HAL Id: tel-00084018

https://tel.archives-ouvertes.fr/tel-00084018

Submitted on 5 Jul 2006

HAL is a multi-disciplinary open access

archive for the deposit and dissemination of sci-entific research documents, whether they are pub-lished or not. The documents may come from teaching and research institutions in France or abroad, or from public or private research centers.

L’archive ouverte pluridisciplinaire HAL, est destinée au dépôt et à la diffusion de documents scientifiques de niveau recherche, publiés ou non, émanant des établissements d’enseignement et de recherche français ou étrangers, des laboratoires publics ou privés.

AMELIORATION DES PERFORMANCES DES LASERS A CASCADE QUANTIQUE - ETUDE DU CONFINEMENT OPTIQUE ET DES PROPRIETES

THERMIQUES

Jean-Yves Bengloan

To cite this version:

Jean-Yves Bengloan. AMELIORATION DES PERFORMANCES DES LASERS A CASCADE QUANTIQUE - ETUDE DU CONFINEMENT OPTIQUE ET DES PROPRIETES THERMIQUES. Physique Atomique [physics.atom-ph]. Université Paris Sud - Paris XI, 2005. Français. �tel-00084018�

Amélioration des performances des Lasers à Cascade Quantique :

Étude du confinement optique et des propriétés thermiques

Thèse effectuée à Thales Research & Technology (TRT) à l’Université de Paris VII

J-Y Bengloan

Performance optimisation of Quantum Cascade Lasers:

Investigation of the optical confinement and thermal properties

J-Y Bengloan

Thèse effectuée à Thales Research & Technology (TRT) Thèse de doctorat de l’Université de Paris XI – Sud (Orsay)

3

PLAN

1. Introduction

2. Waveguide Optimisation in GaAs/AlGaAs QCLs

GaAs based guides (plasmon enhanced) / Limitations AlGaAs and GaInP Guides

3. Enhancement of thermal dissipation properties of GaInAs/AlInAs/InP

QCLs

Selective current injection by proton implantation Thick electro-plated gold

Quantum Cascade Lasers (QCLs)

• INTERSUBBAND transitions

• UNIPOLAR : only one type of carrier used (e-)

Main Properties

Main Properties

hν e -CB Distance (z) Energy5

45 nm

Quantum Cascade Lasers (QCLs)

Active Region (AR) grown by Molecular Beam Epitaxy (MBE)

"MINIGAP"

Transport zone Emission zone

3 2 1

e

-"MINIBAND" "MINIGAP"Transport zone Emission zone

3 2 1

e

-e

-"MINIBAND" • CASCADE scheme : Recycling of carriersSpectral range of QCLs

InP/GaInAsP Wavelength (µm) 0 5 10 15 20 25 100 0.5 1 1.5 2 Classic Laser DiodesGaN/AlInGaN GaAs/GaInAsGaAs/AlGaInP

GaSb PbSe (cryo)

UV Near IR

THz

Mid IR Far IR

Quantum Cascade Lasers

GaInAs/AlInAs/InP ; GaAs/AlGaAs ; InAs/AlSb

3.5 µm < λ < 24 µm and λ> 65 µm

Applications:

• Spectroscopy and high sensitive Gas detection Environmental, Medical, Security

• Free space optical communication

7

QCL History

1994 QCL in GaInAs/AlInAs/InP QCL in GaAs/AlGaAs 2003 1998 2002 QCL in InAs/AlSb Room temperature CW operation for GaInAs/AlInAs/InP QCL 2005 150K CW operation QCL in GaAs/AlGaAs QCL 400mW room temperature CW operation for GaInAs/AlInAs/InP QCL CW: Continuous WaveFrom intersubband emission

to CW laser operation

First Laseroperation operationFirst CW

Pulsed operation CW operation Gain optimisation

78K

78K 78K 300K

Waveguide design optimisation

Thermal management Quantum engineering of Active Region

9

Thesis S.Barbieri - C.Becker

From intersubband emission

to CW laser operation

First laseroperation operationFirst CW

Pulsed operation CW operation Gain optimisation 78K 78K 78K 300K InP-based QCL 1994 (Bell Labs) 2002 (Neuchâtel) 1995 (80K) (Bell Labs)

Waveguide design optimisation

Heat dissipation management Quantum engineering of Active Region

1998

(Thales)

GaAs/AlGaAs

QCL 2000 (30K)(TU Wien)

Waveguide design optimisation

PLAN

1. Introduction

2. Waveguide Optimisation in GaAs/AlGaAs QCLs

GaAs based guides (plasmon enhanced) / Limitations AlGaAs and GaInP Guides

3. Enhancement of thermal dissipation properties of GaInAs/AlInAs/InP

QCLs

Selective current injection by proton implantation Thick electro-plated gold

11

Pulsed operation QCL devevopment:

Reduction of the threshold current density J

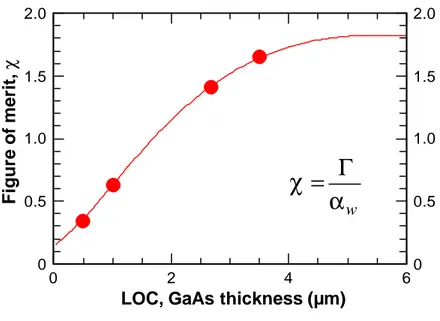

thJth = (αwg+ αm) / g Γ QCL J AR J Optical power Jth

Waveguide design optimisation : αwg, Γ Quantum engineering of Active Region : g

0 5 10 15 20 25 1998 2000 2002 year J th (kA/cm²) 300K 78K GaAs based QCL

Waveguide principle

n2 > n1≥n3 n1 n3 Cladding n2 Core n1 Cladding n2Guiding condition : n

1> n

2Increase figure of merit

χ= Γ / α

wWaveguide optimisation by numerical simulations :

• 1D Simulations : Transfer Matrix Method (TMM)

choice of

appropriate layer

compositions and

thicknesses

Decrease

J

th=(

α

w+α

m)/g

Γ

13

Current GaAs QCL waveguides (1)

GaAs Plasmon enhanced waveguide with highly doped cladding layers

neff=3.19 α = 17 cm-1 Γ = 28% λ = 9.4µm

χ= 1.7

J

th=15kA/cm

2 Distance (µm) -12 -10 -8 -6 -4 -2 0 0 0.2 0.4 0.6 0.8 1Optical intensity (a.u.)

0 2 4 6 8 10 Refractive index AR n+ n+ GaAs GaAs n- n -èAdvantages

l straight-forward MBE growth l good electrical characteristics

èDrawbacks

l free carrier absorption (FCA) losses

Vertical dimension (µm) -12 -10 -8 -6 -4 -2 0 0 0.2 0.4 0.6 0.8 1

Optical intensity (A.U.)

0 2 4 6 8 10 Refractive index Active Region LOC LOC Plasm. Plasm.

Normalised optical intensity

(a.u)

Distance (µm)

Refractive

index

LOC=0,5; α=177cm-1; Γ=63%; χ=0,4

Normalised optical intensity

(a.u)

Distance (µm)

Refractive

index

LOC=1; α= 92,5 cm-1; Γ=58%; χ=0,6

Normalised optical intensity

(a.u)

Distance (µm)

Refractive

index

LOC=2,6; α=25 cm-1; Γ=35%; χ=1,4

Normalised optical intensity

(a.u.) Distance (µm) Refractive index LOC=3,5 ; α=17cm-1; Γ=28%; χ=1,7 0 0.5 1.0 1.5 2.0 0 2 4 60 0.5 1.0 1.5 2.0

LOC, GaAs thickness (µm)

w α χ = Γ

Figure of merit,

χ

Current GaAs QCL waveguides (2)

The χ optimisation is a trade-off between : • Γ, decreasing with the GaAs thickness

15

Dielectric waveguide optimisation

NECESSITY TO REDUCE OPTICAL LOSSES FROM CLADDINGS

è Plasmon enhanced waveguide

strengthened by dielectric layers :

q

AlGaAs layersq

GaInP layers -12 -10 -8 -6 -4 -2 0 0 0.1 0.2 0.3 -12 -10 -8 -6 -4 -2 0 2 2.5 3 3.5 hGaAshDIEL Refractive index

Distance (µm)

Normalised optical intensity (

a.u

)

AR

n+ n+

DIELECTRIC

DIELECTRIC Maximum growth thickness ~10µm

1 2 3 4 0 1 2 3 0 1 2 3 Figure of merit, χ hGaAs(µm)

−

x=20%−

x=36%−

x=70%−

x=94% hAlGaAs(µm) GaAs waveguide -12 -10 -8 -6 -4 -2 0 0 0.1 0.2 0.3 -12 -10 -8 -6 -4 -2 02 2.5 3 3.5 hGaAshAlGaAs Refractive index

Distance (µm)

Normalised optical intensity (

a.u. ) AR n+ n+ AlGaAs AlGaAs

Al

xGa

1-xAs cladding waveguides

With xAl Þ:⇒

∆nGaAs/AlGaAsÞ⇒

Γ Þ17

Al

xGa

1-xAs cladding waveguides

-12 -10 -8 -6 -4 -2 0 0 0.1 0.2 0.3 -12 -10 -8 -6 -4 -2 02 2.5 3 3.5 hGaAshAlGaAs Refractive index

Distance (µm)

Normalised optical intensity (

a.u ) AR n+ n+ AlGaAs AlGaAs

Limitations : lattice mismatch constraint â Al

xGa

1-xAs thickness limit ~1/x

Al!

1 2 3 4 0 1 2 3 0 1 2 3 Figure of merit, χ hGaAs(µm)−

x=20%−

x=36%−

x=70%−

x=94% hAlGaAs(µm) GaAs waveguide With xAl Þ:⇒

∆nGaAs/AlGaAsÞ⇒

Γ ÞAl

0.94Ga

0.06As cladding waveguides / QCL AL94

χ=2.9

è Jth ~2 times smaller than that of the GaAs plasmon enhanced waveguide.

Al0.94Ga0,06As cladding waveguide

Normalised optical intensity

(a.u.) Distance (µm) Refractive index α=12cm-1; Γ=35%; χ=2,9 20 µm I H+implantation (insulating)

2 devices grown and processed identically: èGaAs : GaAs waveguide

èAL94 : Al0.94Ga0.06As waveguide

• Identical 3 quantum-well AR ( same growth set ) • Double trench ridge devices

• H+ implanted for selective current channelling • Low duty cycle to avoid device heating

19 0 0.2 0.4 0.6 0 5 10 15 20

Optical peak power (W)

Current density (kA/cm²)

200K 240K 200K 240K 300K

−

AL94 − −GaAsQCL AL94

5kHz-100nsGood optical performances for QCL AL94:

è Significant reduction of Jth

è Agreement with simulations:

Jth(GaAs) / Jth(AL94) ≅ χ(AL94) / χ(GaAs)≅ 2 è Higher optical peak power

0 0.2 0.4 0.6

0 5 10 15 20

Optical peak power (W)

Current density (kA/cm²)

200K 240K 200K 240K 300K

−

AL94 − −GaAsQCL AL94

5kHz-100nsGood optical performances for QCL AL94:

è Significant reduction of Jth

è Agreement with simulations:

Jth(GaAs) / Jth(AL94) ≅ χ(AL94) / χ(GaAs)≅ 2 è Higher optical peak power

è 300K operation 0 5 10 15 20 25 30 0 1 2 3 4 5 T=240K Bias (V) Current (A)

−

AL94 − − GaAsPoor electrical characteristics for QCL AL94:

è Abnormally high knee: Vc=14V (Vc(GaAs)=5V)

Bad ohmic contacts?

Bad grading between GaAs and AlGaAs layers?

è Higher differential resistances

3x higher for AL94 device compared to GaAs QCL

21

Al

0.36Ga

0.64As cladding waveguides

Electrical conductivity better than Al0,94Ga0,06As layers:

better e- mobility lower effective mass

Al0.36Ga0.64As cladding waveguide

χ=2,5

Norm. optical intensity (

a.u. ) Refractive index Distance (µm) α=15cm-1; Γ=37%; χ=2,5 1 2 3 4 0 1 2 3 0 1 2 3 Figure of merit, χ hGaAs(µm)

−

x=20%−

x=36%−

x=70%−

x=94% hAlGaAs(µm) GaAs waveguideQCL AL36

5kHz-100ns

Good optical performances for QCL AL36:

è Jth significantly lower than Jth(GaAs) è Jth slightly higher than Jth(AL94)

è Higher optical peak power Pmax(AL36)=250 mW at 300K

Electrical characteristics dependant on the temperature:

è Higher differential resistances

èdV/dI= f (T) for AL36 QCL: Eact=132meV è High operating voltage for T<260K

0 10 20 30 40 0 2 4 240K Bias (V) Current (A) AL94 AL36 GaAs 260K 280K 300K 0 0.2 0.4 0.6 0.8 0 5 10 15

Optical peak power (W)

Current density (kA/cm²)

−

240K−

300K AL94 AL94 AL36 AL3623

Ø Ga0.51In0.49P refractive index ≅ Al0.45Ga0.55As refractive index

è Good ∆nGaAs/GaInP for improved confinement: χ=2,9

Ø Good electrical conductivity

Ø Ga0.51In0.49P : lattice matched to GaAs

è no thickness limitation

Ga

0.51In

0.49P cladding waveguides

Drawback : Ga0.51In0.49P re-growth by MOVPE at Thales χ=2,9 è growth in 3 stepsNorm. optical intensity (

a.u ) Refractive index Distance (µm) MBE MOVPE MOVPE α=13cm-1; Γ=38%; χ=2,9

QCL GaInP

5kHz-100ns

Good optical performances for QCL AL36:

è Jth significantly lower than Jth(GaAs) è Jth(GaInP) higher than Jth(AL36)

è High optical peak power at 78K Pmax(GaInP)=1,9W at 78K

è Optical peak lower than QCL AL36 at RT Pmax(GaInP)=150 mW at 300K 0 0.2 0.4 0.6 0.8 0 5 10 15 20

Optical peak power (W)

Current density (kA/cm²)

−

240K−

300K GaInP AL36 AL36 GaInP 0 0.5 1.0 1.5 2.0 0 5 10 15 20Optical peak power (W)

Current density (kA/cm²)

GaAs GaInP

−

GaInP− − GaAs

25

QCL GaInP

5kHz-100ns

Electrical characteristics :

è Higher knee bias: Vc=7V (Vc(GaAs)=5V)

è Lower differential resistance than AL36 è Higher operating voltage than GaAs

0 5 10 15 0 1 2 3 4 Bias (V) Current (A) GaInP AL36 GaAs T=300K 0 0.2 0.4 0.6 0.8 0 5 10 15 20

Optical peak power (W)

Current density (kA/cm²)

−

240K−

300K GaInP AL36 AL36 GaInPGood optical performances for QCL AL36:

è Jth significantly lower than Jth(GaAs) è Jth(GaInP) higher than Jth(AL36)

è High optical peak power at 78K Pmax(GaInP)=1,9W at 78K

è Optical peak lower than QCL AL36 at RT Pmax(GaInP)=150 mW at 300K

Reduction of threshold current densities:

è Low Jth

è Agreement with our predictions for AL94 and AL36:

Jth(GaAs) / Jth(Diel.)≅ χ(Diel.) / χ(GaAs)

Summary of laser performances

Better Wall-Plug efficiencies than LCQ GaAs

èWP(GaInP)=1%= 10xWP(GaAs) at 240K 0 0.2 0.4 0.6 0.8 1.0 0 1 2 3 4 5 Current (A) Wall -plug efficiency (%)

−

−

GaInPAL36−

AL94−

GaAs T=240K 0,1%Best waveguide device :

Best QCLs : QCL AL36 for T> 250 K Electrical degradations

>

Optical performances improvements 0 2 4 6 8 10 12 14 100 200 300 Jth (kA/cm²) T (K) GaAs GaInP AL36 AL94•

•

•

•

10kA/cm² 1%27

Waveguide loss measurements

0 5 10 15 20 -20 -10 0 10 20 αm (cm-1) Jth (kA/cm²) 300K 240K 180K 150K 78K

Waveguide losses αw determined from

Jth=f(αm) plot: Jth=(αm+αw)/gΓ αw=21cm-1 αw=12cm-1 QCL GaInP 21 cm-1 12 cm-1 GaInP 19 cm-1 -AL36 -20 cm-1 GaAs

α

w T≥180K T<180K Reduction of αw at low temperature compared to QCL GaAs αw increase at T ≥ 180K0 200 400 600 0 20 40 60 Energie (meV ) 3 2 1

Gain coefficient

Carrier leakage into the continuum ? Observation of 2 operating regimes

g ∝ τ3 ∝ exp(Eact/kT)

∆Eact=58meV

Carrier leakage into the continuum

Limitation of the conduction band discontinuity of GaAs/AlGaAs for room

temperature operation Jth=f(αm) plot _ gΓ =f(T) 2 4 6 8 0.002 0.004 0.006 0.008 0.010 0.012 g. Γ (cm / kA ) 1 /T (K-1) Eact=57.7meV Eact=53.2meV GaInP AL36

•

•

Arrhenius diagram29

Waveguide study conclusion

Best performances (Jth, Pmax) on GaAs-based QCLs

Limitation from the conduction band discontinuity of

GaAs/AlGaAs underlined for room temperature operation

Application of these waveguides on a bound-to-continuum AR QCL Significant reduction of Jth 0 5 10 15 20 25 1998 2000 2002 2004 2006 year J th (kA/cm²) 300K 78K GaAs based QCL

Degradation of the electrical transport

PLAN

PLAN

1. Introduction

2. Waveguide Optimisation in GaAs/AlGaAs QCLs

GaAs based guides (plasmon enhanced) / Limitations AlGaAs and GaInP Guides

3. Enhancement of thermal dissipation properties of GaInAs/AlInAs/InP

QCLs

Selective current injection by proton implantation Thick electro-plated gold

31

Application to InP-based QCLs

Minigap Miniband 1 2 3 4 Electron injection Electron extraction Miniband MinigapBeck et al., Science 295, 301, (2002)

Active Region: λ~9µm

4 Quantum Wells

Vertical Waveguide Structure: χ~12 Γ~69% α~6 cm-1

Normalised optical intensity

(a.u. ) Refractive index Distance (µm) AR n+ InP substrate InP

No lateral heat dissipation

Standard ridge waveguide

Good lateral heat flow

Buried heterostructure

InP InP based QCLsHeat management in QCLs

InP InP H+ implantationSelective current injection

33

Selective current injection

Lateral mode profile

W D Distance (µm)0 3 7 -7 -3 Intensity (a.u.)

0,5

14

6

D

W

≈

=

For

H+ implantation W DSemi-insulating layers using proton implantation

decrease electrically pumped area

⇒

Pumped area (A)

à

: -50%

⇒

Mode overlap (

Γ)

à

: -20%

⇒

J

th∝ 1/

Γ

Þ

: +20%

⇒

I

th= J

thx A

à

: -40%

Selective current injection in InP QCLs:

L-I-V pulsed characteristics

2 4 6 8 1 0 0 0.1 0 .2 0.3 0 .4 0.5 0 .6 0.7 0 .8 0.9 1 .0 0 1 2 3 4 5 6 7 8 0 0 .1 0 .2 0 .3 0 .4 0 .5 Voltage (V) Optical Power (W ) Current (A) T=78K

Current Density (kA/cm2)

5KHz - 100ns 0 2 4 6 8 10 0 0.5 1.0 1.5 0 1 2 3 4 5 6 7 8 9 10 11 12 0 0.1 0.2 0.3 0.4 0.5 Voltage (V) Optical Power (W ) Current (A) 320K 240K 260K 280K 300K

Current Density (kA/cm2)

@78K: Ith=135 mA, Jth=1,1 kA/cm² @300K: Ith=500 mA, Jth=4,3 kA/cm²

35 0 1 2 3 4 5 6 7 100 200 300 J th (kA.cm -2) T (K) T0=93K

T

0characteristics

T0 : Characteristic temperature from fit : Jth= Jth0 . exp(T/T0)LEAKS LEAKS 0 1 2 3 4 5 6 7 100 200 300 J th (kA.cm -2) T (K) T0=177K T0=93K InP without H+ InP with H+

•

•

SiO2 (Insulator) n-InP Contact (Gold)Standard ridge waveguide

Low T0

H+

Current leakage – implantation breakdown

Ileaks LCQ LCQ Active Region 0.1 0.2 0.3 100 2 00 30 0 10 20 50 Normalised resistance ( Ω .cm 2 ) Temperature (K) Resistance ( Ω ) Tact=1023K Eact=86meVH

+implantation creates shallow defects in n-doped InP material

H

+implantation

works well in

GaAs but not

in n-InP

E

cE

vGaAs

E

cE

vn-InP

37

Selective current injection for InP-based QCLs ?

Selective current injection by H+ implantation inefficient in InP-based QCLs

Fe doped InP

Future : use of Fe-doped InP as insulating layer - Deep defects in InP bandgap

CW operation for H

+implanted InP-based QCLs

4 6 8 10 0 0.2 0.4 0.6 0.8 1.0 1.2 0 100 200 300 400 Tension (V) Optical power ( mW ) Current (A) CW T = 78K 0 20 40 60 0 0.2 0.4 0.6 0.8 1.0 1.2 Optical power ( mW Current (A) CW 0°C 10°C 20°C 350 mW 18 mW 20°CHigh Temperature CW operation

even with current leakage

39

Electroplated Gold (Au) devices

24 µm Gold 20 µm SiO2

epi down

epi up

epi up

epi down + mirror

4 experimental arrangements:

Without Au With electroplated Au

L1 L2 L3 L4

Electroplated Au Device

Very good heat dissipation device

Best performances obtained on QCLs with this type of device Slivken et al, APL (2004)

Effect of Thick electroplated Au

0 50 100 150 200 0 10 20 30 40 50 60 70 Average optical power (mW) Duty cycle (%) T=10°Cepi up

L1P

max= 49mW for DC=12%

L1

41

Effect of Thick electroplated Au

0 50 100 150 200 0 10 20 30 40 50 60 70 Average optical power (mW) Duty cycle (%) T=10°C

epi up

L1 L2P

max= 49mW for DC=12%

L1

P

max= 78mW for DC=25%

L2

Effect of Thick electroplated Au

0 50 100 150 200 0 10 20 30 40 50 60 70 Average optical power (mW) Duty cycle (%) T=10°Cepi down

L1 L2 L3L1

P

max= 49mW for DC=12%

P

max= 102mW for DC=37%

L3

P

max= 78mW for DC=25%

L2

43

Effect of Thick electroplated Au

0 50 100 150 200 0 10 20 30 40 50 60 70 Average optical power (mW) Duty cycle (%) T=10°C

epi down

+ mirror

L1 L2 L3 L4P

max= 49mW for DC=12%

L1

P

max= 175mW for DC=40%

L4

P

max= 102mW for DC=37%

L3

P

max= 78mW for DC=25%

L2

Thick electroplated Au - Summary

epi down

+ mirror

epi down

epi up

epi up

L4

L3

L2

L1

R

th(K.cm/ W)

6

2,9

1,8

1,8

-50%

~ -40%

Buried Heterostructure

(Beck et al, Science295, 2002)

45

Thick electroplated Au - Summary

epi down

+ mirror

epi down

epi up

epi up

L4

L3

L2

L1

R

th(K.cm/ W)

6

2,9

1,8

1,8

Max. CW

temperature

_

130K

240K

278K

Buried Heterostructure

(Beck et al, Science 2002)

PLAN

PLAN

1. Introduction

2. Waveguide Optimisation in GaAs/AlGaAs QCLs

GaAs based guides (plasmon enhanced) / Limitations AlGaAs and GaInP Guides

3. Enhancement of thermal dissipation properties of GaInAs/AlInAs/InP

QCLs

Selective current injection by proton implantation Thick electro-plated gold

47

Conclusion

Use these waveguide on a bound to continuum structure

Thick electroplated Au on selective current injection devices

Breakdown of selective current injection (H+ implanted layers) in InP-based QCLs Significant performance improvements realised in GaAs-based QCLs owing

to waveguide optimisation

Application of Fe-doped InP layer

Significant thermal improvements realised with thick electroplated Au Rth close to that of buried heterostructure

Mid IR QCL Material ?

0 5 10 0 5 10 15 200 0.5 1.0 Voltage(V)Optical peak power (W

)

REF_GaAs

J (kA/cm2)

InP

T=78K GaAs has an intrinsic lower gain than GaInAs (m*>m*)

Increase in Jth Ioperation(Small dynamic current range)

Higher doping in the active region and the claddings Higher losses

49

Which material for which wavelength ?

0 100 200 300 400 2 5 10 20 Temperature (K) III-V compounds phonon bands LN2 Peltier Atmospheric windows 500 Wavelength (µm) 50 100

GaAs based lasers InP based lasers

200 Far Infrared (THz) : GaAs/AlGaAs QCLs Mid Infrared : AlInAs/GaInAs/InP QCLs InAs/AlSb QCLs

Contributions to this work…

Thesis directed by Carlo Sirtori

Epitaxy realised by: X. Marcadet (MBE)

M. Lecomte, O. Parillaud (MOVPE)

Devices processing: M. Calligaro, M. Carbonnelle

Y. Robert, C. Darnazian

Characterisations realised with the help of :

C. Faugeras, L. Sapienza, S. Forget, E. Boër-Duchemin