Publisher’s version / Version de l'éditeur:

Journal of Power Sources, 196, 24, pp. 10625-10631, 2011-09-03

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1016/j.jpowsour.2011.08.080

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Effect of operating parameters and anode diffusion layer on the direct

ethanol fuel cell performance

Alzate, V.; Fatih, K.; Wang, H.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=dd887654-93a4-4035-9bb7-14569acec6ac

https://publications-cnrc.canada.ca/fra/voir/objet/?id=dd887654-93a4-4035-9bb7-14569acec6ac

ContentslistsavailableatSciVerseScienceDirect

Journal

of

Power

Sources

j ou rn a l h o m e pa g e :w w w . e l s e v i e r . c o m / l o c a t e / j p o w s o u r

Effect

of

operating

parameters

and

anode

diffusion

layer

on

the

direct

ethanol

fuel

cell

performance

V.

Alzate,

K.

Fatih

∗,

H.

Wang

NationalResearchCouncilCanada-InstituteforFuelCellInnovation,4250WesbrookMall,Vancouver,BritishColumbia,V6T1W5,Canada

a

r

t

i

c

l

e

i

n

f

o

Articlehistory: Received24May2011

Receivedinrevisedform19August2011 Accepted20August2011

Available online 3 September 2011 Keywords:

Directethanolfuelcells Directalcoholfuelcells Ethanoloxidation

Fuelcelloperatingparameters Cellperformance

a

b

s

t

r

a

c

t

Aparametricstudywasconductedontheperformanceofdirectethanolfuelcells.Themembrane elec-trodeassembliesemployedwerecomposedofaNafion®117membrane,aPt/CcathodeandaPtRu/C

anode.Theeffectofcathodebackpressure,celltemperature,ethanolsolutionflowrate,ethanol concen-tration,andoxygenflowratewereevaluatedbymeasuringthecellvoltageasafunctionofcurrentdensity foreachsetofconditions.Theeffectoftheanodediffusionmediawasalsostudied.Itwasfoundthatthe cellperformancewasenhancedbyincreasingthecelltemperatureandthecathodebackpressure.Onthe contrary,thecellperformancewasvirtuallyindependentofoxygenandfuelsolutionflowrates. Perfor-mancevariationswereencounteredonlyatverylowflowrates.Theeffectoftheethanolconcentrationon theperformancewasasexpected,masstransportlosesobservedatlowconcentrationsandkineticloses athighethanolconcentrationduetofuelcrossover.Theopencircuitvoltageappearedtobeindependent ofmostoperatingparametersandwasonlysignificantlyaffectedbytheethanolconcentration.Itwas alsoestablishedthattheanodediffusionmediahadanimportanteffectonthecellperformance.

Crown Copyright © 2011 Published by Elsevier B.V. All rights reserved.

1. Introduction

Directliquidfuelcellsareanattractivetechnologybecauseof thefuel’shighvolumetricenergydensity,whichtranslatesin sys-temcompactnessandsimplicity.Intheliquidfueloptions,ethanol hastwomainadvantages;itslowtoxicityanditsestablished pro-ductioninfrastructure.Themainissueofdirectethanolfuelcells (DEFC)istheirlowefficiency,mainlyduetothedifficultytobreak theethanol’scarbon–carbonbondatthefuelcell’soperating tem-perature.Inaddition,thepresenceofethanolinthecathode,due tothecrossoverthroughtheNafion®membrane,reducestheopen

circuitvoltageandpoisonsthecatalyst.Becauseoftheimportance oftheelectrochemicalreactionkineticsinthissystemmostofthe researchworkhasbeenfocusedontheanodecatalyst.Platinum–tin basedcatalystshaveshownthebestinitialperformanceforthe ethanolelectro-oxidationreaction(EOR)[1,2],while Pt–Sn con-tainingIrshowedbetterlongtermperformance[3].Almostallof thecatalystsappliedtoEORshowedverylowCO2yieldswithacetic

acidandacetaldehydebeingthemainoxidationproducts.Effortsto increasetheplatinum–tinelectrocatalyticactivityandCO2

selectiv-ityincludedesignofitsmicrostructure[4],addingathird[5–9],and fourthcatalystcomponent[3]andmodifyingthecatalystsupport [10–12].

∗Correspondingauthor.Tel.:+16042213071;fax:+16042213001. E-mailaddress:Khalid.Fatih@nrc.gc.ca(K.Fatih).

Singlefuelcelltestingisoneimportanttoolforfuelcellcatalyst designasitrevealstheperformanceofthecatalystinactual oper-atingconditions.Publishedworkhasshownthatthedirectethanol fuel cell performance is significantly affected by theemployed testingconditions,thefabricationprocessesandmaterialsofthe membraneelectrodeassembly(MEA).Theeffectoftemperature andethanol concentrationontheethanolcrossoverrateandits impactoncellperformancehasbeenstudiedbySongetal.[13]. Theauthorsfoundthatethanolcrossoverincreasedwithincreasing temperatureandethanolconcentration.Similarly,usinga refer-enceelectrodeLiandPickupfoundthattemperatureandethanol concentration have a positive effect on the ethanol oxidation reaction,buttheoppositeeffectwasfoundfortheoxygen reduc-tionreaction,demonstratingthesignificantimpactthatethanol crossoverhasontheoxygenreductionreaction[14].Praminiketal. [15],studiedtheeffectofthetemperatureoftheanodeandthe cathode,separately,aswellastheeffectoftheethanol concentra-tion.Theauthorsfoundaperformancemaximumat90◦Cforthe

anodeand60◦Cforthecathodewiththetestingtemperaturerange

of42–120◦Cand42–88◦Cforanodeandcathode,respectively.The

authorsestablishedanoptimumethanolconcentrationof2M.In additiontothetestingparameters,theMEAfabricationprocesses alsoaffecttheDEFCperformance.Thishasbeendemonstratedby Songetal.,whocomparedtheperformanceandstabilityofagas diffusionelectrode(GDE)basedMEAwithacatalystcoated mem-brane(CCM)basedMEA[16].AlthoughtheCCMMEAhadhigher ethanolcrossoverrate,itsperformance andstabilitywere supe-riorcomparedtotheGDEMEA,havingapeakpowerdegradation

0378-7753/$–seefrontmatter.Crown Copyright © 2011 Published by Elsevier B.V. All rights reserved. doi:10.1016/j.jpowsour.2011.08.080

10626 V.Alzateetal./JournalofPowerSources196 (2011) 10625–10631

Table1

Propertiesoftheanodediffusionlayer.

Anodediffusionlayer Thickness[m] Porosity[%] PTFEloading[wt.%] Description

CFPToray-120 370 78 0 WithoutMPL

CFP-25BCSGL 235 80 5 WithMPL(23%PTFE)

CFCE-tekB-1/B(cloth) 445 – 0 WithoutMPL

of15%against34%fortheGDEMEAina10hlifetest,whichwas attributedtolessdelaminationproblemsinthecaseoftheCCM MEA.Thestructureofthecatalystlayerhasalsobeeninvestigated forDEFC[17].Inthiswork,theauthorsobtainedhighercell per-formanceusingporeformersintheanodecatalystlayer,andby increasingPTFEcontentinthecatalystlayerfrom10to20wt%. Thesetwoparametersweresaidtoimprovetheflowsystem net-workfortheremovalofethanolelectro-oxidationproductspecies andthereforehavingmorecatalystsitesavailableforthereaction. Theobjectiveofthisworkistocreateaclearerandbroader pic-tureoftheeffectofthemainparametersusedduringdirectethanol fuelcelltesting. Specifically,theeffectofcathodebackpressure, celltemperature,ethanolsolutionflow rate,ethanol concentra-tion,andoxygenflowratewillbepresented.Furthermore,three differentanodediffusionmediaweretested.Theeffectofusing car-bonfibrecloth(CFC)andcarbonfibrepaper(CFP)isexamined,as wellasthepresenceofamicroporouslayer(MPL).Thecell perfor-mancewasevaluatedmeasuringthefuelcellvoltageasafunction ofcurrentdensityandcalculatingthepowerdensityfromthese measurements.Theresultsarepresentedaspolarizationandpower curves.

2. Experimental 2.1. Materials

Nafion®N117membranes(DuPont)werepre-treatedat80◦C

with3wt%H2O2and0.5MH2SO4solutionsfor1hand,rinsedand

storedinde-ionisedwater.HiSPEC(JohnsonMatthey)4000(Pt/C) and5000(Pt1Ru1/C)wereusedasthecathodeandtheanode

cata-lyst,respectively.ThecathodediffusionmediawasSigracet®GDL

25DC(SGLGroup),whichhas20%PTFEcontent.Fortheanode,three typesofdiffusionlayerswereused:(i)Sigracet® GDL25BC(SGL

Group),whichisaCFPwitha5%PTFEcontentandamicro-porous layer(MPL)(23%PTFE),(ii)TGP-H-120CFP(Toray)and (iii)CFC (E-TEK).Table1summarizesthepropertiesofthethreedifferent diffusionmediaused.

2.2. ElectrodeandMEApreparation

Electrodeswerepreparedbysprayingthecatalystonthe dif-fusion media. The catalyst ink was composed of the catalyst, Nafion® ionomersolution(5wt% inalcohols/water, Alfa Aesar),

andalcohol/watersolution.Thismixturewastreatedwithan ultra-sonicprocessor(Cole-Palmer)inpulsemodefor1h.Theinkwas sprayedusingan auto-spray(nozzle-XYtable) system.The cat-alystmetalloadingwas2mgcm−2 forbothanodeandcathode,

whiletheNafion®ionomercontentinthecatalystlayerwas20wt%.

TheMEAs werefabricatedby hot-pressingthe Pt/Cand PtRu/C electrodes(5cm2)onto each side of theNafion® membrane at

90kgcm−2and140◦Cfor4min.

2.3. Fuelcellmeasurements

DEFCperformancetestswereconductedina5cm2singlefuel

cellhardware(Fig.1).Serpentineflowfieldgraphiteplateswere used for both cathode and anode. Tests were performed with a commercial test station (Fideris). Prior to polarization curve

measurements,thebreak-inoftheMEAwasperformedbysetting thecellataconstantvoltageof0.2Vfor2–4huntilthecurrent wasstableusing1Mmethanolsolutionasfuel.Fortheactual mea-surementsethanolsolutionsandun-humidifiedoxygenwereused asreactants.Thevariablesandtestingconditionsaresummarized inTable2.Polarizationcurveswereperformedgalvanostatically, eachpointwasmeasuredfor2min,whichwasenoughtimetoget astablepotentialresponse.Aftereachpolarizationcurvedeionised water wasflown throughtheanodecompartment toavoidcell degradation.Beforemeasuringeachpolarizationcurve,thecellwas keptatopencircuitvoltage(OCV)underthetestingconditionsfor 30minforstabilization.

3. Resultsanddiscussion

3.1. Effectofanodediffusionlayer

Theeffectoftheanodediffusionlayerwasstudiedusingthree typesofsubstrates,CFPwithMPL,CFP,andCFC.InhydrogenPEM fuelcellstheMPLisknowntoimprovethecellperformance affect-ingthewatertransportproperties,thecatalystlayerstructureand electricalcontact;inthecaseofmethanolfuelcells,theMPLcan alsoaffectthefuelcrossoverandCO2transport[18].Fig.2shows

theSEMimagesoftheuncoatedandcoatedsurfacesofthe diffu-sionlayers.TheCFPwithMPLhasaveryhomogeneoussurfacewith poresizeslessin1minsize(Fig.2a),whileCFP(Fig.2b)andCFC (Fig.2c)havegreaterandbroaderporesizedistribution.Afterthe catalystlayerissprayedonthesesubstratesacleardifferenceinthe structureisobservedbetweentheCFC(Fig.2f)andtheCFPbased samples(Figs.2dande).ThecatalystlayerdepositedontheCFC hasamoreopenstructurethatfollowsthedirectionofthewoven fibrescomparedtoamoreflatsurfaceintheCFPsamples.Onthe otherhand,thereisnovisibledifferenceinthecatalystlayersurface betweenthesampleswithandwithoutMPL(Figs.2bandd).

Fig.3showsthepolarizationandpowercurvesforthethree typesofanodediffusionlayers.Thetypeofdiffusionlayerdoesnot affecttheOCV,aswellastheperformanceinthekineticcontrolled region;thethreecurvesshowthesamebehaviouruptoacurrent densityof0.020Acm−2.Athighercurrentdensity,theanodewith

theCFPandMPLshowedalowerperformance,reachinga maxi-mumpowerdensityof0.017Wcm−2 comparedto0.028Wcm−2

obtainedwithbothCFPandCFCbasedanodes.Furthermore,the

Table2

Experimentalconditionsusedforeachsetoftest.

Exp.series Variables

Anodediffusionlayer O2flowrate(mLmin−1) Ethanolflowrate(mLmin−1) [Ethanol](M) Temp.(◦C) Cathodeback-pressure(psig)

1 CFP CFP–MPL CFC 300 2 1 90 30 2 CFP 300 2 1 90 0–10–20–30 3 CFP 300 2 1 60–70–80–90 0–30 4 CFP 300 0.6–1–2–5 1 90 30 5 CFP 300 2 0.1–0.5–1–2–5 90 30 6 CFP 50–100–300–500 2 1 90 0–30

cellwiththeCFCbasedanodeachievedthehighestcurrent den-sity.TherearetwodifferencesbetweentheCFPwithMPLandthe othertwosamples.ThefirstoneisthePTFEcontentinCFP(5wt.%). ThehydrophobicityoftheCFPcanreducethetransportofwater butinalesserdegreethetransportofanethanol/watersolution, whichhasalowersurfaceenergy.Inaddition,thePTFEcanreduce theelectricalconductivityoftheCFP.Theseconddifferenceisthe presenceoftheMPL,whichmightactsimilartoabarrierpreventing theflowofliquidtoandfromthecatalystlayerduetothehighPTFE content(23wt.%)aswellastheverysmallporesandlower poros-ity.ConsideringthelowcontentofPTFEintheCFP,theporesizeof

theMPLanditshydrophobicityseemtobecomplementaryfactors inthereductionofthecellperformance.Thispostulategoesinthe samedirectionasthemodellingworkdonebyAndreadisetal.[19] inwhichwasreportedthattheporosityofthediffusionlayerhasan importanteffectontheperformance.Forexamplea22%increasein performancewascalculatedwhenthediffusionlayer’sporosityis changedfrom0.4to0.8.Infacttheirsimulatedpolarizationcurves haveaverysimilarbehaviourastoFig.3,i.e.,thekineticregion isnotaffectedbychangingthediffusionlayerporositywhileat highercurrentstheslopeofthecurveincreaseswithdecreasing porosity.Furthermore,Biswasetal.[17]foundbetterperformance

10628 V.Alzateetal./JournalofPowerSources196 (2011) 10625–10631

Fig.3.Polarizationandpowercurveswithdifferentanodediffusionmediafor1M EtOHfeed(2mLmin−1and0psig)andnon-humidifiedoxygen(300mLmin−1and

30psig)at90◦C.

byincreasingboththeporosityandthePTFEcontent(20%)inthe catalystlayer.However,intheircasethecatalystlayerwas fabri-catedusingporeformers,thereforethePTFEcontentcouldhavea verydifferenteffectcomparedtothepresentwork.

Forthisexperimentalsystemthemajorityoftheproductsare inliquid phase,for theidealDEFCsystemthereactionproduct isCO2,thereforetheflowdynamicswouldbeverysimilartothe

directmethanolfuelcell.Gasmanagementhasbeenacritical fac-torfor directmethanolfuelcells designgiventhat CO2 bubbles

canremaininthediffusionlayer.Thesebubblesgenerallyblock theporesusedfor themethanoldiffusiontothecatalystlayer, leadingtofuelstarvationandtherefore decreasingthecell per-formance.A comprehensivereview waspublishedonthemass transportphenomenainaDMFCsystem[20].Forexample,inan experimentperformedbyLuandWang[21],theeffectoftheanode diffusionmediaofaDMFCwasevaluated.Untreated(hydrophilic) CFC wascompared witha 20% PTFE treated CFP, which had a homemadeMPL.Theauthorsconcludedthattheadditionofthis layerdecreased therateof methanolcrossoverdue tothe low-permeabilitythattheMPLprovides.Ontheotherhandtheremoval ofCO2bubblesfromthebackinglayerwaseasierintheCFCfrom

visualexperiments,although it wasnotclear whetherthis dif-ferencewasduetotheporedistributiondifferencesorthePTFE contentinthematerials.Thereforetheoptimumdiffusionmediafor DEFCanodeswoulddependonthereactantflowregime,including theamountofgasproducedintheanode.

3.2. Effectofcathodebackpressureandcelltemperature

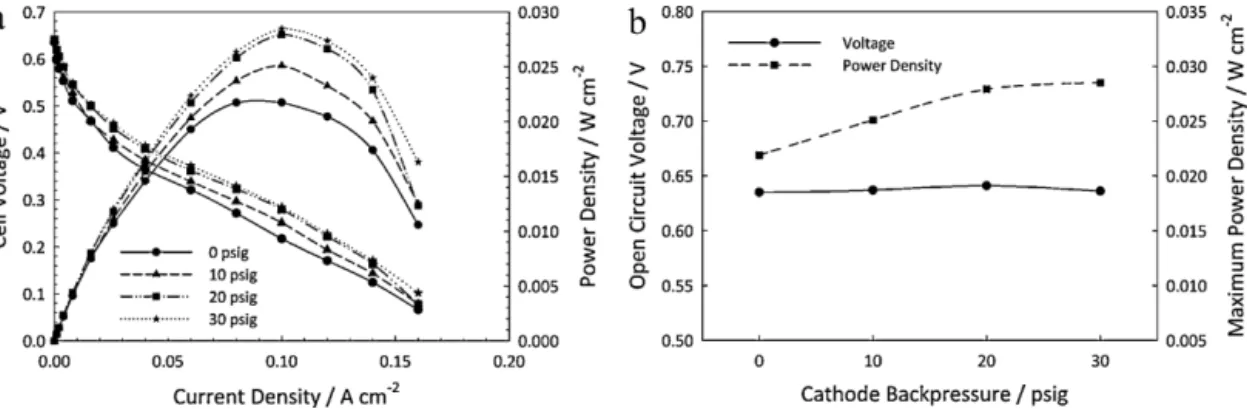

Fig.4showstheeffectofcathodebackpressureonthecell per-formance.Ingeneraltheperformanceimproveswithincreasing thebackpressure,mainlybecauseofthereductionoftheactivation overpotential.Intheohmicregion,thefourcurveshavesimilar behaviour.However,inthemass transport region,the effectof increasingthebackpressureseemstodiminishasthecurrent den-sityincreases.Ethanoltransport in theNafionmembrane takes placethroughthreedifferentphenomena:electro-osmosis; diffu-sionandhydraulicpermeation.Whenthepressureatthecathodeis higherthanattheanode,thereisbackconvectionofethanolfrom thecathodetotheanodeduetothehydraulicpermeation.This resultsinanoverallreductionofethanolcrossover.Thereduction ofethanolconcentrationinthecathodewillreducetheparasitic currentsandpoisoningcreatedbythereactionofethanolonthe cathodeactivesites.Thisenhancestheoxygenreductionreaction kineticsandreducestheactivationoverpotentialasseeninFig.4. Thecathodebackpressurealsoincreasestheoxygensolubilityin

theNafionionomerpresent inthecatalyst layer.Thiswill pro-duceahigheroxygenconcentrationinthetriplephaseboundary, enhancingtheoxygenreductionreactionrate.

Asmentionedpreviously,themaximumcurrentdensityvalues areverysimilaratthefourtestedbackpressures.Athigher cur-rentdensitiestheconcentrationofethanolintheanodecatalyst layerislower,whichaffectsthefuelcellperformanceintwoways. First,theconcentrationoverpotentialattheanodeincreasesand second,thecrossoveroftheethanolduetodiffusiondecreasesas thedifferenceinconcentrationbetweentheanodeandthecathode isreduced.Therefore,thefactthatthemaximumcurrentdensity isnearlyindependentofthecathodebackpressuresuggeststhatin thisregionofthepolarizationethanolmasstransferisgoverning thecellperformance.Thereductionofthecrossoverrateand there-foretheparasiticcurrentwithincreasingcellcurrenthasbeenalso reportedbyAndreadisetal.throughamodellingstudy[22].Inthe samemodellingwork,itwasreportedthattheethanolcrossover ismaximalatOCV.Inthepresent study,Fig.4bshowsthatthe OCVisalmostunaffectedbybackpressurewithastablevalueat 0.64V(variationsareintheorderofmV).Itisimportanttonote thatastabilizationperiodof30minwasusedbeforemeasuring eachpolarizationcurve.TheOCVwasfoundtobeverysensitiveto thechangeofconditionsbutonlyatthemomentwhenthe pertur-bationwasmade.Forexample,anOCVof0.8Vwasrecordedwith increasingbackpressurebutonlyforafewseconds,anditwould slowlydecreaseuntilreachingastablelowerpoint.Itwouldhave beenexpectedthatahigherbackpressurewouldresultinahigher OCVduetothereductionoftheethanolcrossover.Thefactthat thesteadystateOCVisalmostunchangedwithincreasing back-pressurecanbeduetoasteadypoisoningofthecathodecatalyst layer.Thismaybeduetoanaccumulationofethanolatthe cath-odesideofthemembrane,whichlowerstheinitiallyrecordedhigh OCVafterapressure increase.Asforthemaximumpower den-sity,itincreasesalmostlinearlywithincreasingbackpressureupto 20psig(Fig.4b).Byincreasingthepressurefrom20to30psigthe performancedoesnotimprove,thereforeasaturationpointmight havebeenreachedat20psig.Itisimportanttonotethatthereis alsothecrossoverofspeciesfromthecathodetotheanodesuchas oxygen,ethanoland/orreactionproductsofethanoloxidationthat mayaccumulateatthecathodesideofthemembrane,whichwould increasebyincreasingthecathodebackpressure.JamesandPickup havediscussedtheissueofethanoloxidationproducts(aceticacid andacetaldehyde)crossingtotheanodeside[23].WhileJablonski etal.reportedtheeffectofoxygencrossingfromthecathodetothe anodeandreactingchemically[24]withethanoltoproduceacetic acidandacetaldehyde.Ineithercasethepresenceof electrochem-icalreactionproductsintheanodewouldlowerthecell’sOCVand performanceandcounteractthepositiveeffectofbackpressureon thecathodekinetics.

Fig.5showstheeffectoftemperatureontheDEFCperformance withcathodebackpressure(30psig)and withoutcathode back-pressure(0psig).ThepolarizationcurvesinFigs.5a andbshow asimilarbehaviourwithincreasingthetemperature.Thekinetic regionisenhancedandtheslopeoftheohmicregiondecreases. Electrodekinetics,membraneconductivityandmasstransfer prop-erties are thermally activated, therefore it is expected that an incrementin fuelcelltemperaturewillresult ina performance enhancement. Onthe otherhand,fuelcrossoveris alsoa ther-mallyactivatedprocess.WithincreasingtemperaturetheNafion polymerbackbonerelaxesandexpandsallowinghighertransport rates,inadditiontheethanoldiffusivityisalsoenhanced[13,25]. Therefore the cathodekineticshastwo competing effects with increasingtemperature.LiandPickupreportedthattheeffectof ethanolcrossoverissosignificantthatthecathodeperformance decreaseswithincreasingtemperaturealthoughtheoxygen reduc-tionreactionrateincreaseswithtemperature.Theyconcludedthat

Fig.4.Effectofcathodebackpressureonfuelcellperformancefor1MEtOHfeed(2mLmin−1and0psig)andnon-humidifiedoxygen(300mLmin−1)at90◦C,(a)polarization

andpowercurvesand(b)opencircuitvoltageandmaximumpowerdensity.

theoverallcathodebehaviourmaybetheresultofanopposing dependencewithtemperatureduetotheparasiticcurrentand poi-soningofthecatalyst[14].Butoverall,thedependenceofothercell processeswithtemperatureseemstobegreaterthanthecrossover sincetheperformanceisenhanceddespitetheincreaseinethanol crossover.

The maximum power density increases with temperature almostlinearly forboth conditions as seenin Fig. 5c,withthe exemptionofthe60◦Cpointfortheunpressurizedcondition.The

differenceinpowerdensityforthesystemsatthesame temper-aturebutwithandwithoutbackpressureisinthe6–7mWcm−2

rangeforallthepointsexceptforthe60◦Cpointwherethe

differ-enceis3mWcm−2.Thesmallerdifferenceatalowesttemperature

suggeststhatat60◦Cthecrossovereffectislessimportant.

There-foretheeffectofthebackpressureisreduced.TheOCVshoweda verysmallpositivedependencewithtemperatureinboth circum-stances(Fig.5c)andwasslightlyhigherwithcathodebackpressure. WhileSongetal.[13]showedthattheOCVwasgreatlyaffectedby temperature,althoughtheirworkwasdoneatarangelowerthan 75◦C.Forexample,whenthetemperaturewasreducedfrom75◦C

to55◦CtheOCVdecreasedfrom0.62to0.53V.Thiscouldindicate

that,atlowertemperatures,theanodekineticsaremoreimportant thantheeffectofethanolcrossover.Thereforeanincreaseinthe temperaturewouldimprovetheOCV.Inthiswork,athigher tem-peraturesasinFig.5aandc,competingeffectbetweenenhanced anodekineticsandhighercrossoverwithincreasingtemperature, resultedinanalmostinvariableOCVwithtemperature.

3.3. Effectofethanolflowrateandethanolconcentration

Fig.6showstheeffectofflowrateofethanolsolutiononthefuel cellperformanceintherangeof0.6–5mLmin−1.Theperformance

isalmostinvariableinthe1–5mLmin−1rangebutfor0.6mLmin−1

themaximumpowerdensityisarounda10mWcm−2lowerthan

at thehigher flow rates (Fig. 6b).The differencein the perfor-mancebetween0.6mLmin−1andotherflowratesstartstoappear

athighercurrentdensitiesofthekineticregionofthepolarization curve(Fig.6a).Withincreasingcurrent,thedifferencebetweenthe 0.6mLmin−1curveandtheothercurvesremainsconstant,i.e.,the

curvesarealmostparallel.Thereforetheohmicandmasstransfer

Fig.5.Effectofcelltemperatureonfuelcellperformancefor1MEtOHfeed(2mLmin−1and0psig)andnon-humidifiedoxygen(300mLmin−1)at90◦C,(a)polarizationand

10630 V.Alzateetal./JournalofPowerSources196 (2011) 10625–10631

Fig.6. Effectofethanolsolutionflowrateonfuelcellperformancefor1MEtOHfeed(0psig)andnon-humidifiedoxygen(300mLmin−1,30psig)at90◦C,(a)polarization

andpowercurvesand(b)opencircuitvoltageandmaximumpowerdensity.

Fig.7.EffectofethanolconcentrationfuelcellperformanceforaqueousEtOHfeed(2mLmin−1and0psig)andnon-humidifiedoxygen(300mLmin−1,30psig)at90◦C,(a)

polarizationandpowercurvesand(b)opencircuitvoltageandmaximumpowerdensity.

overpotentialsarenotaffectedbytheethanolflowrate.This sug-gestsasurfacephenomenoneffectatlowethanolflowrates,such aslowerremovalofreactionproductsthatblockactivesitesorthe decreaseofin-planetransportofreactantandthereforealower utilizationoftheavailablecatalystsites.

Theeffect of ethanol concentrationon thecell performance is illustrated in Fig. 7. It is seen that the different regions in thepolarizationcurvehavedifferentdependenceontheethanol concentration(Fig.7a).Both,theOCV(Fig.7b)andthefuelcell per-formanceinthekineticregionincreasewithdecreasingethanol concentration.Whileinthemasstransferregiontheperformance increaseswithincreasingethanolconcentrationupto2M.Atvery lowethanolconcentrationtheperformancesuddenlydropsdue tomasstransferlimitations. With0.1Mtheperformancedrops atacurrentdensityofapproximately0.015Acm−2,whereasthis

happensat0.06Acm−2 foraconcentrationof0.5M.Inthecase

of1Methanol solution,thereis a slightinflection inthecurve at0.14Acm−2.Atthesethreepointstheethanolstoichiometries

are8.04,10.72and9.18,respectively(assumingthepartial oxida-tionreactionofethanoltoaceticacid,i.e.,4electronspermolecule ofethanol).Therefore,onecanconcludethatunderthese condi-tionsaminimumstoichiometryofapproximately10isnecessary toavoidmasstransferlimitations.Byincreasingtheconcentration from1Mto2Mtheperformanceisalmostinvariable,differences areonlyseenatthemaximumcurrentdensity.Whileincreasing ethanolconcentrationfrom2Mto5Mproducesadropinthe per-formanceinallregionsofthepolarizationcurve.Intermsofthe maximumpowerdensitythereisamaximumbetween1Mand 2M(Fig.7b).Asseenfromtheseresults,byvaryingtheethanol concentrationthereisaclearcontributionoftwoeffectstothecell performance.Bettermasstransferathighethanolconcentrations andlowerethanolcrossoveratlowethanolconcentrations.Atlow currentsthereisalowconsumptionofethanol;thereforea vari-ationofethanolconcentrationdoesnotaffecttheanodekinetics inthestudiedconcentrationrange.Onthecontrary,thecathode kineticseemstobeenhancedbythelowerethanolconcentration

Fig.8.Effectofoxygenflowrateonfuelcellperformancefor1MEtOHfeed(1mLmin−1,0psig)andnon-humidifiedoxygen(300mLmin−1,0psig)at90◦C,(a)polarization

duetothelowerethanolcrossover.Withincreasingcurrentdensity, theethanolconcentrationstartstoplayaroleintheanoderesponse andtheextremecaseisseenwhenverylowethanolconcentrations weretestedwiththepresenceofalimitingcurrent.

3.4. Effectofoxygenflowrate

Fig.8showstheeffectofoxygenflowrateonthefuelcell per-formance.Thesetestswereperformedatatmosphericpressure.No effectontheperformancewasobservedinthe50–500mLmin−1

rangewith30psigbackpressure(resultsarenotshown).InFig.8a itisseenthattheperformanceincreaseswithincreasingoxygen flowrateupto300mLmin−1,increasingtheflowratefurtherdoes

notproduceanychangeontheperformance.Fig.8bshowsthatthe OCVandthemaximumpowerdensityincreasewithincreasingthe flowrate,whichisduetoahigherconcentrationofoxygenatthe cathodewithrespecttothecrossoverproductsandtoanincrease intherateofremovalofcrossoversubstancesthatcanpoisonthe cathodecatalyst.

4. Conclusions

Theeffectof operatingparameters ontheDEFCpolarization curve,OCVandmaximumpowerdensitywastestedandanalyzed. TheOCVwashighlydependantontheconcentrationofethanolin thefuelstreamandincreasesbydecreasingtheethanolcontent. Incontrast,theeffectoftheotherstudiedparametersontheOCV wasverysmall.Takingintoaccountthesesmallvariationsitcan besummarizedthattheOCVincreasedwiththeoxygenflowrate, cathodebackpressureandtemperature,andwasindependentof fuelflowrateandanodebackinglayer.

Ingeneral,thekineticallycontrolledregionofthepolarization curveswasenhancedbyincreasingthetemperature,the backpres-sureandtheoxygenflowrate,whileitdecreasedbyincreasingthe ethanolconcentration.Theseparametersaffectedeitherorboththe electrodeintrinsickineticsandtheethanolcrossover.Furthermore, thekineticresponseofthefuelcellwasfoundtobeindependent ofethanolsolutionflowrateandanodediffusionlayer.Thecell’s masstransferpropertieswereparticularlyaffectedbytheethanol concentrationandinlesserextentbytheanodebackinglayerand reactantflowrates.

Increasingthetemperatureimprovedthemaximumpower den-sityalmostlinearly.Withbackpressuretheperformanceincreased up to 20psig, further increments in the backpressure did not producehigherperformance.Similarbehaviourwasseenforthe oxygenflowrateatvalueshigherthan300mLmin−1.Higherpower

densitieswerefoundforethanolconcentrationof1Mandethanol flowratehigherthan1mLmin−1.

ThegasdiffusionlayersthatdidnothaveanMPLshowed supe-riorperformance.Intermsofthediffusionlayer,theDEFCsystem isuniquesincereactantsandproductsareallliquids.Thisisnot thecaseforthemoreextensivelystudiedsystemsusingmethanol (liquidfuel–gasproduct)andhydrogen(gasfuel–liquidproduct) asfuels.Thereforemoreworkisneededintheoptimizationofthe DEFCelectrodeproperties,includingdiffusionlayers.

Acknowledgments

TheNational ResearchCouncil Canada-Institute forFuel Cell Innovation(NRC-IFCI) andAgricultureAgri-FoodCanada(AAFC) through the Agricultural Bioproducts Innovation Network Pro-gram(ABIP)supportedthiswork.TheauthorsthankMariusDinu, AndrewMattie,KevinBereraandTomVanderhoekfortheir contri-butioninthefabricationoftheinkauto-spraysystemandfuelcell hardware.

References

[1]C.Lamy,S.Rousseau,E.M.Belgsir,C.Coutanceau,J.M.Léger,Electrochim.Acta 49(2004)3901.

[2]S.Song,P.Tsiakaras,Appl.Catal.B:Environ.63(2006)187.

[3] K.Fatih,V.Neburchilov,V.Alzate,R.Neagu,H.Wang,J.PowerSources195 (2010)7168.

[4]E.Antolini,E.R.Gonzalez,Catal.Today160(2011)28.

[5]E.V.Spinacé,M.Linardi,A.O.Neto,Electrochem.Commun.7(2005)365. [6] E.Antolini,F.Colmati,E.R.Gonzalez,Electrochem.Commun.9(2007)398. [7]A.Kowal,M.Li,M.Shao,K.Sasaki,M.B.Vukmirovic,J.Zhang,N.S.Marinkovic,

P.Liu,A.I.Frenkel,R.R.Adzic,Nat.Mater.8(2009)325.

[8]E.Lee,A.Murthy,A.Manthiram,Electrochim.Acta56(2011)1611.

[9] J.Ribeiro,D.M.dosAnjos,K.B.Kokoh,C.Coutanceau,J.M.Léger,P.Olivi,A.R.de Andrade,G.Tremiliosi-Filho,Electrochim.Acta52(2007)6997.

[10]R.F.B.DeSouza,M.M.Tusi,M.Brandalise,R.R.Dias,M.Linardi,E.V.Spinacé,M.C. dosSantos,A.O.Neto,Int.J.Electrochem.Sci.5(2010)895.

[11] J.E.Thomas,A.R.Bonesi,M.S.Moreno,A.Visintin,A.M.CastroLuna,W.E.Triaca, Int.J.HydrogenEnergy35(2010)11681.

[12]X.Zhao,W.Li,L.Jiang,W.Zhou,Q.Xin,B.Yi,G.Sun,Carbon42(2004)3263. [13]S.Song,W.Zhou,J.Tian,R.Cai,G.Sun,Q.Xin,S.Kontou,P.Tsiakaras,J.Power

Sources145(2005)266.

[14] G.Li,P.G.Pickup,J.PowerSources161(2006)256.

[15]H.Pramanik,A.A.Wragg,S.Basu,J.Appl.Electrochem.38(2008)1321. [16]S.Song,G.Wang,W.Zhou,X.Zhao,G.Sun,Q.Xin,S.Kontou,P.Tsiakaras,J.

PowerSources140(2005)103.

[17] S.K.Biswas,P.Sambu,S.Basu,Asia-Pac.J.Chem.Eng.4(2009)3.

[18]M.Blanco,D.P.Wilkinson,in:D.P.Wilkinson,J.Zhang,R.Hui,J.Fergus,X.Li (Eds.),ProtonExchangeMembraneFuelCell—MaterialsPropertiesand Perfor-mance,CRCPress,BocaRaton,2010,pp.191–303.

[19]G.M.Andreadis,A.K.M.Podias,P.E.Tsiakaras,J.PowerSources194(2009)397. [20]T.S.Zhao,C.Xu,R.Chen,W.W.Yang,Prog.EnergyCombust.Sci.35(2009)275. [21]G.Q.Lu,C.Y.Wang,J.PowerSources134(2004)33.

[22]G.M.Andreadis,A.K.M.Podias,P.E.Tsiakaras,J.PowerSources181(2008)214. [23]D.D.James,P.G.Pickup,Electrochim.Acta55(2010)3824.

[24]A.Jablonski,P.J.Kulesza,A.Lewera,J.PowerSources196(2011)4714. [25]S.Kontou, V. Stergiopoulos, S.Song, P. Tsiakaras,J. Power Sources 171