Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Fire and Materials [Proceedings], pp. 1-10, 2007-01-31

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=c14542e1-ccdd-41f2-a574-9796ee77d1cc

https://publications-cnrc.canada.ca/fra/voir/objet/?id=c14542e1-ccdd-41f2-a574-9796ee77d1cc

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Impact of board orientation on the fire performance of regular gypsum

board walls

Impact of board orientation on the

fire performance of regular

gypsum board walls

Bwalya, A.C.; Sultan, M.A.; Thomas, J.R.

NRCC-49244

A version of this document is published in / Une version de ce document se trouve dans:

Fire and Materials (San Francisco, January 29-31, 200}, pp. 1-10

The material in this document is covered by the provisions of the Copyright Act, by Canadian laws, policies, regulations and international agreements. Such provisions serve to identify the information source and, in specific instances, to prohibit reproduction of materials without written permission. For more information visit http://laws.justice.gc.ca/en/showtdm/cs/C-42

Les renseignements dans ce document sont protégés par la Loi sur le droit d’auteur, par les lois, les politiques et les règlements du Canada et des accords internationaux. Ces dispositions permettent d’identifier la source de l’information et, dans certains cas, d’interdire la copie de documents sans permission écrite. Pour obtenir de plus amples renseignements : http://lois.justice.gc.ca/fr/showtdm/cs/C-42

IMPACT OF BOARD ORIENTATION ON THE FIRE

PERFORMANCE OF REGULAR GYPSUM BOARD

WALLS

ABSTRACT

Alex Bwalya, Mohamed Sultan, Russ Thomas Fire Research Program

Institute for Research in Construction National Research Council of Canada

Ottawa, Canada KlA OR6

Although there have been numerous studies on the fire performance of fire rated wall systems over the years, little attention has been focused upon the fire resistance performance of regular gypsum (non-fire rated boards) that are commonly used in partitions/walls of residential houses. In trying to understand the impact of partition walls in the spread of fire within existing fire compartments, it is important not only that a body of data is established that will aid the development of models that can aid in the prediction of such fire spread but also to determine the inherited fire resistance for these type of non-fire rated boards. Even though construction practices adopted in different countries vary, it is frequently found that these types of partitions are constructed using either vertical or horizontal orientation of the long side of the gypsum boards. The use of horizontally applied boards often result in a more rapid assembly construction process, though at the cost of considerable areas of the resulting board joints being unprotected with studs behind them.

A recent series of studies at the National Research Council of Canada (NRCC) was undertaken to investigate the fire performance of these types of assemblies in order to provide data on this phenomena and for other studies looking at the fire performance of houses. In a series of twelve full-scale fire tests of non-insulated loaded and unloaded wall assemblies, the impact of board orientation was studied using the standard time-temperature curve (CAN/ULC-S101-M891, ASTM E119-882).

Initial studies3 have indicated that the average fire resistance of the unloaded walls with vertical orientation of the gypsum boards is approximately 28 min and that of walls with horizontal orientation of the gypsum board is 30 min. The fire resistance ofloaded walls is approximately 23 min for vertical orientation and 26 min for horizontal orientation of the gypsum boards. These results indicate that the orientation of the regular gypsum board has little effect on the fire resistance of these types of assemblies. The cracked sections of gypsum board tended to fall off earlier in the walls with gypsum boards applied vertically to the studs, resulting in slightly reduced fire resistance and a greater extent of charring to the studs.

Information on the gypsum board characteristics and the impact of board orientation on the fire performance ofthe regular gypsum board is discussed below.

INTRODUCTION

During the last two years the Fire Research (FR) program at the National Research Council of Canada's Institute for research in Construction (NRC-IRC) has begun an investigation of the fire performance ofhouses. One aspect of the performance of typical Canadian houses is the fire behavior of the regular gypsum partitions used to form rooms and areas within the homes.

Current Practices

Although the general practice in Canada when constructing these non-fire-rated separations is to lay the gypsum board vertically with board joints in line with the studs, it is also becoming common to observe gypsum boards being applied horizontally across the studs. Within a single-family dwelling most codes do not require that separations within the dwelling be of fire-rated construction and as a result, regular (non fire-rated) gypsum board is typically used to form the room and other area separations within the house. The horizontal application of gypsum board is sometimes preferred because of the relative ease of application (a single joint at4 ft is easier to tape) and related cost savings.

Although NRC-IRC' s FR program has developed a very substantial body of data on the performance of fire-rated walls over the last 50 years, relatively little of this has included studies of walls using "regular" gypsum board4 and no data has been previously generated on the performance of horizontally applied regular gypsum board. At the same time, there is a growing need to more fully understand the dynamics of fire spread within houses and the degree of inherent protection against fire spread offered by these non fire related separations.

Fire Challenge

Most of the data that has been generated on the fire performance of wall systems has been produced in the context of testing to one or more of the National or International Standards that exist around the world. Typical of these are the ASTM £119-882, the Canadian CAN/ULC-SJOJ-M89\ and the ISO 834-e

standard tests for fire resistance of construction building elements, all of which use fairly similar fire growth curves. Although these standard fire curves are a century old, which may have been representative of the real fires at the time, there is mounting evidence that they are no longer represent the types of fires seen today. This is clearly understandable as there have over the past almost 100 years, been some very substantial changes in both the types and quantities of combustibles found within buildings. This of course includes houses where, if anything, these changes have been considerably greater than in many other settings.

METHOD

At this stage of the investigation into the frre performance of houses, it was decided that the issue of gypsum board orientation would initially be undertaken using the standard fire development curve rather than using the one especially developed for our current houses project. This would permit us to compare the results with our extensive body of existing data on the fire performance of fire-rated wall assemblies. For similar reasons, it was decided to use wood rather than steel studs in the study, as again this would permit comparisons with the larger body of existing data held by the FR program.

These tests were undertaken following the CANIULC-S I 0 l-M89, "Standard Methods of Fire Endurance Tests of Building Construction and Materials" which is similar to the ASTM El19-88 "Standard Test Method for Fire Tests ofBuilding Construction and Materials", for wall assemblies and using the

NRC-IRC

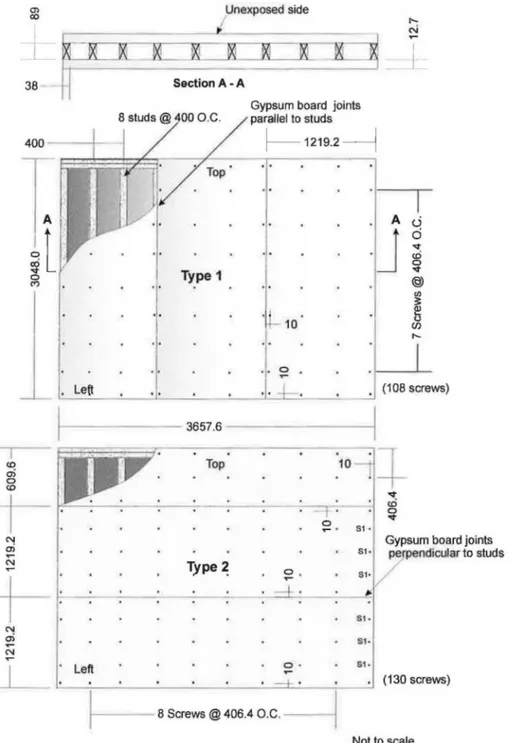

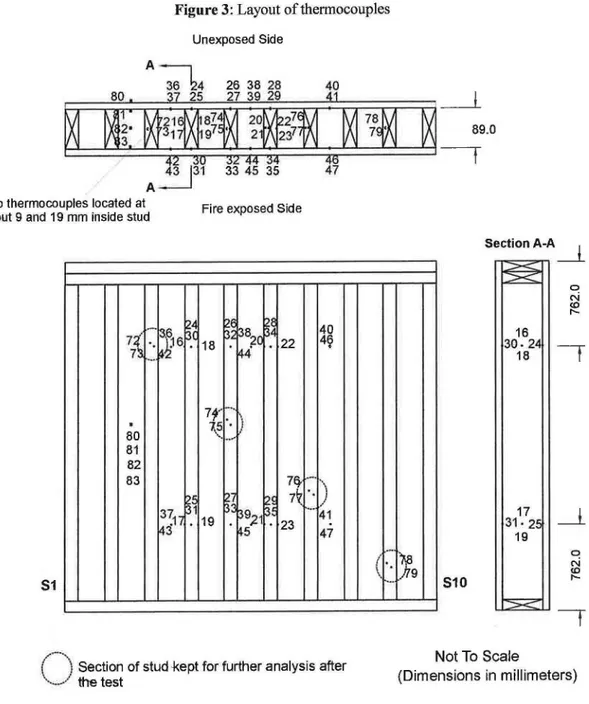

FR program's wall furnace. The furnace temperature was measured by nine (20 gauge) shielded thermocouples and the average of these thermocouples was used to control the furnace temperature in such a way that it followed, as closely as possible, the CANIULC-Sl01-M89 standard temperature-time curve.Details of the assemblies are provided in Figure 1 for both horizontal and vertical orientations of gypsum boards installation. The layout of the standard thermocouples on the unexposed side is presented in Figure 2. The horizontal single layer sheets of 12.5mm regular gypsum bQar4 were derived from a single

board of 12 by 4 foot and the vertical sheets were derived from 10 by 4 foot boards. In addition to the standard instrumentation specified in CAN/ULC-Sl01-M89, numerous thermocouples were also placed within each wall assembly in order to obtain temperature histories at various

Figure 1. Dimensions and layout of wall assemblies (fire-exposed side shown). (Type 1 Vertical orientation; Type 2: Horizontal orientation)

38

Tt

0 C') Unexposed side Section A -A Type 1 Top tケー・セ@Gypsum board joints parallel to studs

セ

QRQYNR

セ@

. Au

·J

i

セ N@ 51 51 · @)セ@

en,._

(108 screws)Gypsum board joints perpendicular to studs

+--

f:----:--:---:--- --=----:---:---___.__,_--:---""S1 .1 N cri セ@ N Left 0 . S1 · 51· ( 130 screws) t - - - - -8 Screws @ 406.4 O.C. - - - 1S1 Screws @ 406 .4 O.C. of each board

Not to scale (Dimensions in millimeters)

locatiQnS- during the fire tests. Type K (20 gauge) chromel-alumel thermocouples, with a thickness of 0.91 mm,-were usc!d-for measuring the temperatures ofthecwaW surface on the gypsum board surfaces facing tbe-Wa.ILcavity, teh\peratures within studs, as. well as the ゥョイ・イヲゥエᆱセ@ betw€en the gypsum board

and stud (see Figure 3).

Figure 2. Location of thermocouples on the unexposed surface of an assembly

3657.6

c

! I 2IZl

10 1 ! 15 7MMMMMセMMMMMMMMM

M M M セMMMMMMMMᄋMMMセMMMMMセM

M M Mᄋ@

i

! I 4 12 14i

3IZl

XX

i

!IZl

8 !

C"'セ@

(C ... 0 0..,.

c

Furnace

J ame

Ceramic ·

blanket

/ - t.IZilnsulated thermocouple (mandatory under the CAN/ULC-S101-M89 standard) X Non-insulated thermocouple (not mandatory)

Not to scale (Dimensions in millimeters)

The assembly was considered to have failed if one of the following failure criteria as per CANIULC-S 101-M891 Standard, should{)ccur:

1. A single point temperature reading measured by one of the nine thermocouples under insulation on the unexposed surface rose 180°C above the ambient temperature,

2. The average temperature measured by the 9 thermocouples under the insulated pads on the unexposed surface rose 140°C above the ambient temperature,

3. There was passage of flame or gases

.hot

enough to ignite cotton waste, and 4. The assembly is no longer able to bear the applied load.Although the main set of tests were conducted using non load-baring designs, one test of each a horizontally applied and vertically applied_gypsum board wall assembly was tested under load conditions (see Table 1).

RESULTS AND DISCUSSION

The key data from the set of experiments are presented in Table I. The data from tests 5 and 6 were not included in the initial analysis nor was the data from the Old NRC test, as each of these represents a slightly dif ferent aspect of the topic under study.

Figure 3: Layout of thermocouples

Two thermocouples located at about 9 and 19 mm inside stud

7A セ@

t-.

80 81 82 83 51 3f16 セ セ@.

3714:P

Unexposed SideFire exposed Side

セセ@

セセ@

j382Cセセ@

40 18 22 49 j44 1?''..

1.5 ·,,.. I)

....

7(}. \

25 21 Rセ@ Wセ@ . Iセᄋ

QQY@

bZセァNRQ@

セQ@

.... / 41 • セU@ • 23 47( - ·) Section of stud -kept for further analysis after

セNNNQ@ the test I-I • \

.

··r-·

セ@ /19 510 Not To Scale (Dimensions in millimeters)Table 1. Experimental parameters, material characteristics and experimental results of the fire tests

Test Gypsum board Applied Failure point Mass of Calculated Mass of wood Fire resistance Failure mode Gypsum board

number orientation 1 load thermocouple Gypsum board frame (min) (regular 1/2 inch)

(kN) number board (kg)

(k )

1

v

-

6 175.8 NA 28 Insulation2 BPB ProRoc/Westroc2 H

-

2 175.8 7.87 69.6 26 Insulation BPB ProRoc!W estroc3 H

-

2 174.0 7.80 69.2 34 Insulation BPB ProRoc/Westroc4 H

-

2 NA NA NA 30 Insulation BPB ProRoc/WestrocI

5

v

68.8-

170.6 7.64 NA I 23 Structural BPB ProRoc/Westroc6 H 68.8

-

172.2 7.71 65.2 26I

Structural BPB ProRoc/W estroc7

v

-

2 169.9 7.62 NA 26 - I Insulation CGCSHEETROCK 8v

-

4 169.3 7.59 62.8 29 Insulation CGCSHEETROCK 9v

-

2 169.2 7.59 66.5 30 Insulation CGCSHEETROCK 10 H-

5 176.1 7.90 67.0 30 Insulation CGC SHEETROCK 11 H-

9 177.6 7.97 67.3 30 Insulation CGCSHEETROCK 12 H-

6 177.6 7.97 68.5 30 Insulation CGCSHEETROCK -Old 26 Insulation NRC3v

-1 Orientation of gypsum board: V - Vertical; H - Horizontal

z

Single-point insulation failure: Temperature of one thermocouple exceeding 180 °C above its initial temperature3 Sultan, M.A., Lougheed, G. D., Denham, E. M.A., Monette, R. C., and MacLaurin, J. W., "Temperature Measurements in Full-Scale Fire Resistance Tests on Non-Insulated

Regular Gypsum Board Wall Assemblies", NRC Internal Report, Vol. No. 674, December 1994. Tests 1-6: First series of tests

Gypsum Board Density

Figure 4 and Table 2 presents a summary of the differences in the density of the gypsum board that was used in the study. Analysis of these data indicate that the gypsum sheets used for the vertical application and sourced from CGC were significantly (F(3,8)=50.6 P<0.004) less dense than any of the other board materials used in the study.

There was though no evidence from the data that the fire resistance as recorded in the experiments were significantly related to the board density (r=O.l611, ns.).

8 (/) c

:ll

7.9 :::2: "0セWNX@

... Ill 0 N .0 E "0 o,7.7 Q)-

セ@ .!!! >-::J ·]j 7.6 uro

c Q) 0 "0 7.5Table 2. Mean Density (Kg/m2) of gypsum board

Horizontal Vertical BPB ProRoc/W estroc 7.835 7.870

CGCSHEETROCK 7.947 7.600

Figure 4. Differences in gypsum board density

H

v

Gypsum board orientation

BPB ProRoc/Westroc; -CGC SHEETROCK

"*

Impact of Board Orientation- Unloaded Assemblies

Four vertically oriented and six horizontally oriented unloaded assemblies were tested and although they all failed due to the insulation criteria in ASTME-119/ULC SlOl after an average of29.3 minutes (SD= 2.31 min.) there was no significant difference between them based upon the board orientation (see Table 3).

Table 3. Time to failure of non fire-rated walls using vertical and horizontal oriented gypsum boards

Horizontal Vertical

Average 30.00 min. 28.17

Std. Deviation 2.53 min. 1.71 min.

Number tested 6 4

Impact of Board Orientation- Loaded Assemblies

Only one test each of a vertically and horizontally oriented loaded wall assembly was conducted in this series of tests. This was with the purpose of ascertaining ifthere was a significant difference in the overall performance from the unloaded wall case. The average duration of fire resistance for the loaded assemblies

Figure 6. Furnace control temperatures at selected levels

(FU-3, FU-6 & FU-9 are at the upper mid and lower levels on the right side of the furnace)

u (I)

.,

.,

1:;,.,

c 1100 1000 900 800 700 u 600 セ@ 15. セ@ 500 400 300 200 100 0 1100 1000 900 800 700 600 500 400 300 200 100 0 0 5 10 15 20 Time (minutes)Figure 7. Furnace and data collection thermocouples for Test 11

Furnace Control TC close to TC 42

/

('

セM 1---+'- --1180 c 5 10 15 Time (minutes) 20 25 25be determined if this finding would hold when a "natural" design fire, such as that presently being used in the NRC-IRC FR program's fire performance of houses project6, is used. These fires tend to have a

faster fire growth than the "standard" fire used in this study. This may result in a greater thermal impact on the gypsum board, which being the main line of defense in such assemblies, could be subjected to excessive cracking and mechanical disruption which may open up the assemblies and permit the entry of the fire into the cavity at an earlier stage and result in assembly failure significantly earlier than that found in the present study.

In addition, the current study indicated that there was no evidence of a systematic impact of regular gypsum board orientation on the studs although it may not be appropriate to extrapolate these finding to fire rated assemblies.

There was evidence of a significant reduction in fire performance for the loaded assemblies compared to that for non-rated assemblies, which is clearly in line with prior findings with fire rated assemblies. In the present case this reduction was in the order of 5 minutes although there was not sufficient data available to indicate if gypsum <>rientation had a significant impact on loaded assemblies.

It was interesting to discover that the gypsum boards that were used in the current study demonstrated a significant difference in their density, although this appears to be confined to a single source7• Although it

was found that with the "regular" (non fire-rated) gypsum board used in this study, there appeared to be no relationship between board density and the fire resistance of the test assemblies. This was somewhat contrary to previous findings where multiple layers of gypsum were used4•

REFERENCES

I. CAN/ULC-S 1 01-M89, Standard Methods of Fire Endurance Tests of Building Construction and Materials. Underwriters' Laboratories of Canada, Scarborough, ON, 1989.

2. ASTM E119-88, Standard Test Method for Fire Tests of Building Construction and Materials, ASTM, West Conshohocken, PA, 1988.

3 Bwalya, A.C. Fire Resistance Tests of Non-Insulated Walls with Parallel and Perpendicular Orientation of Gypsum Board, Research Report, Institute for Research in Construction, National Research Council Canada, 188, pp. 31, June 27, 2005

4 Sultan, M.A.; Lougheed, G.D. Results of Fire Resistance Tests on Full-Scale Gypsum Board Wall Assemblies, Internal Report, Institute for Research in Construction, National Research Council Canada, 833, pp. 88, August 01, 2002

5 Taber, B.C.; Bwalya, A.C.; McCartney, C.; Benichou, N.; Bounagui, A.; Carpenter, D.W.; Crampton, G.P.; Kanabus-Kaminska, J.M.; Kashef, A.; Leroux, P.; Lougheed, G.D.; Su, J.Z.; Thomas, J.R. Fire Scenario Tests in Fire Performance of Houses Test Facility- Data

Compilation, Research Report, Institute for Research in Construction, National Research Council Canada, 208, pp. 86, March 31, 2006

6 Bwalya, A.C.; Carpenter, D.W.; Kanabus-Kaminska, J.M.; Lougheed, G.D.; Su, J.Z.; Taber, B.C.; Benichou, N.; Kashef, A.; mセ。イエョ・ケL@ C.; Bounagui, A.; Thomas, J.R. Development of a Fuel Package for Use in the Fire Performance of Houses Project, Research Report, Institute for Research in Construction, National Research Council Canada, 207, pp. 26, March 31,2006 7 Thomas, J.R.; Sultan, M.A.; Latour, J.C. "Impact ofthe variability ofType X gypsum board,"

2005 Fire and Materials Conference (San Francisco, January 31, 2005), pp. 131-137, January 01,2005