Development and validation of a dynamic material flow analysis model for French copper cycle

Texte intégral

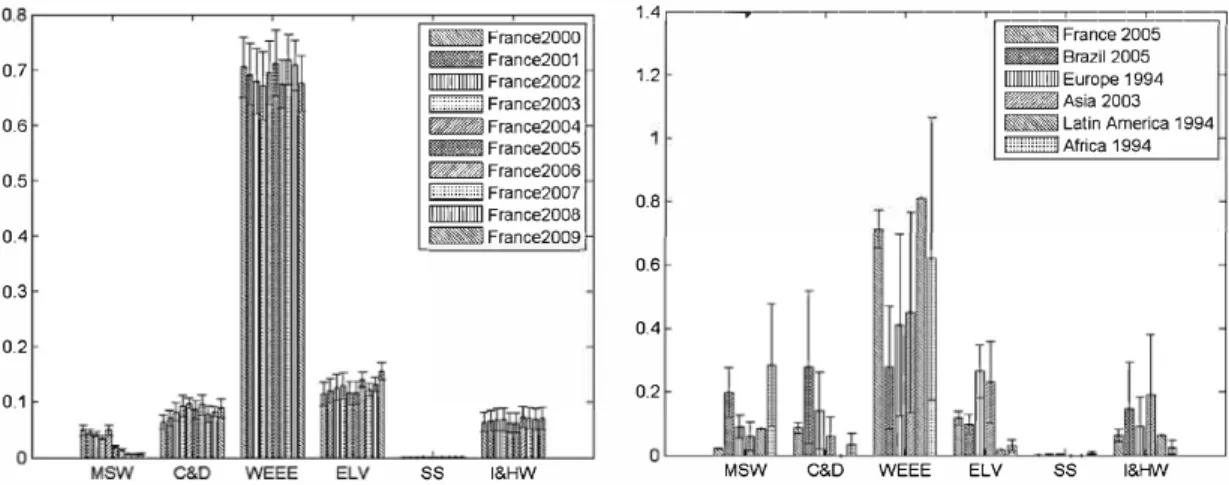

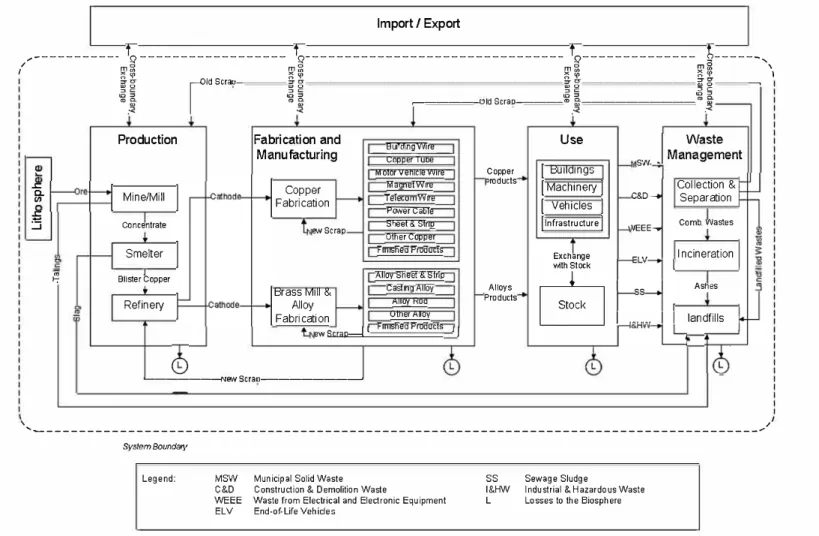

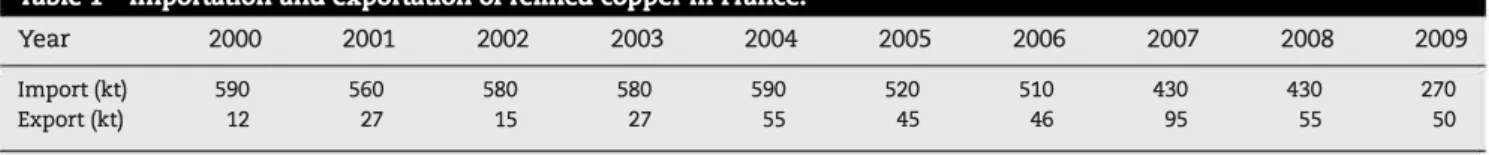

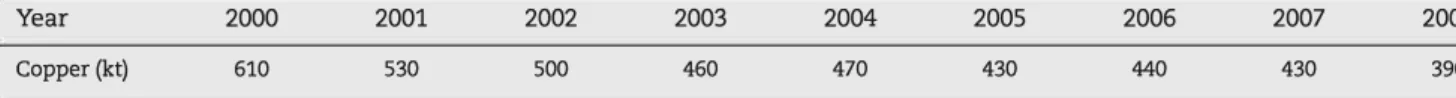

Figure

Documents relatifs

This technique was developed from juvenile seedling material and rejuvenated clonal material by reiterated grafting on young seedling or somatic embryogenesis (Carron , 2003)..

Indeed, the three types (metal casing, black plastic casing and white plastic casing EM) are very different in terms of

The electrical resistivity of different materials (stainless steel, Cu coating) were measured in the range 4.2 K – 300 K. The RRR of Cu coating was deduced from these data: 1) for

Since BIM contains all the information about materials and components with numer- ous life-cycle related data, such as material properties, geographic information, quantities,

With the energy and power data of the sub processes, the total printing energy is calculated from the printing operation list which correlates to the part geometry,

The results show the need for a multi-scale approach as urban life in Paris depends on the suburbs; the consequence of both concentration of activities in the

To verify the relevance of the proposed indicator (Equation 9), predictions drawn from the clustering indicator are compared to the cracking patterns obtained through

We examine the effects of metal price, metal concentration in products, relative concentration ratio (i.e., primary vs. secondary supply), and embodied metal value on the