p t i o n p r o p e r t i e s and suction.

BRICK

E

An I.

R.

A. distribution f o r a lot of 395 of t h e fourthextruded b r i c k i s shown in F i g u r e 9. T h e r a n g e is 3 t o 36 gm/min/30 s q i n . , 80 p e r cent having suctions between 8 and 26 gm/min/30 s q in.

T h i s d i s t r i b u t i o n i s c o n s i d e r e d t h e o v e r - a l l r a n g e for the b r i c k . As noted for B r i c k D, v a r i o u s s h i p m e n t s during t h e p e r i o d of the study have r e v e a l e d m u c h n a r r o w e r suction l i m i t s . In s o m e i n s t a n c e s

s u c t i o n s h a v e r a n g e d below 10 gm, i n o t h e r s between 10 and 20 g m ;

a second I. R. A. distribution i s shown in F i g u r e 10. In t h i s i n s t a n c e 56 p e r c e n t of t h e b r i c k s had suction values under 7 gm, and t h e

r e m a i n d e r w e r e between 7 and 20 gm. P r o p e r t i e s for a r e p r e s e n t a t i v e group of 17 b r i c k s f r o m t h e lot with suction r a n g e 3 t o 36 gm/min/30 s q in. ( F i g u r e 9 ) a r e l i s t e d in T a b l e V, including c o m p r e s s i v e s t r e n g t h v a l u e s f o r ten b r i c k s . Like t h e o t h e r extruded u n i t s , t h e r e have been no

f a i l u r e s d u r i n g f r e e z e -thaw t e s t s for B r i c k E . T h e r e l a t i o n s h i p

between a b s o r p t i o n p r o p e r t i e s and suction values is shown in F i g u r e 11.

GENERAL

A c o m p a r i s o n of the p r o p e r t i e s of t h e five b r i c k s i s shown g r a p h i c a l l y in F i g u r e s 12 and 13. In F i g u r e 12 i t is i n t e r e s t i n g t o note t h e wide r a n g e of I. R. A. values for t h e d r y - p r e s s b r i c k in c o m p a r i s o n with t h e r e l a t i v e l y n a r r o w r a n g e s for t h e extruded b r i c k s . T h e g r e a t e r p e r c e n t a g e of e x t r u d e d b r i c k s h a v e suction values under 20 gm,

e s t a b l i s h e d in t h e l i t e r a t u r e a s t h e d e s i r a b l e r a n g e f o r good m a s o n r y , with d e c r e a s i n g n u m b e r s of two b r i c k s ( D and E ) above t h a t value. B r i c k s B and C, low suction units, h a v e highest c o m p r e s s i v e s t r e n g t h v a l u e s , and B r i c k s A and D a r e a t t h e other end of t h e s c a l e . G r e a t e s t s p r e a d in c o m p r e s s i v e s t r e n g t h v a l u e s was encountered with B r i c k E . Higher values might b e obtained for B r i c k D i f units having lower suction v a l u e s w e r e t e s t e d . One of the m o s t noteworthy f e a t u r e s of F i g u r e 13 i s t h e wide r a n g e of s a t u r a t i o n coefficients for B r i c k s B and C, which had v e r y low suction values within n a r r o w over -all l i m i t s . T h i s m a y r e f l e c t i n t e r e s t i n g d i f f e r e n c e s in t h e p o r e s t r u c t u r e of t h e s e b r i c k s , d e s p i t e t h e r e l a t i v e l y c o n s i s t e n t v a l u e s f o r suction and absorption. It is, of c o u r s e , t r u e that saturation coefficient values a r e not as significant for t h e s e b r i c k s , t h e i r d u r a b i l i t y being a s s u r e d

CONCLUSION

P r o p e r t i e s of five clay-shale b r i c k s manufactured and used in the Atlantic a r e a have been reviewed. Four extruded b r i c k s a r e commonly used in m a s o n r y throughout the a r e a , and the d r y - p r e s s brick i s used t o a l e s s e r degree in one section of the a r e a . A l l five have given good s e r v i c e in the field. T h e r e s u l t s of the study indicate that a l l five b r i c k s m e e t the r e q u i r e m e n t s of CSA 82. 7-1954 for

facing b r i c k s , Grade SW. The study a l s o i l l u s t r a t e s the variation in p r o p e r t i e s that can occur in clay-shale b r i c k s a s a r e s u l t of

( a ) different r a w m a t e r i a l s , (b) methods of forming the units, and ( c j d e g r e e of f i r i n g t o which the units a r e subjected.

BIBLIOGRAPHY

(1) P l u m m e r , H. C. B r i c k and t i l e engineering; handbook of design. Fir s t ed.

,

Washington, S t r u c t u r a l Clay P r o d u c t s Institute, 1950, 392p.TABLE I I.

R .

A. gm/30 s q in. /min PROPERTIES OF BRICK A Absorption (Yo) Apparent 24 hr 5 hr Saturation P o r o s i t ySubm er s ion Boiling Coefficient

'70

Bulk Density gm/cc Compressive Str ength ( p s i )

TABLE I 1 PROPERTIES O F BRICK B I. R. A. p1/30 s q in. /min Absorption (%) 24 h r 5 h r

Subm e r sion Boiling

S atur at ion Coefficient App a r ent P o r o s i t y '30 Bulk Density gm/cc C o m p r e s s i v e Strength ( p s i )

TABLE

I 1 1

PROPERTIES OF BRICK C

Absorption (To)

Bulk

I. R. A. 24 hr 5 hr Saturation P o r o s i t y Density

gm/30 aq in. /min Submersion Boiling Coefficient

'30

gm/ccI. R. A. gm/30 s q in. /min

Compressive Strength ( p s i )

TABLE I V PROPERTIES OF BRICK D I. R. A. gm/30 sq in. /min Absorption

(yo)

24 hr 5 hr Submersion Boiling Saturation Coefficient Apparent Porosity70

Bulk Density gm/cc Compressive Str ength (psi)TABLE V

PROPERTIES OF BRICK E

Absorption ((lo)

Bulk

I. R. A. 24 hr 5 hr Saturation Porosity Density

gm/30 e q i n . / m i n Submersion Boiling Coefficient (lo

V d c c

I.

R. A. gm/30 s q in. /minCompressive Strength (psi)

0 0 0 0 0 0 0 0 0 0

o J r c , * m U , I c m o o

a I I I I I I

- -

0

-

0 0 0 0 0 0 0 ~o J r c ) * m U , I c m m

INITIAL RATE OF ABSORPTION

( G M / M I N / ~ O SO IN.)

FIGURE I

T Y P I C A L IRA D I S T R I B U T I O N O F BRICK A

ABSORPTION % DRY WEIGHT SATURATION COEFFICIENT APPARENT POROSITY, O/o BULK DENSITY ( GM

/c.c.

)INITIAL RATE OF ABSORPTION

( G M / M I N / ~ O SQ IN.)

FIGURE 3

T Y P I C A L IRA DISTRIBUTION O F BRICK B

(180 IN LOT)

0

2 3 4 5 6 7 8

INITIAL RATE OF ABSORPTION

( G M / M I N / ~ ~ SQ IN.) 1 I I - x x x X X - X X x f X * l l x X * a - x x x X a a x - ** a -- a* a * a 24-HA IMMERSION - X 5-HR BOILING I I I I FIGURE 4

RELATIONSHIP BETWEEN IRA AND OTHER PROPERTIES OF BRICK B

BRICKS IN SELECTED IRA RANGE

ABSORPTION

O/o DRY WEIGHT

SATURATION COEFFICIENT APPARENT POROSITY, '10 BULK DENSITY (GM / C . C . )

BRICKS IN SELECTED

IRA

RANGE

O/o

OF TOTAL BRICKS IN LOT

-

-

IU 0 VI 0 VI 017-19

19- 22

22- 23

23-24

24-25

25- 26

26

-

27

27

-

28

28

-

29

29-34

I- z

=

9

52!

i

LIZ 0*

UY LIZ m 0 as

INITIAL RATE OF ABSORPTION

( G M / M I N / ~ O SQ IN.)

FIGURE

8RELATIONSHIP BETWEEN IRA AND OTHER

PROPERTIES OF BRICK D

oa 2881-8 IX i

- 1 X I I 10 13 12 1 X I X x X - --

2 4 - H R IMMERSION-

- X 5-HR BOILING - I I( xX I , x , - - - I X,.

X ' 1I

m

a

-

- - -

M CDV

8 I " a I C I U CI U t 3 zm

a

-

- - -

"

O

'

b

A

C U C U C UINITIAL RATE OF ABSORPTION

$

'FIGURE 9

'TYPICAL IRA DISTRIBUTION O F BRICK

E

(395 IN LOT)

INITIAL RATE OF ABSORPTION

( G M / M I N / ~ O SQ IN.)

FIGURE

10

T Y P I C A L I R A DISTRIBUTION

OF

BRICK

E

( 2 0 0 IN L O T )

BR. 288/-/00 5 10 15 2 0 25 3 0 35 4 0 INITIAL RATE OF ABSORPTION

(GM/MIN/~O SQ IN.)

FIGURE I I

RELATIONSHIP BETWEEN IRA AND OTHER PROPERTIES OF BRICK E

COMPARATIVE IRA RANGES

0

A B C D E

FIGURE 12

COMPARATIVE COMPRESSIVE STRENGTH RANGES

2 4 - H R IMMERSION 5 - HR BOII-ING SATURATION COEFFICIENT

ABSORPTION, '10 DRY WEIGHT