Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Report (National Research Council of Canada. Division of Building Research), 1954-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE.

https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC : https://nrc-publications.canada.ca/eng/view/object/?id=091ad1dd-2ffe-4580-8337-00c242df333f https://publications-cnrc.canada.ca/fra/voir/objet/?id=091ad1dd-2ffe-4580-8337-00c242df333f

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20338292

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Organic Coatings for the Interior of Gasoline Drums

NATIONAL

RESEAHCH C O U N C I L CAilADAO R G A N I C COAllI;L'GS F O R TiiG I N T E l i I O H

O F G A S O L I N C DRUMS

by D. Dennis, B.S, S t a f f o r d , and

J,

HarrisR e p o r t No,

51

of t h eD i v i s i o n o f B u i l d i n g R e s e a r c h

OTTAWA

The s a t i s f a c t o r y s t o r a g e of a v i a t i o n and motor f u e l s i s a v i t a l need i n Canada, e s p e c i a l l y i n a l l n o r t h e r n a r e a s . The problems i n v o l v e d have been u n d e r s t u d y f o r sornc t i m e under t h e d i r e c t i o n of t h e Group on Drum S t o r a g e of F u e l ,

The D i v i s i o n of B u i l d i n g Research h a s been p r i v i l e g e d t o p a r t i c i p a t e i n t h i s work t h r o u g h t h e P a i n % R e s e a r c h

L a b o r a t o r y of i t s B u i l d i n g M a t e r i a l s F e c t i o n , i n c o l l a l ~ o r a t i o n w i t h t h e D i v i s i o n of Mechanical E n g i n e e r i n g : t h e Royal

Canadian A i r F o r c e and t h e o i l companies,

The P a i n t R e s e a r c h L a b o r a t o r y h a s u n d e r t a k e n t o c a r r y o u t a l l n e c e s s a r y l a b o r a t o r y work on t h e e v a l u a t i o n of c o a t i n g f o r m u l a t i o n s f o r i n t e r i o r and e x t e r i o r a p p l i c a t i o n t o s t e e l drums. T h i s f i r s t r e p o r t d e a l s w i t h t h e work done on i n t e r i o r c o a t i n g s ,

Ottawa,

O H G A N I C COATINGS FOR THL INTERIOR OF GASOLINE DRUMS by

D.

G e n n i s , B. S o S t a f f o r d and J, H a r r i sI n t r o d u c t i o n

The P a i n t R e s e a r c h L a b o r a t o r y u n d e r t o o k , f o l l o w i n g a d e c i s i o n rnade by t h e Group o n t h e Drum S t o r a g e o f F u e l on F e b r u a r y 1 0 , 191;3,

t o e v a l u a z e v a r i o u s c o a t i n s f o r m c l a t i o n s f o r i n t e r i o r and e x t e r i . 9 ~ a p p l i c a t i o n t o s t e e l drums, T h i s r e p o r t d e a l s w i t h t h e work t o d a t e on i n t e r i o r c o a t i n g s , An i n t e r i o r c o a t i n g , t o be e f f e c t i v e , must . ? r e v e n t c o r r o s i o n of t h e s t e e l drum and h e n c e i n c r e a s e t h e s t o r a g e l i f e of t h e f u e l b T h i s p r o t e c t i o n may b e needed f o r p e r i o d s a s l o n g a s t e n y e a r s dependfng upon t h e t y p e o f f u e l b e i n g s t o r e d . C o a t i n g s must h a v e good r e s i s t a n c e t o t h e f o l l o w i n g f o r c e s : 1) s o l u t i o n b y t h e f u e l b e i n g s t o r e d ; 2 ) c o r r o s i o n ;

3 )

f r a c t u r e by impact a t low t e m p e r a t u r e s , I n view of t h e c o n s i d e r a b l amount o f r e s e a r c h c a r r i e d o u tf

on t h i s p r o b l e m by t h e U.S. ~ r m ~ ( l s t u d i e s i n t h i s p r o j e c t were l i m i t e d t o t h o s e c l a s s e s of c o a t f n g s which showed most praornise f r o m t h e work c a r r i e d o u t i n t h e U,S.A, These i n c l u d e a v a r i e t y ofm o d i f i c a t i o n s o f p h e n o l i c r e s i n s w i t h v i n y l , a l k y d and epoxy r e s i n s and a l l r e q u i r e b a k i n g , A number o f a i r - d r y i n g v i n y l b a s e form- u l a t i o n s were t r i e d a s w e l l a s s e v e r a l commercial m a t e r i a l s ,

Two s e r i e s of f o r m u l a e were p r e p a r e d and e v a l u a t e d , The f i r s t s e r i e s was e x p l o r a t o r y ; t h e second s e r i e s was a n e x ~ e n s i o n and e l a b o r a t i o n o f t h e f i r s t , F o r m u l a t i o n s f o r a l l t h e c o a t i n g s p r e p a r e d i n t h e l a b o r a t o r y a r e g f v e n i n Appendix A , p a g e s A : t o A l l ,

E l e v e n f o r m u l a t i o n s were o r i p i n a l l y p r e p a r e d . These were a s s i g n e d t h e l a b o r a t o r y numbers 1101L t o 1 1 0 2 4 i n c l u s i v e . The f o r m u l a t i o n s a r e g i v e n i n Appendix A , p a g e s All t o

AS

These c o a t i n g s were t e s t e d on 2

3/4-

b y 6 - i n c h , t w e n t y gauge, S.A,E, 1 0 1 0 , c o l d r o l l e d s t e e l p a n e l s , The P a n e l s were f i r s t c l e a n e d a c c o r d i n g t o t h e p r o c e d u r e o u t l i n e d i n method 1 0 0 . 1 o f t h e C a n a d i a n Government S p e c i f i c a t i o n Board'sf'Schedule o f Methods of T e s t i n g P a i n t s and pigments", 1-GP-71. The C o a ~ i n g s werea p p l i e d by d i p p i n g t o a d r i e d f i l m t h i c k n e s s o f a p p r o x i m a t e l y

5

r n i ~ r o n s ,(1) R e f e r e n c e : l e t t e r and r e p o r t frorn Q u a r t e r m a s t e r - G e n e r a l , W G R T 400, December 22, 1 9 5 2 , N O R O C , f i l e number M2-17-135-6,

The p a n e l s were s u b j e c t e d t o t h e t e s t s d e s c r i b e d below a f t e r t h e r e q u i r e d b a k i n g s c h e d u l e o r i n t h e c a s e o f t h e a i r - d r y i n g c o a t i n g s , a f t e r d r y i n g f o r one week a t 7 3 ' ~

+

3 . 5 " ~

and 5 0 p e r c e n t+ 5

p e r c e n t r e l a t i v e h u m i d i t y . A l l t e s t s w e r e - c a r r i e d o u t i n d u p l i c a t e .A

-

G a s o l i n e R e s i s t a n c eCoated p a n e l s were immersed t o a d e p t h o f two i n c h e s i n a v i a t i o n g a s o l i n e a t 7 3 ' ~ t

3 . 5 ' ~

f o r one h u n d r e d d a y s . They weret h e n removed and a f t e r a r e c o v e r y p e r i o d of two h o u r s , were e x a n i n e d f o r any c h a n g e s which may have o c c u r r e d .

B

-

Heverse Impact a t Low T e m p e r a t u r e sCoated p a n e l s were t e s t e d a t - 2 5 ' ~ and

-SOOc

w i t h a Gardner Impact T e s t e r u s i n 2 t w e n t y . - e i g h t i n c h pounds imi3act, The p a n e l s were a l l o w e d t o r e g a i n room t e m p e r a t u r e t h e n examined f o r c r a c k s o r l o s s of a d h e s i o n on t h e convex s u r f a c e u s i n g a m i c r o s c o p e o f t e n power m a g n i f i c a t i o n , Any change i n t h e c o a t i n g by c r a c k i n g o r l o s sof a d h e s i o n was c o n s i d e r e d a f a i l u r e ,

C

-

C o r r 3 0 s i o n R e s i s t a n c eCoated p a n e l s were t e s t e d f o r r e s i s t a n c e t o s a l t f o g a c c o r d - i n g t o t h e A,S,T,M. method B l l 7 , " T e n t a t i v e Method o f S a l t S p r a y

( F o g ) ~ e s t i n g " u s i n g a 20 p e r c e n t s a l t s o l u t i o n , The e d g e s o f t h e p a n e l s were d i p p e d i n a n a i r - d r y i n g enamel b e f o r e e x p o s u r e t o f o r m a 1 / 4 - i n c h b o r d e r around t h e p a n e l ,

D

-

Steam R e s i s t a n c e---

Coated p a n e l . ~ were suspended i n a s t e m b a t h f o r

4-8

h o u r s , The p a n e l s were removed and examined f o r any c h a n g e s which may h a v e o c c u r r e d ,E

-

A l k a l i R e s i s t a n c eC o s t e d g a n e l s were immersed i n 1 0 p e r c e n t sodium h y d r o x i d e s o l u t i o n a t 1 0 0 F f o r t h i r t y m i n u t e s , The p a n e l s were removed and examined f o r any c h a n g e s which may have o c c u r r e d ,

3 ,

---- Obsepvat+ o n s ----TABLE

I

GASOLINE, IMPACT, STEAM

ANDALIUiLI RESISTATICE OF COATEE PANELS

-

-Laboratory

Gasoline

Reverse Impact

Steam

Alkali

Number

Panel Resistance

Resistance

Resistance desistanc

-2s0c

-soOc

CoRo

C.R.

C o R e

C.R.

C.R.

CeX*

NoCe

NoCa

N.C,

N.C.

NoC

0N.C.

NoCo

N. C

,. N o C eN.C.

NoCo

N.Ce

N.Co

NoCo

MeC.

N.C.

LEGEND:

P

denotes pass;

F

denotes failure;

-

denotes test not done;

N,C,

-

No Change

TABLE I1

CORROSIOTJ RESISTAKCE OF COATED PANELS

L a b o r a t o r y

N-mb e r C o n d i t i o n

11014

Rust s p o t s a p p e a r e d a f t e r one day 11015 R u s t s p o t s a p p e a r e d a f t e r one day 11016 Rust s p o t s a p p e a r e d a f t e r t h r e e days 11017 S e v e r e r u s t i n g and s t r e a k i n g a f t e r t h r e e days A few b l i s t e r s a p p e a r e d a f t e r t h r e e d a y s , b u t no r u s t i n g t i l l n i n e d a y s 11020 Rust s p o t s a p p e a r e d a f t e r t h r e e d a y s 11021 S e v e r e r u s t i n g and s t r e a k i n g a f t e r t h r e e d a y s 11022 S e v e r e r u s t i n g and s t r e a k i n g a f t e r t h r e e days 11023 Rust s p o t s a p p e a r e d a f t e r f o u r t e e n d a y s 11024 Rust s p o t s and s t r e a k i n g a p p e a r e d a f t e r t h r e e d a y sk.

Summarv of R e s u l t s on F i r s t G r o w o f F o r m u l a t i o n s I n t h i s s e r i e s :a ) samples 11015, 11017 and 11023 were t h e most r e s i s t a n t t o f r a c t u r e by impact a t low t e m p e r a t u r e ;

b ) samples 11016, 11019, 11020 and 11023 gave t h e b e s t c o r r o s i o n p r o t e c t i o n t o s t e e l , Sample 11023 was t h e b e s t i n t h i s r e s p e c t ;

c ) a l l f o r m u l a t i o n s t e s t e d were u n a f f e c t e d by steam;

d ) samples 11015, 11019, 11020, 11023 and 11024 had s a t i s f a c t o r y r e s i s t a n c e t o a l k a l i .

5.

P r e p a r a t i o n of and T e s t s on t h e Second Group o f F o r m u l a t i o n sOn t h e b a s i s of t h e f o r e g o i n g r e s u l t s , i t was d e c i d e d t o p r e - p a r e a more comprehensive group o f f o r m u l a t i o n s t o b e t e s t e d i n a

p h e n o l i c - p o l y v t n y l b u t y r a . 1 and s e v e r a l y l a s t i c i zed ~ ~ i n y l c h l o r i d e -,

v i n y l - a c e t a t e copolymer f o r m u l a t i o n s which Report; TvTumber 1 7 8 1 o f t h e N a t i o n a l Bureau o f S t a n d a r d s had shown t o p o s s e s s des?.ral::le c h a r a c t e r a i s t i c s .

The f o r m u l a e a r e g i v e n i n Appendix A , p a g e s

AS

t o A l l , T:I a d d i b i o n , c o a t i n g s numbers 11015, 11017, 11020, and 11023 o f the p r e v i g u s s e t and 10956, 10965, 10968 and 10969 which a r e cornmerc-:.A cpoxy c o a t i n g s were i n c l u d e d i n t h f s s e r i e s .T e s t s on t h e s e samples were c a r r i e d o u t a c c o r d i n g t o t h e metehods d e s c r i b e d on page 2

.

The ~ o s t i m p o r t a n t c h a r a c t e r i s t i c s o f t h e s e c o a t i n g s were r e s i s t a n c e t o c o r r o s i o n by s a l t f o g , r e s i s t a n c e t o f r a c t u r e by r e v e r s e impact a t low t e m p e r a t u r e , and r e s i s t a n c e t o g a s o l i n e , It was d e c i d e d n o t t o t e s t t h e s e c o a t i n g s f o r a l k a l i and s t e a m r e s i s t a n c e s i n c e t h e s e p r o p e r t i e s werc a l r e a d y showri t o be v e r y good f o r these t y p e s o f c o m p o s f t i o n s ,

The c o a t i n g s were t e s t e d on

4-

by 6 - , i n c h , t w e n t y , f o u r gauge,SAE

1020, c o l d r o l l e d s t e e l p a n e l s . They were a n p l i e d a t a d r i e d f i l m t h i c k n e s s o f 1 2 , s+

2.5 m i c r o n s . A f t e r t h e s u i t a b l e b a k i n g s c h e d u l e , o r a f t e r a i r - d F Y i n g f o r one week a t7 3 ' ~

+

3 e 5 0 ~

and 50 p e r c e n t

-

+ 5

p e r c e n t r e l a t i v e h u m i d i t y i n t h e caseRof a i r - d r y i n g . f i n i s h e s , t h e p a n e l s were t e s t e d i n t h e same manner a s t h o s e of t h e p r e v i o u s s e r i e s e x c e p t t h a t t h e r e v e r s e Impact t e s t s were p e r f o r m e d a t O'C,-

20°C and -25OC.These t e s t s were c a r r i e d o u t i n d u p l i c a t e and t h e r e s u l t s a r e g i v e n i n T a b l e s I11 and. I V ,

TAGLE

I11

lILSISTATTCL OF'

COATEL

PklJEL? TO SALT SPliAY COHILO SIOI'JL a b o r a t o r y Cays 3umb e

r

P a n e l Exposed C o n d i t i o n No change Few/#?I

b l i s t e r f n g Kedium#8

b l i s t e r i n ~ Complete l o s s o f a d h e s i o n o v e r t o p h a l f o r t h e p a n e l-

FAILEX~ ~ e d i u r n . chan#e

8

o l i s t e r i n e o v e rSO:,

or tile p a n e lR l i s t e r f n . ~ s i z e and d e n s i - t y hiis i n - c r e a s e d and c a u s e d col;tlpl;.3f;e loss

of . a d h e s i o n o v e r 50:;; of t h e pane7'

-. F'ii 1 LzTJ

Few v e r - s ~ n a l l r u s t s p o t s

L e d i u o ~

$8

b i i s t e r i n f : o v e r p a n e l-

a l l a r e r u s t in:, and trios t of a r e st.realiin,y-

FAILED

No chanpe Piedium#8

b l i s t e r i n g o v e r p a n e l and two l a r y e ( $ ' I d i a a , ) r u s t b l i s t e r s 30'" , .I of b l i s t e r s a r e rus-bin[< anrl. s t r e a k . i n : --

F A I L 3 9 No cLiin2:e K O c h a n : ~ e No clianr1.e Few$8

3 1 i s t e r ic!; ?To chants1~C.edj.u~

776

b l l s t e r i n f i ;-

fel-,J blisters a r e r u s t in,? and s t r e a k i n p - F A I L X IIT,-,

chanpe No chanple Fo c h a n ~ eFew

#(3

b P i s % e r i n ~ 25::. of b l i - s t e r s a r e r u s t streakin.::--

FA

I

T.:XD No chanye No chznpe No chanp;e P'Iedium d e n s e# 9

b l i s t e r i n g i 3 l . i ~ t e r i n . 5 i n c r e a s in?; i n d e n s i t y Dense#q

b l i s t e r i n ? ;-

n o s t o.f b l i s t e r s a r e r u s t i n c-

FAILED

PJo change Few t o medium#9

b l i s t e r a i n gNo

shancye Hediurn89

b l i s t e r i n gTA

.-!L;<I1

I c o n t h u e d . --- Lalooratory Cays E:umL e r--

---

--

P a n e l Exposed-

---

C o n d i t i o n,,

, , , , . i ~ n i p. F! t o medium d.ense#9 51

i s t e r l r r i , - P ~ ~ e n s e# a

S l i s - t e r i n r r <-,-

most 0:;' 5 l i s t e r s a r c r u s t i n $ ;-

F H P ~ ~ ~ ~ . ~ No chanqe 1:ediurnk'9

b l i s t e r i n 5-

1 0 a r e r u s t i n p : antistreak in^

-

FAILED Few t o r i : e d i ~ l n#9

listeri in^

F!Ted4.um

# q

b l i s t e r i n r p-

805: a r e r us t in,; ancl s t r e a k i n y-

FAILED Yo chanrre Few#8

b l i s e r i n m o v e r t o p 20::: of p a n e l-

a l l a r e r u s t i n g 2 0 ' of b l i s e r s have s t a r t e d t o s t r e a l ;-

FAILFT; Fo chang;e P;edfum d e n s eH 8

b l i s t e r i n g over t o p 2wL of p a n e l-

most a r e r u s t i n g and s t r s a k i n s-

F A I L I D No change One s m a l l( l / q r '

d i a m . ) r u s t s p o t Kedium d e n s ek8

b l i s t e i n g Kedium d e n s e t o d e n s e$8

b l i s t e r i n e-

30$ a r e r u s t iiig and s t r e a k i n g-

?'AILED No change No chan,rl;e 1~umerou.s w h i t e s p o t s(3/16"

diam. )-

some a r s b l i s t e r i n g E l i s t e r i n g i n c r e a s i n gNo

chhn,.:e S e v e r e b l i s t e r i n g , r u s t i n ~ ~ n d . s t r e a k i n , y-

FAILED FC) chanc;e R O changeAbout

1.2

a r e a s o f rnediurn ,dense#

8

b l i s t e r i n p ; 257: of p a n e l a r e a a f f e c t e d l ~ ~ e d i u m d e n s e

$8

b l i s t e r i n p o v e r p a n e l No cban!;e P a n e l i s d a r k e n i n g b u t n o s u r f a c e r u s t P a n e l i s s t a r t i n s t o s t r e a k-

FAILED

No c h a n ~ e No change No c h s n ~ e P m e l i s d a r k e n i n g No change No changeTA3LE I11 c o n t i n u e d L a b o r a t o r y Num is e r

---

Pane 1 Days Exposed C o n d i t i o n No change No change Median t o medium#8

b l i s t e r i r ~ ~ Medium dense#8

b l i s t e r i n g-

vest

showinp r u s t

-

FAILED K O chanpeP.?o chanSe

EIediurn

#8

b l i s t e r i n g-

few showing r u s t-

FAILEDK O

chanpe No change No chan e Medium88

b l i s t e r i n g-

501~

a r e r u s t i n g and s t r e a k i n p-

FAILTJ One r u s t s p o t No change Medium dense #8 b l i s t e r i n g50$

of b l i s t e r s a r e r u s t i n g and s t r e a k i n g-

FAILEDMany w h i t e s p o t s (+I' d i a m , )

-

twoa r e showing r u s t S e v e r e r u s t i n g and s t r e a k i n g

-

FAILZD Many w h i t e s p o t s-

3

a r e r u s t i n g and t h e o t h e r s a r e b l i s t e r i n g S e v e r e r u s t i n c and s t r e a k i n g-

FBILZD No change Medium b l i s t e r i n g-

257; of b l i s t e r s a r e r u s t i n p ;-

FAILED No change Few v e r y s m a l l r u s t s p o t s Medium#8

b l i s t e r i n g-

257:

of b l i s t e r s a r e r u s t i n g-

FAILED No change Few#8

b l i s t e r i n g-

a l l a r e r u s t i n g and s t r e a k i n g-

FAILED Few#8

b l i s t e r i n g-

a l l a r e r u s t i n g and s t r e a k i n g-

FAILEC No change About 50 s m a l l b l a c k s p o t s b e n e a t h s u r f a c e No changeBlack s p o t s have s t a r t e d t o show s u r f a c e r u s t

-

FAILED No change Few s m a l l b l a c k s p o t s beneath s u r f a c e About 100 s p o t s now S p o t s i n c r e a s i n g i n a r e a( 3 / 8 "

diam.) S e v e r e r u s t i n g b e n e a t h s u r f a c e-

FAILEDTABLk I11 c o n t i n u e d Laboratory Days Number P a n e l hxposed C o n d i t i o n 11032 A

3

Few#8

b l i s t e r i n g7

No change 11 About 10 b l a c k s p o t s beneath s u r f a c e 1 8 No change$2

No change Area of d a r k s p o t s i n c r e a s i n g but; no s u r f a c e r u s t i n g y e t46

Severe r u s t i n g , b l i s t e r i n g and s t r e a k i n g-

FAILbU B3

No change7

No change11 A few b l a c k s p o t s

(l/ol'

diam.) beneath s u r f a c e18

No changet 2

No change No change46

Severe r u s t i n g , m i s t e r i n g and s t r e a k i n g-

FAILED A3

No change7

No change 11 No change 1 8 No change$2

Panel i s s t a r t i n g t o darken No change4-6

Severe darkening beneath s u r f a c e-

FAILED B3

No change7

No change 11 No change 1 8 No change 25 Panel i s s t a r t i n g t o darken8

No changeSevere darkening beneath s u r f a c e

-

FAILED A3

No change7

No change ' 11 Few #8 b l i s t e r i n g18

B l i s t e r s a r e r c s t i n g and s t r e a k i n g-

FAILED B3

No change7

Few#8

b l i s t e r i n g 11 Few t o medium#8

b l i s t e r s18

Dense#8

b l i s t e r i n g-

FAIL%L a ' r ~ o r a t o r y Xumb e r P a n e l TABLE 111 c o n t i n u e d Cays Exposed C o n d i t i o n

3

2 v e r y s m a l l (1/1011 diam. ) r u s t a r e a s7

No change 11 About 30 w h i t e s p o t s(it'

d i m , ) b e n e a t h s u r f a c e18

White s p o t s have b l i s t e r e d and a r e s t a r t i n g t o r u s t-

FAILED3

No change7

3

v e r y s m a l l (1/16" d i m . ) r u s t a r e a s11 About 1 2 r u s t s p o t s

(if'

diam. ) FAILED3

No change7

Few v e r y s m a l l (1/16" d i m , ) r u s t a r e a s 11 Mediurn #8 b l i s t e r i n g18

SO$

of r u s t s p o t s have s t a r t e d t o s t r e a k-

Ff'iILED3

No change7

Few v e r y s m a l l (1/16" diam, ) r u s t a r e a s 11 No change18

About 50% ,&, b l i s t e r s t h a t a r e r u s t i n g 40% a r e s t r e a k i n g-

FAILEE3

No change7

Few v e r y s m a l l r u s t a r e a s( l / l h t '

d i m . 11 Few#8

b l i s t e r i n g18

80;:

of b l i s t e r s a r e r u s t i n g-

FAILED3

No change7

Few v e r y s m a l l r u s t a r e a s ( l / 1 6 ' t d i a m . ) 11 Few #8 b l i s t e r i n g-

00;%

a r e r u s t i n g-

FAILED3

bout 1 2 r u s t a r e a s(1,/0*

d i m , ) o v e r 25% of p a n e l-

a l s o many w h i t e s p o t s b e n e a t h t h e s u r f a c e ."7

S e v e r e r u s t i n g and s t r e a k i n g-

FAILED3

No change '7I About 20 a r e a s

(in

diam.) ofr u s t

-

FA1LL.D3

Medium#8

b l i s t e r i n g-

a l s o many r u s t a r e a s(1/8"

d i m , ) - FAILED3

No change7

S e v e r e r u s t i n g and s t r e a k i n g-

FAILEG3

No change7

About 20 a r e a s (3/16" d i a m , ) of s e v e r e r u s t i n g . and s t r e a k i n g-

FAILED No change S e v e r e r u s t i n g o v e r t o p 255 of p a n e l-

F'AILED-

-TAbLTi; I I I coiii;inued --

-

.-.- La-::.orat o r y Number Days P a n e l Exposed C o n d i t i o n ..-3

r u s t a r e a s (1/:3" d i a m . ) Few r u s t a r e a s t h a t a r e s t ~ e a k i n g-

FAILED No change Few r u s t a r e a s t h a t a r e s t r e a k i n g-

FAILED S e v e r a l r u s t a r e a s t h a t a r e s t r e a k f n g-

FAILED S e v e r a l r u s t a r e a s t h a t a r e s t r e a k i n g-

FAILEGFew t o mediim

#8

b l i s t e r i n g andtwo s m a l l r u s t a r e a s ( l / f j l ' diam, ) S e v e r a l r u s t s p o t s a t t h e t o p o f p a n e l Tdllich a r e s t r e a k i r l g

-

FAILED No change About 1 0#4

b l i s t e r s o v e r p a n e l -dhich a r e s t r e a k i n g ' - FAILEG Four l a r g e r u s t a r e a s (5/16" d i a r ~ , ) t h a t h a v e s t a r t e d t o s t r e a k-

FA I USD C o a t i n g h a s l o s t a d h e s i o n - FAILED3

S e v e r e r u s t i n g and s t r e a l r i n g o v e r p a n e l-

FAILED3

S e v e r e r u s t i n g and s t r e a l t i n s o v e r p a n e l-

FAILED3

Few r u s t a r e a s(118"

d i a m . )7

Complete l o s s of a d h e s i o n '== FAILE133

F i v e r u s t s p o t s o v e r p a n e l t h a t a r e s t r e a k i n g-

FAILED3

No change7

S e v e r e s t r e a k i n g from medium j'8 b l i s t e r s *-= FAILil,L;3

Plediurn#8

b l i s t e r i ~ g r 9 30% a r e r u s t i n g and s t r e a k i n g.-

FAILED Note: Thesize

and d e n s i t y o f any b l i s t e r s a r e r e p o r t e d a c c o r d i n gt o t h e A.S.T.M. method f o r E v a l u a t i n g Degree o f B l i s t e r i n g

T A B L E I V G A S O L I N E AND R E V E R S E I M P A C T R k , S I E T A N C E OF G O A T E E PAI'TITLS

---

L a b o r t a r y G a s o l i n e N u m b e r Panel R e s i s t a n c e R e v e r s e Impact R e s i s t a n c e 1 0 0 days 0 ° C -:2OUC - 2 5 ° C-

10956

A No C N e C e C.R. COT!O N.C. N.C. i\To,Co N a C e NOC. C o R , N a C e N.C. C o R . C .I?, A N, C. C . R . C , H , C , R o C o R o C , R , C . R . C.Ii. B N.C. C O H O C o R o C a R o N o C o N oC 0 N o C e C o R e C . R o N o C o N e C o C o R o N o C o N o C . N o C e C 0 Ii, C , R o C.R. A N o C o m.3-

BN,

C.-

-

-

-

T A B L E I V c o n t i n u e d L a b o r a t o r y G a s o l i n e N u m b e r P a n e l R e s i s t a n c e R e v e r s e I m p a c t R e s i s t a n c e -

---

100 days 0 ° C - 2 0 ° C-..~sac

N o C e N o C e N.C. N o C e N.C. N e C o No C o N o C. N. C ,PJ,

C , N , C . N o C o N o C a N, C. N.Co N o C e N o C e N.C. NQCO NoCo WOCO N.C. C e R e CUR. N.Co N o C o COHO C O H O C , R . C o R o C o R o C , R . C . R e C o R o C e H , C o R o C o R e C.H. C.R. C o H e C o R o C o R o C o R o C o R o No Co N.C. C o R o C , R , C OR0 C . H a C , R , C O H O C o R e C . R . C.R. C.Ro C .R, COHO C o R e C , R , L E G E N D : - d e n o t e s t e s t n o t done; N e C ,-

N o C h a n g e ; C o R e C r a c k e dTABLB I V continued L a b o r a t o r y G a s o l i n e Numb e r Panel R e s i s t a n c e R e v e r s e I m p a c t R e s i s t a n c e 1 0 0 d a y s O°C - 2 0 P C

-325"

C 11040 A N. C. N o C o N ,c

.

N.C, B N . C o N. C . C O H O C U R .11041

Aram c o

C.R. C o R o C o H - B N e C a C e i i O C o H a C o R e 11042 A N o C o C - R , C , K . C , R . B N e C o C o R o C eH e

C e R e11044

A N o C. C e R e C o H o C o H o B N o C . C o R e C O H O C oHo1104.5

A N e C e C e R o C o K O C OR, B N a C m C a R o C o R o C o R o11046

A N o C e COH

o C o R o C o R o B N o C 0 C o R o Co Ro C o R o11047

A N.C. C o R e C o R a C o R o B N o C o COHO C e R o C o R o11048

AN.

C , C , R , C . R . C o R . B No C a C o R e C * H o C o R o11049

A N . C m N o C e N o C o i\i o C 0 B N.C. N.C.N o

C , N.C. LEGEND: - d e n o t e s t e s t n o t done; N.C.-

N o C h a n g e ; C o R o-

C r a c k e dS u m ~ a r y of t h e Second F e r i e s o f T e s t s The r e s u l t s o f t h e s e t e s t s show t h a t t h ~ c o a t i n g s

10968,

10969, 1 1 0 2 3 , 11032 and 11033 h a v e b e t t e r c o r p o s i o n - r e s i s t z n t p r o p e r t r i e s t h a n t h e r e r n a i n i n ~ f o r 7 - c ~ u l a t i o n s of t h e s e r i e s , S ' m p l e s 1 0 9 6 8 a ~ l ~ d 'C)969 a r e c o m m e r c i a l t t l e r m o - s e t t i n g epoxy f o r m u l a t i d ~ l s , s a m p l e s 11023 and 11033 a r e v i n g l i d e n e c h l o r i d e - a c r y l o n i t r i l e c o p o l g ~ ~ e r 1 o r m u l a t i o n s and 11032 i s a p h e n o l i c - v i n y l f o r r r . u l a t i o n . The t e s t s f o r r e s i s t a n c e t o f r a c t u r ea t

low t e m p e r a t u r e s by i m p a c t were more s e v e r e i n t h i s s e r i e s s i n c e t h e f i l x thickness h a d b e e n i n c r e a s e d . Samples 10965, 10969 and 11049 showed b e s ti m p a c t r e s i s t a n c e i n t h i s s e r i e s . Samples 10965 and 10969 a r e t h e r m o - s e t t i n g epoxy t y p e f o r m u l a t i o n s w h i l e 11049 i s a n a i r - d r y i n g v f n y l f o r m u l a t i o n . A l l t h e c o a t i n g s were u n a f f e c t e d by i m m e r s i o n in a v i a t i o n r a s o l i n e f o r 1 0 0 d a y s , 0

7. E f f e c t o f Using Wask-primed and P h o s p h a t i z e d

-

S t e e l-

The e f f e c t o f u s i n g a wash-primed s u r f a c e and a p h o s p h a t i z e d s u r f a c e was a l s o s t u d i e d i n a n a d d i t i o n a l s e r i e s ,

S t e e l ~ a n e l s o f t h e same z a u g e and t y p e u s e d i n t h e f o r e - g o i n g s e r i e s were c l e a n e d a c c o r d i n g t o method 1 0 0 , l o f t h e C a n a d i a n Government S p e c i f i c a t i o n B o a r d ' s " S c h e d u l e o f Methods o f T e s t i n g P a i 2 t s and p i g m e n t s " , 1-GP-71. These p a n e l s were t h e n

di,.

a,oated w i t h a v i n y l - t y p e wash p r i m e r ( l a b o r a t o r y number 1 1 1 3 0 ) , The formulation of t h i s m a t e r i a l i s g i v e n i n p a s eAll

o f Appendix A,The d r i e d f i l m t h i c k n e s s of t h i s m a t e r i a l w a s l e s s t h a n 2.5 m t c r o n s , The p r i n e r was a l l o w e d t o d r y f o r a p p r o x i m a t e l y one h o u r a t room t e m p e r a t u r e and t h e p a n e l s were t h e n d i r z o a t e d w i t h c o a t i n g s 1 1 0 2 3 , 1 1 0 3 5 , 11040, 1104.2 aqd 1104.6 t o a t o t a l d r i e d f i l m t h i c l i i l e s s b e -

t w e e n 1 0 and

15

m i c r o n s .These c o a t i n g s were a l s o a p p l i e d t o p h o s p h a t i z e d s t e e l p a n e l s . These p a n e l s were o f 24-gauge s t e e l a n d h a d a z i n c p h o s p h a t e c o a t i n g of 200 m i l l i g r a m s p e r s q u a r e f o o t , The o r g a n i c c o a t i n g t h i c k n e s s was b e t w e e n 1 0 and

15

m i c r o n s .A f t e r b a k i n g u n d e r t h e p r e s c r i b e d c o n d i t i o n s o r a f t e r d r y i n g f o r one week a t 7 3 ' ~

+

3.5'F and 50 p e r c e n t+ 5

p e r c e n t r e l a t i v e h u m i d i t y f o r t h e a i r - T r y c o m p o s i t i o n s , t h e p a n e l s were s u b j e c t e d t o t h e c o r r o s i o n and t h e r e v e r s e i m p a c t t e s t s a s d e s c r i b e d f o r t h e p r e v i o u s s e r i e s , A l l t e s t s were c a r r i e d o u t i n d u p l i c a t e ,8,

O b s e r v a t f o n sTABLE; V H E S I S T A X C E O F C O A T I N G S ON P H L T R Z A T E D P A N E L S T O F H A C T U R E BY I M P A C T L a b o r a t o r y W a s h - P r i n e d S u r f ace P h o s p h a t f z e d I T m b e r Panel, S u r f a c e 0 ° C -15°C - 2 S 0 C

oOc

- 1 5 ° C - 2 5 ° C C . R . C a R aN o

C . N , C . No C 0 N , C o N e C o N o C o C o R o C . R , C e R o C e R o C a R e C , R , C U R o C e R o C . R , C o R e C ,R.

C.R. N , C , N o C o C o R ,C,K.

COR. C o R e C m R o C.H, C o R o C.R. C , R , C.R. C . H , cefi.No

C C , I3 0 C * I j a C e R o C o R e C.H, L Z G E J D : C , R e-

C r a c k e d ; N , C o = . NG C h a n g e --

C O i i 8 9 5 1 0 3 T R E S I S T A N C E OF C O A T I N G S ON WASH-PRIMED S T E L L L a b o r a t o r y D a y s N u m b e r P a n e l Exposed C o n d i t i o n S i x#8

b l i s t e r s s c a t t e r e d o v e r p a n e l-

t h e y a r e r u s t i n g and s t r e a k i n g-

F A I L E D N o change N o changeNo

chs*lge A b o u t 500 s m a l l r u s t s p o t s ( 1 / 1 6 " d i a m , :-

20% a r e s t r e a k i n g-

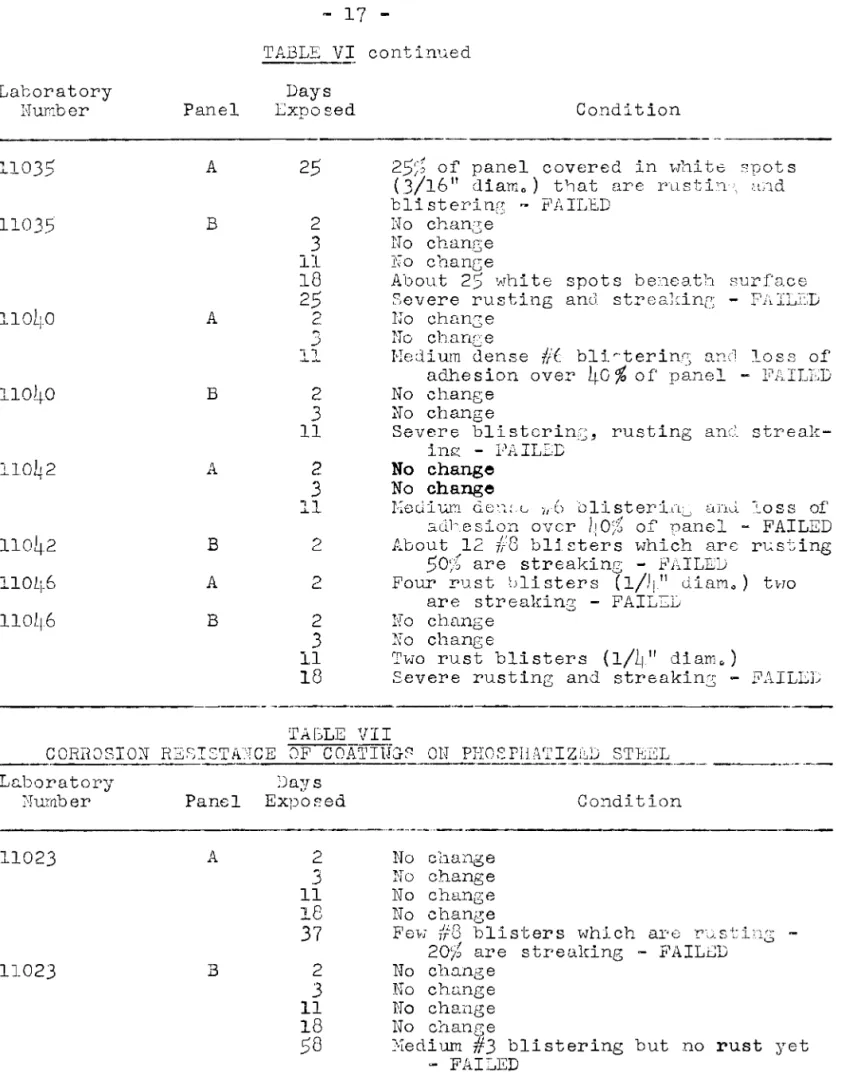

F A I L E D N o change N o change N o change S e v e r a l w h i t e s p o t s b e n e a t h s u r f a c e ( 3 / 1 6 I t d i a m , ) 40% a r e s t a r t i n g t o r u s tTABLE V I c o n t i n u e d Lalr,oratory Days l\T urib e r P a n e l Lxpo s e d -- - -- 1 1 0 3 5 A 25 25;: o f p a n e l c o v e r e d i n ~ > ? n i t ~ : ~ p o t s (3/16" diarn, ) t h a t a r e r 1 i ~ s t i 1 z ; ;:?ld

blister in^

-

FAIL-l5D 2 No chnn:?;e3

TJo change1 1 No change

1 0 About 2 5 w h i t e s p o t s benca.tl:~ ::urTf'ace 2 5 ?;evere r u s t i n g ant? strc:zLl;i~p;

-

I,"ii2:Li:~I;2 IJo c h . a n ~ e

3

?To cln ange 11 1b:edium d e n s e b l l . - t e r i n ? ; ~ar.:; L o s s of a d h e s i o n o v e r1.p $

o f p a n e l-

PI'LILY:,G2

No ch.ange3

No change 11 S e v e r e b l i s t e r i l l ; , r u s t i n g an:' s t r e a . 1 ~ - ills-

FAILLE 2 N o change3

No change11 MeL'liuri cie:l:,c, 1, 0 b l i s t e r l ~ . i ; _ tij-iii loss of'

z~Cil:esi~n o v r b-0$ of n a n e l

-

FAILED2

P*-tjout 1 2$-'8

bl4 s t e r s which a r e r ~ s ~ s i n gSO:.;'

a r e s t r e a k i n g-

I;'I:ILZI; 2 Four r u s t l j l i s t e r s( l / 4 "

d i m , ) two a r e s t r e a k i n g-

FAILLL 2 I\'o ch.ange3

No change 11 Two r u s t b l i s t e r s( l / I . l l f

d i a n i , )18

S e v e r e r u s t i n g and s t r e a k i n 2-

5 3 I L i L -----

--- -----

.---.-. -,- TALLE 7 J j - I---

CORR3SION H3F.;IETH7.'?CE 3F C O A T I I J G W T J PEi:CEPiT:7Y'IZ>i!j STTI;II%

-. --

-

.---.--- .-. - -.-.--.-, --"---

L a b o r a t org :lags 1Iu:cnb e r P a n e l Exuosed C o n d i t i o n No cilange?TO

changc No change Wo changeFetr

#3

b l i s t e r s which art r,s.';f I(- a-

20$ a r e s t r e a k i n g

-

FAILS3 No change No chzngeNO

cl?ai?ge No c h a n ~ e lsledium$3

b l i s t e r i n g b u t no rust y e t-

FAILEDTA1,LE V I L c,on.t in u e d --.-- - L a b o r a t o r y 3ay s JTmb

er

P a n e l Exposed C o n d i t i ~ ~ l i :i\Jo change No change No change No change About6

a r e a s( 3 / 8 "

diam. o f r u . s t l . n g and s t r e a k z n g-

FAILED No change IJo change No change No change About6

a r e a s(3,1'8"

d i a m , ) o f r u s t i r l g and s t r e a k i n g-

FAILEG NG chznge No changeNG

changs About 1 0 a r e a s o f r u s t i 2 g-

3

a r e s t r e a k i n g-

FAILED No change No change No e h a q e No cl-lange S e v e r e r u s t i n g and s t r e a k i n g-

FAILED No change No change No change About 50 w h i t e s p o t s (3/1bYt d i a m , ) b e n e a t h t h e s u r f a c e L o s s of a d h e s i o n o v e r 40$ of p a n e l-

FAILED No change TJo change ITo charwe Few s m a 1 . l PUS^ s p o t s ( l / l h " d i m , ) S e v e r e r u s t i n g and s t r e a k i n g-

FAIL5D About:6

s m a l l r u s t s p o t si,1./0"

d i a r r . )Nc

change One a r e a (20':; - . o f n a n e l j of s e v e r e r u s t i n g and s t r e a l r ~ & and a f ' e w srnall r u s t s s p o t s-

FAILEC No change No change One a r e a (20$ o f p a n e l ) s e v e r e r u s t i n g and s t r e a k i n g-

FAILED9 ,

Summary o f R e s u l t s on P r e t r e a t e d S u r f a c e sThe u s e o f a wash-primed s t e e l surf'ace improved t h e a d h e s i o n and c o r r o s i o n - r e s i s t a n t p r o p e r t i e s of t h e system, S e v e r a l c o a t i n g s w i t h - s t o o d t h i s r e v e r s e i m p a c t t e s t a t

.

2 5 ' ~ when t h e s u r f a c e was wash-primed,The use of the phosphatized surface did not improve the

results obtained i n the reverse impact test, however, this type of

surface pretreatment did inprove the corrosfon-resistant properties

of the system,

10, Summary

Thirty-three samples were tested in this section of the

project, Four of these were commercial thermo-setting epoxy

formulations of which the detailed

compositionswere not known.

The general non-volatile ,vehicle

combinations c,onsidered were:

catalytically cured epoxy

epoxy-phenolis

phencllie

phenolfa,-epoxy-.urea

formaldehyde

phe~olir-epoxy-polyviny1butyrak

phenolic-polyvinyl butyral

phenolic-alkyd-polyvinyl formal

vinylidene chloride-acrylonitrile copolymer

modified vinyl chloride-vfnyl acetate copolymer

The properties of the formulations prepared i n these

laboratories varied markedly,

In

general, sample 11023, which is

vinylidene chloride-aerylonitrire formxiation, had the best all-

round properties, but is difficult to appiy by spraying, Coating

11032,

which is

aphenolic-,vinyl formulation, showed excellent

resistance to corrosion by the method used, however, its resistance

to impact was not as g ~ o d

as many other materials.

Several samples showed better resistance to fracture by

impact at low temper3atures than the remainfng compositions, These

samples, 11031? l1040, and

11049were of phenolic-,epoxy-vinyl.,

phenolic.-.v-f.nyl

and vinyl compc

sition.

All the samples tested showed excellent resistance to

gasoline, From the tests carried out on the ffrst series of

co:tfngs and from general information on the resin structures,

ftmay be assumed that any formulation containing appreciable a m o ~ m t s

of alkyd, polyvinyl butyral or polyvinyl formal resins will

b eattacked by hot caustic

solutions,On the basis of these tes-t

rbesult.s

the following coatings

are recommended for further

testing through field exposures:

1) llOl,rg

Phenolic-polyvinyl butyral coatfng

2 )

21022

Catalytf

eally cilred epoxy coating

3 )

11023

Vinylidene chloride-aerylonftrila copolymer

coating

P h e n o 1 . i ~ - e p o x y - p o l y v i n y l b u t g r a l c o a t i n g Phenoli c-polyvinyl b u t y ~ a l c o a t i n g

.

Vinyl c h l o r i d e - v i n y l a c e t a t e copolymerc o a t i n g

8 )

10965 Commercial epoxy c o a t i n gT e s t s were a l s o c a r r i e d out i n t h i s p r o j e c t with w a s h - ~ ~ i r n e d and phosphatfzed s t e e l a s s u b s t r a t e s f o r t h e s e c o a t i n g s , The t e s t s show t h a t t h e s e s u r f a c e p r e p a r a t i o n s w i l l improve t h e adhesion of t h e organic c o a t i n g s and t h e c o r r o s i o n r e s f s t a n c e of t h e system as well,

It

i s recommended t h a t drums with s u r f a c e p r e t r e a t m e n t be included i n t h e f i e l d t e s t s ,APPENDIX

A

FORPIULATION OF THE COATINGS

A.

Composition of Interior Erum Coatings

Phenolic-Vinyl Coating

Laboratory number llOllC

N,R,P,

50

Parts by weight

-

Phenolic resin solution

:Resinox P-97

51.0

Polyvinyl butyral resfn

:Butvar B-76

13.5

Sol.vent

;Methyl isobutyl ketone

35.5

Baking schedule: 20 minutes at 350°F',

2.

Phenolic-Epoxy Coatfn~

Laboratory number 11015

N.R,P.

51

Parts by weiaht

Phenolic resin solution

:Resinox P-97

30.3

Epoxy resin

"rpon

1007

15.3

Solvent

:n-Butanol

13*2

:Xylene

13.2

:Methyl isobutyl ketone

27.6

Iron oxide pigment

~Mapico

420

1

.

0

Baking schedule: 30 minutes at

3 5 0 ~ ~ ~

Phenolic

---

Vfn;E:P -Coating

-

Laboratory number 11016

N.R*Pa

52-

Parts by weight

Phenolic resin solutfon

:Resinox P-97

Polyvinyl formal resin

a

Formvar F-770

Solvent

:n-But

an01

:

Xylene

:Methyl isobutyl ketone

Baking schedule: 20 minutes at 3 5 0 ' ~ ~

Phenolfc-Vinyl Coatinq Laboratory number 1101.7 Ne30P,

53

-

P a r t s by weight P h e n o l i c r e s i n:R-108

7

05

P o l y v i n y l b u t y r a l r e s i n s o l u t i o n:lo$

s o l u t i o n of Butvar B-76 i n s e c - b u t a n o l 50.0 S o l v e n t : Sec-butanol 294

~ D i a c e t o n e a l c o h o l13.1

C a t a l y s t :857:

Phosphoric a c i d 0.13 Baking schedule: 40 m i n u t e s a t 330°F0 Phenolic-Alkyd C o a t i n 8 Laboratory number 11018 N"R.P,54

P a r t s by weight P a r t A ~ l k y d r e s i n s o l u t i o n : Glypt a 1 2480 60,0

I r o n o x i d e pigment ~ M a p i c o 420 1 0 6 S o l v e n t :n-Butanol 6,O o, Xylene 3 0 9 0 :Methyl e t h y l ketone3

0 0 :Isophorone 3.0 P a r t B P h e n o l i c r e s i n S o l v e n t C a t a l y s t:R-108

20.

o

: E t h y l a c e t a t s 1 1 , O :85%

Phosphoric a c i dom5

I n s t r u c t f m f o r usesOne hundred grams of P a r t A were added w i t h s t i r r i n g t o s f x t y - t h r e e grams of P a r t B, The m i x t u r e was u s e d w i t h i n e i g h t h o w s ,

Laboratory number 11019

N o R o P e

55

Part.s by weight

Phenolic resin

:K-108

22.3

Zpoxy resin solution

solution of Epon

1007 in a mixed

solvent of

66

parts

of toluene to 22

parts of methyl ethyl

ketone to

12parts

'of methyl isobutyl ketone

55.8

Solvent

~957;

Ethyl alcohol

10-6

:

Toluene

10.6

Catalyst

:85%

Phosphoric acid

065

Baking schedule:

25

minutes at 400°F.

Phenolic-E~osrv-Melamine

Formaldehvde Coatina

Laboratory number

11020N,E,P.

56

-

Parts by weight

-

Phenolic resin

:R-108

2000Epoxy resin solution

:SO$

solution of Epon

1007 in a mixed

solvent of

50

parts

of diacetone alcohol

to

50

parts of xylene

32.0

Melamine-f

ormaidehyde re

sin

solution

~Resimene

875

8,o

Solvent

:Gfacetone alcohol

20.0:

Xy-bene

16,0

Catalyst

:85%

Phosphoric acid

002Baking schedule:

26

minutes at

40o0F0

8,

----

Phenolic-Alkyd Coating

Laboratory number

11021N , R , P .

57

Phenolic resin solution

:Re sinox P-97

Alkyd resin solution

:Rezyl

387-5

Solvent

:n-But

an01

:

Xylene

Parts by weight

C o l d S e t t i n g E p o q C o a t i n g L a b o r a t o r y number 1 1 0 2 2

r

58

P a r tA

Zpoxy r e s - i n : i p o n 1 0 0 1 U r e a - f o r l n a l d e h y d e r c s i . n s o l u t i o n : B e e t l e 216-8 S o l v e n t : M e t h y l i s o b u t y l k e t o n e : B u t y l c e l l o s o l v e : T o l u e n e P a r tE

E t h y l e n e di.amine W a t e r I n s t r u c t i o n s f o r Use: I m e d i a t e l g p r 5 o r t o u s e , 1 3 0 g ; r z ; : s of Pa1.t L.werl-;

7 , - t h o r o u g h l y m i x e d with 1 5 0 0 g r a m s o f P a r t A.. ; h i s i s a c a t a l y s e d a i r - d r y i n g f'ornnllati.on. V i n y l i d e n e C h l o r i d e-

l i c r y l o n i t r i - l e Copolymer --- Coati:np; L a b o r a t o r y number 1 1 0 2 3 TJ,H,P, 59 P a r t s1~-

rdei.;ht V i n y l i d e n e c h l o r i d e - ' a c r y l o n i t r i l e c o p o l y m e r : S a r a n F-120, 1 0 0 0 c p s 1 5 . 0 S o l v e n t : M e t h y l e t h y l k e t o n e2,s

0 T h i s i s a n a i r - d r y i n g f o r m u l a t i o n , 11,-

Phenolic-3i;poxy-Polyvinyl .--- B u t y r a l C o a t i n g L a b o r a t o r y number 1 1 0 2 4 N , R , P , 60 P h e n o l i c r e s i n:R-108

20,OLpoxy r e s i n s o l u t i o n

:SO$

s o l u t i o n o f Epon 1 0 0 7 i n a m i x e d s o l v e n t o f 5 0 p a r t s o f x y l e n e t o 5 0 p a r t s o f d i a c e t o n e11. ( c o i i t i n u e d ) P h e n o l i c - E p o x y - P o l y v i n y l B u t y r a l C o a t i n 8 L a b o r a t o r y number 1 1 0 2 4

man,?.

60 -- P a r t s ... .-by

weic;ht P o l y v i n y l b u t y r a l r e s i n s o l u t i o n:lo<$

s o l u t i o n o f B u t v a r S o l v e n t C a t a l y s tB-76

i n

a mixed s o l v e n t o f 50 p a r t s o f x y l e n e t o 50 > a r t s o f d i a c e t o n e a l c o h o l 12,O : M a c e t o n e a l c o h o l 20,O : Xylene 20.0 :85,,:

P h o s p h o r i c a c i d 0 , 2 Baking s c h e d u l e :15

m i n u t e s a t ~ O O ~ F , 1 2 , P h e n o l i c - P o l y v i n y l B u t y r a l C o a t i n g L a b o r a t o r y number 11025 W.H.P. 6 4 P a r t s by w e i g h t P h e n o l i c r e s i n :H-108 P o l y v i n y l b u t y r a l r e s i n s o l u t i o n : 1 0,;

s o l ~ l t l o n of B u t v a rF-76

i n s e c - b u t a n o l S o l v e n t : s e c - S u t a n o l : L i a c e t o n e a l c o h o l C a t a l y s t :35,;

P h o s p h o r i c a c i d Baking s c h e d u l e : 4.0 m i n u t e s a t3 3 0 ~ ~ ~

Phenolic-Lpoxy-Polyvinyl

B u t y r a l C o a t i n q L a b o r a t o r y number 11026 N.H.P.65

P h e n o l i c r e s i n :R-108 P a r t s by w e i g h t Epoxy r e s i n s o l u t i o n :50jl s o l u t i o n o f Epon 1007 i n a mixed s o l v e n t o f 50 p a p t s x y l e n e t o 5 0 p a r t s o f d i a c e t o n e a l c o h o l31.3

P o l y v i n y l b u t y r a l r e s i n s o l u t i o n:lo$

s o l u t i o n o f B u t v a r B-76 i n a mixed s o l v e n t o f 50 p a r t s o f x y l e n et o

50 p a r t s o f d i a c e t o n e a l c o h o l . 24,013

(continued) Phenolic--Epoxy-Polyvinyl

Butyral Coat

i n sSolvent

Catalyst

:Liacetone alcohol

1 6 * ' j ':Xylene

l b $ 7

:85;:

Phosphoric acid

0:1.6

Baking schedule:

15

minutes at 400'~.

Phenolic-Alkyd Coating

Laboratory number 11027

N.R.P.

66

Phenolic resin solu-tion

:Re

sinox P-97

~llkyd

resin soliltion

:Rezyl

387-5

Solvent

:n-But

ano

1:

Xylene

Baking schedule:

30

minutes at

350'~.

Vinyl-Urea-Formaldehyde Coatinq

Laboratory n-~niber

11020

x , t i , p .67

Parts

byIAJ~~S-.~?~

Parts

hgweight

Vinyl chloride-vinyl

acetate copclymer

:V.R.G.H.Urea-formaldehyde resin

solution

:Uformite I"-240

Stabilizer

:A-5

Solvent

:Methyl isobutyl ketone

Baking schedule:

20 minutes at 320°1?,

16,

Epoxy-Urea-Formaldehyde Coatinq

Laboratory number 11029

N.R.P,

69

Parts

by weight

Epoxy resin

:Epon 1007

21,O

Urea-formaldehyde resin

solution

:Beckamhe

P-138

9=0

Solvent

:Methyl isobutyl carbinol

17e5

:Methyl isobutyl ketone

17.5

:

Toluene

1Tj5

:Xylene

17.5

Phenolic-Epow-Vinyl C o a t i s

Laboratory number 11031

N,H,P,

76

- - . -Parts

.)-\- -Lli---ljsic;l~t

Phenolic resin solution

:Bakelite

10673

' '7- < :-

:Epon 1004

Epoxy resin

./ n bPolyvinyl butyral resin

:X.Y.H.L.

5

7

Chlorinated biphenyl

:Aroclor

1254

Solvent

:Methyl isobutyl ketone

3 7 , 3

Baking schedule:

20minutes at 325'F.

18,

Phenolic-Vinyl C o a t i q

Laboratory number 10032

N,R,P,

77

--

Parts

&

if:2i,;!itPhenolic resin solution

:Bakelite

10673

Lk? a3

Polyvinyl butyral resin

:XeY*13*La

5+2

Solvent

:liethy1 ethyl ketone

l s J O:n-Butanol

d ~ O , Oasking

schedule:

20minutes at 325'F.

Vinylidene Chloride

-

Acrylonitrile Copolylner Coatin$

Laboratory number

11033

N.R.P.

89

Parts

by.weight

Vinylidene chloride-

acrylcnitrile copolymer ;Saran F-120,200 cps

1 s O O

Solvent

:Methyl ethyl ketone

8 s O O

This is an air-drying formulation,

Phenolic

-Epoxy Coatinq

Laboratory number

11035

N.R.P,

132

--

Parts

byweight

Phenolic resin solution

:Resinox P-97

12,O

Epoxy resin solution

:50$

solution of Lpon

1001

i n a mixed

Solvent

solvent of SO parts

of xylene to

50

parts

diacetone alcohol

ZR,O

:Methyl ethyl ketone

/ O J 2 L'Laboratory number 11036

N.R.P.

133

Phenolic resin solution

: H esinox P-97

-

Epoxy resin solution

:SO):

solution of Epon

1001

in

amixed

solvent of

-50 pa-tsof xylene to

50

parts

diacetone alcollol

Solvent

:Methyl ethyl ketone

Baking schedule:

30

minutes at

350°F.

Laboratory number

11037

N.H.P,

135

Parts by ;,reight

Phenoli? resin solution

:Resinox P-97

50,OEpoxy resin aolution

~50;:

solution of Epon

1001 i n a mixed

solvent of 50 parts

of xylene to

50parts

of diacetone zlcohol

50,OBaking schedule:

30

minutes at

350'~.

Phenolic-Bpoxy Coatin8

Laboratory n'mber

11038

N.R.P.

136

Phenolic resin solution

:Resinox P-97

Epoxy resin solution

:50$ solution of

EponParts

bywei;;ht

1001 in

a mixed-

solvent of

50

>arts

of xglene to

50

parts

of diacetone alcohol

300.0

Baking schedule:

30

minutes at

350'~.

24-

Phenolic-Polyvinyl Butyral Coating

Laboratory number 11039

N.H.P.

137

Phenolic resin solution

:Resinox P-97

Parts

byweight

21,o

24. ( c o n t i n u e d ) P h e n o l i c - P o l y v i n y l E u t y r a l

--

Coat* P o l y v i n y l b u t y r a l r e s i n s o i u t i o n:lo;:

s o l u t i o n o f P a r t s-

L y wc:l&l P. Butval*L.-76

i n n - b u t a n 0 1 !j,Y4O P h e n o l i c - P o l y v i n y l G u t y r a l Coat* L a b o r a t o r y number 11040iJ.Fi.P. 1 3 8

-..F

Pnr ?-.--A by/----

mi& P h e n o l i c r e s i n s o l u t i o n : R e s i n ~ ~P-97

24 " 0 P o l y v i n y l b u t y r e l r e s f n s o l u t i o n :lo$ s o l u t i o n o f GutvarE-76

i n n-but a n 0 1t10,

0 Baking s c h e d u l e : 20 m i n u t e s a t 3 5 0 ' ~ . 26, P h e n o i i c - P o l y v i n y l-

B u t y r a l C o a t i n g L a b o r a t o r y number 1104.1 N.R.P.139

P h e n o l i c r e s i n s o l ~ t i o n :Hesinox P--97 P o l y v i n y l b u t y r a l r e s i n s o l u t i o n:lo:;

s o l u t i o n o f B u t v a rB-76 in

n-But a n 0 1 Baking s c h e d u l e : 20 m i n u t e s a t 350°i?, V i r m y l c h l ~ r i d e - , V i n y l A c e t a t e Copolymer C o a t i s---

L a b o r a t o r y number 11042 N.R.P.141

---. P a r t s by weigh2 V i n y l c h l o r i d e - v i n y l a c e t a t e copolymer :V.A.G,H, 3 6 , O S o l v e n t :Methyl e t h y l k e t o n e 79,O T h i s i s a n a i r - d r y i n g f o r m u l a t i o n .V i n y l C o a t i n g Lator.at o r g number

ll0!{4

T~'l.il.F. 1 L l=,

Viny 1 . c h l o r i i i e - v i n y l a c e t a t e copolyrner :V.Y.E.F. Yodif i e d v i n y l c h l o r i d e - v i n y l a c e t a t e copolymer :V.M.C.H. S o l v e n t : I l e t h y l e t h y l &retone P a r t s .-. 'by --.--- il:ei&_t, T h i s i s an 2 i r - d r y i l l g formflulation.29

V i n y l Chlor>ide-Vinyl .-- A c e t z t e Copoly-mer-

-.-.coati^^

P a r t s

-

by

---- wei& V i n j r l c h l o r i d e - v i n y l a c e t s t e copolymer:V.A.G.H.

7 @ 0 P l a s t i c i z e r : F l e x 0 1H-2H

S e O

S o l v e n t :Methyl e t l i y l k e t o n e 10,O T h i s i s a n a i r - d r y i n g f o r m u l a t i o n . V i n y l C h l o r i d e - V i n y l A c e t a t e Copolymer -C o a t i n 9 - a L a b o r a t o r y number1101~6

N.R.P.151

--

P a r t s by w e i g h t V i n y l c h l o r i d e - v i n y l a c e t a t e co3olymer :V.A.G.H.2L,Q

P l a s t i c i z e r : B a k e r ? s#16

P a l e Blown C a s t o r O i l g o G S o l v e n t :Methyl e t h y l k e t o n e 70.C310

V i n y l C h l o r i d e - y i n y l A c e t a t e Copolymer .-. Coatti!il; L a b o r a t o r y numbcr 1104.7 1S.E.P. 1 5 6 V i n y l c h l o r i d e - v i n y la c e t a t e copolymer :V.A.

G.H.

2rjOC;P l a s t i c i z e r :Baker 1 s 7716 P a l e Blown

C a s t o r O i l

36c

S o l v e n t :Methyl e t h y l k e t o n e 7 0 0 0 T h i s i s an a i r - d r y i n g f o r m u l a t i o nP a r t s -.-..- V i n y l c h l o r i d c - v i n y l a c e t a t e c o p o l y m e r n l