Publisher’s version / Version de l'éditeur:

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site

LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

Technical Report (National Research Council of Canada. Division of Building

Research); no. DBR-TR-10, 1951-11-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

NRC Publications Archive Record / Notice des Archives des publications du CNRC :

https://nrc-publications.canada.ca/eng/view/object/?id=3e56e207-a38b-45a6-9007-4df3a6744eb2

https://publications-cnrc.canada.ca/fra/voir/objet/?id=3e56e207-a38b-45a6-9007-4df3a6744eb2

NRC Publications Archive

Archives des publications du CNRC

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.4224/20359084

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

Canadian Papers Presented at the Building Research Congress 1951

Morrison, Carson F.; Goudge, M. F.; Gibbons, E. V.; Legget, Robert F.

scr

tiY

TEI

szl.ral

a o . I 0

THE LIBRARY

oJ the^Sational

Beeearcf

@ouncil

OTTAWA, CANADA

\

NATIONAT RESEARCI{ COUNCIL

CANADA

CANADIAN PAPERS PRESENTED

AT

THE BUTLDTNG RESEARCII CoNGRESS

I95]-Sovemben, I95l

T e e h n l e a l R e p o n t N o . 1 " 0

of the

D l v l s l - o n o f B u l l d i - n g R e s e a n c h

0 t t a w a

DBR No " ?6

PREFACE

A B u l l - d l n g R e s e a r c h C o n g r e s s w a s o r g a n i z e d i n G r e a t B r i t a l n

1 n e o n n e e t i o n w l t h t h e F e s t i v a l

o f B r l t a l n

d u r l n g t h e s u m m e r o f

L 9 5 I "

A l t h o u g h a s f i r s t

c o n c e i v e d t h e C o n g n e s s w a s a m o d e s t

e n t e r p r i s e ,

1 t d e v e l o p e d i n t o a n l n t e r n a t i o n a l

g a t h e r l n g o f r e a l

-l m p o r t a n e e .

I t w a s a t t e n d e d b y a b o u t t h i r t e e n

h u n d r e d p e o p l e

f r o m f l f t y

d l f f e r e n t

c o u n t r i e s .

T h e C o n g r e s s w a s h e l d l n L o n d o n o E n g l a n d n f r o m S e p t e m b e r 1 1

t o 2 0 , L 9 5 L o ft was the first

g a t h e r i n g

o f t h l s t y p e e v e r t o

b e h e l d .

I t s p r l n c l p a l

f u n c t i o n w a s t o r e v l e w t h e p r o g r e s s

m a d e i n r e s e a r c h l - n r e l a t l o n

t o a r c h l t e e t u r e ,

b u l l d i - n g , a n d t h e

a s s o c i a t e d b r a n e h e s o f c i v t l

e n g l n e e n l n g "

T h e C o n g n e s s w a s d i v l d e d l n t o t h n e e d l v l s i o n s

a n d m e e t l n g s

v u e r ' e h e l d c o R c u r r e n t l y ,

D l v i s i o n

I d e a i t w i - t h t h e e n g l n e e r l n g

a n d s t r u c t u r a l

a s p e c t s o f b u i l d l n g "

D i v l s i o n

2 d e a l t w l t h

b u l l d l n g

m a t e n l a l s a n d D t v l s l o n

I d e a l t w i t h t h e v a r i o u s f a c

-t o n s w h i c h i n f l u e n c e

t h e c o m f o r t a n d e f f i e i e n c y

o f p e o p l e l n

b u i l d l n g s

"

A b o u t o n e h u n d n e d p a p e r s w o r e p n e s e n t e d t o t h e C o n g r e s s o

A l l w e r e p r l n t e d

b e f o n e t h e C o n g r : e s s a n d i s s u e d l n t h r e e v o l u m e s o

A f o u r t h

v o l u m e h a s b e e n p r e p a r e d t o c o n t a i n t h e r e c o r d o f d l s

-e u s s l o n s a n d s p -e -e c h -e s a t t h -e C o n g r -e s s o S o m -e -e x t r a s -e t s o f , t h -e

f o u r v o l u m e s a r e s t l l I

a v a i l a b l e

a s t h l s p u b l i c a t l o n

g o e s t o

p r e s s o

T h e y m a y b e o b t a l n e d o n a p p l l e a t i o n

t o t h e O r g a n l z l n g

S e e r e t a r y , 5 l O n s l o w G a r d e n s u L o n d o n , S o W o 7 e E n g l a n d , a t a

p r l c e o f t h e e q u l v a l e n t o f f i f t y

s h l l l t n g s "

T h r e e p a p e r s f r o m C a n a d a w e r e p r e s e n t e d t o t h e C o n g r e s s o

T h e D l v i s i o n

o f B u i l d l n g R e s e a r e h e o n s i d e r o d t h a t t h e e e t h r e e

p a p e r s s h o u l d be availahle

f o r u s e b y t h o s e i n C a n a d a w h o a r e

l n t e r e s t e d

j - n t h e l r e o n t e n t s .

T h e D i v l s i o n

l - s t h e r e f o n e g l a d

t o p r e s e n t t h l s s e t o f r e p r l n t s "

f t w i l l

b e n o t e d t h a t o n e

p a p e r c o m e s f r o m t l l e D l v l s l o n ;

o n e l s a j o t n t

c o n t r l b u t i o n

from the ltriines Branch of the Department of Mlnes and Teehnleal

S u r v e y s a n d t h e D l v l s i o n ;

a n d t h e t h l r d

i s a c o n t r i b u t i o n

f n o m

P r o f e s s o r C o F o M o r u l s o n o f t h e U n i v e r s t t y

o f T o r : o n t o o P r o

-f e s s o s ' M o r r l s o n h a s k i n d 3 - y a g r e e d to the lneluslon

o f h l s

p a p e r i n t h i s r e p r i n t u

e v e n t h o u g h i t w a s a n l n d l v l d u a l

c o n t r i

-b u t l o n o

T h e D i - v l s i o n i s g l a d i n d e e d t o b e t h u s e n a b l - e d t o

p r e s e n t t h l s r e p n l n t o f a l l C a n a d l a n c o n t r l b u t i o n s

t o t h l s t m *

p o r t a n t

C o n g r e s s w i t h t h e p e r m i s s i o n

o f t h e O r g a n l z l n g C o m m J . t t e e o

O t t a w a

N o v e m b e r , I 9 5 I

R o b e r t F

"

L e g g e t

D i r e c t o r

TAFT..,E

OF CONTENTS

€

Eeeg

Ng-e-R e s e a n c h o n t h e S t r u c t u r a l

U s e o f G l u e d

L a m l n a t e d T i m b e n b y C a r s o n F " M o : l r i s o l l o o o o o o o o o o o o o o 2

The Effeet

of Low Temperatune on the

Per-f o r m a n e e o Per-f B u l l d l n g

M a t e r l a l s

1 n

C a n a d a b y M " F o G o u d g e a n d E . V . G l b b o n s o o o o a d o o o o ' . l h

S p e c i a i F o u n d a t l o n P r o b l e m s l n G a n a d a

Research on the Strueti.lral

Use

of Glued Lamlnated Timber"

by

C a r s o n F " N l o r n l s o n

l"-Glued Laminated Timber

Useful exploitation of the world's resources has taken many directions. Not the least important of these, and certainly one of the most fascinating, has been the comparatively recent discovery that the size and value of timber can be enhanced thiough welding by glue of layers of wood into solid units. By shop processes there can be produced a timber unit larger and stronger than to be found in the forests of any land. German and Swiss engineers, some years after the turn of this century, were the first to realise the advantages of glued laminated wood construction. They, no doubt, were prompted by aesthetic as well as practical considerations. But, in any event, from there spread the word throughout Europe and then to the North American continent that, in addition to producing beauty in architecture, a substitute had been found for structural steel.

This, in brief, is the romantic as well as the practical side of the picture. The importance of the former in a studv of the development of anv branch in industrv should"not be overlook'ed, but here of necessity, emphasis is placed upon the latter.

It must be recognised that this is not a substitute, inferior material. " Glulam," as it is commonly known in the trade, has replaced structural steel in a con-siderable degree, even when steel is in good supply. Moreover, it is not merely a substitute for big timber sticks that might no longer be available in a given market. It has won for itself a permanent place in the field of construction because, when properly made, glued laminated timber is a quality product.

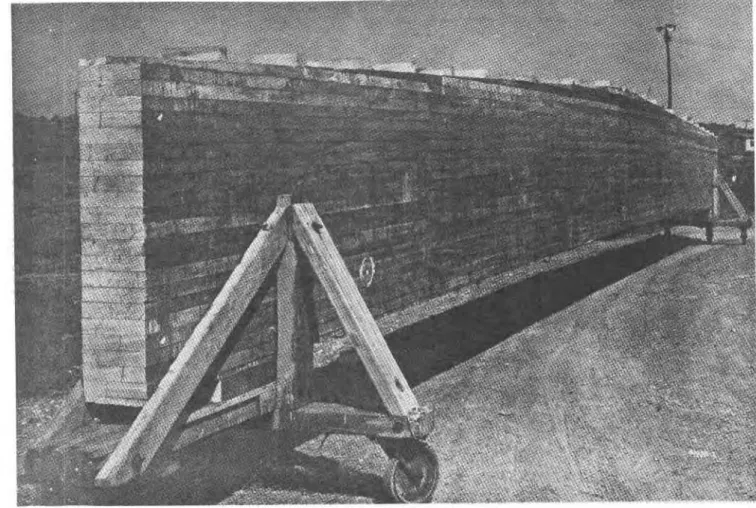

When used for straight members such as columns, beams, girders, and truss chords, these uses can be considered largely as substitutes for sawn solid members. Fig. r shows a large beam made by gluing small pieces together. Mose usual and effective uses are as curved rafters, truss chords and arches of various shapes. In Canada and the United States one of the greatest demands for glued laminated timber has been for arch rafters used in constructing barns, warehouses, and light industrial buildings. Arches have been used for rinks, gymnasia, auditoria, churches and bridges. Bowstring trusses and tied rafters have been used for industrial and mining structures, warehouses, rinks and bridges. Fig. z is an illustration of an arch after removal from clamping device.

Because of the dimensions of the laminations it is possible to dry the material in much less time than would be required for large size structural timbers. This is a most important economic factor.

Increasing adoption is undoubtedly because of the many advantages offered by glued laminated timber construction. While this processed material is of high quality and more readily obtainable than large sawn solid structural timbers, it must at the same time be realised that it is an expensive product and its field of usefulness is therefore restricted. There are, however, many instances when it should and will be used because of its superior effectiveness and efficiency. It offers sizes and shapes of distinct strength and beauty which are not obtainable in sawn timber.

Research on the Structural Use of

Carson F. Morrison(Associate Professor of Ciail Engineering, University of Toronto, Canada)

It should be noted that in cases where structural designs using glued laminated timber were selected in preference to other designs the cost factor was not overlooked.

Species

Most generally used species for glued laminated members for construction are Douglas fir and southern yellow pine because of their availability and superior strength and suitability for gluing. White or eastern spruce has also been used, giving a product with much lower strength than the other two mentioned. Although they have not been used to any extent until now there is no doubt that other softwood species such as red pine, pine, white hemlock and cedar would be suitable

material. Selection would depend upon strength,

availability and cost.

Cost of a member includes the cost of lumber ; drying and surfacing of laminations ; glue ; application of glue ; assembly of laminations ; application of pressure; curing of glue, sometimes at elevated temperatures; removal of clamps and handling of finished product. Because the cost of lumber is only a fraction of the cost of the glued laminated member, the saving in cost of the lower strength species will not justify their selection in most instances.

There are cases, however, when economic factors other than cost, usually availability, dictate the use of material which may be low-strength.

Glues

In all uses of lumber, the material is presumed to have defects which reduce its strength to some fraction of the strength of clear material, the fraction depending upon the magnitude of the defects which establish the classification or " grade " of the lumber. Presuming a defect factor of twenty-five per c ent. (z5o/), the residual strength factor would be o.75 which is what is classified by Canadian Standards Association (C.S.A.) as " select structural " grade. Other grades presume a correspond-ing residual strength factor.

Any definition of " satisfactory gluing " in connection with lumber laminating is, of necessity, arbitrary. As a requirement for satisfactory gluing the writer suggests that :- glued joints shall withstand a shearing stress not less than ninety per cent. (9oo/") of the shear strength, parallel to the grain, of clear material of the species used and shall maintain this strength throughout the life of the

member-Tests on small clear specimeris at the Forest Products Laboratories at Ottawa, Ontarir\, and Madison, Wis-consin, have established parallel-to-grain shearing strengths as shown in Table r: According to the requirements suggested above, glue joint test specimens should show strengths ninety per cent. (9oo/o) of those tabulated.

Strength differences of various glues are not a factor in their selection except in so far as the required

minimum must be provided. The important factors

in glue selection are: cost; storage life of the glue; pot life; assembly time ; pressure required on gluing

-2-Fig. 1.-45 ft. span beam using l* tn. x 7f spruce lamlnatlons and casein glue. GlutnS pressure was obtained by nailtng PJnto. courresy General Engineering Company (Canada) Lirnited, Ontareo

TABLE l.-Maxlmum shearing strenEths, parallel-to-$rain, of clear speclmens

Douglas fir, Spruce, Pine, coast region lvhite or eastern southern yellow Testing

laboratory

Maximum shearing strength (p.s.i.) at moisture content shown in brackets

Ftg. 2.-Sectlon of three-hin$ed arch uslng t-fu lamlnations of southern yellow plne. Note arch forn

and clampinE device

I'Loto. courlesy The Borden Company, Neut Yorh

r , 4 8 5 925

air-dry I r,r4o (rz) | r,o7o (rz) green I SEo (96) | 7ro (46\7 o ( r z ) |

r , 3 r o ( r z ) ro (46) | 8so (8r)

surfaces ; species and moisture content of laminations for which the glue is suitable ; time and temperature requirements for curing ; durability ; resistance to decay, weathering and attack by organisms; damaging or weakening effect on wood fibres; difficulty of surfacing laminated member; reaction to wood pre-sefvatlves,

One of the most significant characteristics of a glue is the temperature range satisfactory for setting and curing a joint using the glue. According to a report on " Laminating of Structural Wood Products by Gluing "r publisied by the United States Departmenl of Agriculture, glues are classified according to curing temperatures as follows : Ottawa air-dry green Madison (rz)

(s+)

9 6 0 ( r 3 )73o (6e)-3-Required temperatures for satisfactory curing within

practical time limits.

(") Hot-setting. Require higher temperatures

than those comrrionly at-tained in heated chambers, for which the maximum is about zrooF.

(b) Intermediate- Require heating in excess of

temperature- nonnal room temperatures

setting. (about 65' to 8o'F.) but

do not require temperatures above 2ro"F., the max-imum that can ordinarily

be attained in heated

chambers.

(c) Room- Requires no heating above

temperature- no[nal room temperatures

setting. (about 65' to 8o'F.), but

do not cure satisfactorily at lower temperatures.

(d) Cold-setting. Set or cure below normal

workroom temperatures

(minimum about 65"F.), and some may set satis-factorily at temperatures as low as 3zoF.

Table z copied from the above mentioned reportl gives use characteristics of several types of glue and the various conditions under which they are suitable for lumber laminating.

Since most glued laminated members which have been produced in North America to date (r95o) have been for interior use where the member is not subjected to severe moisture conditions, casein glue has been most generally used. Assembly line production methods in certain laminating shops have established the fact that resorcinol-formaldehyde-resin glue is particularly

suitable because of the accelerated set which is obtained by the use of radio-frequency heating, particularly when high quality, weather proof bond is desired.

A thorough description of the properties and use characteristics of the various types of glues tested in Table z is included in the above mentioned reportl. Because of space limitations, only that portion referring to casein glue will be quoted here.

Casein Glues

" Casein glue is classed as water resistant because of its relatively high resistance to moisture compared to that of vegetable and animal glues. Its basic constituent is dried casein of milk, which, combined with alkaline chemicals; usually lime and one or more sodium salts, is water soluble. Prepared casein glue is supplied in powder form, and, when mixed with water in the correct proportions, it is ready for use. It sets as a result of chemical reaction and of loss of moisture to wood and air. If the joints are well made, casein glue will develop the full strength of the wood, especially in softwood species, and will retain a considerable portion of its strength even when submerged in water, for a few days. In laboratory tests of ply'wood continuously soaked in water, however, casein-glue joints dropped in strength and ultimately failed completely. Under continuous exposures involving high humidity, casein-glue joints weaken so rapidly that these casein-glues are not recommended where the relative humidity is 9o per cent. or higher for appreciable periods. The relatively recent introduction of casein glues containing sufficient toxic chemicals to retard mould and other micro-organisms, has considerably improved the durability of casein-glue

joints at high humidities. Casein-glue joints have

demonstrated good resistance to dry heat. Results of exposures to temperatures as high as r58oF. for periods up to four years (duration of test period) have indicated that the slue bonds are about as resistant as the wood

Setting characteristi cs Inter-mediate tempera-ture Days Classification moisture content of wood Glue type Casein Urea, pow-dered with catalyst Inter- mediate- tempera-ture-setting phenol Resorcinol I\Ielamine NormaI interior Normal interior Interior and exterior Interior and exterior Interior and exterior Minutes 30-60 Yes No No No (e*-cept with low-density species) No Yes Yes No (e*-cept with some low-density species) Yes Exposure suited for Storage life at 8ooF. r 5 I O Per cent.

,

2 0 60-r 3o Per cent, r 8 r 5 r 7 Yes Yes Yes I O O r o o r o o I O O r o o 250 250 250 2 5 0 ) - t J - / r-7 r ) r 7 r 5 250lThe values given in this table are approximations; for more exact information consult the text.

2Where glue is completely cured by application of heat accompanied by adequate humidification before pressure is removed, merely cooling to room temperature is sufficient; where no heat is applied, a 5 to 7-day conditioning period is desirable.

TABLE 2.-Use characteristics of laminating gluesl

-L-to this type of exposure. Temperatures that char and burn wood will cause decomposition of casein glue. Charred wood exposed to fire, however, conducts heat to its interior very slowly so that softening of casein glue joints will take place only immediately adjacent to burning wood.

Casein glue will produce adequate bonds with wood from approximately z to 18 per cent. moisture content. A range of 6 to rz per cent., however, is usually preferred, as it approximates the moisture content of the glued member in service. It is also desirable to have all laminations for one assembly at approxi-mately the same moisture content (allowable differences betu'een boards up to five per' cent.) to avoid their unequal shrinking or swelling as the moisture content equalises in service.

Casein glue, in general, has a storage life of a year or more when kept dry. Its working life varies with the difierent formulations, but is usually at least five hours at 7o" to 75'F. The glue should meet the requirements of the specifications listed at the end of this section.

Casein glue may be spread on small areas by brush

and whether single or double spreading is employed' Higher temperatures, extremely dry wood, and species of wood that readilv absorb moisture, will reduce

when the assembly is put under pressure.

Casein glue will set at temperatures almost as low as the freezing point of water; but its setting requires a period that varies from several days to several weeks, according to the species glued and the moisture content of the wood, to develop strong joints at such tempera-tures. The wet strength developed at low temperatures may never be so good as that developed at room temperatures. A pressing period of four hours at 7ooF. is considered the minimum for straight members, and for curved members a somewhat longer pressing period is desirable.

Gluing pressures of roo to zoo pounds per square inch are satisfactory for low-density hardwoods and softwood species, such ab Douglas fir and southern yellow pine. Pressure of r5o to z5o pounds per square inch are recommended for species of higher densities. Glue lines produced with such pressures on well-surfaced laminations will be relatively thin and strong. Thick glue lines indicate low gluing pressure and usually are weaker. When thin glue lines of good strength can be produced uniformly with pressures below the foregoing ranges, such pressure will be adequate. After removal of pressure, a conditioning period of about a week at room temperature is required for development of maximum joint strength.

To assure high quality, casein glue should meet the requirements of Federal Specificatiqn C-G-456,

and mould resistant casein glue should pass the per-{ormance tests of U.S. Army Air Forces Specification N o . t 4 t z z . "

Manufacturinp Processes

Significant features of the manufacturing process are: preparation of lumber;

mixing and spreading of glue ;

assembly and application of pressure; curing of glue in assemblies;

storage of finished product; use of preservatives.

Preparation of Lumber

Species to be used will be selected on the basis of consideration of availability, strength and cost.

Moisture content for gluing will be established by the requirements of the glue to be used and the moisture content of the member during its service life. In ordpr to minimise the stresses which would be induced by unequal shrinkage or swelling of the lamination it is desirable to have uniformity of moisture content throughout the member as a whole as well as throughout each lamination. Satisfactory results are obtained with variations in moisture content of as much as five per cent. between different points at a section of a member. Table z gives values for acceptable ranges of moisture contents of lumber for use with the difierent t1'pes of glue. Air drying or kiln drying may be used to bring the material to the required moisture content.

Experiments and experience have established that planed surfaces are most satisfactory for gluing. Laminations must be of uniform thickness and when edge joints and/or end joints are pre-glued it is usually necessary to re-surface them to obtain the required uniformity.

Gluing Procedures

Choice of glue depends upon species used and conditions of service of the member. Table z gives characteristics of the various types of glues.

Because of the variety of types of glue and the large number of brands available in any particular type it is not possible to'give general instructions for mixing and handling of glue. Manufacturers supply specific instructions for all gluing products and for best results these should be followed.

Much valuable information concerning assembly techniques and other aspects of manufacturing is contained in " Laminating of Structural Wood Products by Gluing."'

Preservative Treatment

For usual service, that is, where members are not subjected to moisture or excessive humidity there is no bconomic advantage in pieservative treatment.

When exposure is such that preservative treatment of the wood is desirable this may be done (a) by treat-ment of the glued laminated member, or (b) by gluing together laminations which have been treated. In most cases the latter is preferred because of ease in handling. Tests have indicated that certain types of glues, plrticularly those which produce weatherproof bonds, perform satisfactorily with laminations treated rvith oil-base preservatives.

For any particular problem it is necessary to obtain specific information regarding the preservative treatment3 and glue to be used.

Research Projects

Much investigation work has been done in the Forest Products Laboratories at Ottawa and Madison

-5-and by commercial laminators to obtain data concerning glue and the gluing of wood. Some of the tests which are of special interest in connection with the use of glued laminated timber in the construction field, listed chronologically, are:

46 ft.-span three-hinged glued laminated arches for a service building at Forest Products Laboratories, Madison, Wrsconsin, built in 1935.4

45 ft.-span roof beams for factory buildings near Toronto, Ontario, tested in 19416.

15 ft.-span beams using difierent glues, cross sections and methods of applying pressure made and tested at Forest Products Laboratories, Ottawa, Ontario, tested in 1944.6

Tests of glued laminated wood beams and columns and development of principles of design, published November, 1947, Forest Products Laboratories, '

Madison, Wisconsin.?

47 ft.-span glued laminated arch made and tested at Forest Products Laboratories, Ottawa, Ontario, reported in rg5o.t

Complete information regarding the results of these tests is available in the references noted. Only a brief discussion is given here of the most important findings of the investigations.

46 ft.-span three-hinged glued laminated arches lor a service building at Forest Products

Labora-tories, Madison, Wisconsin

Species: southern yellow pine; practically free from knots.

Glue : casein.

Minimum radius of curvature : 39 in. Thickness of lamination : 0.5625 in.

R

Ratio - 69 (laminations were not steamed before bending).

S e c t i o n a t k n e e : r r i n . \ 2 4 . 2 5 i n .

Gluing pressure was obtained with screw clamps. Two specimens were loaded to failure in testing

macnlne.

Dr parrBo IN FLEXURE ,

,

At section of maximum moment : - - 6,86o psi. ; P S

- : 23o Psl. A

Maximum shearing stress developed : 4r3 psi. Dz nerrnp IN sHEAR:

Maximum shearing stress developed : 4zo psi. M

At section of maximum moment: - : 5,3oo psi. ; P S

- : 25r Psi. A

47 ft.-span glued laminated arch made and tested at Forest Products Laboratories, Ottawa,

Ontario, reported in 1950

Species : white spruce, select merchantable and merchantable grade.

Glue : casein.

Minimum radius of curvature : 87.5 in. Thickness of lamination : o.875 in.

.R

Ratio - : roo (laminations were steamed before t

bending).

Gluing pressure was obtained by nailing adjacent laminations : no clamps were used.

Section at knee : rr in. x 25.375 in.

One arch was erected and loaded to the equivalent of dead load plus twice the design snow load with sand in boxes suspended from the arch. Later the loading was carried to destruction by using hydraulic cylinders connected between earth anchors and the structure. Failure occurred in longitudinal shear in one of the vertical portions of the arch.

At maximum load the following stresses were induced

:-3 V

shearing stress at section failin-g, a : - - : 458 psi. M 2 A

Bending stress at knee, -: 3,o$o psi. (no failure). P S

Direct stress at knee, - : 254 psi. (no failure). A

Tests on these two arches give information on two distinctly different examples. In one case high quality species, grade and manufacturing process were used to produce a high quality product. In the other case; a lower quality species, grade and manufacturing process resulted in a correspondingly lower quality structural member. Selection of the type to be used for any given project will depend upon the availability and cost of glue, equipment, labour and the different species and grades of lumber.

45 ft.-span roof beams for factory buildinps near Toronto, Ontario, tested in 1941 In r94r, to provide space for a munitions factory near Toronto, Ontario, 45 ft.-span roof beams rvere constructed of laminated timber. Before adopting this design one beam was made and loaded to two and one-half times the load anticipated in design.

Species : white spruce, merchantable grade. Glue : casein.

.Laminations were r$ in x 7f in. planks, of random lengihs ; joints were plain scarf (r to v). Adjacent laminations we;e held in contact by nails; no clamps were used. Beam section at mid-span was 7f, in. x 4of; in.

Flexural stress existing at maximum load applied, M

I : 2,ooo psi'

. J

Shear stress existing at maximum ioad applied, 3 V

zo5 psi. 2 A

No signs of flexural, shear or glue joint faiiure were observed.

The beam was not loaded to failure.

Test results indicated that the design would be satisfactory and it was used for the project. . A total of five hundred and forty-five (545) beams were used giving an aggregate lengi-h of over four and one-half miles and requiring Tro,ooo f.b.m. of lumber.

After over nine years of service these beams were recently (r95o) inspected by the writer and were found to be in excellent condition. There was no evidence of delamination. In the light of present day knowledge regarding this type of structural member it is reasonable to expect that beams of smaller section would have been satisfactory, but in view of the experimental nature of the project the extra precaution was un-doubtedly warranted.

15 ft.-span beams using different glues, cross sections and methods of applying pressure, made and tested at Forest Products Laboratories,

Ottawa, Ontario, in 1944

In t944, an investigation was made at the Forest Products Laboratory, Ottawa, Ontario, to determine strength characteristics of thirty glued laminated timber beams using two different species, two types of glue and various methods of obtaining pressure on the glue joints. Tests were included to study the effectiveness of using nothing but nails to obtain the required gluing pressure between adjacent laminations.

Species used were white spruce and Douglas fir. Many defects, particularly knots, were present in all the material. The better oieces were selected and used as outer laminations. Mbisture content ranged from ro per cent. to 15 per cent.

Six of the thirty beams were made using the stronger species, Douglas fir, for outer laminations and spruce for the interior laminations. For the remainder of the beams spruce was used throughout.

Some of the beams were made using full-length laminations while in others there were joints in some of the laminations. Butt 'ioints were used in some, plain scarf (r to rz) in otheis.

Beams of rectangular section were made of eight horizontal laminations, rf in. x S* in., to provide a section 5$ in. x 14 in. I-section beams were used to increase the probability of failure in shear; for this section rf; in. x 5! in. pieces were used for the two outer sets of laminations and four rf, in. x lt in. pieces for the others.

All of the six beams with Douglas fir in the outer laminations were made with gluing pressure provided in the screw press ; all failed in flexure. At maximum load the following stresses were induced :

Modulus of rupture (psi.) : average 8,54o ; maximum 9 , 3 o o ; m l n l m u m 7 , 2 o o ;

Shear stress at maximum load (psi.) : average 416 ; maximum 45r ; minimum 356.

Of these, four were made using casein glue and the others urea-formaldehyde. Those using urea-forrnal-dehyde developed moduli of rupture of g,zzo psi. and 9,rzo psi. which are higher than the average of the group. Since no glue joint failure was observed in

f ig. 3.-f 5 ft. span bearn : exterior larninati4ns Douglas fir ; lnterior lamlnations spruce with butt Joints; casein glue; 150 p,s.i. pressure applied ln

screw press; rnodulus of rupture : 9,300 psi. Note: no evidence of {ailure of glue joints.

Photo. courtesy F.P.L., Ottawa, Canad,a

the test it is presumed that the difference was due to variations in defects in the laminations.

The ten spruce beams made in the screw press which failed in flexure developed the following stresses at maximum load:

Modulus of .rupture (psi.) : average 5,404; maximum 7,32o , minimum 4,280.

Shear stress at maximum load (psi.) : average 355 ; maximum 564; minimum 238.

The spruce beams made in the screw press which failed in shear developed shear stresses of 296 psi. and 346 psi.

The ten beams made of spruce, using one 3-in. nail for every 33 in., of glue joint, failed at an average modulus of rupture of. z,7go psi. with evidence of an appreciable amount of glue-joint failure. This indicates that the nailing arrangement used was not satisfactory.

The two beams made of spruce, using one 4f in. nail forevery 33 in.'of glue joint, failed at moduli of rupture of 6,88o psi. and 6,38o psi. respectively with no evidence

The difierence in strengths of beams using 3-in. nails and those using 4$ in. nails is of particular importance and in view of these test results the followini rule is proposed: if pressure for gluing is to be obtained by the use of nails only, the nails shall not be shorter than tuo and one-half (z$) times the thickness of a lamination ; nailing pattern shail be such that faces of laminations to be glued will be held in close contact and will be dictated largely by the warp in the laminations and the number of nails required to straighten them.

Results of these tests and of the 45 ft.-span beam tested by the General Engineering Company (Canada) Limited indicate that glued laminated structural members exhibiting satisfactory strength characteristics have been produced using nails only, to provide the required pressure on the glue joints. Whether or not

manpower.

Fig. 4 shows a comparison of cross sections of beams made by using nails only and by using clamp pressure.

Tests of glued laminated wood beams and columns and development of principles of design, published November, 1947, Forest Products

Lab-oratory, Madison, Wisconsin

This was an extensive series of tests which has contributed much to our knowledge of the slructural behaviour of glued laminated timber members. Two species were used, Douglas fir and southern yellow pine. Whereas all the Douglas fir is classified as " coast region," material used in different series of tests came from different areas within the coast region and results indicate an appreciable variation in " ilear " material from the difierent areas. Althoueh most members lvere made with horizontal laminations, one series of beams with vertical laminations was included in the tests. Resorcinol resin glue was used for all members and they were cured for not less than 16 hours at a temperature from 75"F. to gooF.

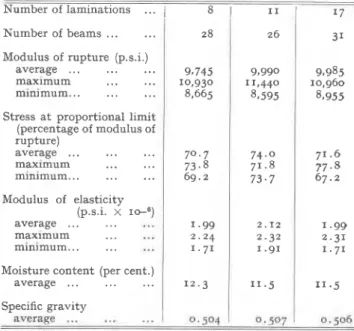

Table 3 shows strength characteristics of beams which failed in flexure and illustrates the effect of varying the size ancl number of laminations to make up a section of a specified size. Althougli all material

-ZACH PCINT REPAE5EN.IS lHE alERAgE cF TEN BEAnS 1egTeD EXCEPT FOB- EEAAS HAVTNq, I('O \HeRe AveRAgE- cF 85 BeAns ts PLcT.reO. d

B

q e o a o o tFig. 4.-Cross sectlons of bearns using l| in, x 5| ln. spruce lamlnations

Left: casein glue, pressure obtained by 4$ in. nails. Right: urea-formaldehyde glue, pressure of r5o p.s.i.

obtained in screw press.

Note: little difference in thickness of glue line is apparent. P h o t o . c o u r l e s y F . P . L . , O t t a a a , C a n a d a

was " clear," the variation (+ 14 per cent.) from the average modulus of rupture of rr-lamination beams was greath' in excess oi the difierence (z| per cenr.,l between 9,245 psi., the average modulus of rupture for S-iamination beams and 9,990 psi., the average modulus of rupture for rr-lamination beams. Accord-ingl1', it is cohcluded that variation of thickness of lamination used in making a member of a specified size does not affect the strength of the member appreciably. Table 4 gives test results to show strengths of beams with joints in bottom lamination as compared to strengths of control beams usine matched laminations withoiut joints. Notwithstanding lhe figure of 9o per cent. for the S-lamination beam with a one to five olain scarf joint in the bottom lamination, it should-be noted that for curved members difficultv would probablv be encounterecl in bending laminations having'scarf joints as steep as one to five. Because manufacturing pro-cedures are less exacting than those used in making the test specimens, percentage ratings of commercially produced scarf joints should be somewhat lower than the values tabulated. Accordingly the following are recommended for plain scarf joints :

S l o p e . . . r - i r z r : r o r : 8 r : 5 E f f r c i e n c y o . 9 o o . 8 5 o . 8 o 0 . 6 5 Tabulated values show that the serrated scarf ioint is not appreciably better than the .plain scarf joint and consequently, because of its greater cost, it is not recommended.

According to figures in Table 4 the Onsrud joint is no stronger than the butt joint.

Flexural strength of a timber member is dependent upon the magnitude of defects in the member. Most significant defect is the knot. Table 5 gives strength characteristics of various groups of laminated beams having knots of different sizes. Relation between residual strength of beam and magnitude of defects is illustrated in Fig. 5.

lrel ggcTloN fretc* I?jt ' X

FiS. 5.-Effect of defects on flexural strength of plued laminated beams

Defining:

16 : gross moment of inertia of cross section ; /x : moment of inertia of the parts of the critical

cross section occupied by knots; Ie -- Ix tc : net section factor :

' .Ic

F : residual strength factor;

Study of Fig. 5 reveals that as -Ir increases the rate of decrease of the residual strength factor, F, increases.

TABLE 3.-Strength characteristics of glued larninated bearns* whlch failed in flexure, showing the effect of

varying the size and nurnber of laminatlons

Numberof laminations ... I 8 | rr I rZ Number of beams . ..

Modulus of rupture (p.s.i.)

a v e r a g e . . , maxrmum m r n t m u m . . .

Stress at proportional limit (percentage of modulus of rupture) a v e r a g e . . . maxrmum m l n r m u m . . . ro-u) z 8 9 , 7 4 5 r o , 9 3 0 8 , 6 6 5 7 0 .7 7 3 ' 8 6 9 . 2 r . 9 9 2 . 2 + | . 7 r r 2 . 3 z 6 9,990 I r , 4 + o 8 , 5 9 5 7 4 . o 7 r . 8 7 3 . 7 2 . 3 2 I , 9 I I I . 5 3 r 9,985 ro,96o 8,955 7 r . 6 7 7 . 8 6 7 . 2 r . 9 9 2 - 3 r r . 7 r I I . 5 Modulus of elasticity ( p . s . i . x a v e r a g e . . . maxrmum m l D t m u m . . .

Moisture content (per cent.) a v e r a g e , . .

Specific gravity

*All beams were 6 in. x rz in. x 14 ft. long made with Douglas fir laminations having no visible defects.

f . (za -o 6)---- o c>x >

-8-/ J 63 v ) 9 r O L 9o 7 7 73 84 92 92 Plain scarf r

TABLE 4.-Strengths of beams* which failed ln flexure,

showing the effect of jdints in larninatlons

Type of joint I Number of laminations

I I

*All beams were 6 in. x rz in. X r4 ft. long, made with clear Douglas fir laminations. Joints were in the bottom lamina-tion at mid-span. Tabulated values are average results lrom tests of moduli of rupture of beams expressed as a percentage of the modulus of rupture of the control specimen without joints.

Accuracy of measurement and prediction does not warrant the use of a more accurate relationship than :

F : r between the limits r . o and o.8o ;

F : zx - o.8 between the limits o.8oand o.6o. Table 6 gives results of tests of glued laminated beams with different species and different directions of laminations. Marked difference in average modulus of rupture for series C and series D illustrates the variation in Douglas fir, .coast region, from different areas within the region. The average modulus of rupture of beams in series V was about five Der cent. below the average for beams in series D and lbout 15 per cent. below the average for those in series C. This may have been because a lower strength material was used or because of the difference in direction of laminations. Indications are that the same material will develop a higher modulus of rupture with horizontal laminationi than with vertical laminations.

Discussion in the report? suggests that the material xsed in the series YP might not be truly representative of " southern yellow pine." Average modulus of rupture for this series, while higher than the corresponding figure {or series D and E, is about nine per cent. below the figure for series C.

Table 7 gives values of shear stress induced in beams which failed in shear. There is no entry in this table {or beams in series YP because none in that series failed in shear.

It is noted that the material in series D exhibited substantially higher strength in shear than did the material in series C, notwithstanding the fact that relation of flexural strengths was the reverse (see Table 6).

TABLE 5.-Effect of knots on the streng,th

TABLE 6.-Results of tests of various Slued larninated bearns* which failed in flexure, showing the effect of

using different species and different direction of

larninations Series D YP N u m b e r o f b e a - r . . . j 8 5 Species - f i i Douglas Direclion of lamina-t i o n s . . . l h o r i z o n t a l lVlodulus o{ ( p . s . i . ) : .optor" I llodulus of elasticity averaSe ( p . s . i . x r o - o ) i 2 . o 4 Moisture content I t horizontal It southern yellorv plne I vcrtical jhorizontal I I 4 D o u g l a s fir r 5 Douglas fir 9 , 9 0 5 i 8 , 8 7 o 8 , 4 6 o 9 , r 3 o a v e r a g e . . . . . i 9,905 i d,d7o b , + o o 9 , r 3 o m a x i m u m . . . 1 r r , 4 4 o j S , 8 g o r o , 5 2 0 r o , 8 r o m i n i m u m 8 , 5 S 5 7 , 4 r o 5 , 7 6 0 7 , 3 4 8 z . z 4 i z . z t 1 r 6 l a v e r a g e ( p e r c e n t . ) | r r . S I r r . 6 i t r . . r r . z Specificgravity I i I ^i l a v P f a o c l o < o ? o < 2 ? o < " x l n < ( a v e r a g e ) o 5 o 7 0 . 5 3 3 I o . 5 2 8 | o . 5 3 o *All beams were 6 in. x rz in. X 14 ft. Iong. Most of the specimens were made with clear lumber : in the others only - minor defects existed. In cases where defects existed their effects were evaluated in terms of clear specimens and the strength characteristics tabulated have been "-adjusted to clear."

Whereas beams in series V developed an average modulus of rupture somewhat lower (about five per cent.) than those in series D, the average shearing stress of beams in series V which failed in shear is 28 per cent. above the corresponding figure for those in series D. These test data indicate tfrat vertical lamination, that is with the glue surfaces parallel to the plane of bending, produces a member stronger in shear, and not as strong in bending, as one with horizontal laminations.

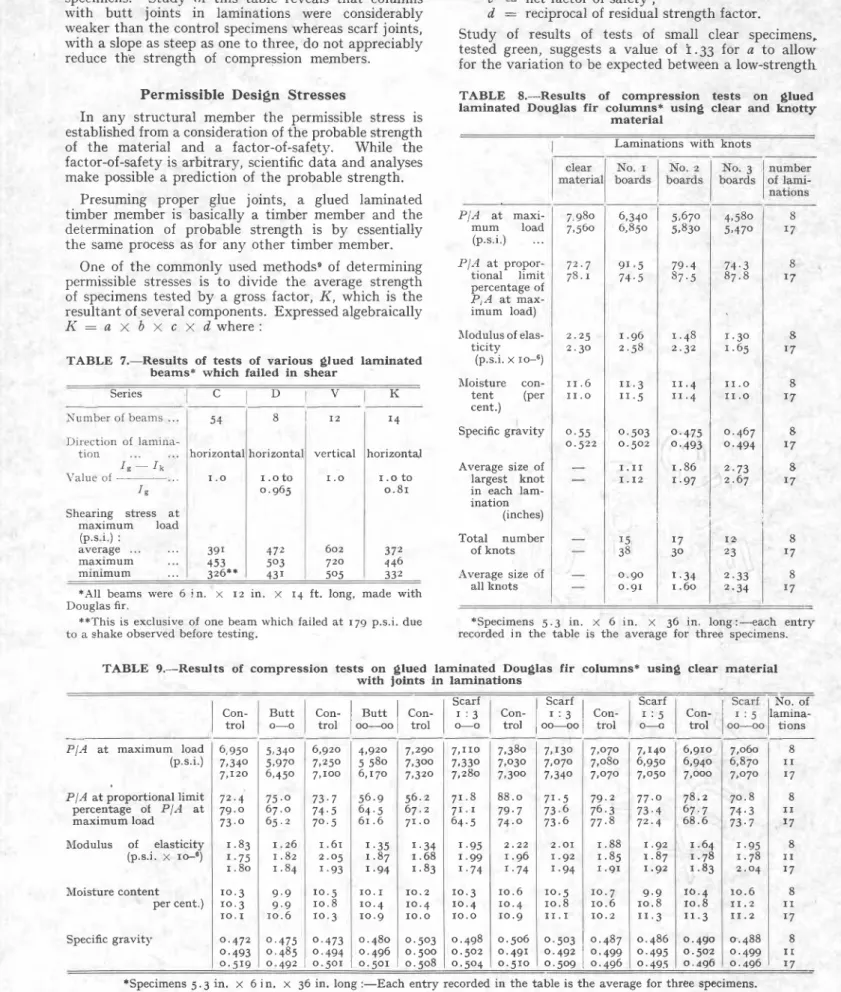

Table 8 shows the results of tests on two series of compression members, one series having eight lamina-tions and the other having seventeen. Quality of lumber used was varied in each series. Increase of size of knot resulted in decrease in streneth as would be exDected. Members with seventeen laminations carried consistently higber loads than those with eight lamina-tions when knotty material was used. With clear material the eight lamination specimens carried higher Ioads than the seventeen lamination members althoueh there is no rational exDlanation for this except that there is a natural variatibn in the strength of wobd.

Table 9 gives the results of tests of columns with and without ioints in the laminations. Clear material was used and members with eight, eleven and seventeen laminations were tested. Table ro shows the results

characterlstics of beams* which falled in flexure

Value of I E Number of beams

Modulus of rupture average Stress at proportional limit

/ / . J 7 6 . 4 7 8 . o a r U J . !r 8 6 . o 8 E . + 7 9 . 2

2 . 0 6 t . s 7 2 . o o l r . g . r . 9 3 ] , . r , : t . 7

r"- rx

*All beams were 6 in. X rz in. X 14 ft. long, made of Douglas fir. Eighty-five were of clear materi.al, r.o, twenty-eight having 8laminations, twenty-six having rr laminations and thirty-one having, t7 laminations. Thirty of the knotty beams had 8 laminations, sixty had 17 laminations.

r , o 8 5 9,905 7 r . 8 o . 9 r r I O 8,953 7 8 . 6 (percentage of modulus of rupt\rre)

Modulus of elasticity average

-9-of the tests -9-of columns with joints in laminations expressing the strength characteristics as percentages of the corresponding characteristics of the control specinlens. Study of this table reveals that columns with butt joints in laminations were considerably weaker than the control specimens whereas scarf joints, with a slope as steep as one to three, do not appreciably reduce the strength of compression members.

a : efrect of variability in strengths of different

specimens ;

6 : long-time loading efiect ;

c : rlet factor-of-safety ;

d, : reciprocal of residual strength factor.

Study of results of tests of small clear specimens, tested green, suggests a value of i.33 for a to allow for the variation to be expected between a low-strengtlr-Permissible Design Stresses

In any structural member the permissible stress is established from a consideration of the probable strength of the material and a factor-of-safety. While the factor-of-safety is arbitrary, scientific data and analyses make possible a prediction of the probable strength.

Presuming proper glue joints, a glued laminated timber member is basically a timber member and the determination of probable strength is by essentially the same process as for any other timber member.

One of the commonly used methods, of determining permissible stresses is to divide the average strength of specimens tested by a gross factor, K, which is the resultant of several components. Expressed algebraically

K : a X b X c x d w h e r e :

TABLE 7.-Results of tests of various glued laminated

beams* whlch falled in shear Series C D Number oI beams I)irection of ]amina-t i o n I * - I x \ralue o{ I s

TABLE 8,-Results of cornpression tests on glued

larninated Doullas t"

TIN#;1:| uslnp clear and knotty

Laminations with knots

t 2 vertical r . o 7 '98o 7 , 5 6 c 7 2 . 7 7 8 ' r 2 . 2 5 2 . 3 0 r r . 6 I I . O o . 5 5 o . 5 2 2 9 r 5 7 4 . 5 o . 9 0 o . 9 r I I . 3 I I . 5 o . 5 0 3 o . 5o2 I . I T t . 1 2 7 9 . 4 8 t .s r . 4 8 2 . 3 2 r r . 4 r r . 4 r 7 3o r ' 3 4 r . 6 0 o . 4 7 5 o . 4 9 3 r . 8 6 r . 9 7 4 , 5 8 0 5 ' 4 7 0 J L . A R r R r . 3 0 r . 6 5 I I . O I I . O o . 4 6 7 o . 4 9 4 2 . 7 3 2 . 6 7 t 2 2 3 : . J J 2 . 3 4 K PIA at maxr-mum load ( p . s i. ) PIA at propor-tional limit percentage o{ P,A at rnax-imum load) Xlodulus of elas-ticity ( p . s . i . x r o - 6 ) nloisture con-tent (per cent.) Specific gravity Average size of largest knot in each lam-ination (inches) Total number of knots Average size of all knots 6 , 3 4 0 | 5,670 6 , 8 5 o 5 , 8 3 0 r . 9 6 2 . 5 8 r J 3 8 8 r 7 8 r 7 8 r 7 8 r 7 8 r 7 8 r 7 5 4 horizontal r . o 8 horizonta r . o t o o . 9 6 5 r 4 horizontal r . o t o o . 8 r Shearing stress at maximum load ( p . s i. ) : a v e r a g e . . . maxlmum mlnlmum 3 9 r 453 326*+ 5 0 3 43r 6oz 7 2 0 505 446 3 3 2 8 r 7 8 r 7 *AlI beams were 6 in. x rz in. x r4 ft. long, made with

Douglas fir.

**This is exclusive of one beam which failed at r79 p.s.i. due to a shake observed before testing.

* S p e c i m e n s 5 . 3 i n . X 6 i n . X 3 6 i n . l o n g : - e a c h e n t r y recorded in the table is the average for three specimens.

TABLE g.-Results of compression tests on

,8oiHS ,]:i?tlf;l"SoDouglas

fir columns* using clear rnaterial

Scarf I : 3 o-o Con-trol 7 , o 7 0 7 , o 8 0 7 , o 7 0 7 9 . 2 Z 6 . 3 7 7 . 8 r . 8 8 r . 8 5 r . 9 t r o .7 r o . 6 r o . 2 I Scarf I C o n - | r : 3 | trol J oo-oo I Scarf I : 5 o----{ 1 Scarf I r : 5 I oo-oo No. of Con-trol Butt

o-o C o n - l B u t t l C o n -trol oo-oo I trol

Con-trol

lamina-trons PIA at maximum load

( p . s . i . ) P lA at proportional limit

percentage cil PIA at maximum load I\{odulus of elasticity ( p . s . i . x ro-8) Nloisture content per cent.) Specific gravity 6 , 9 5 0 7 , 3 4 0 7 , r 2 0 7 2 . 4 7 9 . o 7 3 ' o r . 8 3 1 . 7 5 r . 8 o r o ' 3 r o . 3 I O . I o . 4 7 2 o . 4 9 3 o . . 5 r 9 5 , 3 4 0 5 , 9 7 0 6 , 4 5 o 7 5 . o 6 7 . o 6 5 ' 2 t z 6 r . 8 z r . 8 4 9 . 9 9 . 9 r o . 6 o . 4 7 5 o . 4 8 5 6,92o 7,250 7,roo 7 3 . 7 7 4 . 5 / w ' J r . 6 r 2 . o 5 r . 9 3 r o . 5 r o . 8 r o . 3 o . 4 7 3 o . 4 9 1 4'920 5 58o 6 , r 7 o 5 6 .9 6 + . s 6 r . 6 r . 3 5 r . 8 7 r . 9 4 I O . I r o . 4 r o . 9 o . 4 8 o o . 4 9 6 7 , 7 r O 7,330 7,280 7 r . 8 7 r . r 6 + . 5 r . 9 5 r . 9 9 r . 7 + r o . 3 1 0 . 4 r o . o o ' 4 9 8 o . 5 o 2 o . 5 0 4 738a. 7,o30 7,300 8 8 . o 7 o . 7 7 4 . o 2 . 2 2 1 . 9 6 7 . 7 4 r o . 6 r o . 4 r o . 9 o . 506 o . 4 9 r o . 5 r o 7 , r 4 0 6 , 9 5 0 7 , o 5 0 7 7 .o 7 3 . + 7 2 . 4 r . 9 2 r . 8 7 r . 9 2 9 . 9 r o , 8 I I . 3 o . 4 8 6 o . 4 9 5 o . 4 9 5 6 , 9 r o 6,94o 7,ooo c e o 6 7 . 2 6 8 . 6 r . 6 4 r . ? 8 r . 8 3 1 o . 4 r o . 8 I I . 3 o . 4 9 o o . 5 o 2 o ag1 7,o60 6 , 8 7 o 7 , o 7 0 7 a . 8 7 4 . 3 7 3 . 7 r . 9 5 t o R 2 . 0 4 r o . 6 t t . 2 t t . 2 o . 4 8 8 o . 4 9 9 o . + 9 6 7 '290 7,300 7 '320 5 6 . 2 7 r . o | . 3 4 r . 6 8 r . 8 3 t o . 2 r o . 4 r o . o o . 5 0 3 o . 5 o o o 4 9 2 o . 5 o r J o . 5 o r 1 o . 5 o 8 7 , r 3 0 7 , o 7 0 7 , 3 4 0 / L . J 7 3 . 6 7 3 . 6 2 . O I 7 . 9 2 r . 9 4 r u . ) r o . 8 I I . I o . 5 o 3 | o . a s 7 o . 4 9 2 I o . 4 9 9 o . 5 o 9 t o . 4 9 o 8 I I r 7 8 I I I 7 8 I I r 7 8 I I r 7 8 I I r 7 * S p e c i m e n s 5 . 3 i n . x 6 i n , x 36in. long:-Eachentryrecordedinthetableistheaverageforthreespecimens. o-o indicates joints in outer set of laminations ; oo-oo indicates joints in outer two sets of laminations.

All specimens 5 3 in. x 6 in. x 36 in. long :-Each entry recorded in the table is the average for three speCimens.

-10-TABLE l0.-Strength characteristics of Doug,las fir colurnns wlth jolnted larninatlons as a percentag,e of the corresponding characteristics of the control specimen

Iype oi Jolnt rn lamrnatrons Scarf r : 3 o-o oo-oo S c a r f r : 5 o-o oo-oo Number of Laminations

PIA at maximum load

PIA at proportional limit

Modulus ol elasticity o-o 7 6 . 8 8 r . 3 8 9 . 2 7 9 . 7 6 8 . 8 8 o . 8 6 8 . 5 r 0 3 . o t o 2 . 2 7 r . o 7 7 . o 8 7 . o 5 + . 9 66.6 7 6 . o 9 7 .5 I o o . 3 9 9 . 5 r 2 4 . 4 r 0 6 . r 9 0 . 3 r 4 5 . 5 r 1 8 . 4 9 5 . 2 9 6 . 5 r o o . 5 r o o . 6 7 8 . 5 9 2 . 9 I O O . O 9 0 . 5 9 8 . o t t r . 2 I O I . O 9 8 . o s 9 . 8 9 8 . 2 9 4 . 5 9 2 . 8 t o 2 . o 9 9 . o I O I . O 9 2 . 5 r o 8 . 5 r o 8 . 3 r r 8 . 7 I O O . O I I I . 8 3 . 8 9 r . 3 r o o . 5 r o 2 . o I O I . O r o o .

o-o indicates joints in outer set of laminations ; oo----oo indicates joints in outer two sets of laminations. All specimens 5 . 3 in. x 6 in. x 36 in. long :-Each entry recorded in the table is the average for three specimens.

be

specimen and the average. Long-time loading ex-periments have established a value of t.78 for b. An arbitrary value of r.67 has been used in many specifica-tions for c. The residual strength factor depends upon the grade : for " select structural " Douglas fir, according to C.S.A. Specifications it id o.75. For this grade d would be the reciprocal of o.75, namely r.33. Since tests at the Forest Products Laboratory, Ottawa, Ontario, have established a value of 8,roo psi. for the average modulus of rupture,. tested green, bf Douglas fir, coast region, the permissible design stress for " select structural " grade of this species calculated according to the previously outlined method, would

8 , r o o

Using the method outlined above and making appro-priate adjustments in the various components of the gross factor-of-safety, the permissible design stress in flexure for permanent loading is calculated as follows :

Variability of manufactured product is not as great as with natural timber ; use a : t.z5 ; b : r .78 ; c : 2 . 5 o ' d : t . 2 5 : t h i s w i l l d e p e n d u p o n t h e s i z e a n d l o c a t i o n o f d e f e c t s . K : a X b X c X d : 6 . g 5 . permissible stress : r4'8oo : 2,r3o psi.

6 . g s

A value of. z.5o for c the net factor-of-safety is used rather than r.67 which has been used in the C.S.A. specifications.

Duration of loading has an important effect-on the ability of timber fibres to withstand load. The value of r.78 for D has been established by a study of results of tests of various species loaded for different lengths of time. When tabulated strengths of clear specimens are based on short-time loading tests it is necessary to include this component, b, to obtain long-time or permanent loading strength. When loading of shorter duration is being considered, an appropriate increase in permissible stress should be made. Most present-day structural timber specifications give coefficients for adjustment of permissible stresses for durations of loading other than permanents, These adjustments should be applicable to permissible stresses in " Glulam " also.

When a lamination is curved stress is induced in the fibres by the bending moment which is applied to produce the required curvature. To allow for these initial stresses the permissible stress should be reduced, depending upon the ratio of the radius of curvature to the thickness of the lamination. A suggested{ re-duction factor is:

2,OOOtr

r.o - where: R : radius of curvature; R A R

I : thickness of lamination; - shall be not less

than roo. t

Concluslons

Glued laminated timber is an efiective structural material which is superior to sawn solid timbers in many applications. It will undoubtedly be used more extensively because of its aesthetic features and economic advantages.

: r,53o psi. A value r . 3 3 x r . 7 8 x t . 6 7 x t . 3 3

of r,6oo psi. is specified by the C.S.A. specifications which indicates a certain adjustment of the overall Jactor. Whereas this same process would be applicable {or the determination of permissible design stresses in glued laminated timber members, adjustment of certain factors should be made.

Residual strength factors of individual laminations are not correct measures of the strength of a member o{ which the lamination is a component. In general, because any defect will be limited in extent to the thickness of the lamination in which it is present, the residual strength factor will be higher for the built-up member than for the individual lamination graded-as a joist or plank.

A most significant difference exists because of the {act that dried material is used in making glued laminated members. Permissible stresses for sawn solid structural timbers are determined from strength tests on " green material " notwithstanding the fact that the members will be " air-dry " during most of the service life and in many cases before the design load is applied to them. The reason for not determining the design stress from strength of " air-dry " specimens rather than " green " specimens is that it is anticipated that additional defects will develop in the members accompanying the drying, usually " checks," which will ofiset the increase in strength of the fibres. This argument is not applicable to glued laminated members and consequently allowance should be made for the fact that " air-dry " material is used in the manufacture of the member

Douglas fir, coast region, has an average modulus of rupture of r4,8oo psi. for " air-dry " clear specimens as determined by tests at the Forest Products Labora-tory, Ottawa, Ontario.

-11-Although clamping devices to provide pressure on the glue joints will produce a better member, satisfactory strength characteristics have been produced using nails only, to provide the required pressure on the joints.

In most instances, the saving in cost of lower strength species will not justify their selection because the cost of lumber is only a fraction of the cost of a glued

lamin-References

llaminating of Structural Wood Products by Gluing (1948) Report No. Dr635. United States Department of Agriculture, Forest Service, Forest Products Laboratory, Iladison, Wisconsin.

2The Gluing of Wood (1929) by T. R. Truax, Bulletin No. r,5oo, FPL, Madison, Wisconsin.

sWood Preservation, by Hunt and Garratt, published by McGraw-HiI].

aThe Glued Laminated Wooden Arch, by T. R. C. Wilson, (1939), Technical Bulletin No. 69r, United States Department of Agriculture, Washington, D.C.

EReport on Laminated Timber Beams (t94r) by H. L. Tamplin, The General Engineering Company (Canada) Limited, Toronto, Ontario.

oStrength Properties of Larninated Beam and Arch Con-struction (1946), by C. F. Morrison and W. E. Wakefield. Progress Report No, 3, Project z4o, Forest Products Laboratory, Ottawa, Ontario.

?Tests of Glued Laminated Wood Beams and Columns and Development oI Principles of Design (rg+Z), by T. R. C. Wilson and W. S. Cottingham, Report No.'Rr687, U.S. Department of Agriculture.

8The Construction and Testing of a Glued Laminated Wooden Arch of 47-foot Span (r95o), by D. E. Kennedy, Mimeogtaph o-r52, Forest Products I-aboratory, Ottawa, Ontario.

sWood Handbook (r94o), United States Department of Agriculture.

-r2-The Effeet

of Low Temperature

o n t h e P e r f o r m a n e e o f B u i " l d l n g M a t e r l a l s

by

M . F " G o u d g e a n d E " V , G i b b o n s

-The Effect of Low Temperature

on the Perforrnance of Builditg Materials

in Canada

M. F. Goudge

(Industrial Minerals Diz.,ision, Department of Mines and Technical Suraeys, Ottaula, Canada)

and E. V. Gibbons

(Dizti.sion

of Bwilding Research, Nati,onal

Research Council, Ottawa, Canada)

Introduction

Canada has no ancient buildings from which direct evidence can be obtained as to the long-time effect of low temperatures on various building stones, brick and other construction materials. Such old buildings as do exist, and they are not old by European standards, are in parts of the country where extremely low tempera-tures do not occur. In the far north, wood has been the commonly used building material until recently. However, in the course of studies made at the Mines Branch, C)ttawa, during the past forty years, of the durability of Canadian building stones and brick, some interesting facts have been brought to light as to the effects of low temperatures. From these studies and from observations made on the condition of outcrops of rock in various parts of the country some deductions may be drawn.

There is a wide variety of climate in Canada. The Maritime Provinces, bordering on the Atlantic, have a relatively mild winter with many periods when the temperature is well above freezing and there are con-sequently many cycles of freezing and thawing. The

average annual minimum temperature is -lOoF. As

we go westward, or inland, the winters become colder and steadier. The average annual minimum tempera-ture at Ottawa is -35oF. and at Toronto -20o . There are also many fewer cycles of freezing and thawing. On the prairies the winters are cold and steady and there is relatively little precipitation either in the form of rain or snow. The average annual minimum temperature at Winnipeg'is -40oF. and at Saskatoon -45oF. On the West Coast the winters are mild and there is an abundant rainfall. The average annual mini-mum temperature at Vancouver is 10oF. and at Victoria 20oF. The northern prairie country has a colder winter than much of the Arctic and the coldest area of all is in Yukon where at Snag in 1947 a temperature of -83oF. was registered-this being the lowest temperature ever recorded on the North American continent.

From this brief generalised statement of the winter weather in various parts of the country, it may be seen that building materials in various parts of Canada are subject to a wide variety of conditions. Fronr our observations on the durability of building materials in structures in various parts of the country, it may be said that there is in general greater evidence of deterio-ration in building materials in parts of the country where the winter is tempered by frequent mild spells than in parts where the cold weather remains unbroken

for long periods.

It has proved a difficult task in writing this paper to find actual instances of damage to building materials that could be ascribed solely to low temperatures. In the first place, most of the structures in the far north

of Canada are of wood, and secondly, none of them are more than a few years old when compared with build-ings in Europe where the effects of centuries of wear and tear can be observed in a great many instances. It is doubtful if extreme cold, alone and maintained, causes much deterioratiorr of buildings unless the build-ing materials are saturated with water that cannot escape. It isonlywhen f reezing temperaturesoccur imme-diately after the building material has been thoroughly vretted that damage occurs. It is the number of cycles of freezing and thawing that accounts for the deterio-ration and these cycles do not occur in greatest number in the coldest parts of the country but in the warmer parts. In Nova Scotia, for instance, where the usual minimum temperatures rarely exceed -10oF., there is more deterioration of building stone etc., than in the midwest where the minimum temperature is -40oF. to -50oF. This is because in Nova Scotia there are many more cycles of freezing and thawing and also a wetter climate than in central Canada where the cycles are much less numerous and the climate is drier.

'-[he

20-year old concrete structures of the Hudson Bay Railway terminal at Churchill, Manitoba, where the average minimum temperature during the winter is -45oF. show no deterioration of an unusual nature. Similarly, stone and concrete used in the older build-ing in Yukon where the average minimum temperature is -55'F, show no excessive or unusual deterioratron.

We must therefore turn to theoretical considerations and to the results of artificial f.reezing and thawing tests made in laboratories in an effort to determine the probable relative durability of building materials of various kinds under conditions of freezing and thawing in the presence of moisture.

Mechanical Action of Low Temperature on

Building Stone

The principal effects of low temperatures on build-ing stone are of a mechanical nature.

l. They cause a change in volume of the indi-vidual grains composing the rock.

2. When water is present in the pores of a rock a temperature below freezing converts the water into ice and sets up great internal stress. Each mineral composing a rock has a different rate of expansion. Where the rock is of a homogeneous nature such as marble, limestone or sandstone, the effect of temperature change is at a minimum but where the rock is of a heterogeneous composition such as granite and gneiss, the differences in the rate of expansion of the different minerals set up additional stresses. The final result is the formation of incipient cracks between the mineral grains into which water may enter when opportunity offers.

-11+-expansion of the water during and after freezing. l. Each mineral substance has a different coeflicient of expansion. With rocks consisting mainly of one mineral such as limestone and sandstone this effect is at a minimum, but with rocks composed of several min-erals such as granites, gneisses and schists the effect is greater and may be serious where diurnal temperature changes are great and where annual variations are also large. Diurnal changes are often as much as 35oF. in Canada and.annual variations may approach 135oF. Examination of some coarse-grained granite monu-ments in some of the old cemeteries in Nova Scotia

monuments, water has easy access along the cracks, and the crumbling process is accelerated by the alternate freezing and thawing of the water during the winter. The,fine-grained granites are less affected and marbles and sandstones show little if any disintegration from this cause over the period of time involved .

2. Freezing of water within the stone occasions

tons per square foot when the water is confined. The disruptive effect on stone can be readilv realised. For this rea.son the -repeated alternate f.reezing and thawing of specimens of stone saturated with waGr is taken ai

. The speed and intensity with which freezing takes olace in a laboratory test is usually much great6r than

under natural conditions. As many as eighty separate cycles of freezing and thawing may occur in one winter in Maritime Canada and yet building stones there stand up for many years, whereas a stone which will with-stand fifty cycles in a laboratory test is considered durable.

ing escape of some of the water as pressure increases. Low temperatures may have a destructive effect on stone in ways other than by causing mechanical dis-ruption through the formation of ice. During the winter in cities, soot collects on the snow and when spring approaches, the water from the melting snow is heavilv charged with sulphurous matter. This water stays in pools in contact with the stone and if it is a porous limestone it penetrates it, causing the formation of calcium sulphate which in turn causes disintegration of the stone. Several examples of this have been observed in buildings in Canada possessing parapets constructed of porous limestone. It could beprevented by properly flashing the base of the parapet. The same limestone elsewhere in the building is not a{Tected adverselr,.

Brick

Bricks are widely used in Canada in the facing of buildings and when properly made and properly used they give excellent service in all parts of the country, including the coldest parts. When failures do occur it is when they are wrongly used for base courses or are used in parapets without adequate flashing. In these parts of structures the bricks become saturated with water and are subject to damage by frost. Repeated freezing and thawing results in a crumbling or spalling of the exposed face of the brick and in time the bricft

Bricks are made from clay or-shale in some eighty plants scattered across Canada from Newfoundlan-d tb British Columbia. Three processes are used in their manufa_cture. (1) Stitr-mud; (2) Dry-press; (3) Soft-mud. Specifications cover thrie grailes as

foilows:-submersion in boiling water).

2. Grade MW. Brick intended for use in walls where exposed to temperatures below freezing but unlikely to be saturaied with water. These have-similar phy5icai requirements to those of Grade SW except that the maximum saturation coefficient mav be 0.85.