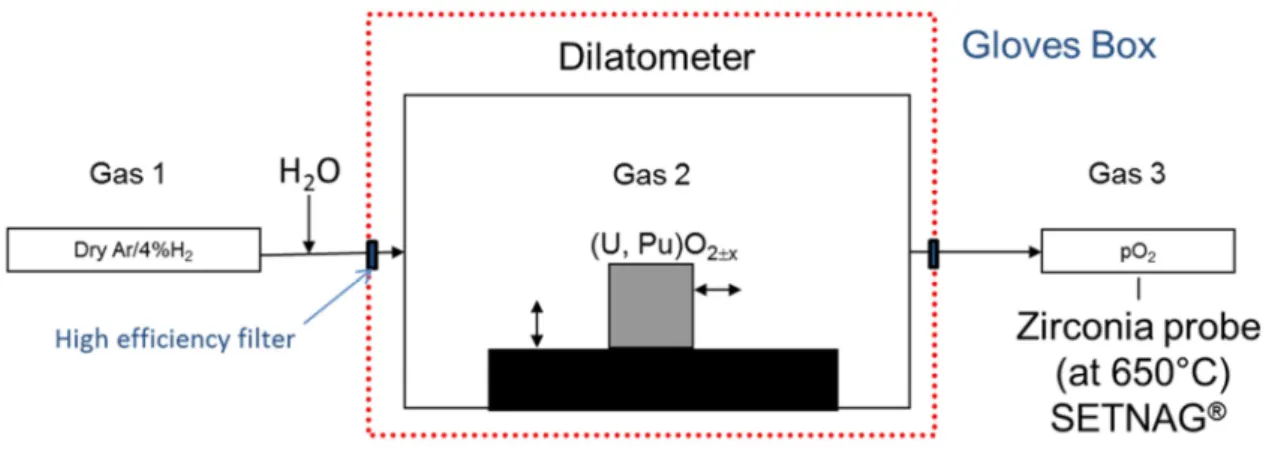

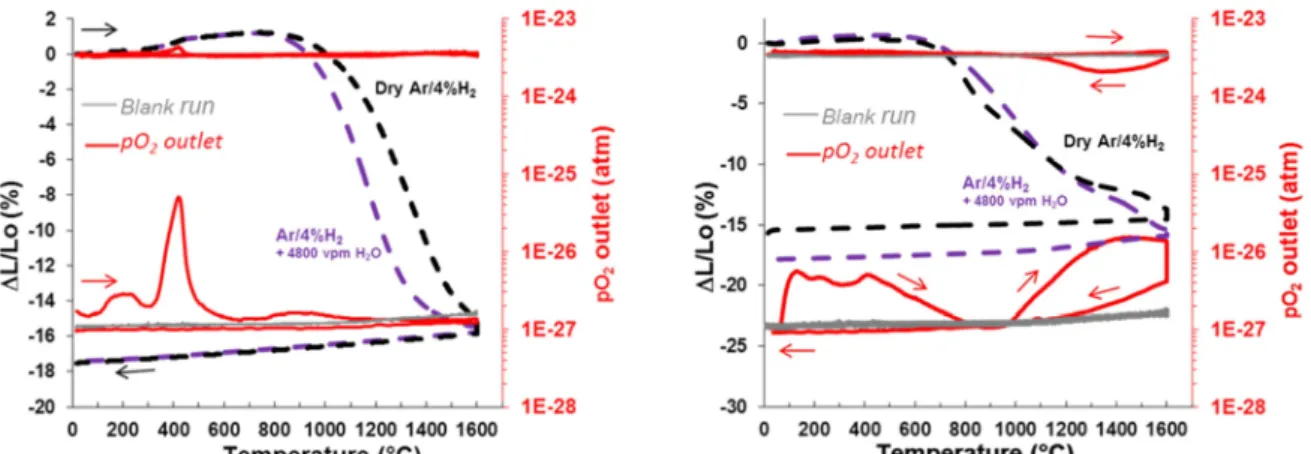

Development of a continuous O/M measurement technics during sintering for MOX application

Texte intégral

Figure

Documents relatifs

iii - For N3 pre-oxidized samples also, the stationary stage is observed for shorter times than in as-sintered N3 samples, but the steady creep rate is higher (fig. After

Therefore, precise knowledge of the functional changes in oxygen delivery is mandatory to, first, correctly inter- pret data from monitoring tissue oxygenation and, second, culture

[r]

Direct numerical simulation of a pulverized coal jet flame employing a global volatile matter reaction scheme based on detailed reaction mechanism. Numerical

In order to address this concern, a platform or walkway was proposed to make getting from one side of the test frame to the other easier and safer.. The walkway was required to

The profiles provide a guide to divide the atmospheric boundary layer into characteristic zones for penetrative convection, namely the superficial layer at the ground, the

(2001) the investment behaviour of small firms does not display a significantly higher cash-flow sensitivity than that of large firms, the large magnitude of the cash-flow effect,

´ E crire l’´eq uation d’E uler de ce prob l`eme et en d´eduire q ue la valeur du minimum est b ien la premi`ere valeur propre et q ue les points de minimum sont des vecteurs