Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Ice in the environment: Proceedings of 16th International Symposium on Ice, Dunedin, New Zealand, December 2002, 2002

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=b7c6076d-e905-4abe-96fb-3390bdca9f00 https://publications-cnrc.canada.ca/fra/voir/objet/?id=b7c6076d-e905-4abe-96fb-3390bdca9f00

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Can dynamic recrystallization and bulk pressure melting explain characteristics of ice crushing? Discussion

Ice in the Environment: Proceedings of the 16th IAHR International Symposium on Ice Dunedin, New Zealand, 2nd–6th December 2002

International Association of Hydraulic Engineering and Research

CAN DYNAMIC RECRYSTALLIZATION AND BULK PRESSURE

MELTING EXPLAIN CHARACTERISTICS OF ICE CRUSHING?

DISCUSSION

Paul Barrette and Ian Jordaan1

ABSTRACT

This paper addresses the comments made by Gagnon (this volume) regarding the model of Jordaan and colleagues to account for cyclic loading during ice-structure interaction. We emphasize the existence of a zone of damaged ice at the indentor interface, whose internal structure conforms with what is observed from confined compressive testing. There is no evidence that dynamic recrystallization cannot take place at very high strain rates as our observations indicate. Pressure melting is thought to occur only locally. Spall formation and layer extrusion cannot be distinguished on video sequences. Gagnon’s statements on the numerical modeling are corrected and put into proper context. Indentor displacement on load upswing is not negligible and is sufficient to drive layer formation. The model is compared with Gagnon’s interpretation of load cycling and questions about his model are outlined.

INTRODUCTION

This Discussion has been written in response to the paper presented by R. Gagnon during the Ice Crushing Workshop (this volume), which raises a number of objections aimed at invalidating the model of Jordaan and his co-workers. We appreciate this opportunity to clarify concepts that are either misunderstood or overlooked in Gagnon’s paper.

THE MODEL

The model conceived by I. Jordaan and his collaborators (Jordaan et al. 1999, Jordaan 2001) attempts to reconcile and explain all evidence documented from the interaction between ice and an engineered structure (typically a steel indentor). It is, by necessity, relatively complex and it departs significantly from the perspective traditionally adopted by engineers when dealing with ice failure. An outline of this model is provided in Barrette et al. (this volume). It should be noted that we consider fractures and spalls most important in the scale effect of ice-structure interaction. Spalls reduce considerably the contact area in high pressure zones and fractures can remove them entirely. The

1

Ocean Engineering Research Centre, Memorial University of Newfoundland, St. John's, NF, Canada A1B 3X5

issue referred to by Gagnon is concerned with the failure of high pressure zones themselves, which in the model is associated with the development of a damaged layer in the ice.

GAGNON’S OBJECTIONS Layer or no layer?

Critical to Jordaan et al.’s model is the occurrence of a layer of damaged ice at the ice-structure interface which has been documented by several investigators (see references in Barrette et al., this volume). The best observations available of this layer were made by Sinha and Cai (1992) in carefully prepared ice specimens from various indentation surfaces. They show that the areas of ‘blue ice’, or apparently undamaged ice near the centre of high pressure zones, are in fact strongly recrystallized. A layer of damaged ice is also reported in Barrette et al. (this volume) from a scaled-down version of medium-scale field indentation. Features strikingly similar to those described from the field are observed in the laboratory specimens. It should be noted that this layer was observed in all the indentation events that were examined by Sinha and Cai (1992) in the field and those that we performed in the laboratory.

The observations gathered during Gagnon’s own field and laboratory investigations have revealed little if any evidence of such damage. This intriguing discrepancy may be explained by the fact that Gagnon’s observations were made from areas along the ice-structure interface where the layer, for some reason, did not occur. This may be the case, for instance, if the observations were made from a very small high pressure zone. In order to distinguish grain refinement due to recrystallization and that due to microcracking, appropriate lighting conditions (with both transmitted and reflected light) are required during thin section examination. Another possibility therefore is that the observer failed to recognize the nature of the ice damage. Yet another alternative is that such damage in the ice was observed but was not considered significant. This is the case in Gagnon (1998) where Figure 10 shows such grain refinement (the nature of which is not explained) near the surface of the ice and what appears to be a recrystallized texture 25 mm below the surface.

Effects of confinement on the deformation behaviour of ice

Ice is eminently brittle. Upon rapid loading, it fractures even when it is near or at melting temperature. This is in sharp contrast to many other materials which, at very high homologous temperatures, will dent like a bar of soap when dropped on a hard surface. But what if the loading event takes place under a confining pressure that is high enough to prevent the formation of cracks? A survey of previous investigations on confined testing of ice (Barrette 2001) indicated that very few included thin section examination of the ice following testing. Those that did reported microcracking from tests done at low confining pressures (Mizuno 1998, Stone et al. 1997). Recrystallization was documented from tests done at higher confinements (Stone et al. 1997) and from triaxial configurations (Schulson and Gratz 1999). The most comprehensive study was done by Meglis et al. (1999), who showed a strong recrystallization texture for tests done at a confinement of 50 MPa and higher, without evidence for microcracking. Contrary to the densely microcracked ice, which is opaque, recrystallized ice is transparent.

remarkably well with those documented from indentation tests. This is not fortuitous: Very high pressures (up to 70 MPa) were recorded during indentation. Recrystallized ice occurs in the centre of the high pressure zones, and is surrounded by microcracked ice toward the margins of these zones (Sinha and Cai, 1992, Barrette et al. this volume).

Recrystallization

The example of recrystallization provided by Gagnon was retrieved from the research done by Chris Wilson and his colleagues in the early to mid-80’s with a plane strain deformation apparatus. This device is described in Wilson (1984) and additional information on the deformation behaviour of ice is provided elsewhere (Wilson 1986, Wilson et al. 1986). They report on several mechanisms taking place in the ice, including the one described by Gagnon. This includes: slip band formation, grain rotation, kinking, grain nucleation and grain boundary migration. These investigations resulted in a very effective means of illustrating recrystallization processes taking place in ice (although care should be taken in applying these observations to a fully confined environment, as suggested by the resulting distributions of c-axis orientation, which showed double maxima instead of the expected small-circle girdles). They demonstrate that dynamic recrystallization is a phenomenon that is much more complex than implied by Gagnon. What he refers to as ‘initial disruption’, presumably the process by which energy is initially stored into the material as crystal defects, occurs simultaneously with the rearrangement of the atomic structure into a more stable form. This is why the mechanism is defined as dynamic.

We understand that dynamic recrystallization in ice has traditionally been assigned to slow deformation, typically that which occurs in glaciers. But what evidence is there that this phenomenon can not occur at much faster strain rates? Gagnon correctly points out that it is a thermally activated process. On that basis, he argues it must therefore be slow. We argue the opposite, keeping in mind that ice, under conditions of engineering interest, is a very high temperature material. Recrystallization mechanisms will be promoted, especially under high hydrostatic pressures with associated high strain energies. Barrette and Jordaan (2001) provide indications that the abrupt failure of a highly confined ice specimen occurred through recrystallization processes. We fully expect to see evidence for even faster rates emerge eventually from future research.

Pressure melting

Gagnon found the need to elaborate on bulk pressure melting after discarding, on questionable grounds as discussed above, the effectiveness of dynamic recrystallization. His argument is based on the analysis of a grain that is 14 mm in diameter. The model conceived by Jordaan et al. considers an ice mass with grains that have been refined, through recrystallization and microcracking processes, to sizes as small as 1 mm.

Barrette and Jordaan (Barrette, P.D. and Jordaan, I.J. Pressure-temperature effects on the compressive behavior of laboratory-grown and iceberg ice. Cold Regions Science & Technology 36: 25–36) document a considerable reduction in the compressive strength of ice at high hydrostatic pressures. This occurs concurrently with a sharp increase in activation energy, indicative of pressure melting. Note that this mechanism is suspected to occur only locally, perhaps at grain boundary junctions where the pressure is highest. It may become progressively more important as the ice approaches its melting point.

On the question of the amount of melt produced, all that is required is the amount of temperature variation. Is Gagnon suggesting that there is another mechanism for the temperature change? The location of the high pressure zones continually fluctuates and we consider it most likely that pressure melting occurs in zones of high pressure. Perhaps further experiments are required. We also note that the process of melting and freezing is a reversible phenomenon, and not associated with dissipation.

Spall or extrusion event?

Gagnon’s data collected from in situ observations during medium-scale field testing events document the sudden sideways motion of material, coinciding with a drop in load. This information is fully consistent with the present model. The difference lies in the nature of the contact between the material that moves and the material that remains in place. Gagnon considers it is a fracture surface—or spall. Jordaan et al’s model advocates a boundary between the opaque microcracked ice and the clear recrystallized ice. This boundary, as thin section observations demonstrate, is remarkably sharp (see Fig. 13 in Jordaan 2001). The video recordings made during these tests do not allow to distinguish between these two possibilities.

It is not necessary for the ice to resume its original strength after each cycle, as stated by Gagnon. In fact, this is one of the key facets of layer dynamics and is what makes it such a challenge to reproduce with a numerical model, both in terms of calibration against laboratory data and constitutive modeling.

Numerical modeling

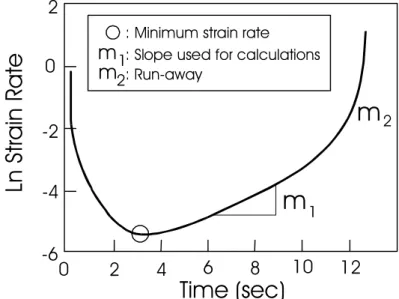

The model considers that the state of strain in the layer is much beyond that normally envisaged in conventional ice engineering methodologies, where the ultimate yield strength and the strain at which it occurs (typically below 1 or 2 %) are the main test parameters. Calibration of the numerical simulation of the model is therefore done with ice specimens deformed to very large strains (over 30 %). The details of data analysis and theoretical approach is provided elsewhere (Melanson et al. 1998, Jordaan et al. 1999). An example of a strain rate response is shown in Fig. 1. To date, our simulations relied on the portion of the curve immediately following the minimum strain rate. Some specimens have also shown, as indicated in this figure, what we refer to as run-away

0 0 2 2 -2 4 -4 6 -6 8 10 12

Time (sec)

Ln

S

tr

ai

n

Ra

te

m

m

m

m

: Minimum strain rate

: Slope used for calculations : Run-away

Figure 1: Example of a deformation curve used to derive the damage parameters.

1

1 2

behaviour, where the strain rate undergoes a rapid increase until specimen failure. This was our first evidence of a material instability and it has to be handled carefully. The challenge is to factor in the actual response of the ice and the levels of strains that should be considered. What are the strain levels in the damage layer? It is one of a number of aspects we are still working on to improve the numerical simulations.

The use of the load simulation in Figure 5 of Gagnon’s paper is inappropriate. The slopes on the upswing do not agree with the measurements, showing that the actual area of ice carrying the load is certainly much smaller than was assumed in the model (we are not sure how Gagnon arrived at this comparison).

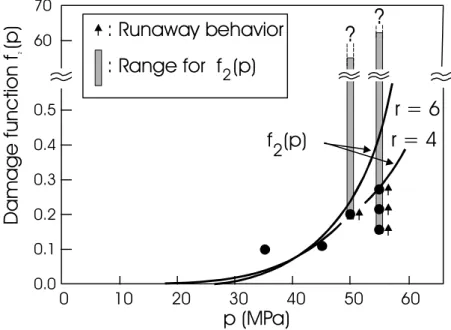

In his Figure 6 and accompanying text, Gagnon omitted information from Jordaan et al. (1999), where the data was accompanied by arrows, along with the following text: ‘The value of r is difficult to assess, since a runaway situation developed …, indicated by the arrows in Figure 11.’ Our arrows in the original paper were intended to indicate the presence of material softening with extremely high strains. Gagnon did not refer to the runaway situation. On that basis, he questioned the choice Jordaan et al. (1999) made for the value of r. Figure 2 shows the data as it could have been presented to illustrate the consequences of run-away (the higher range of r values were determined from the steeper part of the deformation curve in Fig. 1). It can be seen from Figs. 1 and 2 that, depending on whether or not a material instability exists, extremely high values for r can be achieved.

No numerical simulation can fully match reality. But we are encouraged by the progress made over the years, particularly in the reproduction of the downswing in load. We believe that a slip plane develops due to the very high strains between the damaged layer and the (relatively) undamaged ice behind. Slippage along this boundary, referred to as a pulverization front, accompanies extrusion. The finite element model is a continuum model that does not easily permit inclusion of such phenomena. We suspect

Dam a ge f u nc tio n f (p)2 p (MPa) 0.0 0.1 10 0 20 30 40 50 60 0.2 0.3 0.4 0.5 60 70

r = 4

r = 6

f (p) : Runaway behavior : Range for f (p)?

?

Figure 2: Clarification of the presentation in Figure 11 in Jordaan et al. (1999). Gagnon’s paper overlooked the small arrows used in the original paper to indicate that the data points are lower bound values.

2

removal of this limitation will explain further details, such as raising the value for r to almost infinity.

Indentor displacement

According to the data presented by Gagnon (1998, Fig. 7) and taking into account his correction for the compliance of the ice (0.29 mm/MN), the displacement on the upswing of the loading events is 20–30 % of that on the downswings, which is far from negligible. Considering that the zone in which ice damage takes place is very thin, this displacement translates into a relatively high local strain, sufficient to drive layer development. A detailed analysis of this issue is provided in Meaney et al. (1996).

A COMPARISON WITH GAGNON’S MODEL

Figure 3 summarizes and compares the main features of Jordaan’s et al.’s model with Gagnon’s account of cyclic loading based on his own observations. The main difference between the two stances lies in what is thought to happen during the upswing in load (A and B). The present model considers that a small amount of forward indentor motion takes place on the upswing, which provides the energy required for damage production in the ice. Gagnon does not acknowledge such damage and considers that indentor motion is negligible while the ice remains mostly intact but under increasingly higher load. In C, both stances envisage removal of ice from the ice-structure interface during the load downswing, concurrent with most of indentor displacement. In Jordaan et al’s model, this would correspond to the outward burst—or extrusion—of crushed material upon failure of the high pressure zone through recrystallization mechanisms and localized pressure melting. Gagnon considers that, upon leaving the ice-structure interface, a sliver of ice—or spall—causes the load to be concentrated in the high pressure zone. The latter collapses due to viscous flow of water generated by pressure melting, which generates heat and causes rapid additional melting of the ice.

It can be seen from Figure 3 that there are a number of issues Gagnon’s interpretation does not address. They are summarized as follows. 1) As mentioned earlier, a proper understanding of the interaction event should account for the presence of a layer of crushed ice, with recrystallized textures in high pressure zones. 2) It appears improbable that, when ice is carrying 20–70 MPa of pressure and associated shear stresses, it would deform only elastically. 3) Given the random nature of crack formation, it is highly unlikely that the regularity of the load cycling associated with these events is caused solely by multiple fracture events (spalling). 4) The process after each failure needs clarification. How do the spalled ice become crushed ice? 5) Very thin ice slivers (2–3 mm?) result from regular failures. It is hard to visualize the failure process composed of parallel failure planes at this spacing and how such small resolved shear stresses would be capable of producing spalls. 6) The failure plane traverses material with varying stress from low pressure and high shear at the outside, to higher pressure and higher shear part way to the center, to high pressure and small shear at the centre. A single failure criterion for all of these stress states is not appropriate.

INDENTOR

Mc Mc Rx+Pm Rx+Pm Elastic strain Elastic strainFo

rc

e

Time

A

B

C

Jordaan et al.

Gagnon

Liquid Pulverization front Spall Heat

A

B

C

Extrusionit

it

it 1 2 31

2

3

Figure 3: A comparison between the Jordaan et al’s model and Gagnon’s explanation for cyclic loading. Mc: Microcracking; Rx: Recrystallization; Pm: Pressure melting; it: Intact ice. See text for discussion. Relative thickness of damage layer (left), spall and liquid layer (right) not to scale.

CONCLUSION

Jordaan et al.’s model hinges on the existence of a layer of damaged ice along the ice-structure interface. Gagnon does not acknowledge this feature and this represents a major point of contention between the two viewpoints. This paper discusses other objections raised by Gagnon and shows that they are not justified. Future endeavor should consider a test series allowing in situ observation of an indentation event perpendicular to actuator motion (as opposed to parallel to it as done previously).

REFERENCES

Barrette, P.D. Triaxial testing of ice: A survey of previous investigations. In Proceedings of the 16th Conference on Port and Ocean Engineering under Arctic Conditions, Vol. 3, Ottawa (2001) 1375–1384.

Barrette, P.D. and Jordaan, I.J. Creep of ice and microstructural changes under confining pressure. In IUTAM Symposium on Creep in Structures, S. Murakami and N. Ohno eds., Kluwer Academic Publishers, Boston (2001) 479–488.

Gagnon, R.E. Analysis of visual data from medium scale indentation experiments at Hobson’s Choice Ice Island. Cold Regions Science and Technology 28: 45–58 (1998). Jordaan, I.J., Matskevitch, D.G. and Meglis, I.L. Disintegration of ice under fast

compressive loading. International Journal of Fracture 97: 279–300 (1999).

Jordaan, I.J. Mechanics of ice-structure interaction. Engineering Fracture Mechanics 68: 1923–1960 (2001).

Meaney, R., Jordaan, I.J. and Xiao, J. Analysis of medium scale ice-indentation tests. Cold Regions Science and Technology 24: 279–287 (1996).

Meglis, I.L., Melanson, P.M. and Jordaan, I.J. Microstructural change in ice: II. Creep behavior under triaxial stress conditions. Journal of Glaciology 45: 438–448 (1999). Melanson, P.M., Jordaan, I.J. and Meglis, I.L. Modelling of damage in ice. In Ice in

Surface Waters. Proceedings of the 14th International Symposium on Ice, H.T. Shen ed., A.A. Balkema, Brookfield (1998) 979–988.

Mizuno, Y. Effect of hydrostatic confining pressure on the failure mode and compressive strength of polycrystalline ice. Journal of Physical Chemistry B102: 376–381 (1998). Schulson, E.M. and Gratz, E.T. The brittle compressive failure of orthotropic ice under

triaxial loading. Acta Metallurgica 47: 745–755 (1999).

Sinha, N.K. and Cai, B. Analysis of Ice from Medium-Scale Indentation Tests. NRC Laboratory Memorandum IME-CRE-LM-002 (1992) 63p.

Stone, B.M., Jordaan, I.J., Xiao, J. and Jones, S.J. Experiments on the damage process in ice under compressive states of stress. Journal of Glaciology 43: 11–25 (1997).

Wilson, C.J.L. Shear bands, crenulations and differentiated layering in ice-mica models. Journal of Structural Geology 6: 303–319 (1984).

Wilson, C.J.L. Deformation induced recrystallization of ice: the application of in situ experiments. In Mineral and rock deformation: Laboratory studies – The Paterson Volume, B.E. Hobbs and H.C.Heard eds., American Geophysical Union, Geophysical Monograph 36 (1986) 213–232.

Wilson, C.J.L., Burg, J.P., Mitchell, J.C. The origin of kinks in polycrystalline ice. Tectonophysics 127: 27–48 (1986).