Publisher’s version / Version de l'éditeur:

Textures and Microstructures, 19, 3, pp. 175-188, 1992-01-01

READ THESE TERMS AND CONDITIONS CAREFULLY BEFORE USING THIS WEBSITE. https://nrc-publications.canada.ca/eng/copyright

Vous avez des questions? Nous pouvons vous aider. Pour communiquer directement avec un auteur, consultez la

première page de la revue dans laquelle son article a été publié afin de trouver ses coordonnées. Si vous n’arrivez pas à les repérer, communiquez avec nous à PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca.

Questions? Contact the NRC Publications Archive team at

PublicationsArchive-ArchivesPublications@nrc-cnrc.gc.ca. If you wish to email the authors directly, please see the first page of the publication for their contact information.

NRC Publications Archive

Archives des publications du CNRC

This publication could be one of several versions: author’s original, accepted manuscript or the publisher’s version. / La version de cette publication peut être l’une des suivantes : la version prépublication de l’auteur, la version acceptée du manuscrit ou la version de l’éditeur.

For the publisher’s version, please access the DOI link below./ Pour consulter la version de l’éditeur, utilisez le lien DOI ci-dessous.

https://doi.org/10.1155/TSM.19.175

Access and use of this website and the material on it are subject to the Terms and Conditions set forth at

The elastic strain ratio, the Lüders strain ratio and the evolution of

r-value during tensile deformation

Daniel, Dominique; Jonas, J. J.; Bussière, J.

https://publications-cnrc.canada.ca/fra/droits

L’accès à ce site Web et l’utilisation de son contenu sont assujettis aux conditions présentées dans le site LISEZ CES CONDITIONS ATTENTIVEMENT AVANT D’UTILISER CE SITE WEB.

NRC Publications Record / Notice d'Archives des publications de CNRC: https://nrc-publications.canada.ca/eng/view/object/?id=cab2f5c6-d1b1-4d9e-b4ef-48fad52f38f7 https://publications-cnrc.canada.ca/fra/voir/objet/?id=cab2f5c6-d1b1-4d9e-b4ef-48fad52f38f7

Photocopyingpermittedbylicenseonly

THE

ELASTIC STRAIN

RATIO,

THE

LODERS

STRAIN RATIO AND

THE EVOLUTION OF

r-VALUE

DURING TENSILE DEFORMATION

DOMINIQUE DANIEL and J. J. JONAS

Department

of

Metallurgical Engineering, McGill University, 3450 University St, Montreal, Quebec, H3A2,47, CanadaJ.

BUSSIIRE

NationalResearch CouncilCanada, IndustrialMaterialsResearch Institute, Boucherville, Quebec, J4B6Y4, Canada

(Received September17, 1991)

The elasticcounterpartof theplasticstrain ratio is derivedfrom ultrasonic data measured ontwenty

commercialdeepdrawingsteels.Itis shownthat theobservedvariations inplasticrarerelatedtothe

evolution of texture, and are not affected either by the elastic range of deformation or by the propagation of Liiders bands. Further quantitative analysis suggests that the elastic strain ratio,

determined non-destructively, can be used to predict plastic r-values by means of an empirical relationship.

KEYWORDS Texture, ODF coefficients, plastic anisotropy, elastic anisotropy, r-value, Liiders

deformation, cold rolled steel sheet.

1.

INTRODUCTION

The plastic strain ratio or Lankford parameter

(Lankford

et al.,1950)

is well understood physically as a measure of the capacity to resist thinning. It isgenerally

referredto as the r-value:e22

In

Wo/Wf

(1)

es3In

to/tf

whereE22and e33arethetruestrainsin thewidthandthicknessdirectionsdefined by the initial and final widths and thicknesses w0, wf,

to

andtf.

Because oftheorthorhombic symmetry of rolled sheet, it need only be measured between the

rolling

(0

deg)

and transverse(90

deg)

directions. In practice, the average isusedtocharacterize amaterial:

1/4(to

+ 2r4s +

r9o)

(2)

Whiteley et al.

(1961)

showed that the higher the i, the deeper the draw. The parameterAr

isusedin turn to quantifythe planar anisotropy:Ar

1/2(ro-

2r45 +

r9o)

(3)

which isrelatedto the tendencytoform four-fold ears.

One of the problems involved in r-value measurement is that it is frequently

observed to vary with strain

(Arthey

and Hutchinson, 1981; Welch et al.,. 1983;Liu, 1983, Liu and Johnson 1985;

Hu,

1983; Lake et al.,1988).

The rate ofchange ofr-value isparticularly rapid in theearly stagesof deformation

(Daniel,

1990; Danieland

Jonas, 1990),

leadingto thepossibility that elasticphenomena, including the elasto-plastic transition, are involved. The present work wasundertaken with the aim of determining the extent to which elastic r-values,

whichgenerallydifferfrom the plastic ones, playa role in thisvariationofr.

2.

ELASTIC

STRAIN RATIOThe elastic r, rel, canbe calculatedfromtherelationbetweenthe stateofstress 0

and the resultingstate ofstrain

(Hooke’s

law),

asexpressed by:(4)

where Sijktare the components of the fourth order elasticcompliance tensors.

In

uniaxial tension alongthe 1 direction

(2

isthe widthdirection),

the elastic strain ratio is thereforegiven by:E S1122

re,

(5)

et ’1133

These matrices can be transformed from the rolling frame to the tensile reference frame

(inclined

at an angle 0to the rollingdirection)

usingthe tensortransformation rule:

$Okl airnainakoalpSmnop

(6)

where the prime indicates thevalueoftheconstant in thetensile system, the are the direction cosines relatingthe rolling and tensile coordinateaxes, and the

products are summed over all the mnop indices of the tensor.

For

a given 0,r,(O)

isdefinedby:s122

cos20sinE0(Sllll

+

s22224s22)

+

(cos

40+

sin40)s22

(7)

s133 COS 20 $1133+

sin2

0s23It

shouldbe noted thatPoisson’s ratioo12(=--e22/e)

isthe elasticcountea

of the plastic contraction ratio q.

ese

are the quantities measured in practicesince the thicknessstrain e33 cannotbe accuratelydeterminedonthinsheets.

e

relationsbetween re, and o12 and

rp,

and qcan be writtenas:and

rp=

(8)

r,

1 o12 1 q

where

rp,

is the plastic strain ratio. Since ViE in steels falls in the range0.2

<

ViE<

0.7, r, can be expected tova

from about 0.25 to 2.e

latter istherefore smaller than

rp, (except

whenrp,

takes valuesbetween 0 and 1.5, asit isshown

later).

As aresult, rgenerallyincrees asthe materialpasses

through the elastic-to-plastictransition.3.

PROBLEMS ASSOCIATED WITH

THE EXPERIMENTAL

DETERMINATION

OFTHE

ELASTIC AND PLASTIC STRAINRATIOS

a. Derivation

of r

from

ultrasonicmeasurementsThe deformations associated with the elastic straining of a sample are so small that theycannot readilybe measured directly.

However,

the elastic constants of the sheet can be derivednondestructively

from measurements of the ultrasonic velocities(Sayers,

1982).

The anisotropies of the longitudinal and shear sound velocities propagating in the rolling plane lead to a partial description of thepolycrystal

stiffness tensorCk (Thompson

et al., 1987, 1989; Hirao etal., 1988,1989).

More

precisely, theseultrasonicdataleadtoonlythreeindependentelastic parameters,expressed

linearly in terms of Cl, C2222, Cl122 and c1212(Sakata

et al., 1990; Daniel, 1990; Daniel etal.,1991). A

polycrystal elasticitymodel, such as the 2nd order Hill approximation(Bunge,

1974)

is then needed in order todetermine the entire stiffness tensor ct, from which the compliance tensor sgt

can be obtainedbymatrix inversion. Theseoperationsleadto

r

accordingtoEq.

(7).

b. Directmeasurement

of

rp

According to

ASTM

standard E517-81 pertaining to the plastic strain ratio, thewidth and length changes are measured after elongations of 15 to 20%. The thickness strain is then calculated by assuming volume constancy. This requires

thatthe errors in thelength andwidth measurementsbefore and afterstretching notexceed about

10/m

for thewidth and 25to50/m

for the length, depending on thegage

length.As

a result of these stringent requirements, the quality of r-value measurementsdepends

sensitively on theaccuracy

of the measuring techniqueand on theskillof theinvestigator.The physical significance of the conventional definition

(i.e.

the accumulated strain ratioe/e

at 15% elongation) has, however, been questioned because of the evolution of the plastic anisotropy during straining. It has been pointed out that,both in mathematicalmodelingaswellasfor thecharacterizationofmaterial drawability, r should be defined in terms of the instantaneous ratiode/det

atzero strain

(Welch

et al.,1983).

This was suggested earlier by Hill(1948),

butneglected

because of the practicalproblems

associated with carrying out experiments at such small strains.Measurement

of the desirable instantaneousstrain ratio requires complex equipment andinvolves acontinuous recordof the

length

and width changes during straining for later back extrapolation to zero strain. The need for accurate studies of plastic anisotropy has led to intensiveresearch on the evolution of the strain state in tension

(Liu,

1983; Liu andJohnson, 1985; Lakeetal.,

1988).

Thistypeof investigationhas shownthat, for awide

range

ofmaterials,the relation between the width and lengthstrainscan be considered aslinear to afirstapproximation.From

straindata, such as those obtainedin thisstudy,

two different definitions of r-value can be used. Thefirst isthe conventionalone, consistingof theratioof the accumulated width to thickness strain at a specified elongation, usually 15%(e

0.14).

Thesecond,called the regressionrin thepresent work,usesthesloper15 regression conventional pl regression

rpl

81

81

ie 1 Schematic illustration ofthe definitionsand strain dependencesof the conventionaland

regression r-values(caseofapositiveintercepta).

strains measured during the course of (relatively) uniform elongation. These

definitions areexpressed, respectively, bythefollowing equations:

conventional Ew rpl

(9)

E""

E b rregression(10)

pl 1 b andThe major distinction between these two parameters is their different

depend-ences on the strain. The conventional r varies with elongation, at a rate that

dependsonthe value ofa.

By

contrast, theregression r is constantby definition,which makes it attractive for characterizing the drawability. Figure 1 illustrates the differences between these twodefinitions.

The angular

dependence

of rpl on 0(inclination

to the rollingdirection)

can also be predicted from texture data(ODF

coefficients). It

was shown in earlierpublications

(Daniel,

1990; Daniel andJonas,

1990; Daniel et al.,1991),

thatcalculations using the

RCa

relaxed constraintmodel are ingood

agreement with experimentalmeasurements when appropriate values are selected forthe critical resolved shearstress ratiosfor each steel.3.

EXPERIMENTAL WORK

a. Materials

Twenty

samplesof low carbon steelsheetswerecollectedfrom variousproducers

in Canada, United

States

andJapan.

These were divided into fivetypes:

(1)

batch-annealed Al-killed drawing quality

(AKDQ)

steels,(2)

commercial-grade rimmed steels(denoted

asRIM

in the presentwork),

high-strength low-alloy(HSLA)

steels, and(4)

and(5)

twotypesof interstitial-free(IF)

extra-low-carbonsteel. The latter distinction was made because ofthe different texturesobserved

which induced different plastic anisotropies. In the first type of interstitial-free

steel

(IF1),

the P-values fell in the range from 1.5 to 1.9, and the Ar’sof0.2 to0.4werebelowthose of the AKDQ steelsinthesamePrange. Inthesecondtype

(IF2),

the f-valueswere above 2.0, and the Ar’s were still smaller, rangingfrom -0.2to0.2.b.

X-ray

and acoustoelastictextureanalysesThetextureofeachsteelwas analyzed bymeansofthe

X-ray

reflectiontechnique on a Siemens’ goniometer system, consistingof a Digital Equipment PDP-11/73controlled vertical diffractometer

(D-500),

attached to the theta(i.e.

theBragg

angle

0)

circle of the Huber Eulerian cradle. Standard numerical methods(Bunge,

1982)

provided the ODF coefficients from the incomplete pole figure datauptolmax

22.The present elastic measurements were carried out using electro-magnetic

acoustic transducers, referred to as EMAT’s. Two types of guided plate wave

modes were employed: the lowest order symmetrical Lamb

(So)

and the shearhorizontal

(SH0)

modes. The Lamb waves consist of a pair of transverse waves superimposedon apairoflongitudinalwaves. Theirdirection ofpropagation lies in theplaneparallel

to the surface of theplate. For agiven plate thickness, thewavevelocityisa strongfunctionof

frequency,

sothat measurements areusuallymade in a frequency rangewhere this dependence isweak. For the fundamental

So

mode, thisrangecorresponds

tofrequenciesfar below the cutofffrequenciesofthe higher modes and the associated vibrations occur approximately parallel to

thepropagationdirection.Nevertheless,there is asmall lateral motionduetothe

planestress boundarycondition because thewavelength islong but notinfinitely

so

(zero

frequency).

The

So

andSI10

mode velocities were measured along three directions ofpropagation

(0

,

45 and 90 fromRD)

using Magnasonics EMAT’sat a nominalfrequency

of 500kHz. TheSo

mode velocities were extrapolated to zerofrequency

tocorrect forthedispersion effectassociated withfiniteplatethickness(Daniel,

1990).

This correction affects the measured values by 0.5%, which ismore significant than in the case of the resonant frequencies measured by the Modul-r tester. This is because the correction term is inversely proportional to

the

square

of thewavelength,which isaround 20cm inthe Modul-rcaseand 1cmin the

EMAT

method.Due

tothe sheet symmetry,theSHo

mode velocities at0 and 90 are equal. The 4th and 6th order texture coefficients were derived fromthe ultrasonic databythe method of Sakataetal.

(1990),

andusedfor calculation ofthe elasticand plasticr-values.c. Tensile testing

To

avoid the technicalproblems

associated with the double extensometertechnique, a time consuming but easier method than the interrupted test

procedure

was devised. Tensile tests were carded out on specimens cut from sheetsat several orientations withrespect tothe rollingdirection, i.e.every

15,

22.5 or 45.

For

each orientation,two standard, parallel-sided, 200mmx

20 mmstrip specimens

(type B

ofASTM517-81)

were firstprepared.However,

in orderthespecimensweretaperedfrom20to 19.3mm withinthegage length, following

thesuggestionof Liu

(1983).

In

thepresent work, agridof4mmby4 mmsquareswasscribed,using alaser beam technique,which led to a line width of about 50#m.One

of each pair ofspecimenswas first stretchedto5% elongationandthento10% atastrain rateof 2

x

10-3s-l;

the secondsample was stretched to 20% in a single test. The

elongationsin thefirstsample rangedfrom5to 12% alongthecenterofthegage

length

after the secondtest. The strains inducedby

thetaperranged

from 15 to 25% along the second sample. Grid measurement was carried out at sevenlocations along the

gage

length by means of a toolmaker’s microscope, which ensuredan absoluteaccuracy

of2.5#min thereadings.Due

tothe linethickness,the widths and lengths were determined with an accuracy of 20#m

(---0.2%

error).

The grid deformation was measured on 3x

3 or 3x

2 unit rectangleslocatedalong thecenter linesofthe specimens.

4.

RESULTS

ANDDISCUSSION

a. Evolution

of

rplduringtensile testingFor

eachsample

direction, an approximately linear relation betweenew

and elwasobserved in therangeofuniformdeformation, asreported byLiu

(1983)

and Liu and Johnson(1985)

for low carbon steels. Typical results for an IF1, anAKDQ and a

RIM

steel are presented in Figure 2.An

interesting difference between theIF

and other steelslies inthehomogeneous yieldingbehaviourof the formergrade,whichaffects theevolutionof r-valueduring straining,asdescribedby

Artheyand Hutchinson(1981)

and Lake etal.(1988).

As

outlinedbyLakeetal.

(1988),

the absolute value of theintercepta of the linear regressionis higherfor steelswhich undergo inhomogeneous yielding (Figure2b and

2c) (lal -0.009)

than forthe

IF

steels(Figure2a) (la[

0.0015).

Also,awasfoundtobe generally positive,although

sometimesit wasnegative.Although this value is subject to experimental error

(Liu

and Johnson, 1985;Lake etal.,

1988),

the large number ofmeasurements carded outin the present work indicate that the a-value is close to zero for steels which yield homogene-ously and non-zero for the others.In

the latter case, highvalues oflal(>0.005)

were found in the

RIM

andHSLA

samples displaying high yield point elongations(---4-5%).

Thedata for thesespecimens showlargerdeviations from linearity(see

Figure2c),

which add some uncertaintyto the a-values.Moreover

these steels display earlier plastic instability than the AKDQ and

IF

grades.These two factors reduce the range of uniform deformation used for the

regressionandinduce localinhomogeneities, which canalso affect the

determina-tion of the convendetermina-tionalASTM r-value.

To

avoid the difficulties associated with the transition to homogeneousdeformation, the regression proposed by Liu

(1983)

seems to be an appropriate technique for calculating the average strain ratio during deformation afterpropagation of the band. Furthermore, the number of points obtained at increasingstrains improvesthereliabilityoftheestimated value. Thesestatistical regressiontechniquesleadto a95% confidence intervalfor b, which corresponds to an error in r of +0.04 to +0.08

(for

steels displaying high yield point15 10 a)IF1 15 15 10 10 5 5 0 0

"

25 0 25 0 25 E E 15 10 b)AKDQ

0 10 0-45O/

0 25 0 25 E 10 0:90 E 25 15 10 c)RIM

-/" 15 15 10 5 0-45 0 -i 0 10 5 0 90 Y 0 25 0 25 0 25 E E EHgare2 Examplesofexperimental el, ewdata(in%) obtained on(a)anIF1 steel, (b)anAKDQ steel and(c)aRIMsteel.

elongations and a narrow range of uniform plastic

deformation)

for 12 datapoints,

compared

to a common error of +0.15 in the r’s determined in theconventional manner.

It

is of interest that, for the cases where a non-zero a intercept was obtained, the conventional and regression r values differed by as much as0.10to 0.25.b. Elasto-plastictransition

of

r-valueFigure 3 shows the evolution of the conventional plastic r-value measured at

various tensile strains

(from

0.07to0.25)

in three typical steels. Ther(et)

curvewas derived in that range of deformation from the observed quasi-linear relationshipbetween eland

ew.

It

isobvious(from Eq.

(9))

that thea parameter, which was found to be generally positive in the case ofinhomogeneous yielding andclosetozeroin mostcasesofhomogeneous

yielding,depends

ontheshape

of ther(el)

curve. The elastic r-value is also displayed, but it is clear that theelasto-plastic transitiondoes not account for thevariation in

r(el)

observed.As

expected from

Eqs (9)

and(10),

the conventional r approaches the regression r asymptoticallyat highstrains.The non-zero value of a obtained even in the case of homogeneous yielding suggests that the -e, vs el plots are curved between 0 and 15% longitudinal strain

(as

showninFigure 1, theyhavetopass throughtheorigin). Thistransition behaviour can be relatedtotherapid changesin grainorientation that takeplace asthe ),-type fibertexture ispartially destroyedand thetexture evolvestowardsastable configuration. Most of the measurements show positive a-value, which correspondsto adownwardcurvature of thefirstpart of the

--eq

VS elandisalsoassociatedwith adecrease in r.

In

most cases of inhomogeneous yielding, the conventional r-value decreases asymptotically with strain(a >0)

(Arthey

et al., 1981;Hu,

1983; Lake et al.,1988).

Thequestiontherefore arises about the effectof Liidersbandpropagation on the evolution of r-value during straining. The initial stages of plastic deformation, corresponding to Liiders band propagation, are in plane strain. After passage ofthe band, further deformation takes place by uniaxial tension.The first strain path involves lateral constraint and does not result from pure

uniaxial loading; accordingly, two different r-valuesare displayed by thesample

in the course of deformation. Liiders propagation leads to lengthening

perpen-dicular to the front, which is generally inclined at 50 to the tensile direction. Consequently

e

ande

(positive) are nearly equal and rLiider is ---0.5. Following propagation of the band, the rate ofchange ofr ismostrapid during the firstfewpercent

of deformation(see

theexamplesofthe HSLA and AKDQ steels inFigure3).

Thecase ofinhomogeneous yieldingisshownschematicallyin Figure 4. Thus, as in homogeneous deformation, positive a is seen to be associated with back extrapolation from a linear fit to data obtained at larger strainswhenrisdecreasing.No clear quantitative relation can be derived between rel and

r(e)

because ofthe complex phenomena involved in yielding and in the propagation of Liiders

bands. Qualitatively, all the samples studied are represented by the three cases

displayedinFigure 3. It appearsthatwhenrpl tendstoavaluelargerthan 1.5, r! issystematicallyless thanrpl (Figure

3c).

Figure 3a illustrates thecase whererp

isconventional

TextureI

:.

rpl

effect regressionrpl

1

rLiiders

lr,gure4 Schematic illustrationof theevolutionofrin caseof inhomogeneous yielding.

less than 1 and the corresponding r.,isgenerallygreater than

rp,.

The elastic andplastic r’s are approximately equal when

rp,

tends to a value between 1 and 1.5(Figure

3b).

These differences were not found todepend

on the type of yielding behaviour.c. Planarvariation

of

r.,andr,

In

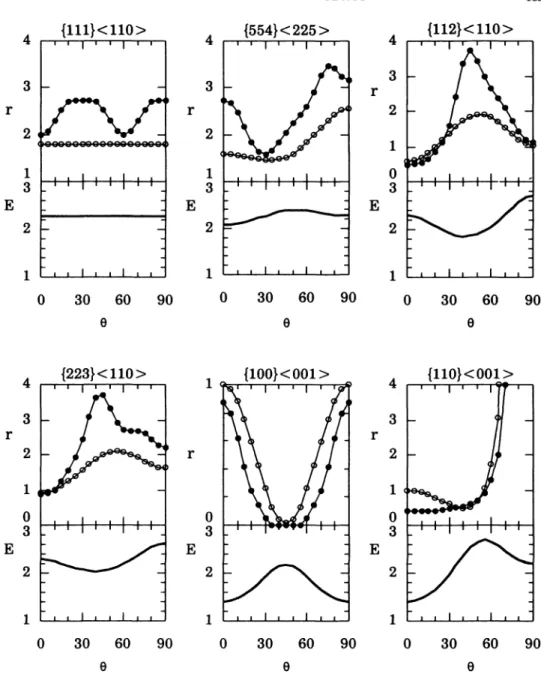

Figure 5, the angular variation of the elastic and plastic strain ratios arepresentedwhichpertaintothemain idealorientationsobservedexperimentallyin

steel sheets. These textures were simulated using a gaussian type of orientation distribution so as to account for the normally occurring misorientation of

individual grains with respect to an ideal orientation.

A

15 gaussian spreadwasemployed. The

rp,(0)

results were calculated using a relaxed constraint(RC3)

model, with bcc deformation taking place by mixed

{110}

{112}

(111)

glidewith

CRSS’s

onthetwo setsofsystems suchthat Z’(1120.95Z’(11o

(Daniel,

1990;Daniel and

Jonas,

1990). Young’s

modulus data are also included since this quantity was used by Stickels and Mould(1970)

to establish their empiricalcorrelation with r-value.

As expected,

E(O)

andre,(O)

display oppositedepend-ences on 0.

It

is of interest that there,(0)

curves follow the general tendenciesdisplayed by the

rp,(0)

curves, eventhoughit wasshown above thatrp,

andre,arenot proportional alonga given 0 direction. Figure 5 also shows that re, isalways significantlyless thanrpi, exceptforcomponents Or specificdirectionsalongwhich

rp

is less than 1. This can be related to the observations made aboveregarding Figure3.{111}<110>

0 30 60 90 E 3 0 3 E 1 1{112}<110>

I

t

0 30 60 90 0 30 60 90o

0 0 3 0 3E

{223}<110>

{100}<

001>{110}<

001> 4 3 r 2 1 2 1 0 30 60 90 0 30 60 90 0 30 60 90 0 0 0$ Predictionsofrp,(0)bytheRC model(0)and ofre,(O bythe Hill approximation(O)for common texture components composed of a gaussian spread of 15 around the respective ideal orientation.ThedependenceE(O)isalsoindicatedfor comparisonpurposes.

Figure6

compares

r,(0)

andrp,(O)

for four of the steels studied.In

thecase of the low drawability steels(i.e. RIM

andHSLA),

the elastic and plastic strainratios are inrelatively

good

agreement.However,

for theIF

and AKDQ grades,the

r(O)

andrpl(0)

curves display similar tendencies, but without quantitative0 30 60 90 0

AKDQ

0 3O 60 90 0HSLA

0 30 0 60 90 0 30 60 90 0Hillapproximation(---)withthe experimental data x).

Comparisonofrp,(0)calculatedfrom theRC model()andre,(O determinedfromthe

d. Empiricalcorrelations

between/el

andrp,

The results described above suggested that it would be of interest to derive empirical correlationsbetween theanisotropiesofthe elastic andplasticr-values. Such analyseswere carried out in the past using

Young’s

modulus(Stickels

andMould,

1970)

or the ultrasonic velocities(Bussi6.re

et al.,1987). However,

itappears

thatre, isphysically more relevant sinceit characterizesthe resistance to thinningin the elasticrange

of deformation much as r# typifies it for the plastic range.The empirical correlationsbetween the values of elastic andplastic

,

Ar

and6r(=r(90)- r(0))

are illustrated inFigure7.(6r

representsthe tendencytoform two-foldears.)

No

detailedregression analysiswas carried outdue tothe limited number ofsamples. Qualitatively, it can be concluded that the dispersion of the datais withintheexperimentalerror(+0.1

inrp,),

indicatingthat theelastic strain ratio, readily measured ultrasonically(i.e.

non-destructively), can be used toestimate the plastic one with the same accuracy as in the Stickels and Mould

1.8 elastic 1.4 1.2 .5 1.5 2 2.5 plastic .5 elastic -.5 -.5 0 .5

Ar

plastic .5 .4 elastic 0 0 .2 .4 .6 .8r

plasticFigure 7 Correlation between the elastic and plastic i, Ar and 6r. The plastic quantities are

experimental data and theelasticones were calculated fromultrasonicdata.

5.

CONCLUSIONS

Analysis of the evolution of

rp=

during conventional tensile deformation shows that the changes in rpt are not related to the elastic-to-plastic transition.Nor

isLiidersbandpropagation responsiblefor the increaseordecreasein

rp

observed.It appears

instead that thevariations inrp=

are due totexture evolution, which is in turn responsible for non-zero values of a in the case of homogeneousdeformation.

As a result of the rapid initial evolution of

rp,

theback-extrapolated

conventionalvalue whena

>

0(and

rp

isdecreasing), andlower whena<

0(and

rp

isincreasing).For

plastic r’s greaterthan 1.5,re

issystematicallyless thanrp;

this difference decreases when theplasticrisless than 1.5,and becomes negative when

rp <

1.This study shows that the elastic strain ratio can be readily determined from

ultrasonic measurements. The

re(O)

andrp(0)

curves displaysimilar tendencies.So,

the elasticr, determinednondestructively, can be usedto estimate itsplastic counterpart with the aid of empirical relationships. Such correlations are physically better based than the ones relating r-value toYoung’s

modulus orultrasonic velocity.

ACKNOWLEDGEMENTS

The authors are indebted to Prof.

J. Szpunar

of McGill University for assisting with the texture measurements. They are grateful to the Kawasaki SteelCorporation, Stelco Steel

Inc.,

DofascoInc.

and the Algoma Steel Corporationforsupplyingsteel sheets. They acknowledgewith gratitude thefinancial support received from the Canadian Steel Industry Research Association, the Natural Sciences and Engineering Research Council of Canada, and the Ministry of Education ofQuebec

(FCAR

program).

References

Arthey,R. P. and Hutchinson,W. B.(1981).Metall. Trans., 12A, p. 1817.

Bunge,H.J. (1974).Kristall Tech., 9, p.413.

Bunge,H. J.(1982).TextureAnalysisin MaterialsScience, Butterworths, London.

Bussi6re,J.F.,Jen, C.K.,Makarow,I.,Bacroix,B., Lequeu,Ph. andJonas,J.J.(1987).Proc.2rid

Int. Syrup. onNondestructive CharacterizationofMaterials, Montreal,July 21-23, 1986,Ed.by J.

F.Bussi6reetal., PlenumPress,NewYork,p. 523.

Daniel,D.(1990).PhD Thesis,McGillUniversity, Montreal,Canada.

Daniel,D.andJonas,J. J. (1990).Metall. Trans.,21A,p.331. Daniel,D.,Sakata,K.andJonas,J. J. (1991). Trans. ISIJ,31,p.696.

Hill,R. (1948).Proc.Roy. Soc. London, Ser.A, 193, p.281.

Hirao,M., Hara,N. and Fukuoka,H.(1988).J. Acoust.Soc. Am.,Ikl,p.667.

Hirao,M.,Fukuoka,H.,Fujisawa, K.andMurayama, R. (1989).Metall. Trans.,?,0A,p.2385.

Hu, H. (1983).Metall. Trans., 14A, p. 1521.

Lake,J. S.H.,Willis, D. J.and Fleming,H. G. (1988).Metall. Trans., 19A,p.2805. Lankford,W. T.,Snyder, S. C. andBauscher, J.A. (1950). Trans. ASM, 42, p. 1197. Liu,Y.C.(1983).Metall. Trans., 14A, p.1199.

Liu,Y. C.andJohnson,L. K.(1985). Metall. Trans., 16A,p. 1531.

Sakata, K.,Daniel,D.,Jonas,J. J.andBussi6re, J.F. (1990).Metall. Trans., 21A, p.697.

Sayers,C. M.(1982).J. Phys., D15,p.2157.

Stickels,C.A. andMould,P. R.(1970).Metall. Trans., 1A, p. 1303.

Thompson, R. B., Lee, S. S. and Smith, J.F. (1987). Ultrasonics, 25,p.133.

Thompson, R.B.,Smith, J.F.,Lee, S. S.andJohnson,G. C.(1989). Metall. Trans., 20A, p.2431. Welch,P. I.,Ratke,L.andBunge,H. J. (1983).Z. Metallkde, 74, p. 233.