Microstructural-based analysis and modelling of the fatigue behaviour of cast Al-Si alloys

Texte intégral

Figure

Documents relatifs

On the right side of the photo, the grain traces are clearly observed, whereas after the point 1 (Figure 6b), the fracture surface appearance change, change which is attributed to

The reasons for the outstanding performance of AI-Li alloys are manifold. It is argued that part of the improved crack growth resistance can be attributed to the

The opening normal stress applied to the slip band is not then relaxed by plastic deformation on secondary slip systems and remains very high, 1121 leading to the crack

From a scientific point of view the crack extension during the delay stage ad, the crack growth rate during the retardation stage (da/dN)D, the AKeff value after

The model predicts the evolutions of the plastic intensity factor under variable amplitude and non-proportional mixed mode conditions, and the plasticity rates pre- dicted by

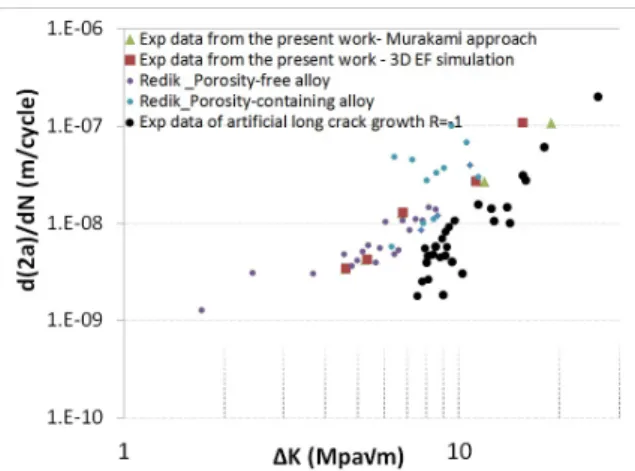

The fact that specimens with artificial internal defects and those with surface artificial defects cycled in vacuum (no Region I) fall on the same curve tends to indicate that, for

The fatigue crack growth rate (FCGR) is shown as a function of crack length a, for tubular specimen with a horizontal notch and crack growth curves are shown in Fig.. A very

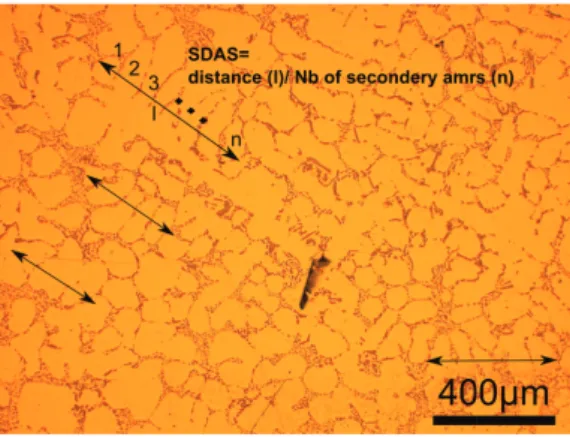

Quantitative analysis of the crack path was performed by characterizing the main crack and observing its interactions with different phases present in the