Publisher’s version / Version de l'éditeur:

Construction Specifier, 50, Dec 12, pp. 28-41, 1997-12-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Chemical prescription for durability

Mailvaganam, N. P.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=37a3ba59-9ea7-406b-ba45-55f6af908129

https://publications-cnrc.canada.ca/fra/voir/objet/?id=37a3ba59-9ea7-406b-ba45-55f6af908129

four primary roles in concrete technology: 1. improve the quality of concrete 2. compensate for adverse environmental

effects during placement and curing 3. facilitate proper scheduling of

con-struction activities by improving

placing and finishing operations 4. afford economy in concrete production

and placing.

This discussion is confined to modifi-cations that improve the durability of concrete structures.

Air entrainment. Air entrainment has

proven beneficial in many applications but nowhere more dramatically than in freeze/thaw conditions. In North America, concrete is exposed not only to severe freeze/thaw cycles but also to the damaging effects of ice removal salts. Highway bridges often span water, and abutments and piers are in areas where wet and dry conditions alternate"" To adequately pro-tect against freeze/thaw, most North American specifications for durable con-crete include requirements for a low w/c ratio and the proper amount of air.

Admixtures decrease the water content of the mix, thereby reducing the potential for cracking due to shrinkage stresses; increase the compressive strength; reduce permeability; and increase resistance to freeze/thaw cycles (seeFigure B, page 36).

Decreased permeability reduces the entry of moisture and damaging deicing salts and thus the potential for the concrete to attain critical saturation, while the air void system provides a release mechanism for the internal pressure developed due to the freezing of the moisture in the concrete, reducing it to a level where damaging stresses do not develop. Hence, durability is improved, the degradative effects of carbonation and deicing salts are much

Admixtures

Most of the concrete placed in North America, whether precast, site batched, or ready-mixed, contains an admixture. An admixture is usually a chemical other than water, aggregate, and cement used as an

ingredient during mixing of concrete or mortar.

Concreting is really a chemical process determined by the reaction between cement and water and can be represented by three stages (seeFigure A):

i. diffusion of water through the surface layers of cement grains and formation of some hydrates such as lime 2. formation oflong fibers of the cement

gel that bridge the water-filled spaces of the cement grains

3. the final stage during which the remainder of the water-filled spaces are filled with short fiber cement gel (CSH), which gradually provides a more dense structure.

The more long fibers formed in stage two the higher the ultimate strength. This stage is longer at low temperatures and determines the final strength. Retardation of setting either by temperature or by admixture gives more long-fibered CSH and therefore increases the final strength; high temperatures or accelerating admix-tures give smaller amounts of long-fibered CSH and consequently reduces strength.' However, at temperatures near or below

o

°C (32OF)the concrete can freeze, signif-icantly affecting the hardening properties. Consequently, there may be no option but to sacrifice some strength so that cold weather concreting is made possible with the use of admixtures.Admixtures produce their effects by deflocculating and dispersing the cement agglomerates (seePhoto1).'They play Author

NOEL P. MAILVAGANAM Is manager of evaluation and repair programs, Institute for Research In Construdlon at the National Research Council of Canada, In Ottawa, Ontario.

ADDITIONAL INFORMATION

Concrete durability on the quality of the concrete and its ability to withstand In-service ellposure condi-tions. Durable concrete typicaliy has a low water/cement ratio to reduce per-meability, Is well consolidated through Improved workability, and resists freeze/thaw damage by a stabilized alr-. void systemalr-. Many of thesepセセセセセセイZウN

are achieved using a

29

Nセ

Stage III

7 24

3. Reduction in total heat evolved. The construction of large caissons for use in jetties involves large pours of concrete mixes with high cement contents (>375 kg/m'). High core temperatures that build up, particularly in hot weather, are maintained for long periods due to the poor dissipation of heat to the hot sur-roundings. Consequently, there is a great risk of thermal cracking when the units repeated dosages are limited to specific uses or problem areas. Method four is flexible and is a more readily controllable means of reducing slump loss problems than method two, three, or five."

<

HOURS>

Stage

n

time of hydration (stagesin cement hydration}

10 3

セ

Stage [PHOTO 1 Deffloculation of superplasticizers

FIGURE A Stages in hydration of cement

Five methods used to overcome this problem are: 1) producing a high initial slump, allowing the natural slump loss to occur before discharge; 2) using retarders to allow late additions of the mix water;

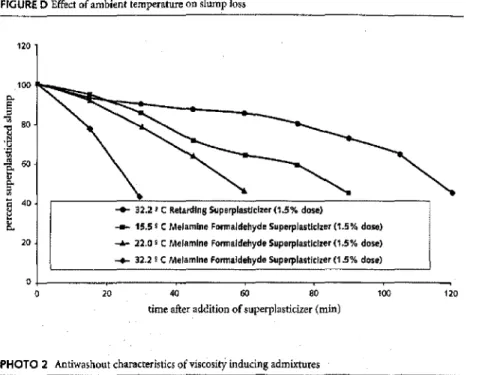

3) adding a second dosage of a superplas-ticizer to restore the original slump; 4) using a new type of superplasticizer with improved slump retention properties; and 5) adding a hydroxycarboxylic (H.C.) type retarding admixture before adding a superplasticizer (seeFigureD, page39).

Method one is counterproductive since it obviates the water reduction obtained through using a superplasticizer and

In climates where hot weather prevails for most of the

year, concrete is adversely affected unless it is designed

and placed with special precautions.

reduced, and the protective environment of the steel reinforcement is more endur-ing.Figure B, page36, shows the effect of air entrainment on the resistance of con-crete to freeze/thaw conditions.

Adverse climates.Inclimates where hot weather prevails for most of the year, concrete is adversely affected unless it is designed and placed with special precau-tions. Typical concrete parameters specified to offset the damaging effects of hot weather include minimum cement content, minimum seven and 28 day strengths, low wlc ratios, maximum slump, and proper curing.'"

Commonly sought mix modifications (improvements) under hot weather condi-tions include the following:

1.Water reduction. Cracks resulting from shrinkage and thermal stresses allow entry of Chemical contaminants. The solution is to use low wlc ratios. In hot weather, the water reduction achieved with conventional types of water reducers does not permit adequate cement reduc-tion to offset drying shrinkage and thermal cracking. Superplasticizers, on the other hand, depending on the dosage rate, afford up to 30 percent water reduc-tion, while maintaining stipulated strength values and minimizing cracking (seeFigureC, page 36, andTable2, page 37). The good workability attained at low slumps provides a well-compacted, dense, watertight concrete. Reduced permeability and cracking through the use of a super-plasticizer coupled with proper curing increases the durability and serviceability of the concrete.

2. Retardation of rate of initial set and rate of workability loss. Many of the con-crete mixes produced in hot weather are susceptible to a rapid slump loss even at a normal temperature of22 "C (72 "F). This trend accelerates at temperatures exceed-ing 22 "C (seeFigureD, pageSYINGセQャ Even under less rigorous weather conditions prolonged mixing in ready-mix trucks induces loss of consistency. Consequently, the mix is often retempered with additional water to provide the desired workability. The serious loss of strength that results from the addition of water and any action with the potential for serious reduction in strength and durability warrants concern.

n

are taken from the mold, even after 72 hours. Cement reduction from 11 percent to 20 percent is possible using superplasti-dzing admixtures in such mixes while maintaining desired strength levels (see

Tables 1, page 30, and 2, page 37).B The

permissible cement reduction could well reduce the core temperature and hence the potential cracking.

To withstand damage from cold weather, concrete should attain a compressive strength of 5 MPa (0.73 ksi) before expo-sure to freezing temperatures and 20.7 MPa (3 ksi) before being subjected

to freeze/thaw cycles. Since low tempera-ture has a retarding effect on both the set-ting time and strength development of concrete, acceleration of these element gains are desirable in concrete placed at low ambient temperatures."

Admixtures used in cold weather con-creting are expected to offset the slowing hydration reaction by accelerating the rate of hydration of the cement. They also are expected to reduce the potential of the concrete freezing by depressing the freez-ing point of water and decreasfreez-ing the amount of freezable water in the concrete

(by good water reduction). The effects produced on hydration by cold weather and accelerating admixtures are quite noticeable when the heat of hydration curves are examined (seeFigure E, page

39). Low temperatures not only lower the peak temperature but also significantly extend the course of the reaction."

The protection required to prevent frost damage to freshly placed concrete depends on critical factors such as the degree and duration of saturation of the plastic concrete. Approximately 65 percent to 70 percent of the water in a concrete

The three principles of architectural precast concrete (APe) connec-tions are hang it securely, let it move, and

"make

, ,. it easy to connect,. ,セ:,-<セA secure installation must withstand multiple forces, namely gravity, wind pressure and suction. and seismic- and temperatui-e':: related movement The force transfer diagram inFigureAillustrates

Architectural Precast

Concrete Connections

the

e he ent

mix provides the workability required for placing operations. Such water is usu-ally present as physicusu-ally bound and free water filling the pores. If the required plasticity can be achieved with a much reduced water content, then the degree of saturation and vulnerability to frost attack is lowered. The 6 percent to 20 percent water reduction afforded by conventional water reducers and superplasticizers, therefore offers a significant advantage in winter concreting."

Antiwashout underwater concrete.

Another product increasingly used in

demanding construction environments is the viscosity enhancing antiwashout admixture (AWA), which allows concrete to be poured under water. The main com-ponent of most AWAs is water soluble gums, cellulose ethers, Or water soluble acrylic-type polymers. The admixture's cohesion-inducing action is achieved by an increase in the viscosity of the water in the mix, which makes the concrete more thixotropic and more resistant to segrega-tion and cement washout (seePhoto 2,

page 39)." A tremie (a long pipe with a funnel-shaped opening) has been used,

b1Jt the procedure is slow and if water gets into the tremie, cement is washed out. This results in cement-deficient layers of concrete, many of which go undetected.

AWAs have afforded considerable cost savings in the underwater repair of struc-tures such as locks and dams. Since approximately 50 percent of the cost of repairing such structures is for dewatering, the money saved in not having to dewater can be substantial."

Corrosion mitigation.Many of the high-way structures constructed in the 1950s are in an advanced state of deterioration

duetothe corrosion of embedded steel reinforcement. Corrosion protection for bridges is therefore one of the big markets for coatings and corrosion inhibitors. Attempts to solve the problem included reducing the wlc ratio and increasing the cover over reinforcing steeL Although chloride ingress was significantly reduced, such measures only slightly increased the time to corrosion.I'

More enduring methods of corrosion inhibition include using epoxy-coated rebar and corrosion inhibitors with silica fume in the same concrete batch.

Corrosion inhibitors such as calcium nitrite have been reported to delay the ini-tiation and control the rate of corrosion by stabilizing the passivating layer of iron oxide film on the embedded steel. Combining both silica fume and a corro-sion inhibitor in the same concrete batch and using epoxy coated rebar provides vulnerable structures with multiple Hnes of defense.

Curing of Concrete

Rapid evaporation of water from freshly placed concrete adversely affects concrete's

durability. Short-term problems include shrinkage cracks and reduced wear resis-tance of the surface in decks and flat slabs. The critical durability requirement of low permeability is also significantly affected. Few realize how little water can be lost from the cement/water system before the inhibition of hydration.'·

Cessation of hydration can occur if water lost from the concrete pores produces a relative humidity below 80 percent in the cement/water system. Low permeability is generally attained only if hydration proceeds uninterrupted to the stage when

セN capillaries :ed. The ;s primarily eachieved I at early lues of the 5,three lary(see セ plastic r-based gthe shut-of days. セsufficiently eof the us wetness :eeping e spraying llyplaced form a lon the " ,vent based, rater loss is i±1.10 ·C. e is negligi-,getting Ie concrete. セウ , action, in a vapor 5of the con-'these can Water finds )ores, cracks, セエ have not or sealed. moisture セカ・ョエ・、 or ment of the ie absorption retard mois-セ」イ・エ・N it of a struc-assage of liq-'ressure." eved either orporating lixture in the mt materials roups: prod-le concrete

FIGUREB Effect of air entrainment on freeze/thaw resistance of concrete 2000 0

'e

セ

セ 1600セ

セ1

1400 .$ 12006

.£ -€I !lI

1000 0:>'"

...

800 ..gf

600]

...

'5

セ 400 '-0 セ"&

200 I. I '. !セ

)( u >< .i:'- 120 E1

100 p., ... 0 805

'0·Iii

60 8 40 '20 0 .4 .736 The Construction Spe<:lfler December 1997

the initially formed continuous capillaries within the cement gel are blocked. The period for this to occur depends primarily on the wlc ratio but can only be achieved by the effective curing provided at early ages. For example, when the values of the

wlc ratio lie between 0.4 and 0.5, three

to 14 days curing will be necessary (see

Figure F, page 40)."'"

Current curing methods use plastic sheets, wet burlap, and polymer-based curing membranes, or retaining the shut-tering for a specified number of days, Neither of these methods can be sufficiently carried out in the field because of the difficulty of ensuring continuous wetness and the costs associated with keeping shuttering in place.

Thus, the best choice may be spraying curing membranes on the freshly placed concrete. Curing membranes form a water-vapor impermeable film on the concrete. They are water or solvent based, and the maximum allowable water loss is restricted to 0.55 kglm2at 37.8± 1.10

'c.

The cost of a curing membrane is negligi-ble compared to the benefit of getting more impermeable and durable concrete.

Protection of

Concrete Structures

Hydrostatic pressure, capillary action, wind-driven rain, a difference in a vapor pressure between the two sides of the con-crete, or some combination of these can force water through concrete. Water finds its way most readily through pores, cracks, structural defects, or joints that have not been properly designed, built, or sealed. The ingress and migration of moisture in liquid and vapor can be prevented or retarded to varying degrees.

Dampproofing is the treatment of the concrete to retard, not stop, the absorption of water or water vapor or to retard mois-ture transmission through concrete. Waterproofing is the treatment of a struc-ture's surface to prevent the passage ofliq-uid water under hydrostatic pressure."

Dampproofing can be achieved either

by treating the surface or incorporating an integral waterproofing admixture in the concrete mix. Surface treatment materials can be categorized into two groups: prod-ucts that penetrate and seal the ,concrete

of the surface of decks and flat slabs.

they perform three functions: accommo-date joint movement, prevent solid matter such as dust and sand from infiltrating the joint, and prevent water from entering the structure. Adhesion and cohesion are two of the most important properties of a sealant used in a working joint. The sealant must adhere to the sides of thejoint it is sealing and withstand internal stress caused by joint movement.

The generic types of sealants used in industrial and domestic buildings and other engineering structures include acrylic latexes, butyls, solvent release acrylics, polysulphides, urethanes, silicones,

Rapid evaporation of water from the freshly

shrinkage cracks and reduced wear resistance

durability. Short-term problems include

placed concrete adversely affects concrete's

branes, prefabricated sheets, and liquidcold-applied elastomeric materials (the most widely used materials in both new and rehabilitation construction).

A number of liquid-applied mem-branes are available, induding hot-applied rubberized asphalts, cold-applied liquid neoprene, and cold-applied polyurethanes (both one- and

two-component systems).Figure I, page41, shows multi-layer mem-brane systems for parking garages and bridge decks that provide a watertight

barrier and elasticity to maintain integrity under the influence of temperature-induced structural movement. On drying, the membrane produces a smooth, dense, continuous film that provides a moisture barrier to water soluble salts, and a mild chemical attack of the concrete. Suitable surface (sealers) and products that provide

a surface film (barrier coatings).FigureH, page41,shows how the different materials achieve their barrier effect. Sealers are gen-erally low viscosity, nonvolatile materials, while coatings are barrier-type materials that form thinfilmson the concrete surface.

A good sealer penetrates the concrete or masonry, and the dry film produces an effective barrier to water and salt infiltra-tion, which prevents buildup of dirt and deleterious matter within the pores of the concrete surface while providing a breath-able film that allows transmission of moisture vapor.

Sealer breathability is important to prevent freeze/thaw scaling, which could result when moisture enters the structure through an untreated surface and becomes trapped beneath the treated surface, satu-rating it. Materials that have been used as sealers on concrete surfaces indude epox-ies, silanes, siloxanes, silicones, siliconates, acrylics, methacrylates, linseed oil, ure-thanes, sodium silicate, and silicofluorides of zinc and magnesium.

Three broad types of dampproofing tly

It-s

I,

coatings are available: Portland cement/ latex coatings, waterborne polymer latex coatings, and solvent-borne polymeric coatings. Latex-cement coatings are for-mulated with flexible polymer resins, contain high polymer/cement ratios, and provide some degree of crack bridging. Solvent-borne polymeric coatings are low nonvolatile solutions of compounded organic resins in organic solvents. Some of the inexpensive materials contain tar or bituminous ingredients. In general, the films form solely through evaporation of the solvents without reliance on a chemi-cal reaction.

Waterproofingsystems can be grouped according to fabrication and application methods, as follows: built-up sheet

mem-materials are classified according to their ability to bridge post-application cracks up to 3 mm. Advantages provided by the system are easy application; prevention of lateral movement of water between mem-brane and concrete due to the continuous bond formed; and a more elastic membrane than built-up membranes.

As much as 20 percent of the early fail-ure of highway structfail-ures can be attributed to poor joint performance. Sealants, there-fore, are a major focus in North America's infrastructure rebuilding program. Sealants are flexible polymeric materials used to plug irregular gaps between two rigid surfaces and to provide a dynamic bridge between two surfaces that move relative to one another. In this capacity,

and some flexible epoxies available in four consistencies-putty grade, gunnable or non-sag. pourable and self-leveling, and extruded tapes. The construction market consumes about half of the more than 22million kg (49 million lb) per year of sealants made in North America."

Chemical process industries such as the pulp and paper, petroleum, and fer-tilizer industries are characterized by a wide variety of corrosive service condi-tions. Concrete floors and other structures in such industries are exposed to spillage, leakage, atmospheric vapors/ fumes, and constant immersion service conditions in a wide range of chemicals. pH ranges from 2.0 or less to 13.0 or more, with temperatures ranging from

120 1000 100 With accele,ator (10'C) 600 time (min) 40 60 80

time after addition of superplasticizer (min)

__ 32.2' C Relardlng Syperplastlcller (1.5% dose)

__ 15.5SC Melamine Formaldehyde Superplasllclzer(t.50/0 dose) ... 22.0' C Melamine Formaldehyde SuperplastlclZtlr (1.50/0 dose) ... 32.2!CMelamine Formaldehyde SyperplastiClze, (1.5% dose)

200 20 BLセNL

...

,.....

...

<*"*'./10 ...,. .' \ "...

".... NNNセ⦅NMN⦅NMN⦅N⦅N⦅N⦅...

_

..-._.-.-._

....

...セエ •••••• •..•..·WlthOul admixture (10· C) セwGNZZZN⦅N⦅N⦅N⦅N⦅N⦅N⦅セ⦅...

t"-''''' oMャMMMMMセMMMMセMMMセMMMM⦅⦅イ⦅MMMMN⦅⦅⦅MMMセ o 20 100 With a_lallllor (20· C) 120 Without admixlyre (20·Q Nセ 4.a

セ セ 2 ..cl 'Cl!

0L - .1..-_ _セ N N N ャ N ⦅ - ' - ...i.- _ i . _ _ oFIGURE 0 Effect of ambient temperature on slump loss

PHOTO 2 Antiwashout characteristics of viscositY inducing admixtures

FIGU RE E Effect of low temperature and accelerating admixtures on the heat of hydration

curve of cement .

ambient to 65 ·C (150 'F) and higher for the various processes."

Chemically resistant materials used under adverse conditions include many nonmetallic, inorganic, and organic mate-rials. They can be used independently or as composites to attain a liquid-tight, fully resistant system that provides extended service. The materials possess excellent chemical resistance to a broad range of corrosive chemical environments and high thermal stability.

The various materials consist of masonry units such as brick or tile, mor-tar, tile grouts, castables, polymer concrete polymer-based membranes, and joint compounds. The brick and bonding mor-tar and monolithic surfacing usually are used to shield the membrane.

The membrane, which may be liquid-applied or prefabricated sheeting, serves as a fluid-tight barrier between the some-what permeable brick and mortar lining, and the substrate supporting the structure. Monolithic surfacing used with chemically resistant materials are similar to polymer toppings but are more resin rich and include curing agents, which provide the highest chemical resistance, and inert aggregate with a wide variety of particle sizes. The formulations are more tolerant of thermal cycles and more thermally resistant than polymer toppings applied for general use.

Repair Materials

Bonding agentsare natural, compounded, or synthetic materials used to join individual members of a structure without mechanical fasteners. These products are often used in different repair applications, such as bonding of new concrete to old, sprayed concrete, or sand/cement repair mortar to assist in achieving a reliable bond.

The main types of bonding agents used in the building industry are latex emulsions and epoxies. Although a good bond may be obtained without a bonding agent, generally a bonding layer of cement and sand slurry, cement/latex slurry, or epoxy increases bond strength. In some situations their use is critical. For example, overlay-ing a deteriorated concrete deck with an abrasion-resistant concrete will require strengthening the friable substrate surface fr

d.

t ro

1eet

ne

rhy

-the

nection nberof .eregn

and

onding gn-1to

y's

e

ror-s.

le pastca-.de

uture

セウlreP

cifica-ine er ShortNotes

1. V:S. Ramachandran, RoE Feldman, and J,J. Beaudoin,Con"ete Science.Heyden (1981): 54-55. 2 M.Ro Rixom and N.P. Mailvaganam,Chemical

Admixtures for Concrete.E.&E N. Span (1985); 33-35.

3. ACI Committee 201. "Durability of Concrete" lACI 201.1R.92). Detroit: American Conaete Institute, August 1992.

4. Ramachandran, Feldman, and Beaudoin,op.cit. 5. Rixom and Mailvaganam,op. cit.

6. Ramachandran, Feldman, and Beaudoin,op.cir. 7. ACI,op. dt.

8. Ibid.

9. P.G. Fookes and L Collis, "Problems in the the Middle East:'COllcrete,vol. 9, no. 7, (1975); 11-13. 10. N.P. Mailvaganam, "Slump Loss in Flowing

Concrete," International Symposium on Superplasticizers in Concrete, Ottawa, Canada (May 1978).

II. T. Kay and D. Slater, "Specifying Conuele for Adverse Weather,"Concrete(May/Tune 1995): 21-23. 12. D.Ravina, "Retempering of Prolonged Mixed

Concrete with Admixtures in Hot Weather:' ACI

JoumalProceedings.LXXII,no.8 (june 1975): 291-295.

reduce cost. Current products are available in a variety of consistencies, ranging from a highly filled paste (for use in overhead work), to liquids with viscosities of

100 cps, similar to that of water.

Conclusion

Industrial research has for the past three decades taken the lead in developing inno-vative materials, which when used to their potential, greatly enhance the properties of concrete. The above examples clearly demonstrate that chemicals produce significant improvements in concrete's rheological, structural, and durability characteristics that are not readily realized when conventional concreting materials are used. Concrete is often a mixture of admixtures, and the combined use of these chemicals produces synergistic effects that result in a range of modifications enabling highly durable concretes to be placed under a variety of conditions.

Notwithstanding the highly beneficial role played by admixtures, the inherent shortcomings of concrete in chemically aggressive environments should be recog-nized at the design stage and a suitable coating that is able to withstand the aggressive chemicals encountered in service should be specified. Such coating systems provide long-term protection and increase . the structure's ability to remain functional

in the intended service environment.III

water system. However, not all emulsions are compatible with cement, and selecting an emulsion for a given application requires an appreciation of the materials' chemistry or consulting the product manufacturer.

Variousepoxies are available for bonding

freshly placed concrete to cured concrete as well as concrete to steel. Most contain 100 percent solids resins, which may contain thixotropic fillers and other addi-tives to enhance a particular property or

250

セ

f

220セ

190 280absorption relative to rontrol

FIGURE FComparison of different turing systems

160

130 ' - - _ - ' -...e-...'--L-'--'-,...-_"'--_ _... ....

100

310

FIGURE G Age for tapillary disoontinulty for differentwitratios

as well as formation of an efficient bond that can resist both the shrinkage-induced tensile curling stresses of the overlay and traffic-induced shear stresses.

There are a variety of different appli-cations forlatex emulsions as bonding

agents. Some types have a greater degree of water resistance than others. The emul-sions generally used in cementitious com-positions are the oil-in-water type and may contain more than 50 percent water. They are generally stable in the cement/

l

1;ii!"tri" , 'JI

セG「ャG

セッュr

dI

,I :'ee lnO-heir es Iy1.\. ACI,op. cit.

iセN Anon, "Hot-Weather Concreting," tips to minimize the effects of hot weather,Contrete Construction(1994): 841.

15. Rixom and Mailvaganam,op. cit.

16. Anon.,op. cit.

17. K,Khayat, "Eff"ts of Antlwashout Admixtures on the Properties of Hardened Concrete,"ACI Materials tournai,93 (1996): 134-136.

18. Ibid.

19. Anon.,op.dt.

FIGUREH Classification of protective measures

20. Rixom and Mailvaganam,op.cit.

21. R. Shridar and Y.P. Kapoor, "Role of Construction Chemicals in Ensuring Durability of Concrete Structures."The Indian Contrete Journal(June

1994): 301-305.

22. K. Kovler, "Shock of Evaporative Cooling of Concrete in Hot Dry Climates,"Concrete International(October1995): 65-69.

23. N.P.Mailvaganam, ed.,Repair and Protection of Concrete Structures,Boca Raton, Florida: CRC Press(1991): 55-58.

24. J.E Dunphy, "Chemicals Shore up the U.S.

Infrastructure,"Chemical Week(March1985): 30-35.

25. N.P.MaHvaganam, ed.Repair and Protection of Concrete Structures, op. cit.

composite systems Coating higher solids polymer solutlom Sealers polymer solullon low solids film fonnlng pore sealing non film fonnlng !'enetratlnll silane Sealer ,ese hat ling zed 1s f ce s se al

,-,

55, 3. 3.FIGUREt Cross section showing various layers of a parking deck membrane

TIe coat

Wearlnll course

Waterproofing membrane

Primer or sealer

concrete deck