Publisher’s version / Version de l'éditeur:

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

RILEM Workshop on Repair Mortars for Historic Masonry [Proceedings], pp. 1-12,

2005-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=c8a59127-53c3-47c3-9cae-3b6f955a9f5d https://publications-cnrc.canada.ca/fra/voir/objet/?id=c8a59127-53c3-47c3-9cae-3b6f955a9f5d

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Preliminary evaluation of the freeze-thaw resistance of hydraulic lime

mortars

Preliminary evaluation of the freeze-thaw resistance

of hydraulic lime mortars

Maurenbrecher, A.H.P.; Trischuk, K.;

Subercaseaux, M.I.; Suter, G.T.

NRCC-47646

A version of this document is published in / Une version de ce document se trouve dans :

RILEM Workshop on Repair Mortars for Historic Masonry, Delft, The Netherlands,

January 26-28, 2005, pp. 1-12

Preliminary evaluation of the freeze-thaw resistance of

hydraulic lime mortars

A. H. P. Maurenbrecher, K. Trischuk, M. I. Subercaseaux & G. T. Suter

Institute for Research in Construction, National Research Council Canada (author 1 & 2) Heritage Conservation Directorate, Public Works and Government Services Canada (3) Suter Consultants Inc., Victoria, B.C., Canada (4)

Preprint for the RILEM workshop on repair mortars for historic masonry 26-28 January 2005, Delft University, the Netherlands

Abstract

Hydraulic lime is regaining popularity in restoration work. This paper describes the results obtained from an initial assessment of mortar made using hydraulic limes available in Canada. The emphasis was on resistance to frost damage, a major consider-ation in Canada’s cold winters. The mortars, all air-entrained to improve frost resistance, were tested as part of small stone masonry specimens to more realistically simulate performance in practice (as opposed to mortar samples on their own). The frost dura-bility was assessed by subjecting the specimens to a uni-directional freeze-thaw test. The results show hydraulic lime mortars with air entrainment have the potential for good performance in terms of freeze-thaw resistance. Factors which influenced freeze-thaw resistance were the type and source of hydraulic lime, length of initial damp curing, mortar compaction, stone wetting before mortar application, and sand grading.

1. Introduction

Hydraulic lime is regaining popularity in restoration work. In contrast to non-hydraulic lime, it has hydraulic properties allowing it to harden by reaction with water. In addition, like non-hydraulic lime, it also gains strength by reacting with both carbon dioxide and moisture in the air. Hydraulic limes were traditionally divided into three types: feebly, moderately and eminently hydraulic. The European standard on building limes [1], classifies the three types in terms of strength (for example NHL 2, NHL 3.5 and NHL 5 for natural hydraulic limes). Hydraulic and non-hydraulic limes were used in the past as the binders in mortar but their use as sole binders in mortar declined due to the much faster strength development of mortars containing Portland cement. Non-hydraulic lime continued to be used with Portland cement to give the mortar better workability. But the decline in the use of non-hydraulic and hydraulic lime mortars has meant expertise in the

application of such mortars was lost. There is a need to regain knowledge and experience in its use. Hydraulic limes, imported into Canada from USA and Europe, are beginning to be used again in restoration. There are no current standards in Canada for hydraulic lime or for mortars using hydraulic lime. Guidance is especially needed on appropriate mortar mixes and their application in Canada.

2. Test Program

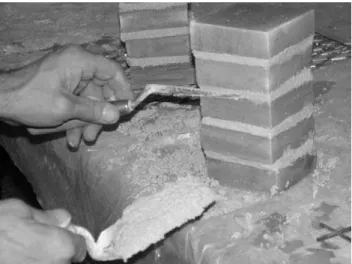

The objective of the test program was to provide an initial assessment of hydraulic limes that were available for use in Canada. This would provide a basis for future guidance and further investigations. The main emphasis was put on resistance to frost damage, a major consideration in Canada’s cold winters. An air-entraining agent was added to all the mortars to improve frost resistance. Properties of the mortars and their bond to stone were also assessed. The mortars were tested as part of small stone masonry specimens to more realistically simulate performance in practice. The 5 stone high specimens were built by two different masons using a jig and a mortar template (Fig. 1).

Figure 1 Mortar joints being finished flush with surface after construction of the masonry prism. Nominal size of stones is 90 x 90 x 30 mm.

2.1 Materials used

The hydraulic limes tested were Unilit HD system BFluid X/A (from Belgium/Italy), Riverton with an integral air entraining agent (from USA), St Astier NHL2, 3.5 & 5 (from France) and a Canadian pre-mix mortar (HL1 containing St Astier NHL3.5, a manufactured sand and an air entraining agent). Riverton and Unilit were assumed to be moderately hydraulic limes (equivalent to NHL3.5). Three sands were used: masonry sand, concrete sand with particles greater than 2.5 mm removed, and a manufactured

sand. Figure 2 shows the grading curves. A fine, powdered, modified resin, air-entrainer was added to hydraulic limes without an integral air-entrainer. The masonry specimens were made with St Canut sandstone, a replacement stone for the Nepean sandstone used in the buildings on Parliament Hill in Ottawa (the local Nepean stone is no longer quarried). Table 1 gives the stone properties. Both new stone and cleaned stone from previous test specimens were used.

0 10 20 30 40 50 60 70 80 90 100 0.1 1 10 Sieve size (mm)

Percentage sand passing

Fine limit for masonry sand CSA A179-04 mortar standard [2]

Coarse limit for masonry sand CSA A179-04 mortar standard [2] Masonry

sand

Manufactured sand

Sieved concrete sand

Figure 2 Sand grading

Note: The grading of the manufactured sand in the pre-mix mortar is proprietary; the pre-mix mortar ingredients all pass through a 2.5 mm sieve.

Table 1 Properties of St Canut stone

Bulk density (kg/m3) 2527

Porosity based on bulk & absolute densities (%) 5.4 Water absorption by immersion (% by weight)

24 hour 0.77

Vacuum saturation 1.75

Water absorption by capillary action

Initial rate of absorption (kg/m2/min) 0.078 Water absorption coefficient (kg/m2/sec½) 0.0060

2.2 Test specimens

The test program was divided into two phases. The first phase of the test program covered:

• Mortars made with St Astier NHL2 & NHL3.5, Riverton, Unilit and the pre-mix. • Mortar proportions were nominally 1:3 lime:dry sand by volume (the pre-mix

proportions are proprietary).

• Mortars were evaluated with the masonry and manufactured sands.

• Masonry test specimens were cured damp for 4 days after construction, and then in laboratory air at 50-55% relative humidity and 23°C until tested. A total curing period of approximately 60 days was envisaged because hydraulic lime mortars gain strength at a slower rate than mortars with Portland cement. The 4 day initial damp cure was meant to simulate the length of damp curing likely to occur on a building site. At an age of 56 days the test specimens were immersed in water for 7 days and then only subjected to one freeze-thaw cycle because of equipment breakdown. The specimens were returned to the laboratory. When the specimens were about 220 days old the freeze-thaw test was finally restarted with an initial 7 day immersion.

In the second phase the following changes were made:

• The St Astier NHL3.5 lime was replaced by the NHL5 lime. • A nominal lime:sand proportion of 1:2 was used in addition to 1:3.

• A local concrete sand with a coarse particle grading was used instead of the masonry and manufactured sands. Particles greater than 2.5 mm were removed. This sand was available locally and expected to give better performance than the masonry sand. • The masonry test specimens were built with stone pre-wetted by two different

procedures (stone was either soaked or briefly misted; in phase 1 they were misted). The soaked stone was immersed in water for approx 12 hours and then allowed to stand in air for about 45 minutes before use.

• A different mason built the masonry test specimens. He compacted the mortar more during construction.

• The masonry test specimens were cured damp for a longer period after construction (7 and 28 days instead of 4 days), and thereafter in laboratory air at 50-55% relative humidity and 23°C until tested at an age of 62/63 days.

2.3 Mortar properties

Actual batching of the mortar mix ingredients was by weight. The water content was adjusted to give an initial mortar consistency, as measured by the Vicat cone [3], in the range 20 to 30 mm (flow 47-80% [4]). Air content of the fresh mortar was in the range 11-18% (mostly 12-16%). Properties of the hardened mortar are given in Table 2. Values for porosity, vapour transmission & water absorption are meant as a rough guide (tests on single mortar joints of nominal thickness 10 mm). The depth of carbonation of the mortar joints was low. In phase 1, check tests on mortar joints taken from 7 months old masonry specimens showed carbonation had only penetrated 2 mm.

Table 2 Hardened mortar properties Lime Mix Sand Compressive strength

MPa Poro-sity Water vapour Rate of Phase 1 Phase 2 % trans- water

28d air dry cube 240d air dry cube 27d damp cube 62d air dry cube mission g/m2/h abs kg/m2 /sec½ (first 7d damp) (first 27d damp)

Unilit 1:3 Mnf 0.85 0.52 - - - - 0.034 1:3 Con - - 1.4 3.0 27.1 7.2 0.025 1:2 - - 2.3 5.0 23.8 6.8 0.032 Riverton 1:3 Mnf 1.4 1.9 - - 30.7 7.9 0.132 Mas 1.3 1.7 - - 31.4 8.4 0.080 1:3 Con - - 1.6 3.8 24.1 8.2 0.032 1:2 - - 3.5 7.2 23.1 6.5 0.030 St Astier 1:3 Mnf 0.33 0.44 - - 32.9 10.1 0.042 NHL2 Mas 0.32 0.42 - - 30.9 12.3 0.025 1:3 Con - - 0.66 1.9 28.2 5.9 0.064 1:2 - - 0.92 2.1 26.3 9.2 0.066 1:2 Mnf - - 0.77 1.9 31.7 7.9 0.062 St Astier NHL3.5 1:3 Mnf 0.73 0.78 - - 32.7 8.2 0.042/ 0.030 Mas 0.63/ 0.75 0.76/ 0.92 - - 31.3 9.3/8.4 0.041/ 0.032 St Astier NHL5 1:3 Con - - 1.6 3.1 26.3 7.5 0.032 HL1 - Mnf 5.7 7.5 - - 30.5 4.2 0.031 pre-mix - - - 4.2 9.4 29.4 9.1 0.009 Notes to Table 2:

(1) Sand: Con (sieved concrete sand), Mas (masonry sand), Mnf (manufactured sand).

(2) Compressive strength based on 50/51 mm mortar cubes (values average of 3 cubes). After initial damp curing, cubes kept at 50-55% relative humidity and 23°C until tested.

(3) Porosity derived from bulk and absolute densities. Vapour transmission is based on the wet cup method in ASTM standard E96 [5]. Rate of water absorption is based on EN1925 [6].

2.4 Freeze-thaw test

The mortar in the masonry specimens was subjected to a uni-directional freeze-thaw test adapted from a Dutch standard [7]. The specimens were first immersed in water for 7 days, and then exposed to 24 one-day long freeze-thaw cycles before a first complete visual evaluation (Figs 3 & 4). The test was then extended to approximately 60 cycles to obtain a better idea of the comparative durability of the different mortars. The performance of mortar was based on visual signs of failure such as cracking, spalling, or significant erosion of the mortar, and loss of bond between stone and mortar. Cracks

within the mortar joint and bond between the mortar and stone, difficult to assess visually during the test, were checked when the masonry specimens were taken apart after the test. An assessment of comparative durability is the main usefulness of the tests. It is more difficult to relate the results to performance in practice. Mortars surviving 24 cycles are assumed to perform adequately in vertical wall surfaces in buildings protected by a water shedding detail at the top. More data is needed to relate test results to field performance. From limited field observations of hydraulic lime mortars in the Ottawa region over the past eight years, performance has been good so far except in locations subject to high moisture and poor drainage.

Figure 3 Insulated masonry specimens in the freeze-thaw cabinet during a thaw cycle.

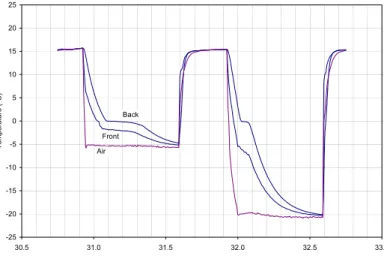

-25 -20 -15 -10 -5 0 5 10 15 20 25 30.5 31.0 31.5 32.0 32.5 33.0 Time (days) T e mper atur e ( °C ) Front Back Air

Figure 4 Temperature at the front and back face of a masonry specimen during two typical freeze-thaw cycles

2.5 Results

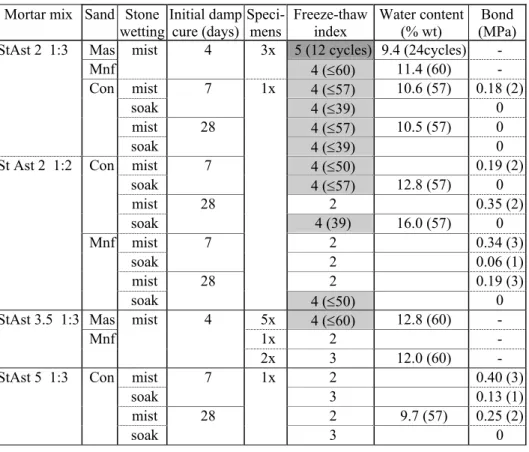

Table 3 lists the freeze-thaw test results, the moisture content in a few mortar joints immediately following the test, and the flexural bond strength of mortar joints with bond following the freeze-thaw test. Freeze-thaw performance was given a provisional classification using the following indices:

At completion of test (Phase 1, 60 cycles; Phase 2, 57 cycles): 1. No apparent damage

2. Light surface erosion and/or debonding of one mortar joint.

3. Debonding of two or more mortar joints, and/or minor damage to corner of one mortar joint.

At or before completion of the test:

4. Damage to mortar after 24 cycles (cracks, spalling or severe surface erosion). 5. Damage to mortar before 24 cycles (cracks, spalling or severe surface erosion). In phase 1, with an initial damp curing period of 4 days, mortar damage occurred to the St Astier NHL2 & NHL3.5, and Unilit mortars. These were also the mortars with the lowest compressive strengths (less than 1 MPa cube strength at the start of the thaw test; Table 2). The NHL2 mortar with masonry sand failed before the 24 freeze-thaw cycle limit while the same mortar with manufactured sand passed the 24 cycles but failed before 60 cycles (Fig. 5). The NHL3.5 mortar with masonry sand passed 24 cycles but failed before 60 cycles. No mortar damage occurred with the mortar with manufactured sand. The Unilit mortar performance was unexpected – it failed by the 2nd cycle even though a manufactured sand was used (Fig. 4). It indicates the Unilit mortar may be very sensitive to the initial damp curing condition (in phase 2 no damage occurred by the end of the test when the damp curing period was extended to 28 days). No mortar damage occurred to the Riverton and pre-mix mortars. These two mortars also had higher compressive strengths (1.7/1.9 MPa for the Riverton and 7.5 MPa for the pre-mix). Loss of bond occurred in some or all of the mortar joints with all the mortars. Separate flexural bond tests on other prisms had also shown very low bond strengths (<0.2 MPa).

In phase 2, performance improved (no observed mortar damage before 24 cycles). The main reasons for this are likely to be the longer initial damp curing periods and the stronger mixes (1:2 in addition to 1:3). Better compaction of the mortar may also have contributed. Damage to mortar was mainly confined to some of the St Astier NHL2 mortar mixes (Fig. 7); this mortar also had the weakest compressive strength (~2 MPa cube strength at the start of the freeze-thaw test). Damage was also observed in one joint of a pre-mix mortar and possibly in a Riverton mortar. In both cases in masonry specimens built with stone which had been pre-wetted by soaking before construction. Masonry specimens with ‘soaked’ stone usually had poorer performance including less bond between the mortar and stone. In comparison to phase 1, bond strength was greatly improved for specimens built with misted stone (tests were conducted on mortar joints which had survived the freeze-thaw test without loss of bond). A 1:2 mix instead of a 1:3 mix improved performance for the NHL2 and Unilit mortars. The NHL2 mortar with

manufactured sand also performed better than the one with sieved concrete sand. This may be due to the greater angularity of the sand particles in the manufactured sand. Mortar which had been damp cured for 28 instead of 7 days tended to perform better but not in all cases (there was not enough space in the freeze-thaw cabinet to evaluate a 7 day damp cure period for the Unilit mortar). Overall the freeze-thaw performance of the mortars was good considering the low compressive strengths of many of the mortars. Uneven wetting patterns were observed in some NHL2 mortar joints showing moisture distribution was not necessarily uniform. Two examples are shown Figure 8; the cause of these patterns is not known. Table 3 gives the average water content of some mortar joints immediately after completion of the freeze-thaw test.

Table 3 Freeze-thaw results for masonry specimens Mortar mix Sand Stone

wetting Initial damp cure (days) Speci-mens Freeze-thaw index Water content (% wt) Bond (MPa) StAst 2 1:3 Mas mist 4 3x 5 (12 cycles) 9.4 (24cycles) -

Mnf 4 (≤60) 11.4 (60) -

Con mist 7 1x 4 (≤57) 10.6 (57) 0.18 (2)

soak 4 (≤39) 0

mist 28 4 (≤57) 10.5 (57) 0

soak 4 (≤39) 0

St Ast 2 1:2 Con mist 7 4 (≤50) 0.19 (2)

soak 4 (≤57) 12.8 (57) 0 mist 28 2 0.35 (2) soak 4 (39) 16.0 (57) 0 Mnf mist 7 2 0.34 (3) soak 2 0.06 (1) mist 28 2 0.19 (3) soak 4 (≤50) 0

StAst 3.5 1:3 Mas mist 4 5x 4 (≤60) 12.8 (60) -

Mnf 1x 2 -

2x 3 12.0 (60) -

StAst 5 1:3 Con mist 7 1x 2 0.40 (3)

soak 3 0.13 (1)

mist 28 2 9.7 (57) 0.25 (2)

Mortar mix Sand Stone wetting Initial damp cure (days) Speci-mens Freeze-thaw index Water content (% wt) Bond (MPa) Riverton 1:3 Mas mist 4 3x 3 9.8 (57) -

Mnf 3 10.9 (57) 0

Con mist 7 1x 1 0.59 (3)

soak 2/4 (≤57) 11.7 (57) 0.15 (2)

mist 28 1 0.77 (4)

soak 3 11.0 (57) 0.10 (1)

Riverton 1:2 Con mist 7 2 0.87 (3)

soak 3 11.0 (57) 0.69 (2) mist 28 1 0.71 (4) soak 3 0.24 (1) Unilit 1:3 Mnf mist 4 3x 5 (≤2) 10.1 (24) 0 Con mist 28 1x 3 0 soak 3 9.5 (57) 0

Unilit 1:2 Con mist 2 0.27 (2)

soak 1 0.23 (2) Pre-mix Mnf mist 4 3x 3 - 2x 2 11.6 - mist 7 1x 3 14.4 0 soak 4 (≤50) 0 mist 28 1 1.22 (3) soak 2 0.23 (2) Notes to Table 3:

1. Sand: Mas (masonry sand), Mnf (manufactured sand), Con (sieved concrete sand). 2. The freeze-cycle when mortar damage was first observed is noted in brackets (mixes with

freeze-thaw indices of 4 or 5).

3. Water content of single mortar joints after the freeze-thaw test is shown. Value in brackets shows the freeze-thaw cycle when the masonry specimen was removed from the cabinet. 4. Flexural bond strength was determined using a bond wrench. The masonry specimens, taken

from the freeze-thaw cabinet, were allowed to air dry in the laboratory before testing. The value in brackets is the number of mortar joints tested (maximum for one specimen is four). 5. In phase 1 (4 day initial damp cure), specimens were just over 7 months old at the start of the

freeze-thaw test. The test was meant to start at 56 days but it was stopped after 1 cycle because of a malfunction of the freeze-thaw cabinet. This meant the specimens had an additional 7 day wet curing before this aborted test. While the masonry specimens were in the environmentally controlled room following the breakdown of the cabinet, selected specimens were additionally intermittently sprayed with water once or twice a day 47 times over a period of 39 days. This did not seem to affect their performance in the freeze-thaw test.

6. In phase 2 (7 or 28 day initial damp cure), specimens were 63 days old at the start of the test. One specimen with Riverton lime is given two indices. A hairline crack parallel to the face of the mortar joint was observed after the freeze-thaw test (30-40 mm from face). If this were caused by the test, the freeze-thaw index would be 4.

Figure 5 Damage by erosion to exposed face of mortar joint. Mortar with 1:3 Unilit lime:manufactured sand after 24 cycles (4 day initial cure / misted stone).

Figure 6 Damage to exposed face of mortar joint. Mortar with 1:3 St Astier NHL2 lime:masonry sand after 24 cycles (4 day initial cure / misted stone).

Figure 7 Failure at exposed face of bottom mortar joint. Mortar with 1:3 St Astier NHL2 lime:concrete sand after 57 cycles (28 day initial cure /misted stone).

Figure 8 Unusual dampness patterns in mortar joints with St Astier NHL2 lime. Mortar with 1:3 masonry sand after 24 cycles (4 day initial cure /misted stone), and with 1:2 concrete sand after 57 cycles (7 day initial cure /soaked stone).

3. Conclusions

The test results show hydraulic lime mortars with air entrainment have the potential for good performance in terms of freeze-thaw resistance and tensile bond with the St Canut stone. The following interim conclusions were drawn from the tests. Further testing and evaluation is needed to confirm them and also the validity of their application to masonry units other than St Canut stone.

1. Hydraulic lime from different manufacturers can vary. Therefore it is important to determine the properties in each case.

2. The weakest lime, St Astier NHL2, had the poorest performance in terms of resistance to freeze-thaw. This was expected. Unexpected was the very poor perfor-mance of the Unilit mortar with 4 days initial damp curing. When the damp curing period was extended to 28 days, performance greatly improved.

3. Sand with a coarse particle grading improves resistance to freeze-thaw action. Greater angularity of the sand particles may further improve performance.

4. Excessive wetting of the stone before application of the mortar reduces freeze-thaw resistance and tensile bond strength.

5. The Unilit and St Astier NHL2 mortars with a mix proportion of 1:2 lime:sand had better freeze-thaw performance than 1:3 mixes.

6. Better compaction of the mortar is likely to improve tensile bond strength between the stone and the mortar, and may also improve freeze-thaw performance.

7. Longer initial damp curing can improve performance in terms of freeze-thaw resistance and tensile bond strength. The length of the damp curing period needed in the laboratory is dependent on how well hydraulic lime mortars gain strength in field conditions. Laboratory results need to be correlated to field performance.

8. The cause of observed anomalies in the moisture distribution observed in some mortar joints following the freeze-thaw test needs to be determined.

4. Acknowledgements

This paper is the result of a collaborative effort by a team brought together by the Heritage Conservation Directorate at Public Works & Government Services Canada (HCD/PWGSC). The team members are M.I. Subercaseaux, L. Fontaine (HCD), G.T. Suter, K. Blades (Consultant in the Conservation of Historic Buildings Inc), K. Trischuk and A.H.P. Maurenbrecher. The PWGSC Heritage Masons, Daubois Inc., and Liner-Rolpanit Inc. provided help and materials.

5. References

1. EN459-2001. ‘Building Lime’. European standard available from the British Stan-dards Institution.

2. CSA A179-04. ‘Mortar and grout for unit masonry’. Canadian Standards Associa-tion. Mississauga, Ontario. Canada.

3. ASTM C780-02. ‘Test method for preconstruction and construction evaluation of mortars for plain and reinforced unit masonry’. ASTM International, West Consho-hocken, PA, USA.

4. ASTM C270-04. ‘Specification for mortar for unit masonry’. ASTM International, West Conshohocken, PA, USA.

5. ASTM E96-00. ‘Test methods for water vapour transmission of materials’. ASTM International, West Conshohocken, PA, USA.

6. EN1925-1999. ‘Natural stone test methods: Determination of water absorption coefficient by capillarity’. European standard available from the British Standards Institution.

7. NEN2872:1989. ‘Testing of stone like materials - determination of frost resistance (uni-directional freezing in a fresh water environment)’. Netherlands Standards Institute.