Publisher’s version / Version de l'éditeur:

Proceedings of the ANTEC (Annual Technical Conference) Society of Plastics

Engineers, 2009, 2009-06

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Melt Extruded Water-Soluble Starch-Based Films

Chapleau, Nathalie; Li, Hongbo; Huneault, Michel A.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC:

https://nrc-publications.canada.ca/eng/view/object/?id=c91d4a73-70c9-4213-a8dc-2a0a9f7d9457 https://publications-cnrc.canada.ca/fra/voir/objet/?id=c91d4a73-70c9-4213-a8dc-2a0a9f7d9457MELT EXTRUDED WATER-SOLUBLE STARCH-BASED FILMS

Nathalie Chapleau, Hongbo Li and Michel A. Huneault

Industrial Materials Institute, National Research Council Canada

75, de Mortagne Blvd., Boucherville, Quebec

J4B 6Y4 Canada

Abstract

The interest for biodegradable and water-soluble packaging films has gained attention as they have a potential in several applications such as pouches for powders and liquids, liners and bags, and medical delivery devices. In this work, starch-based materials are used to produce melt extruded films. Starch is a biopolymer that can be gelatinized to form thermoplastic starch (TPS). The gelatinization is carried out in an extruder by applying shear and heat in presence of plasticizers. The influence of the TPS composition on the final properties of the films will be investigated. The crystalline structure, the mechanical properties and water solubility will be evaluated.

Introduction

Starch is particularly a good candidate for the manufacturing of environmentally friendly materials, especially as a replacement for synthetic films in food packaging. Starch is totally biodegradable and of low cost. Starch granules, which consist of amylose and amylopectin, are semi-crystalline. Pure starch films are brittle because of the strong interactions in the macromolecular chains. Starch-based films are often prepared by dilute solution casting. Although commercially viable, this technique has many drawbacks and melt extrusion can be an interesting alternative. Starch can be gelatinized to form thermoplastic starch (TPS) and produce flexible films. The gelatinization is carried out in an extruder by applying shear and heat in presence of plasticizers such as water and glycerol. The resulting TPS material can then be processed into sheets or films. Potential applications for TPS films include food packaging, where barrier properties are critical, and water-soluble pouches or coatings, for which the solubility behavior is important. The addition of the plasticizers and other additives such as salts and surfactants will greatly affect the final properties of the films. Several studies have addressed the film forming capacity of starch by using solution casting [1-4]. However, there are few studies on the production of starch-based films by melt extrusion and the impact of processing conditions and incorporation of additives on the final properties of the films [5-8].

In this work, water-soluble TPS films will be produced by melt extrusion. Several types of starches will be investigated: wheat, acetylated corn, rice and triticale. Glycerol and sorbitol, and mixtures of the two, will be used to gelatinize the TPS. The effect of the incorporation of additives such as sodium chloride and a polysorbate surfactant will be addressed. Differential scanning calorimetry and X-ray diffraction will be used to evaluate the level of gelatinization of the TPS. The tensile mechanical properties and the dissolution in water of selected films will be evaluated.

Experimental

Materials

Several types of starch were used. Wheat starch Supergel 1203 was obtained from ADM. An acetylated corn starch (Kofilm80) was supplied by National Starch & Chemical and rice starch (Remy Fg) by Quadrachemicals. Some work on a triticale starch, a hybrid of wheat and rye, was also initiated.

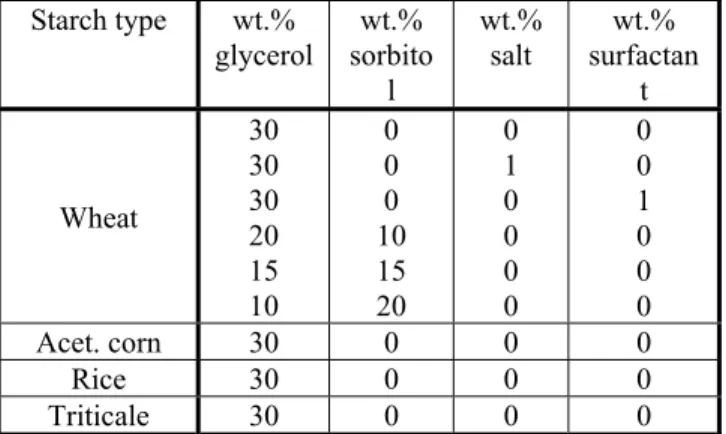

Glycerol and sorbitol were used as plasticizers. The glycerol was a 99.5% pure USP grade supplied by Mat Laboratories. The sorbitol used was D-sorbitol provided by Aldrich Chemical company, with a purity of 98%. All formulations contained 30 wt.% glycerol, except for wheat starch, for which the glycerol/sorbitol ratio was varied. Wheat starch was also used to address the effect of the addition of a salt (sodium chloride) and a surfactant. The surfactant was Span 20 obtained from Merck Chemicals, a polysorbate with an HLB (hydrophilic/lipophilic balance) of 8.6. Table 1 summarizes the TPS formulations prepared.

TPS Preparation

TPS films were prepared on a Leistritz 34 mm co-rotating twin-screw extruder with an L/D ratio of 42. Compounding consisted in feeding the starch in dry-form at the primary feed-port and pumping the plasticizers further down along the extrusion line in the first barrel section. The first three barrel sections were used to gelatinize the starch. No devolatilization step was

required. This approach enabled the plasticizer incorporation and the gelatinization to be carried out in a single continuous operation without any need for pre-mixing. The melt temperature was 120oC. A 20 cm wide flat die was mounted at the end of the extruder. The films were calendered between water-cooled rolls maintained at 20oC and had final thicknesses of 900 and 125 microns, the latter being the lowest achievable without breakage. Table 1. TPS film formulations.

Starch type wt.% glycerol wt.% sorbito l wt.% salt wt.% surfactan t Wheat 30 30 30 20 15 10 0 0 0 10 15 20 0 1 0 0 0 0 0 0 1 0 0 0 Acet. corn 30 0 0 0 Rice 30 0 0 0 Triticale 30 0 0 0 Characterization

The TPS films were characterized and tested right after extrusion and, in some cases, after conditioning at 25oC and 50% relative humidity using a controlled temperature and humidity chamber.

The level of gelatinization of the TPS was investigated by differential scanning calorimetry (DSC) and X-Ray diffraction. DSC measurements at a heating rate of 10oC/min were performed using a Perkin-Elmer DSC-7. Wide angle X-Ray diffraction patterns were obtained by exposing the samples at 40 kV and 40 mA. The scanning was carried out at a rate of 1 step/s and a step size of 0.03o in the angular region (2θ) of 2-40o. The effect of orientation was assessed by aligning the films with the X-Ray beam along both machine and transverse directions.

The moisture content of the TPS films was evaluated using a weight loss method. The weight loss was measured after drying at atmospheric pressure in a desiccating dryer at 105° for 3 days.

The tensile mechanical properties were measured at room temperature at 50 mm/min according to ASTM D-638. The tests were performed on rectangular 19 mm wide X 15 cm long strips, in both machine (MD) and transverse (TD) directions. The elastic modulus, the tensile strength and the elongation at break were evaluated. A video extensometer was used to determine the elastic modulus. All reported values are the average of five tests.

Dissolution tests in water were performed on some films. Square samples (1" X 1") were cut out from the films and put into water-filled 100 ml bottles, which were placed on a Fisher hematology mixer at a frequency of 1 rev./s for 24 hours. After that period, the samples were removed and dried overnight at 100oC. The specimens were weighed before and after drying to determine water loss and amount of dissolution of the TPS in water.

Results and Discussion

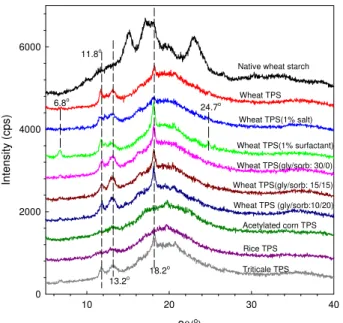

Differential scanning calorimetry and X-ray diffraction were used to evaluate modifications in the starch crystalline structures as a method to insure that complete gelatinization was achieved. Starch becomes amorphous if gelatinized. The DSC thermograms obtained for all the TPS films produced did not exhibit any crystalline peaks, indicating that the process and plasticizers used in this study were adequate to efficiently gelatinize the different starches. This was confirmed by X-ray diffraction measurements. Figures 1 and 2 present X-ray diffraction intensity as a function of angle 2θ for all TPS films, as extruded and aged for one week, respectively. Measurements were performed in the machine and transverse directions of the films; however, identical results were obtained both directions therefore only the results for MD are presented. Also, no effect of the film thickness was observed, thus results are shown exclusively for the thickest films (900 microns).

Native wheat starch is known to have two distinct crystalline forms know as the A-type and B-type. The typical A-type structure present in native starch leads to diffraction peaks at 15.0, 18.1 and 22.9º, while the B-type structure peaks are formed at 2θ = 22.3 and 26.1º. In Figures 1 and 2, native starch is shown as a reference. The peaks observed around 15, the 16 to 18 range and 23º correspond to those expected from the A-type crystalline structures. These peaks have disappeared in all TPS films, regardless of the TPS formulation and ageing process.

In the case of the films tested just after extrusion (Figure 1), sharp new peaks appear at 11.8, 13.2 and 18.2o, except for the rice and acetylated corn starches, which exhibit different patterns with less pronounced peaks. When starch is gelatinized, both A and B-type structures are destroyed. However, if alcohols, fatty acids, monoglycerides or lipids are present, new structures may form from the complexing of these compounds with amylose. This is reflected in the shape and intensity of the peaks when the surfactant is added and the glycerol/sorbitol ratio is varied. The addition of salt has little effect on the intensity pattern compared to the neat wheat TPS. Figure 2 shows the diffraction patterns for samples aged for one week at 25oC and 50% relative humidity. The peak at 18.2o previously observed for the

neat wheat TPS has disappeared and is of lesser intensity for the other formulations. The peak at 24.7o, only before seen in the case of the surfactant-based TPS, was observed in all cases.

2θ(o) 10 20 30 40 In tensity (cps ) 0 2000 4000 6000

Native wheat starch

Wheat TPS Wheat TPS(1% salt) Wheat TPS(1% surfactant) Wheat TPS (gly/sorb:10/20) Wheat TPS(gly/sorb: 15/15) Wheat TPS(gly/sorb: 30/0) Acetylated corn TPS Rice TPS Triticale TPS 18.2o 13.2o 11.8o 6.8o 24.7o

Figure 1. X-ray diffraction patterns for all TPS films studied. Measurements were made on 900 microns thick films in the machine direction.

2θ(o) 10 20 30 40 In tensity (cps ) 0 2000 4000 6000 18.2o 13.2o 11.7o 6.8o 24.7o 19.8o

Native wheat starch

Wheat TPS Wheat TPS(1% salt) Wheat TPS(1% surfactant) Wheat TPS (gly/sorb:10/20) Wheat TPS(gly/sorb: 15/15) Wheat TPS(gly/sorb: 30/0) Acetylated corn TPS Rice TPS Triticale TPS

Figure 2. X-ray diffraction patterns for all TPS films studied, aged for one week at 25oC and 50% relative humidity. Measurements were made on 900 microns thick films in the machine direction.

The effect of the plasticizer (type and proportion) and additives on the TPS film moisture content was investigated. The moisture level is critical and will define the potential industrial applications. The initial moisture content was 6 wt.%. Table 2 presents the water level in various TPS films aged for one week at 25oC and 50% relative humidity. The results show that there are no major differences in the moisture level, which range from 9 to 12 wt.%, depending on the formulation. The highest values were for the acetylated corn and rice-based TPS films, which were shown to exhibit dissimilar X-ray diffraction patterns than the other TPS films studied. Table 2. Moisture level of TPS films.

Starch type wt.% gly. wt.% sorb. wt.% salt wt.% surf. wt.% moisture Wheat 30 30 30 20 15 10 0 0 0 10 15 20 0 1 0 0 0 0 0 0 1 0 0 0 12.1 11.9 11.8 11.0 10.2 9.8 Acet. corn 30 0 0 0 12.6 Rice 30 0 0 0 12.5 Triticale 30 0 0 0 11.9

The tensile mechanical properties of the films were measured. The results for the elastic modulus, tensile strength and elongation at break for 900 microns thick films of all TPS films studied, as extruded and after ageing, are presented in Figures 3 and 4. As in the case of the X-ray diffraction results, the values for MD and TD were very similar therefore only the data for properties evaluated in the machine direction are shown. Figure 3 compares the properties for the wheat starch-based TPS films, as extruded and after ageing for one week at 25oC and 50% relative humidity. The effect of adding a salt or a surfactant, and varying the glycerol/sorbitol ratio on the mechanical properties is shown. The addition of the salt or surfactant does not affect significantly the elastic modulus and tensile strength, which are quite low. The elongation at break increases from 150 to 225 % when 1 wt.% of surfactant is added. The most significant effect on the mechanical properties is observed when sorbitol is added. For the films containing a (10/20) glycerol/sorbitol mixture, the increase of the elastic modulus and tensile strength is dramatic. The modulus increases by nearly a factor 10 compared to the formulation containing exclusively glycerol. The elongation at break decreases slightly with sorbitol content but the values are comparable to the 30 wt.% glycerol films. In general, upon ageing, the modulus, strength and elongation at break remained similar or dropped compared to the values of the as extruded films. As observed in the X-ray diffraction patterns, the location and intensity several

peaks varied when samples were aged depending on the composition. This is reflected in the variation of the mechanical properties with time.

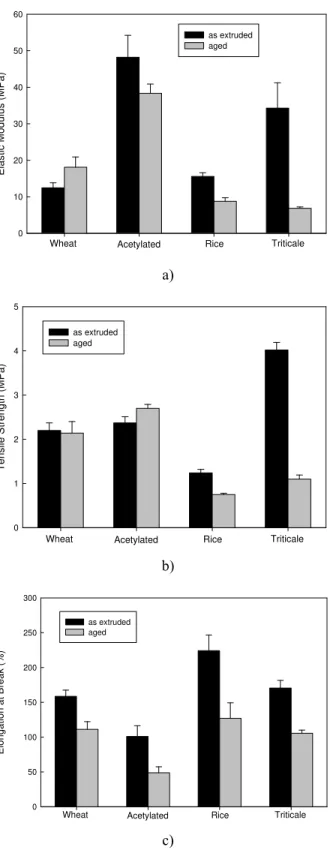

Figure 4 compares the properties of as extruded and aged wheat, acetylated corn, rice and triticale starch-based films. All films contained 30 wt.% glycerol. As it can be seen in Figure 4a), the acetylated corn starch based TPS has the highest modulus. However, it has the lowest elongation at break (Figure 4c). Rice-based TPS has the lowest modulus and strength, with a very high elongation at break around 225%, for as extruded films. This value however decreases significantly, by almost a factor of two, upon ageing. In all cases, the elongation at break remained comparable or decreased with ageing. As observed in the X-ray diffraction results, the spectra of the wheat starch based films remained essentially unchanged with or without ageing. This was not the case for the three other starches studied, where the location and intensity of the peaks changed before and after ageing. This indicates again that ageing can yield some modifications of the interactions between the components and have an important effect on the mechanical properties.

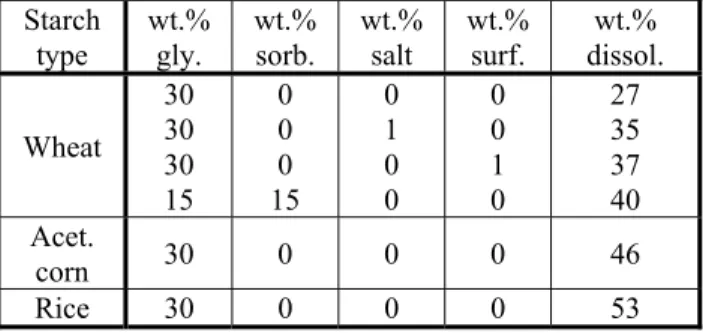

Preliminary dissolution tests in water were performed on some films. Samples were cut out from the films and put into water for 24 hours. The specimens were weighed before and after drying to determine water loss and amount of dissolution of the TPS in water. The thicker films (900 microns) did not dissolve significantly. Dissolution values were similar regardless of the TPS formulation and ranged from 25 to 30%. The results for the thinner films (125 microns), which dissolved more rapidly, are reported in Table 3.

Table 3. Dissolution data for selected TPS films. Data is reported for 125 microns thick films.

Starch type wt.% gly. wt.% sorb. wt.% salt wt.% surf. wt.% dissol. Wheat 30 30 30 15 0 0 0 15 0 1 0 0 0 0 1 0 27 35 37 40 Acet. corn 30 0 0 0 46 Rice 30 0 0 0 53

Only the film based on wheat TPS containing 1 wt.% surfactant exhibited noticeable disintegration; samples broke up into small flakes upon dissolution. All other TPS studied retained their structural integrity and could be recovered as films at the end of the test. The incorporation of additives such as the salt and the surfactant accelerated the dissolution significantly compared to the TPS containing only glycerol. Using a mixture of glycerol and sorbitol had the same effect. This

is attributed to the different interactions between the TPS components. The acetylated corn and rice-based TPS films dissolved the fastest; it was shown using X-ray diffraction that these two had different patterns and smaller intensity peaks than the other TPS films studied.

Conclusions

Water-soluble thermoplastic starch-based films were produced by melt extrusion. Several types of starches were investigated: wheat, acetylated corn, rice and triticale. Glycerol and sorbitol, and mixtures of the two, were used as plasticizers to gelatinize the TPS. The effect of the addition of a salt and a surfactant was also addressed. Differential scanning calorimetry and X-ray diffraction were used to validate that the process used was adequate to gelatinize the TPS. X-ray diffraction patterns revealed several interactions between the components of the formulations, which resulted in significant changes in the tensile mechanical properties, both for as extruded and aged films. The dissolution in water of selected films was evaluated. It was shown that the dissolution levels increased with sorbitol content for the wheat starch-based TPS films. The acetylated corn and rice starch exhibited the highest dissolution values.

References

1. D. Lourdin, L. Coignard, H. Bizot and P. Colonna, Polymer, 38 (21), 5401 (1997).

2. M. Rodriguez, J. Osés, K. Ziani and J.I. Maté, Food Research International, 39, 840 (2006).

3. O.V. Lopez, M.A. Garcia and N.E. Zaritzky, Carbohydrate Polymers, 73, 573 (2008).

4. J.H. Wang and B. Shi, U.S. 2008/0147034 (2008). 5. M.L. Fishman, D.R. Coffin, R.P. Konstance and C.I.

Onwulata, Carbohydrate Polymers, 41, 317 (2000). 6. L. Wang, U.S. Patent 2005/0260316 (2005).

7. R. Muller and F. Innerebner, U.S. Patent 2006/0004193 (2006).

8. H.A. Pushpadass, D.B. Marx and M.A. Hanna, Starch, 60, 527 (2008).

Key Words: thermoplastic starch, gelatinization, melt extrusion, films, water solubility.

% (glycerol/sorbitol) El as ti c Mod ul us ( M Pa) 0 20 40 60 80 100 120 as extruded aged (30/0) (30/0) + 1% salt (30/0) + 1% surf. (20/10) (15/15) (10/20) Elas ti c M o du lus ( M Pa) 0 10 20 30 40 50 60 as extruded aged

Wheat Acetylated Rice Triticale

a) a) % (glycerol/sorbitol) T e n s ile S tren g th ( M P a ) 0 1 2 3 4 5 6 7 as extruded aged (30/0) (30/0) + 1% salt (30/0) + 1% surf. (20/10) (15/15) (10/20) b) Te ns ile Str en gth ( M Pa ) 0 1 2 3 4 5 as extruded aged

Wheat Acetylated Rice Triticale

b) El onga ti on at Br eak (%) 0 50 100 150 200 250 300 as extruded aged

Wheat Acetylated Rice Triticale

% (glycerol/sorbitol) El ongat ion at Br eak (%) 0 50 100 150 200 250 as extruded aged (30/0) (30/0) + 1% salt (30/0) + 1% surf. (20/10) (15/15) (10/20) c)

Figure 4. Tensile mechanical properties of several types of starch in TPS films. Results are shown for specimens tested in the machine direction, as extruded and after ageing for one week at 25oC and 50% relative humidity. a) elastic modulus. b) tensile strength. c) elongation at break.

c)

Figure 3. Tensile mechanical properties of wheat based TPS films. Results are shown for specimens tested in the machine direction, as extruded and after ageing for one week at 25oC and 50% relative humidity. a) elastic modulus. b) tensile strength. c) elongation at break.