HAL Id: hal-02319375

https://hal.archives-ouvertes.fr/hal-02319375

Submitted on 17 Oct 2019HAL is a multi-disciplinary open access archive for the deposit and dissemination of sci-entific research documents, whether they are pub-lished or not. The documents may come from teaching and research institutions in France or abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est destinée au dépôt et à la diffusion de documents scientifiques de niveau recherche, publiés ou non, émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés.

Distributed under a Creative Commons Attribution - NonCommercial - NoDerivatives| 4.0

The economics of non-GMO segregation and identity

preservation

David S Bullock, Marion Desquilbet

To cite this version:

David S Bullock, Marion Desquilbet. The economics of non-GMO segregation and identity preserva-tion. [Research Report] Inconnu. 2000, 35 p. �hal-02319375�

'TEâ*#$8S?JK'*

iln"

ndotPhe Bobierrecs

61ro3

"$âi

âiiiTs'"f3i"

The economics

of

non-GMO

segregation and

identity

preservation

Bullock,

D.S.,

Desquilbet,

M.*

October 2001

oocurutltnttot,l Éc0t,lottitrE RURALT RTt'tt'tES

I

ililt

|ilililil

ilil

lllll

lllllllll

llll

*008087*

David S. Bullock, Department of Agricultural and Consumer Economics, University of Illinois, 326 Mumford Hall, 1301 W. Gregory Drive,Urbana, IL 61801, United States, Phone (217)333-5510, Fax:

(217)333-5538,e-mail: iisbLrl I *i,'(ii).ui uÊ.s:du

I

tl

Marion Desquilbet, Institut National de la Recherche Agronomique, Economie et Sociologie Rurales, ruel-l.

Adolphe Bobierre, CS 61103,35011 Rennes cedex, France, Phone: (33) 223 48 56 08 . Fax: (33)223 48 53 80.A

e-mail: aesmdbift{sÀ*g}:".tlxa.**

Senior authorship

not

implied. The

authorswould

like to thank

ElisavetI.

Nitsi for

outstanding research support.

E

S

FT FTE

t\

tvt

D

1Abstract

Reiection

of

genetically modified organisms (GMOs) by some consumers worldwide hasled

to

the creationof

market signals encouragingthe

segregation andidentity

preservation(IP)

of

non genetically modified(GM)

grain fromGM

grain. This article examines the costsof non-GMO segregation and IP

for

seed producers, farmers and grain handlersin

the UnitedStates. For soybeans, costs

of

segregation and IPfor

farmers appear to come mainly from theproduction process

itself (i.e. from

foregoingplanting

of

cost-reducingGM

varieties).Additional costs

of

segregation for farmers, coming from cleaning farm machinery and havingto

haul grain fartheron

average, appearto

be small.A

major costfor

handlers appears tocome

from a flexibility

loss dueto

the

necessityof

dedicating equipmentto

oneof

twohandling channels (one

for

GMOs and onefor

non-GMOs).For

maize, an additional majorcost comes from the necessity of preventing pollination of non-GM varieties by

GM

pollen atthe

seedand farm

production

stages. Tolerancelevels

area

key

elementof

costsof

segregation,

and

zero-tolerancelevels may

be

impossible

to

obtain

without

major organisational and economic costs.keywords:

Genetically modified organisms; Consumer preferences; Grain handling system;The Economics of

Non-GMO

Segregation andIdentity

PreservationIntroduction

Much

controversy surroundsthe

production and marketingof

agricultural geneticallyrnodified organisms (GMOs).

Many

consumers worldwidewoffy that food

derived fromGMOs may be unhealthy, or that the production

of

GMOs may have negative environmentalor

social consequences.As

a result, regulations onGMO

authorisation andGMO

labellinghave increased and markets

for

non-GM ingredients have developedin

many countries veryrecently. Regulations are variable depending on the country and the market use, and are in

rapid evolution (Roberts et al., 2001). Demand for non-GM products by private buyers, who

have

to

complywith

government regulations they are facing,is

encouraging segregationof

non-GM

products

from

GM

products

and identity

preservationof

non-GM

products throughout the grain production and handling system.Available

empirical evidence suggests thatthe

actual impactof

non-GM

demand onglobal trade flows has remained limited so far. However, the potential impact seems huge,

if

regulations continue to strengthen andif

consumer concern remains high @lberhi, 2001). Thisimpact

will

crucially depend on theability of

producers and handlersto

segregateGM

fromnon-GM

cropsin

countries where productionof

GMOsis

adoptedon a

large scale.As

aresult,

the

feasibility

and costsof

non-GM

segregation andidentity

preservation(IP)

arecentral to understanding current and future market developments, as

well

as current and fufure intemational negotiations on regulations concerning GMO standards.In

this

context,the

aim

of

this

articleis

to

explorethe

costs createdby

non-GMOsegregation and

IP,

andhow

these costs dependon

standards defining goods as non-GM.Although this question may affect producers and consumers

of

any food product worldwide,we focus on the specific cases

of

soybeans and maize in the United States (US), the EuropeanUS

rnaize acreswere

plantedwith

geneticallymodified

(GM)

varietiesin

2001

(USDANASS, 2001). The

US is

a major world producer and exporterin

both markets, and the EUand Japan are

major

destinationsfor US

soybean and maize products @allenger, 2000).Moreover,

a

market

for

segregatedand

identity-preservednon-GM

productshas

alreadyappeared

in

the US, so that empirical evidence on segregation feasibility and costsis

already available. The purposeof

this

articleis

to

use the available datato

examinethe

economiceffects

of

GMO

regulations and consumer preference shifts on US, EU, and Japanese grainmarkets.

In

thefirst

section we present cuffent GMO regulations in the EU and Japan that defineminimum

standardsfor

non-GM

demand addressedto

the US.

In

the

second section wediscuss the steps

to

be taken to maintain purityat

each vertical stageof

the US grain supplychain, from the seed production to the processing stage. The third section addresses questions

of information asymmetry, testing, and contracting costs. In the final section we identi$i some

observable quantitative elements of current premium levels for non-GM products.

EU and Japanese

GMO

authorisation andGMO

labelling standardsRegulations on

GMO

authorisation define minimum product standardsfor

domestic use.Labelling

regulationsdefine minimum

standardsthat

a

food

productmust meet

to

berecognized as

"non-GM".

These standards,which

are imposedon

suppliers,may

concerntolerance

levels

for GM

productsin

non-GM

products, markets subjectto

regulations,products subject

to

labelling, and

governmentrules

to

check

complianceof

private stakeholders.Different

standards may leadto

different costsof

segregation-

generally the higher is the standard, the more costlyit

is to meet.In

the

EU

and Japan, tolerancelevels

are zerofor

unauthorisedGMO

transformationevents.l As a consequence, the import of any seed containing GMO transformation events not

authorised

for

domestic plantingis

illegal,

asis

the import

of

any food

or

feed productcontaining GMO transformation events not authorised for domestic marketing.

For rnaize, nineteen events of transformation have been authorised for production in the

US,

of

which onlytwo

are acceptedfor

all usesin

the EU, and ninein

Japan (Agriculture&

Biotechnology Strategies

Inc.,

200D.2 Failure to keep traces of unauthorised maize types outof

maize exportsto

Japanor

theEU

can leadto

trade disruption and considerable politicalturmoil, as evidenced by a recent episode in which US-produced

Starlink

maize, which is notauthorised

in

Japan,was found

commingledwith

shipmentsof

authorised maize types toJapan

(USDA

FAS, 2001a).Cunently

seed companies are postponing salesof

maize seedvarieties

with

GMO

transformation eventsthat arc

not

approvedin

export

destinations(Pioneer, 2000). Such precaution is being taken

to

avoid possible comminglingin

the grainhandling system of authorise d maize with maize not authorised in the EU and Japan.

In

the

sameway,

for

soybeans,the

American Soybean Association andthe

NationalOilseed

ProcessorsAssociation state

that

they

have

"successfully

influenced

thebiotechnology seed companies"

to

prevent commercial growingof two GM

soybeans thathave been authorised

in

the US but notin

theEU

and Japan (Anderson, 2000). Dueto

thisaction,

only

one typeof GM

soybeans, Roundup Ready soybeans,is

currently availablefor

commercial planting in the US. The corresponding GMO transformation event is approved

for

all uses in Japan, and for marketing in the EU. Of these destinations, the only market in which

US

soybeanscurently

facea

zero-tolerance levelfor

the presenceof

commercialised GMsoybeans is the market

for

soybean planting seeds destined for the EU.For food

products containing domestically authorisedGMO

eventsof

transformation,laws for mandatory labelling have been passed

in

the EUin April

2000 andin

Japanin April

2001.

Statedroughly, labelling

is

requiredfor

any food

productwith

presenceof

thesedomestically authorised GMOs above a Io tolerance level in the EU and a 50 toLerance level

in Japan.

More precisely,

in

the EU, a food productis

exempt from mandatory labellingif

in

eachof

the

product's ingredients, theDNA

or

protein content resultingfrom

an EU-authorisedgenetic rnodification makes

up

less than lYoof

the ingredient's totalDNA

or

protein. Also,any presence

of GM

materialin

the ingredient must be adventitious (i.e., operators must beable

to

demonstratethat they

have used appropriate stepsto

avoidthe

presenceof

GMmaterial

in

the

ingredient,even

though tracesof

GM

material

might

exist).

If

these requirements are not met for every ingredient in a food product, the product has to bear a labellisting

the ingredientsnot

meeting the requirements as beingGM

(European Commission,2000).

In

Japan, regulations cite twenty-four "basic ingredients" as subject toGM

food productlabelling laws.

A

basic ingredient is subject to GMO labelling requirementsif

three conditionsare

met:

1)if

DNA

or

protein resultingfrom a

genetic modificationis

presentin

the basicingredient; 2)

if

the basic ingredient is one of the top three ingredients of the product in termsof

weight; and3)

if

the weightof

the basic ingredient accountsfor

5%or

moreof

the totalproduct.

A

basic ingredient meeting these three conditionsin

a food product must be listed onthe product's label as "genetically modified"

if

it

comesfrom

aGM

shipmentfor

which IPprocedures were followed. This basic ingredient may be,

but is

not requiredto

be, listed as "not genetically rnodified"if

it

comes from a non-GM shipment for which IP procedures werefollowed.

If

the basic ingredient comes from a shipmentfor

which noIP

procedures (either"GM

and non-GM elements werenot

separated." The regulation does not define anofficial

tolerance level

for

adventitious comminglingof

GMOsin

non-GM products. However, theJapanese

Ministry

of

Agriculture has set

an

unofficial

5%

maximum threshold for

adventitious commingling. (USDA FAS, 1999 and 2001b).

As

these labelling regulationsdo not

applyto

animal feed, feed companies currentlyvoluntarily labelling their products as "non-GM" do not have to comply with the lo/o and 5%;o

tolerance levels.

In

addition, food products (such as soy sauce) for which all tracesof GM

or proteinDNA

have been eliminating during processing are exempt from labelling regulations.It

can be foreseen that more stringent labelling regulationswill

evolve in the future. TheEU

is

cunently working on legislation that would extend mandatory labelling to animal feed,define thresholds

for

adventitiousGM

presence in non-GM seeds, and require traceabilityof

GMOs.

Enactmentof

the

proposedtraceability

requirementswould mean

that

even ingredients produced from GMOs but no longer containingGM DNA

or proteins would haveto be labelled as

GM

(European Commission, 2001). The Japanese Ministry of Agriculture is also proposingto

extend labelling requirementsto

some processed products produced fromGMOs,

but

in

which

GM DNA

or

proteins areno

longer present(USDA

FAS, 2001b).In

addition, regulations aiming at normalising detection methods

of GMO

content are expectedin the future.

Maintaining

thepurity

ofnon-GM

grainsGMO

regulations discussed above define current standardson

acceptable non-GMpurity

levels that US grain producers and handlers haveto

meetif

they desireto

exportnon-GM

products (or evento

exportGM

products, but without unapproved GMO transformationevents)

to

Japan and theEU. But

there are several placesin

theUS

grain supply chain in which the purity of non-GM grains may be compromised by inadvertent comminglingof GM

grains

with

non-GM grains. The challengesin

the US grain supply chainfor

segregationof

GMOs and non-GMOs to meet Japanese and

EU

regulations are discussed below. The maintopics developed below are summarised in Table 1.

INSERT

TABLE

l

Maintaining non-GM seed

purity

Non-GMO segregation and IP must start with the seed industry. Efforts to maintain seed

purity

have always existedin

the

seed industry,but

absolute seedpurity

has never beenobtained.

A

rnajor potential source of impuritiesin

seeds is pollendrift,

which can occurwith

cross-pollinated crops. Seed

purity

levels are generallylower

for

maize thanfor

soybeans, because rnaizeis

mostly

cross-pollinated,while

soybeansare

almost

exclusivelyself-pollinated.3

Seedimpwity may also

come

from

inadvertentcommingling

in the

seedproduction, harvesting,

andbagging

processes.Current

seedpurity

levels

obtainedby

identification

of

plants according to morphological characteristics are around 99%ofor

maize,and

99.8Yofor

soybeans (Langer, 2000).4 These nurnbers indicatethat

potential GMOpresence

in

non-GM seed could be a problem under usual practices,for two

reasons. First,unapproved

GMO

transformation events facinga

zero-tolerancelevel

couldbe

presentin

seeds. Second,

it

is not certain that non-GM food products containing maize products wouldmeet the

EU

l%

tolerance level.Different

steps may be takento

increase seedpurity

levels.For

maize and soybeans,these measures

include eliminating plants

showingtypical

aberrationsand

segregatingvarieties

in

seed manufacturing plants.In

addition,for

maize,purity

levels can be increasedby

planting

all-male borderrows and

increasing temporaland

spatial isolationof

seed-producing fields from other fields. However, such measures are imperfect because pollen can

high

purity

levels,but

cannot ensure absenceof

unapproved transformation eventsin

maizeseeds.

To

completely avoid the presenceof GM

pollenin a

field

producingnon-GM

maizeseed,

it

would

be necessaryto

designate whole geographic areasin

which no

GM

maize isgrown

for

miles.But

the possibilitiesthat

such"non-GMO"

areas couldbe

institutionallyorganised

currently

seem remote.At

present there existsno

regulatory framework underwhich

to

define such areas. Government attemptsto

mandate thatGM

seeds could not beplanted

in

some regions yet allow them to be plantedin

other regions would surely facestiff

political

opposition from farmers. To define and administrate such areas on a voluntary basiswould

require

extensive consultations between participants.It

would

require

convincingfanners and handlers

who

otherwisewould

havethe

legalright

to

adoptor

store GMOvarieties not

to

do so. Seed companies, processors, exporters, orthird-party

certifiers mighttly

to organise agreements among farmers and elevators in a wide areaby

designing contractsoffering economic incentives to not produce

or

storeGM

maize.Yet

evenif

all

farmers andhandlers

in

a

fairly

largeregion could

be

convincedto

sign

such contracts, monitoringcompliance among them would prove

difficult

and expensive. Evenif

an entire region madeplanting GM maize illegal, smuggling of GM seed into the region might occur.

The

difficulties

brought aboutby

cross-pollinationin

maize varieties might be solved inthe near future, however. Scientists have used conventional breeding methods

to

build

agenetic bartier in hybrid maize to prevent cross-pollination. They claim that commercial

non-GM

varietieswith this

gene couldbe

sold

commerciallyin

2003((ermicle

and Gerish

2000). This would enable seed companies

to

sell non-GM seed maize and farmersto

sell IPnon-GM maize without having to cope

with

cross-pollination. However, more timewill

haveto pass before the commercial feasibilrty of this genetic barrier is known.

In

addition

to

the

commingling

of

commercialnon-GM

seedby

GM

seed, otherpossibilities

for

commingling come about during the farmer's planting, growing, harvesting,storage, and transportation of grain.

If

a fanner chose to plant bothGM

and non-GM varieties,it

would be necessary for himto

clean

out the

planter and

the

combine betweenGMO

and non-GMO planting

andharvesting *rrs.S For a typical planter used

in

the Midwestern US,in

an average situation,it

would take approximately 40

(for

an 8-row planter)to

55 minutes(for

a

l2-row

planter) toclean very thoroughly a typical planter (Hanna, 2000; Hanna and Greenlees, 2000). Using a

combine previously used

to

haruestGM

grainin

an entirely non-GMfield,

very high puritylevels of harvested grain can be expected

by

cleaning out the combinefor

approximatelyhalf

an hour, and then running the combine through a

field of

non-GM grainin

orderto

harvestand

unload

1.60-1.90 tonnesof

soybeans (Greenlees,2000; Greenleesand

Shouse, 2000).Then, the mixture of non-GMO and GMO grain obtained when flushing the combine must be

sold at the lower GMO prices.6

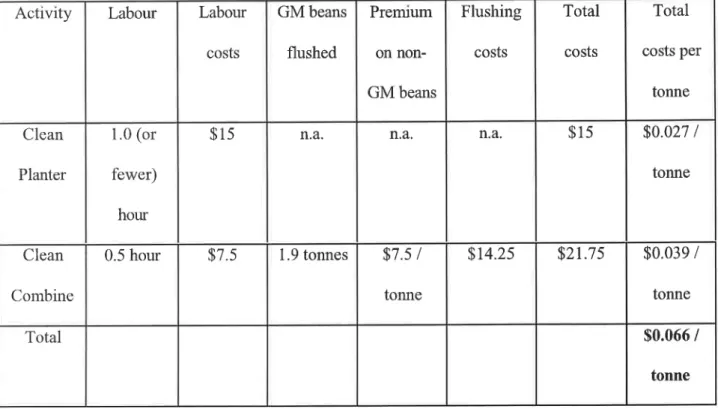

In Table 2 we show calculations of per-tonne costs of planter and combine cleaning, once

per

season,to

maintainnon-GM

soybean segregation andIP,

for

a typical

farmwith

200hectares

of

soybeansyielding

2.8 tonnes per hectare. These calculations assume that farmlabor can be hired

for

$15 per hour and that a typical premium paidto

farmersfor

non-GMsoybeans

is

approximately $7.5ltonne@uPorrt,200la).

Forthis typical farm, the

costsof

planter and combine cleaning are minuscule, approximately $0.066 per tonne.

INSERT

TABLE

2Since soybeans do not cross-pollinate, there should be few additional costs to the farmer

of

segregation andIP.

It

seems reasonable that similar small costsof

planter and combinecleaning would prevail for non-GM maize segregation and IP. But the costs of arranging wide

significantly to these costs. Farmers growing maize for grain are advised to

follow

some stepstaken

by

farmersgrowing

maizefor

seedto

maintainpurity,

namely spatial and temporalisolation

of

fields

from GM

maizefields

and separate harvestingof

borderrows

(Burris,2000; Nielsen, 2000).

As

for

maize seeds, the only wayto

meet very high non-GMO puritystandards

for

maize(well

over 99.5yo, say) may beto

createvery

large isolation zonesin

which only

non-GM

maizeis

grown for miles around. But, as stated beforein

the contextof

seed production,

it

could be very expensiveto

setup

and administrate such isolation zones,and to enforce compliance by neighbouring farmers and elevators.

After

aUS

farmer harvests grain, he generally either deliversit

by

truckto

a grainhandler, or stores

it

on his farm to be delivered to a handlerlater. There are various categoriesof

grain handlers,including

country elevators,river

elevators, and export(or

"terminal")elevators.

In

eachof

these typesof

elevators, segregation andIP

of

non-GMOswill

imply

some extra costs.

Maintaining

purity

in country elevatorsTypically,

US

country elevators arerelatively

smallgrain

storagefacilities

locatedalong railroad tracks, scattered every

few

kilometresin

the

countryside. Country elevatorsprovide

the sewice

of

storagefor

farmerswho do

not

possesssufficiently large

on-farmstorage facilities

to

takein

an entire harvest. They also serveto

load graininto train

cars,which cany the grain either

to

domestic processors orto

an export (or"terminal")

elevator.Commingling

of

GMOs

and non-GMOs can occurat

several points alongthe "paths"

inwhich grain at a country elevator is moved, stored, and loaded.

To

prevent comminglingof

GMOs and non-GMOsat

country elevators,it

is

firstnecessary

to

dedicate some storage binsto

GMOs

and other storagebins

to

non-GMOs.crop from the other, but not necessarily allowing segregation

of

different qualitiesof

a givencrop. Consequently,

not

all

country elevators are ableto

segregate GMOs and non-GMOswithin

afacility

(at least, without additional investment). Evenwith

storage bins dedicated toGMOs

or

non-GMOs, several potential sourcesof

commingling appear at various points inthe grain path

of

dump pits, boots, legs, dryers, conveyor belts and spouts that makeup

acountry elevator

facility.

These piecesof

equipment usually remain reasonably clean withouthuman intervention,

but

they arenot

designedto

remain"kernel

clean." Under traditionalgrain movement, storage, drying and loading practices, some pieces

of

grain become caughtin

the equipment,only

laterto

bejostled

free and commingledwith

other grain shipments.Therefore, extremely strict tolerance levels

for

comminglingof

GM

grainswith

non-GMgrains would not be met under traditional handling practices at country elevators. The steps to

take to prevent excessive commingling

of

GMOs with non-GMOs then depend greatly on thedemanders' level of commingling tolerance.

To ensure very high purity levels of non-GM grain,

it

would be necessary to clean thegrain path equipment thoroughly, whenever

it

is

usedfor

non-GM

grain after having beenused

for GM

grain. This could be doneby

sweeping clean the pits, boots, conveyor belts,storage

bins

and

distributors,and

especially disassemblingand

cleaningthe

legs

of

theelevator, and the dryer

(for

maize). Another possibility would be to"flush"

the equipment byrunning some non-GM grain through

it,

and then storing the grain used in the flushwith

GMgrain. Using one of these procedures to clean the grain path between every shipment

of

grainwould be arduous and costly. The practical solution currently observed in the US Midwest is

to dedicate entire paths (and not only storage bins) to either GMOs or non-GMOs, at least

for

a given period

of

time. This may involve dedicating existing equipment, or investingin

newDedicating entire grain paths

to

either GMOs or non-GMOs avoids the direct costsof

cleaning the grain paths.

Still,

there are indirect costsof

dedicating grain path equipmentin

this way. First, there may be an indirect cost because of capacity underuse. This could occur,

for

example,if

grain

quantities deliveredat a facility

dedicatedto

non-GMOswere

not sufficient tofill

up the non-GM bins. To adjust flowsof

grain delivered by farmers and flowsof

grains delivered to processors or terrninal elevators to capacity, the handler would have toincur additional management costs, and possibly the additional costs

of

settingup

contractswith fanlers

and processors or terminal elevatorsto

organise grainflows.

Second, handlingfacilities

with

only one grain path would have to dedicate the entire facilrty to either GMOs ornon-GMOs, but never both. Then, farmers would have

to

drive abit

farther, on average, todeliver

their

grainto find

a buyer who handlesit.

Fuel andtime

costsof

this extra haulingwould

typically

be very small, because some country elevators would be dedicatedto

GMOsand some others

to

non-GMOsin

close proximity. However, longer grain hauling at harvesttirne could be quite costly

for

farmers, who always preferto

harvest rapidlywhile

weather permits.In

addition, nearby elevators may belong to different companies.It

may be costlyfor

a given company

to

acceptonly

one typeof

grain at a given location, becauseit

may causesome farmers nearby to switch to competitors.

In

addition to the indirect costof

dedicating equipment, there would also be a costof

perfoming

tests on GMO content at delivery. When a truckfilled

with what is claimed to benon-GM grain arrives at a country elevator, an employee typically uses a chemical "rapid strip

test" on a sample

of the

grain, allowing detectionof

GM

soybeans and certain typesof

GMrnaize. The direct cost

of

such testing is estimated later in the article. There is also an indirectcost

of

testing, because the farmertypically

mustwait

tento

fifteen minutes before the testshows whether

his

loadis

accepted as non-GMO. Because testing takes time,it

potentiallyfarners during the busy harvesting season. To avoid the development of longer queues, and to

be able

to

dedicate some facilitiesto

non-GMOs at non-harvesttime while

using them forGMOs at harvest time, grain handling companies have begun signing contracts

with

farmersbefore planting

time.

In

signing such contracts, farmers and handlers agree the numberof

acres harvested that

will

be

deliveredto

the

elevator directly after harvest, andhow

many acreswill

be stored on-farm and brought at a date to be named later by the grain handler. Suchcontracting enables grain handlers to plan out when they

will

receive deliveries in the monthsfollowing harvest.

Maintaining

purity

in river elevalorsThe principal site of US soybean and maize export is New Orleans, where most grain

arrives by barges that have received grain at elevators located on the Mississippi river and its

tributaries.

River

elevators' storage andloading

services aresimilar

to

thoseof

countryelevators, except that they tend to load grain onto barges instead oftrains. Barges do not have

holds, therefore

it

is not possible for one barge to simultaneously carry and segregate GM andnon-GM

grains.After

unloading, barge owners always pay private companiesto

clean outtheir barges, no rnatter what the barge's cargo has been. Therefore no extra costs are entailed

by

cleaning out a barge that has carriedGM

grainin

order thatit

might next carry non-GMgrain

without

commingling.In

general, the costsriver

elevators facefor

segregation and IPare similar to those of country elevators discussed above.

Maintaining

purity

in export("terminal")

elevatorsThe physical set-up

of

export elevators is similar to those of country and river elevators,except that generally export elevators are much larger. Export elevators can receive grain by

country and river elevators, export elevators provide "blending" services in addition to storage

and

loading.When loading

a

ship's hold,

export elevators frequentlyfill

the hold

with

blended

grain

comingfrom

several different bins,to

closely meetthe

specificationsof

acontract they have signed

with

a customer. This "blending" service is a major source of exportelevator profits,

If

a large exportfacility

decidesto

handle many more varietiesof

grain becauseof

theappearance

of

GMOsin

the market, then givenits

numberof

storage bins,it

cannot storeseparately as many qualrty levels as

it

did when no GMOs were presentin

the market. Thisimplies a loss in blending

flexibility

for export elevators, at least in the absence of investmentin

additional capacily. Thereis

a trade-off here;in

order to provide the marketwith

a choicebetween GMO and non-GMO grain, the grain handling system has to provide the market

with

less choice among quality levels of that grain.

In

the short run, given the size and numberof

current storage bins,

the

costof

the

trade-off between GMO/non-GMO choice and grainquality choice cannot be avoided.

In

the long-run, handlers may respond to this trade-off by building more and smaller storage bins.Maintaining

purity

at the processing stageMethods used

to

preserve non-GM identity, and additional costsof

segregation and IPwill

vary

among typesof

processing plants, dependingof

their physical make-up.But

it

ispossible

to

makethe

general statementthat

processorswill

facethe

samekind

of

costincreases as do grain handlers because

of

the appearanceof

GMOsin

the market. That is,processors

will

face additional costsfrom

dedicating soms processing equipmentto

GMOsand other equipment to non-GMOs.

To

rnaintain avery

low

GMO

content along the vertical supply chain,two

actions arenecessary

at

eachvertical

stage:making

surethat

the

grain

purchasedis

non-GM,

andpreventing GMO commingling before selling the grain to the next stage. Simple observation

by the buyer does not reveal whether the seller has made these two types of effort or not. This

information asymmetry may be solved in two ways: using chemical tests at different stages

of

the vertical supply chain

to

estimate the GMO contentof

the purchased grain; and designingand monitoring contracts and quality assurance schemes whereby different stakeholders agree

on production and handling practices.

We

estimate the testing costs necessaryto bring

grainfrom a

farmer growing non-GMsoybeans to a river elevator, and from there to an importer

in

Japan or the EU.It

is typical fora

farmerto

haul non-GM

soybeansby

a truck

containing approximatelyeither

10or

20tonnes, directly from his farm to a river elevator on the Mississippi,

Illinois

or Ohio rivers.At

the

river

elevator,typically

one strip test is used per truck. The strip testis

a"dipstick"

test,which requires only minimal equipment and skill, and can be conducted practically anywhere.

It

is a

qualitative test,giving

a

yes/no answer (detectionor

not

of

targetedGMOs

in

thesample). Strategic Diagnostics,

Inc.

(SDI) sells a strip testfor

the detectionof

glyphosate-tolerant

("RoundupReady")

soybeans(the

only

GM

soybeans availablefor

commercialplanting). Each SDI test costs $3.50 and takes five to ten minutes to conduct. Assuming a $15

per hour labour cost ($2.50 per ten minutes), the total cost of a test is approximately $6.

After

being storedin

the binsof

theriver

elevator, soybeans are loadedinto a

barge,containing approximately 1500 tonnes in a single hold. When loading abarge, a sample of the

grain

is

takenwith

a

diverter sampler. The most economical testto quanti$r

glyphosate-resistant soybeans

in

this sampleis

an ELISA test, which must be conductedin

a laboratory.The shipping cost

for

sending a two-kg sample to Central- Hanse Analytical Laboratory,LLC

in

Louisiana, is $15. This company offers this test at $100 per one-kg sample. The laboratoryis

ableto

issuea

certificateby

thetime

the barge arrivesin

New

Orleans(Central

HanseAnalytical Laboratories, LLC, 2000; Russell, 2000).

When loading an ocean vessel,

six

samples are takenwith a

diverter samplerfor

eachhold of the ship,

with

one sample for every 1200 tonnes, and sent to the testing lab. The oceanvessel then leaves

for

Japanor

theEU,

whereit

typically

sailsto

different import elevator locationsin

orderto

unload different holds. Another quantitativeELISA

testis

conductedwhen unloading the hold of the ship. Table 3 gives an approximation of the testing costs with

this example.

INSERT

TABLE

3Table

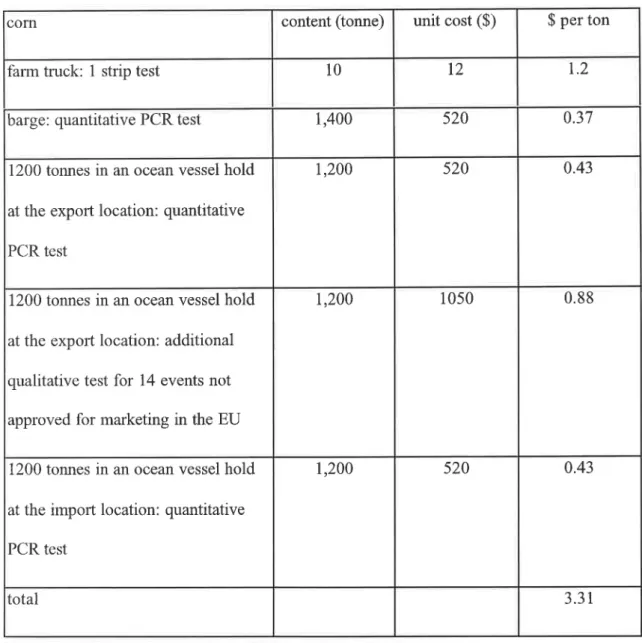

4

shows whatthe

testing costswould be

for

maizewith

the

samegrain flow

described above

for

soybeans. Testing for GMO contentin

maize is more complicated than insoybeans because multiple transformation events have to be recognised

by

a testin

order toassess the

GMO

contentof

aUS

maize product. The companyEnvirologix

sellstwo

striptests

for

detection of the three Bt toxins currently expressed inGM

insect resistant maize, theCrylAb,

CrylAc

andCrygc(or Starlink)

proteins. EachEnvirologix

test costs $3.50 everytirne

it

is

used and takes five-ten minutesto

conduct. Assuminga

$15 per hour labour cost($2.50 per ten minutes), the total cost of both tests is approximately $12. However, these strip

tests cannot detect herbicide tolerance events

it

maize.A

quantification of theGM

content inmaize

can

be

attainedusing

a

PolymeraseChain

Reaction(PCR)

test.

Central-HanseAnalytical Laboratory,

LLC

offers a PCR test allowing assessmentof

the total percentageof

GM maize at $505 per sample, to which shipping costs of $15 should be added.

A

qualitativetest

to

proveby

PCR the absenceof GM

events not approvedin

theEU

or Japan would add$75

for

each event to this cost (Central Hanse Analytical Laboratories,LLC.,

2000; Russell,more expensive, and because an additional test

is

neededto

recognise individual events notapproved for import in the EU or in Japan.

INSERT TABLE 4

Contracting

with

sellersis

complementaryto

testing. The chancesthat

a

shipmentpresented as "non

GM"

will

actually prove to be commingledin

a test are lowerif

the sellerhas

conrmittedto

segregation andIP

practicesin

a

contract. Consequently,the

costsof

rerouting shiprnents brought as non-GM

to

aGM

channel are lower. Conhactingin

advancealso enables the buyer to plan volumes and flows

of

GMOs and non-GMOs. In addition, testsare imperfect

by

nature, and even more problematicin

the

caseof

small tolerance levels,because sampling is imperfect and because detection methods are themselves imperfect. Then, when a test performed at one stage of the vertical supply chain may be contradictory to a test

made at another stage, contracts may help resolve the contradictory evidence.

Identifying

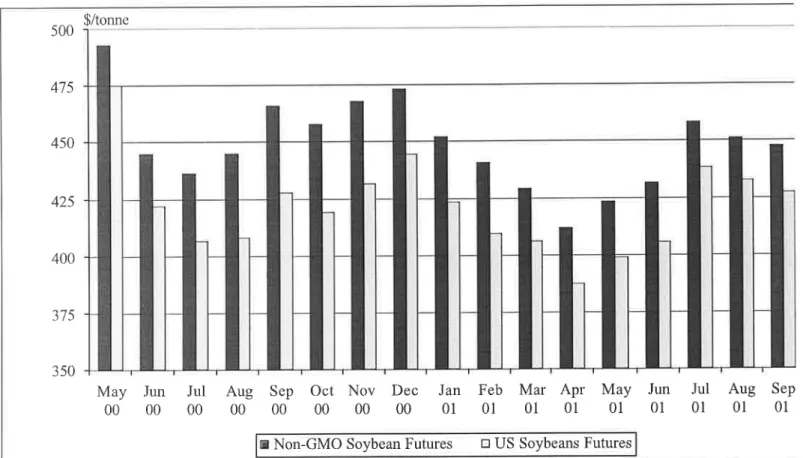

premiums and cost changesFigure

2

illustrates some

of

the

currently

observablequantitative

aspectsof

segregation and IP of non-GM grains. First, monthly average premiums to Japanese importers

of

non-GM

soybeanson the Tokyo

Grain Exchange (calculated asthe

difference betweenmonthly prices

of

non-GM andGM

soybeans) have varied between $18 and $39 per tonnebetween

May

2000 and September 2001,with an

averageof

$27.50 per tonne(Figure

1) (Tokyo Grain Exchange, 200D.7INSERT FIGURE 1

Next, elevators have recently paid farmers premiums

from

$7.3to

$11 per torure fornon-GM soybeans delivered

with

a signed contract (DuPont Specialty Grains, 200Ia,2001b).The size of premiums paid

to

farmers varies by geography, by whether the farmer has signeddelivered. Farmers

who

sign contracts agreeingto follow

specific production and deliverypractices (to clean out the planter, flush the combine, etc.) to maintain non-GM purity, tend to

receive higher premiums than farmers who

just

"showup"

at the elevatorwith

a deliveryof

non-GM

soybeans.Given

the

variety

andthe

contract status,farms

deliveringto

riverelevators generally receive

the

highest premiums.This

occurs because farms located nearriver

elevators tendto

shiptheir

soybeansby

barge toNew

Orleans, whenceit

is

exported.Since the highest demand

for

non-GM grainis

from overseas sources, the price differentialbetween

GM

and non-GM grainis

greater nearer rivers thanfar

awayfrom

rivers, wherefarmers tend to supply to domestic processors who have less demand for non-GM soybeans.

Fanners are consistently

willing

to sign contracts tofollow

segregation and IP production practices onlyif

premiums cover the increased production costs borne when growing non-GMsoybeans

instead

of

GM

soybeans.Any

difference between

the

premium and

the aforementioned costson the farrn

areprofits

to

the

farmer.

As

stated before, costsof

segregation and

IP

(costsof

cleaning the planter and combine, and costsof

driving

furtherwith

the

grainto

the

elevator) appearto

be

rather small anddo

not

seemto

explain thepremium levels alone.

This

suggests that the major costof

non-GM segregation andIP

tofarmers

rnay

comefrom the

production processitself.

For

many

farmers,GMOs

lowerproduction costs, and a price premium must be available

to

convince themto

give up usingcost-reducing

GM

seeds.I

Taking

as

basesthe

$27.50per

tonne premium receivedfor

non-GM

soybeansby

.Tapanese impofters

and

a

$7.50per

tonne premium receivedby

farmersfor

contracted soybeans, currentlyit

mustnot be

costing more than $27.50-

$7.50:

$20 per tonnefor

handlers and exporters combined to segregate and preserve the identities of non-GM soybeans

to

the

50Â tolerancelevel

acceptableto

Japanese importers.(For

otherwise theywould

benumbers

are

illustratedin

figure

2.

For

grain

handlers,in

the

main

the

extra

costsof

segregation and

IP

do not appearto

come from testing costs, which are approximately only$0.87 per tonne (Table 3). Rather, additional costs appear to come from less

flexibility

in the grain handling system, because of the necessityof

dedicating some equipmentto

GMOs andother equipment to non-GMOs, and from contracting costs.

INSERT FIGURE 2

In

figure

2, we implicitly

attachall

the

segregation coststo

the non-GMO

channel.Actually, the GMO channel may also bear some segregation costs.

It

seems apriori

that thesewould be

mainly

costsof

lessflexibility

becauseof

dedicated equipment, and costsof

non-GMO

IPfor

shipments first considered as non-GMO then rerouted at some stageto

the GMchannel because

of

excessive commingling (although these costs shouldbe

diminished bycontracting procedures).

It

is

hardto

assess the importanceof

these costs,but

it

seems thatsubstantial costs

of

lessflexibility for

GMOs would arise onlyin

the caseof

asubstantially-sized non-GMO channel.

Costs

of

GMO/non-GMO segregation and non-GMOIP

mayvary

with

the respectivevolurnes

of

theGMO

and non-GMO channels. 'Whether or not economiesof

size should beexpected is an open question.

It

is possible that grain paths currently dedicated to non-GMOshave a comparative advantage over others

in

segregating non-GMO soybeans at alow

cost.eIn

this case,in

the short run, marginal costsof

segregation and IP may increaseif

the sizeof

the non-GMO channel increases.

Costs

of

GMO/non-GMO segregation and non-GMOIP,

and premiumsfor

non-GMOgrains,

may

also change over time. Economic incentives existin

grain marketsto

developbetter and

less expensive proceduresto

store,move

and processgrain

while

preventingcommingling, and

to

test

GMO

content.In

addition,it

canbe

expectedthat new

grainlower costs. While current demand for segregation and IP are brought about

by

consumer fearof

GMOs, a new typeof

demandfor

segregation and IP may come about because consumerswill

bewilling

to pay for positive attributesof

specialised crops, some of these even possiblybeing GMOs

(Buckwellet

a1., 1999).If

more

specialised cropswith

positive

consumer attributes are developed, then even a larger varietyof

grainswill

be availablein

the supply chain, and therewill

exist demand for more varieties to be segregated and identity-preserved'However, because of the large fixed costs of building grain handling facilities, any adjustment

to

a

new grain handling systemwith

more and smaller handling facilitiesis likely to

be

alengthy one.

Conclusions

Two

very

different issueson GMO

commingling are raisedby

current regulations onGMOs:

how

to

prevent excessive comminglingto

complywith

labelling laws; and how toprevent

any

comminglingat

all

to

comply

with

authorisationlaws.

Segregationand

IPprocedures presented here aim at preventing commingling above given tolerance levels set in

labelling laws. These tolerance levels are probably a key element

of

costsof

segregation andIP,

although informationto

assesshow

costsvary

with

tolerancelevels

is

scarce. Quitedifferently, without the undertaking

of

huge organisational and economic procedures,it

maybe

simply

impossibleto

preventall

commingling andthus

ensurethe

regular absenceof

unapproved transformation events. This seems especially

to

be the casefor

maize,with

theproduction externality resulting from cross-pollination.

If

zero-tolerance is not manageable (at least without drastic organisational and economicrneasures), regulatory as

well

asliability

issues are raised. There are onlytwo

ways to avoidproblems

following

from zero-tolerance to arise: either loosening authorisation regulations, orbefore rnarketing new GMO varieties. Some steps have been already taken in both directions.

On

the

one hand, the zero-tolerance issue has been broughtto

the public debatein

the EUafter several cases

of

unapproved transformation events being foundin

imported seeds. TheEU

Commission has recently proposedto

set up "specific conditions under which technicallyunavoidable presence

of

unauthorised GMOs could be permitted" (European Commission, 2001). On the other hand, as statedin

the article, US seed companies are postponing salesof

varieties approved

in

the US but notin

major destination countries. How this issueof

zero-tolerance

for

unapprovedevents

of

transformationwill

be

resolvedwill

probably

be detenninant for the future possibility of a non-GMO IP channel in the US.In link

with

this zero-tolerance issue, another typeof

cost that we did not discuss here isthe cost

of

being held liablefor

comminglingof

GMOsin

non-GM products.Liability

costsfor

lossof

export markets due to the presence of events not approved in these markets couldbe huge. The possibility

of

being made liablefor

such losses could significantly influencedecisions

of

companies alongthe

supply chain. Thisliability

problem has been brought to evidenceby

the

recentStarlink

episodein

the US. The Starlink

caseis

not

completelygeneralisable, however, because

it

initially

came aboutonly

becauseof

a lack

of

domesticapproval. (That

is,

Starlink maize was authorisedfor

usein

animal feedbut not

for

directhuman consumption in the US). Absence of efforts to keep

Starlink

maize out of the generalmaize supply as well as to prevent cross-pollination of non-

Starlink

maizeby Starlink

maizein

neighboring f,relds ledto

large amountsof

comminglingof

Starlink

maizein

the

generalUS maize supply in the years 1999 and 2000.

A

huge row ensuedin

year 2000 after tracesof

Starlink

nraize were discoveredin

processed food productsin

the United States. Costsof

removing Starlink maize from the general supply channel were partly subsidised

by

Aventis,however, that a biotech company could be made liable

in

courts of law for releasing a varietythat is domestically approved, but not approved in export markets.

In

this article we report the startof

what should be further empirical investigations intothe effects ofsegregation and identity preservation on grain production and handling costs. To

understand

the

effectsof

non-GMO segregation andidentity

preservationon

the prices atvarious

stagesof

the vertically linked grain

markets,it

is

importantto

separate outconceptually

the

effects

of

three

related phenomena.First,

the

introduction

of

GMOtechnology reduces farm costs

of

production, which tendsto

lower grain prices as the lowercosts are

passedthrough different

stagesof

the vertically linked

grain

sector. Second,information about possible

risks

of

GMOs lowersthe

demandfor

both GMOs

andnon-GMOs,

if

consumers haveno way

of

distinguishing between them.Third,

segregation andidentity

preseruationlower

the

demandfor GM

grain further

(sincenow

consumers canidentify the good they perceive as risky), and raise the demand for non-GMOs (since they are

now

identifiable and perceived as safe). Segregation and identity preservation raise costsof

handling both non-GM and

GM

grain, however, creating forces that help keep prices of bothhigh.

Takenall

together,the

effect

of

segregationand identity

preservationon

prices istheoretically ambiguous. Whether

their

introduction raisesor

lowers pricesis

an empiricalquestion, in need of more empirical research. The numbers reported in this article on the costs

References

Agriculture

&

Biotechnology Strategies (Canada) Inc., 2001. Global database of plants withnovel traits. hup://www.aebios.com/. Accessed October 15, 2001.

Anderson, T., Ambrose,

A.,

2000. Approval Status of Biotechnology-Derived US Soybeans. American Soybean Association, National Oilseed Processors Association. PressRelease, December

t4,

2000.Ballenger, N., Bohman,

M.,

Gehlhar, M., 2000. Biotechnology: Implications for US Corn&

Soybean Trade. Agricultural Outlook AGO-270, USDA ERS.

Buckwell, A., Brookes, G., Bradley, D. (1999). Economics of Identity Preservation for

Genetically Modified Crops. Final report of a study for Food Biotechnology

Communications Initiative (FBCI), 83 p.

Bunis, J., 2000. Recommendations for producing non-GMO corn and soybeans:

A

plan foryear 2000. http://wrvw.agry.purdue.edr/extlcorn/news/articles.00/GMO Issues-()00309.htnr1.

Central-Hanse Analytical

Laboratory,LLC,200I.

Price List, February 1.DuPont Specialty Grains, 2001a.2001 PTI Identity Preserved non-GM Soybean Program,

Protein Technologies International, [nc.; Bloomington,

IL

Area. Grower Agreement:non-GM S oybeans. S ample Contract. http ://oscar. dupontsq.com/

SarnpleContract. asp?ID:O SCR000002 84&CropYear:200 I .

DuPont Specialty Grains, 2001b. 2001 PTI Identity Preserved non-GM Soybean Program,

Protein Technologies International, Inc.; Crestland Cooperative. Grower Agreement:

non-GM Soybeans. Sample contract. http://oscar.duponts g.com/

S anpleContract. asp ?ID:OS CRO000029O&CropYear:200 1 .

Elberhi,

A.

(2001). Regulations and Market Segmentation of Biotech Crops: Implicationsfor

Modern Agriculture: A New Industry at the Dawn of the Centuryr', ICARB, Ravello

(Italy), June 15-1 8, 2001.

European Commission, 2000. Commission Regulations

n"

4912000 and n"50/2000of

10January 2000,

Official

Journal of the European Communities.European Commission, 2001. Commission Improves Rules on Labelling and Tracing

of

GMOs in Europe to Enable Freedom of Choice and Ensure Environmental Safety.Press release, Brussels, 25 JuIy

200L

Greenlees, W.J., Wallace, J., 2000. Agricultural Engineering Field Specialist,Iowa State

University Extension. Personal communication.

Greenlees, W.J., Shouse, S.C., 2000. Estimating Grain Contamination from a Combine. Iowa

State University Extension, Paper Number MC00-103.

Hanna, M., 2000. Extension Agricultural Engineer, Iowa State University. Personal

communication.

Hanna,

M.,

Greenlees, W.J. , 2000. Planter Tips when Changing Seed Varieties. Integrated Crop Managemenl Iowa State University Department of Entomology.:llwwu,

Kennicle, J.L., Gerrish, S.L.. Gene Barrier in Corn May Boost Trade, Environment. Press

release fi'om the University of Wisconsin, Madison. Oct. 11, 2000.

Langer, D. , 2000. Director of Parent Test Research, Pioneer Hi-Bred International, Inc.

Personal communication.

Nelson, G.C., Josling, T., Bullock, D., Unnevehr,

L.,

Rosegrant, M.,Hill, L.,

1999. Theeconomics and politics of genetically modified organisms in agriculture: Implications

Nielsen,

8.,

2000. Minimizing pollendrift

&

commingling of GMO and non-GMO cornGrain. hjtp://wrvw.aqrv.purdue.edu/ext/corr/news/ar1icles.00/GMO

Issues-û00307.htm1

Pioneer Hi-Bred International, Inc., 2000. Pioneer Postpones Sales of Six Hybrids to Reduce

Market Confusion For Its Customers. Press release, 18 December 2000.

Roberts, D.,

L.

Unnevehr, J. Caswell,I.

Sheldon, J. Wilson, T. Otsuki, D. Orden, 2001.Agriculture in the WTO: the role of product attributes in the agricultural negotiations.

IATRC Commissioned Paper no 17.

Russell, M., 2001. Director of Central-Hanse Analytical Laboratory,

LLC.

PersonalCommunication.

Tokyo Grain Exchange, 2001. On-line monthly market reports, various issues,

http://www.tge.orjp.

Treu, R., Emberlin, J., 2000. Pollen Dispersal in the crops Maize (Zae mays),

Oil

Seed Rape(Brassica napus ssp oleifera), Potatoes (Solanum tuberosum), Sugar beet (Beta vulgaris ssp. vulgaris) and Wheat (Triticum aestivum): Evidence from Publications.

Report for the Soil Association, pp.

I2-I7.

htç://www.soilassociation.org.USDA, Foreign Agriculture Service, 1999.

GAIN

Report #JA9I54. Japan: AgriculturalSituation. MAFF Issues GM Food Labeling Standards (Revised).

USDA, Foreign Agriculture Service, 2001a. GAIN Report #JA1026. Japan: Grain and Feed

annual. 23 March 2001, 31 p.

USDA, Foreign Agriculture Service, 2001b.

GAIN

Report #JA1091. Japan: Biotechnology.MAFF's

Biotech Food Labeling Standards (Revised). 18 September200I,7

p.USDA, National Agricultural Statistics Service, 2001. Prospective plantings, March 30.

Notes

I

An

"event"

is a

successful transgenic transformation whereby gene(s)of

interest fromanother species

and

genetic materialare

insertedin

the

DNA

of

the

crop.

Events varydepending on the components of the genetic package and on where the novel

DNA

is inserted.2

Thr""

additional events are authorised only for marketing in the EU, and one in Japan.3 Matry experiments report maize cross-pollination

from

several hundred meters away(freu

and Emberlin, 2000). a

These numbers do not mean that average non-GM punty levels

for

non-GM seed varietieswould

be

99oÂfor

maize and 99.80Âfor

soybeans. On the one hand, lower non-GM purltylevels

could

be

obtained, because moleculartests

on

GMO

contentmay

detect moreimpurities than identification according

to

morphological characteristics. On the other hand,higher non-GM

purity

levels could also be obtained, because impurities arenot

necessarilyGM.

5 Thes" cleaning costs were

not

included at the seed production stage, because planter andcombine cleaning are standard procedures for seed-producing farmers.

6 This

methodis

more economical than removing every kernelfrom the

combine's inner workings, which would take 2 people 4 hours each.7

It

is

important thatthese figures are

for

soybeans importedin

Japan, where the tolerancelevel

for GMO

conrminglingis

50Â. Premiumsto

meetthe

I%oEU

tolerancelevel

couldpossibly be higher.

No

systematic information similar to the Japanese Tokyo Grain Exchangetransactions is currently available for the EU.

8

Production cost savings from glyphosate-resistant soybeans vary widely

by

farm, dependingOnly

farmerswith

much lower

savings arelikely

to

find

a

$7.50per

tonne premium asuffrcient incentive to grow, segregate, and identity preserve non-GM soybeans. e

An

example

of

compantive advantageof

some grain paths is elevatorswith

multiple grainTable 1. Segregation and IP in the Food Supply Chain

Additional Costs of Segregation and IP

a Costs ofreduced land used for actual

grain production

Costs of giving an incentive to others not to grow GM crops near non-GM zones

a

a Costs of capacity under-use

Costs of managing new grain flows Costs of moving grain farther Costs of reduced blending ability

a

a Testing costs

Contracting costs

Indirect costs of waiting for test

results the result ofthe test

a

a

Methods Used to Preserve Identity and Prevent this Type of

Commingling

a Plant all-male border rows

Increase spatial and temporal

isolation ofnon-GM seed fields

a

.

Clean equipment.

Dedicate equipment to GMOs or non-GMOsa Tests on GMO content

Contracts

a

Level of Verlical Supply Chain at which this

type of Commingling May Occur

a Seed production,

Farm production

a

a seed production (bagging equipment) farm production (planter, combine and on-farm storage, truck to elevator) handling system (elevator grain paths) processing system (machinery)

a

a

a

A1l levels Possible Causes of Commingling

Cross-pollination (maize)

Equipment not clean

Commingling of a GM lot thought to be

Table 2. Per-tonne on-farm costs of non-GM soybean segregation and IP

Note: Assumed wage : $15 / hour. Assumed total yield on farm: 560 tonnes.

Activity

Labour Labourcosts GM beans flushed Premium on non-GM beans Flushing costs Total costs Total costs per tonne Clean Planter 1.0 (or fewer) how

$1s n.a. n.a. n.a. $1s $0.027

I

tonne Clean Combine 0.5 hour $7.s 1.9 tonnes $7.s

I

tonne $r4.2s $2t.7s $0.039/

tonne Total $0.066/

tonneTable 3. Unit costs of non-GM tests on soybeans

caffler content (tonne) unit cost ($) $ per tonne

farm truck:

I

strip test 10 6 0.6barge:

ELISA

test 1,500 115 0.0771200 tonnes in an ocean vessel hold

at the export location: ELISA test

r,200 1I5 0.096

1200 tonnes in an ocean vessel hold

at the import location: ELISA test

I,200

115 0.096Table 4. Unit costs of non-GM tests on corn

com content (tonne) unit cost ($) $ per ton

farm truck: 1 strip test 10

l2

1.2barge: quantitative PCR test 1,400 520 0.37

1200 tonnes in an ocean vessel hold

at the export location: quantitative PCRtest

1,200 520 0.43

1200 tonnes in an ocean vessel hold

at the export location: additional qualitative test

for

14 events notapproved for marketing in the EU

1,200 10s0 0.88

1200 tomes in an ocean vessel hold

at the import location: quantitative PCR test

1,200 520 0.43

Figure 1. Premiums for non-GMO Soybeans ($ / tonne) 500 475 450 425 400 375 350 $/tonne

May

Jun00

00Dec

Jan00

0l Jul 00Aug Sep Oct

Nov00 00 00

00 Feb 0l Mar 0l May 0t Jul 0l Apr 01 Jun 01 Aug 01 sep 01E Non-GMO Soybean

Futures

tr US Soybeans FuturesSource: Tokyo Grain Exchange (2001), On-line monthly market reports, May 2000 to September 2001, Monthly Volumes and Total Contract Prices of Futures Contracts Traded. Yen to dollar monthly exchange rates calculated from cuffency converter fi'orn www.oanda.com, unit contract volume is 30 tonnes for US soybeans, and 10 tonnes for non-GMO soybeans.

Figure 2. Premiums for selling and costs of producing non-GM soybeans (dollar per tonne) $ per tonne 30 25 20 15 10

Costs to handlers of loss of

flexibility

Costs to handlers of designing and monitoring contracts

Handlers

profit

from segregation and IP (varies by elevator)Testing costs

:

$0.87/tonne5

$27.50 per tonne premium to importer of non-GMO soybeans in Japan (observable)

$7.50 per tonne premium to farmers delivering

contracted non-GMO soybeans (observable)

0

Extra costs from not using GM technology on farm Extra costs of driving further to elevator, waiting

longer to deliver non-GM grain

Extra costs of writing a contract with the buyer Farm

profit

from segregation and IP(varies by