OATAO is an open access repository that collects the work of Toulouse

researchers and makes it freely available over the web where possible

Any correspondence concerning this service should be sent

to the repository administrator:

tech-oatao@listes-diff.inp-toulouse.fr

This is a Publisher’s version published in:

http://oatao.univ-toulouse.fr/23650

To cite this version:

Benchikhi, Mohamed

and El Ouatib, Rachida and Guillemet, Sophie

and

Er-Rakho, Lahcen and Durand, Bernard

Molten Salt Synthesis and

Characterization of CuIn(1-x)GaxS2 (x ≤0.3) Nanoparticles. (2015) Journal of

Chemical Sciences (Jchem), 2 (1). 21-25. ISSN 2339-5079

Molten Salt Synthesis and Characterization of

CuIn

(1-x)

Ga

x

S

2

(x ≤0.3) Nanoparticles

M. Benchikhi, R. El Ouatib, S. Guillemet-Fritsch, L. Er-Rakho, B. Durand

Abstract-Solid solutions CuIn(1-x)GaxS2 (x ≤ 0.3)were synthesized, with a yield of 70%, by reaction in molten KSCN at 400°C for 24h of CuCl2, InCl3 and GaCl3 with a ratio KSCN/Cu=15. The homogeneous solid solutions obtained are formed of nano-sized grains (70–100nm), with a specific surface area of 6.5 m2/g and a band gap between 1.5 and 1.8 eV.

Keywords-Chalcogenide, morphology, Semiconductor, Molten salt.

I. INTRODUCTION

Chalcopyrite compounds, of general formula Cu(In,Ga)(S,Se)2,have been studied extensively in

recent years [1-8] due to their applications as absorbers in solar cells[2-6], as well as for their use as photocatalysts [7]. These materials have a high absorption coefficient (greater than 104 cm-1) [8] and a

direct band gap from 1.04 (CuInSe2) to 2.43 eV

(CuGaS2) depending on their composition [9, 10].

Several studies have shown that the insertion of Ga in CuInSe2with contentbetween 25 and 35 molar %

allows obtaining the best photovoltaic efficiencies [5, 6]. Hanna et al [10] showed that the defect density in

CuIn(1-x)GaxSe2 is minimum at x = 0.3. Various reports

have shown that the physical properties of CuIn(S,Se)2

could be improved by doping [4,9-14].

Many studies have shown that the morphology and the particle size may significantly affect the intrinsic properties of CuInS2 [15-17]. Numerous

methods for the synthesis of Cu(In,Ga)(S,Se)2 have

been developed, such as laser removal [18], sputtering [14], co-evaporation [13], electrodeposition [19], sol-gel [20], spray pyrolysis[4,12], solvothermal [7] and organometallic routes [21]. Recently, Benchikhi et al. [1,22] proposed a process route to the fabrication of

ternary and quaternary chalcogenides by reaction in molten salts at 400°C.

In this paper, we report a simple method for the preparation of CuIn(1-x)GaxS2 nanoparticles by

reactions in molten salts. By analogy with CuIn (1-x)GaxSe2, which have a minimum defect concentration

at x= 0.3[10], we have limited the domain of solid solution at x =0.3.

II. EXPERIMENTAL

The solid solutions CuIn(1-x)GaxS2(x ≤0.3) were

synthesized by molten salts method using the following reactants: Copper chloride dihydrate CuCl2.2H2O

(Aldrich, 99.8 %), indium chloride InCl3 (Aldrich, 99.9

%) and gallium chloride GaCl3 (Aldrich, 99.9%).

Potassium thiocyanate KSCN (Prolabo) was used both as solvent and sulfurizating agent.

Figure 1 shows the schematic flow chart for the synthesis of CuIn(1-x)GaxS2(x ≤ 0.3) nanometric powders

by reaction in molten KSCN. The metal salts are mixed in the desired stoichiometric ratio and added to KSCN in the molar ratio SCN/Cu=15. The precursors were heat treated at 400 °C for 24 h under nitrogen flow in a vertical furnace. The heating and the cooling rates were stated at 2°C/min. After cooling at room temperature, the sulfides were extracted from the excess of salts by washings in deionized water, absolute ethanol and finally dried at 60°C for 12h. The reaction yield reached 70%.

The black powders obtained at the end of the process were characterized by X-ray diffraction (Brucker AXS D4, λCuKα = 0.15418 nm), by scanning (JEOLJSM 6400), and transmission (JEOL2010) electron microscopies, specific surface area

This work was supported by two French-Moroccan projects: Volubilis Partenariat Hubert Curien (PHC no. MA 09 205) and Projet de Recherches Convention Internationale du CNRS (CNRS-CNRST no w22572).

measurement (BET) (Micrometrics FlowsorbII2300), Raman(JobinYvon Labram HR 800) and UV-visible(UV-1601) spectroscopies.

Figure 1. Flowchart of the synthesis of CuIn(1-x)GaxS2(x ≤ 0.3) by

reaction in molten KSCN

III. RESULTS AND DISCUSSION

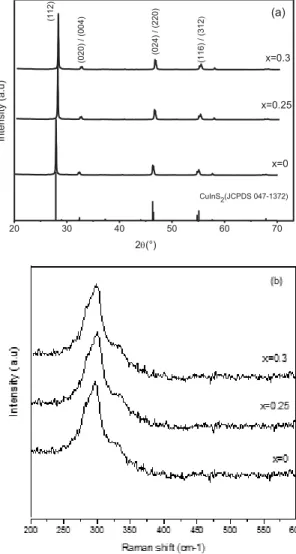

Structural characterization: The XRD patterns of the powders obtained at 400 °C for 24 h are given in figure 2-a. For the gallium contents lower than 0.3, all the peaks can be indexed to the chalcopyrite phase CuInS2 (JCPDS 047-1372), no impuritie can be

detected from this figure. The diffraction peaks shift slowly to the higher diffraction angle with increasing the gallium content. Lattice parameters (a and c) were determined for each composition by means of the Rietveld method.These lattice parameters decrease with the increase of Ga content (x) in the CuIn(1-x)GaxS2(x ≤

0.3) series (table1). This shows that the solid solution

CuIn(1-x)GaxS2 (x ≤ 0.3) is of substitution in which

indium atoms are substituted by smalleratoms of gallium.

TABLE1.LATTICE PARAMETERS AND BAND GAP (Eg)OFCuIn

(1-x)GaxS2(x≤ 0.3).

x= Ga/(Ga+In) a (nm) c (nm) c/a Eg (eV)

x=0 0.5521 1.1097 2.0099 1.51

x=0.25 0.5479 1.0941 1.9969 1.67

x=0.3 0.5461 1.0881 1.9925 1.78

In addition to the XRD, Raman investigation was performed to fully characterize the samples. The spectrum of CuInS2 (x=0) powder (figure 2-b) exhibits

a main peak close to 295 cm-1 and a shoulder close to

314-315 cm-1. These peaks are attributed to the

principal mode (A1) and secondary mode (B2/E)

observed in the chalcopyrite phase [1]. The frequency of the main peak (A1) increases with Ga-content; this result is in good agreement with the literature [23].

20 30 40 50 60 70 (a) (11 6) / ( 3 1 2 ) (02 4) / ( 22 0) (02 0) / ( 00 4) (11 2) Intensi ty (a.u) CuInS2(JCPDS 047-1372) x=0 x=0.25 x=0.3 2q(°)

Figure 2. Structural characterization: (a) RXD patterns and (b)

Raman spectra of CuIn(1-x)GaxS2powders.

Mechanism of formation: various reactional mechanisms have been proposed for the formation of the metallic sulfide in molten KSCN [1, 22,24]. This mechanism involves several steps:melting of KSCN and dissolution of metal salts, then the reduction of Cu2+ by SCN- via reaction (1) and lastly the thermal

decomposition of KSCN starting at 275°Cwith S and S2- formation via reactions (2) and (3)and the formation

of the chalcopyrite phase via reaction (4):

Cu2+ + 2 SCN-= Cu++ ½(CN)

2 + SCN- + S (1)

SCN- = CN- + S (2)

2CN- + S = S2- + (CN)

2 (3)

Washing and drying 400°C /24h

Reaction mixture

Black powder metal chloridesKSCN

CuIn(1-x)GaxS2 SCN/Cu=15Cu++(1-x)In3++xGa3+ +2S2-=CuIn

(1-x)GaxS2` (4)

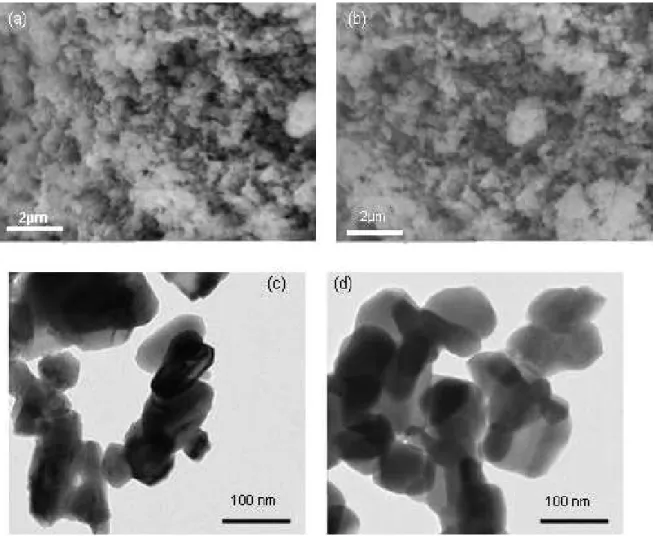

Morphological characterization: The influence of the Ga-content on the morphology of powders was evaluated. SEMobservation of the CuInS2 and

CuIn0,7Ga0.3S2 synthesized, by reaction in molten KSCN

at 400°C, (Figure 3) shows aggregated particles of

micronic size with a poly-disperse size distribution. Transmission electron microscopy (TEM) shows that these particles are constituted of nano-sized grains (70-100 nm) with more or less elongated shape (Figure3). Table 2 gives the average size of primary particles of each composition as well as their specific surface area.

Figure 3. Morphology: SEM micrographs of CuInS2 (a) and CuIn0,7Ga0,3S2 (b).TEM micrographs of CuInS2 (c) and CuIn0,7Ga0,3S2 (d).

Powders are constituted of relatively spherical particles.We calculated, from the specific surface area, the particle size (D) according the following equation (5):

D = 6 / (ρ S) (5) Whereρ is the densityand S the specific surface area. The determined values are given in table 2. According to these results, we can deduce that the Ga-content has no significant influence on the nanoparticles morphology.

TABLE2. SIZES OF PARTICLES OF CuIn(1-x)GaxS2(x=0 and x=0.3)

OBTAINED BY REACTION IN MOLTEN KSCN.

x=Ga/(Ga+In) Grain size MET (nm)

S (m2/g) Grain size

BET (nm)

x=0 80-100 6.0 205

x=0.3 70-100 6.5 195

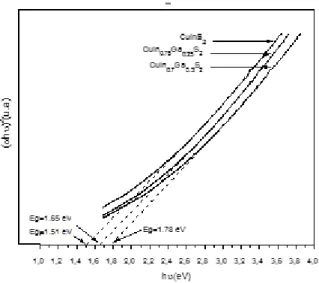

Measurement of the band gap Eg: The fundamental absorption (Eg) corresponds to the excitation of electrons from the valence band to the conduction band.

Optical absorption can be used to determine the optical band gap.

CuIn(1-x)GaxS2are direct band gap

materials[9,10].Their absorption coefficient (α) is related to the incident photon energy (hʋ) by the following equation (6) [25]:

(α hʋ) = A(hʋ –Eg)1/2(6)

Where A is a constant, Eg is the band gap and hʋ the energy of the incident photons (eV).The optical band gap Eg is determined by the intersection of the linear part of the curve (αhʋ)2 versus hʋ (Figure 4). The

values obtained show that Eg increases with the gallium content (table 1).This is in agreement with the previous experimental investigations[4,9].

Figure 4. Plot of (αhʋ)2 versus (hʋ) for CuIn

(1-x)GaxS2 (x≤ 0.3)

samples

IV. CONCLUSION

Solid solutions CuIn(1-x)GaxS2 (x ≤ 0.3) were

synthesized by reaction in a molten KSCN at 400°C for 24 h with the ratio KSCN/Cu=15. We have employed XRD, and Raman spectroscopy to confirm that the galliumis successfully incorporated into the chalcopyrite crystal structure (I-42d).The powders obtained are constituted of primary crystallites with sizes in the range 70–100 nm and exhibits a specific surface area close to 6.5 m2/g. The optical band gap has

increased from 1.51 to 1.79 eV with increasing Ga concentrations from 0 to 0.3.

REFERENCES

[1] M.Benchikhi, R. El Ouatib, S.Guillemet-Fritsch, J.Y.Chane-Ching, J.J.Demai, L.Er-Rakho, and B.Durand, “Synthesis of

CuInS2 nanometric powderbyreactioninmolten KSCN, ” Mater.

Lett., vol.136, pp.431-434, December 2014.

[2] Z.Hao, Y.Cui and G. Wang, “Colloidal synthesis of wurtzite

CuInS2 nanocrystals and their photovoltaic application,” Mater.

Lett., Vol.146, pp. 77-80, May 2015.

[3] M. Baneto, A. Enesca, C. Mihoreanu, Y. Lare, K. Jondo, K.Napo and A. Duta, “Effects of the growth temperature on the

properties of spray deposited CuInS2 thin films for photovoltaic

applications,” Ceram Int, Vol.41(3B), pp.4742-4749, April 2015.

[4] M.Ajili, M.Castagné and N. KamounTurki,

“CharacteristicsofCuIn1-xGaxS2 thin films

synthesizedbychemical spraypyrolysis,” Journal of

Luminescence, vol.150,pp. 1-7, January 2014.

[5] I. Repins, M. A. Contreras, B. Egaas, C. DeHart, J.Scharf , C. L

. Perkins, B. To, and R. Noufi,“19.9% efficient

ZnO/CdS/CuInGaSe2 solar cell with 81.2% fill factor,”

Prog. Photovolt.: Res. Appl.,vol.16(3), pp. 235-239, May 2008 [6] P. Jackson, D. Hariskos, E. Lotter, S. Paetel, R. Wuerz, R.

Menner, W. Wischmann, and M. Powalla, “New world record

efficiency for Cu(In,Ga)Se2 thin-film solar cells beyond 20%,”

Prog. Photovolt.: Res. Appl., vol.19(7), pp. 894-897, November 2011.

[7] C. Li, Z. Xi, W. Fang, M. Xing, and J. Zhang, “Enhanced

photocatalytic hydrogen evolution activity of CuInS2 loaded

TiO2 under solar light irradiation,”J. Solid State Chem., vol.

226, Pages 94-100, March 2015.

[8] H.M. Pathan, and C.D.Lokhande, “Chemical Deposition and Characterization of Copper Indium Disulphide Thin Films”, Appl. Surf. Sci., vol. 239, pp.11-18, 2004

[9] R.Kaigawa, A.Ohyama, T.Wada and R.Klenk, “Electrical

properties of homogeneous Cu(In,Ga)S2 films with varied

gallium content,” Thin Solid Films, vol. 515(15) pp.6260-6264, May 2007.

[10] G.Hanna, A.Jasenek, U.Rau, and H.W Schock, “Influence of

the Ga-content on the bulk defect densities

ofCu(In,Ga)Se2, Thin Solid Films, vol. 71, pp.371-373, 2001.

[11] N.Kamoun Allouche, N.Jebbari, C. Guasch, and N. Kamoun Turki, “Influence of aluminum doping in CuInS2 prepared by spray pyrolysis on different substrates,” J. Alloys. Compd., vol. 501(1), pp. 85-882, July 2010.

[12] C.Mahendran, and N.Suriyanarayanan, “Effect of Bi incorporation and temperature on the properties of sprayed

CuInS2 thin films,” Physica B: Condens Matter, vol. 408, pp.

62-67, January 2013.

[13] M. Ben Rabeh, M. Zribi, M. Kanzari, and B. Rezig, “Structural

and optical characterization of Sn incorporation in CuInS2 thin

films grown by vacuum evaporation method,” Mater. Lett,. vol. 59( 24),pp. 3164-3168,October 2005.

[14] M. Nie, and K. Elmer, “Growth and morphology of thin

Cu(In,Ga)S2 films during reactive magnetron co-sputtering,”

[15] S.Peng, J. Liang, L. Zhang, Y. Shi, and J. Chen, “Shape-controlled synthesis and optical characterization of chalcopyrite

CuInS2 microstructures,” J. Cryst. Growth, vol. 305 (1), pp.

99-103, July 2007.

[16] P.Guha, D. Das, A.B. Maity, D. Ganguli, and S. Chaudhuri,

“Synthesis of CuInS2 by chemical route: optical

characterization,” Sol. Energy Mater. Sol. Cells, vol. 80(1), pp.115-130, October 2003.

[17] P.Guha, S.Gorai, D. Ganguli, and

S.Chaudhuri,“Ammonia-mediated wet chemical synthesis of CuInS2,” Mater. Lett., vol.

57(12) , pp. 1786-1791, March 2003.

[18] A.K. Shuaibov, and M.P. Churchman, “The parameters of

Laser Plasmas Formed Using Polycrystalline CuInS2,Copper,

and indium Targets,” Technical Physics Lett., vol.29(6), pp.485-487, December 2003.

[19] J. Herrero, and J. Ortoga, “Electrodeposition of Cu-In alloys for preparing CuInS2 thin films,” Sol. Energy Mater., vol. 20 (1–2), pp. 53-65 , January1990.

[20] F.Aslan, M.Z. Zarbali, B.Yesilata, and J.H. Mutlu, “Effects of Cu/In ratio and annealing temperature on physical properties of dip-coated CuInS2 thin films,” Mater. Sci. Semicond. Process., vol.16(1), pp.138-142, February 2013.

[21] T.Kino, T.Kuzuya, K.Itoh, K.Sumiyama, T.Wakamatsu, and M.Ichidate, “Synthesis of Chacopyrite Nanoparticules via Thermal Decomposition of Metal- Thiolate,” Mater.Trans., vol.49 (3), pp.435-438, January 2008.

[22] M.Benchikhi, O. Zaberca, R.El Ouatib, B. Durand, F. Oftinger, A. Balocchi, and J.Y. Chane.Ching, “A high temperature route to the formation of highly pure quaternary chalcogenide particles, Mater. Lett., vol. 68(1), pp. 340-343, February 2012. [23] J. Zhong, W. Xiang, Y. Zhao, Q. Cai, Y. Wang, J. Wang, H.

Yang, and X. Liang, “Synthesis and characterization of

flower-like CuIn1−xGaxS2 (x = 0.3) microspheres,” Mater. Research

Bull.,vol. 47(3), pp. 861-866, March 2012.

[24] S. Collado, A. Laca, and M. Diaz, “Catalytic wet oxidation of thiocyanate with homogeneous copper(II) sulphate catalyst,”J. Hazardous Mater.,vol.177(1-3) pp. 183-189, May 2010. [25] N. Serpone , D. Lawless , and R. Khairutdinov, “Size Effects

on the Photophysical Properties of Colloidal Anatase TiO2 Particles: Size Quantization versus Direct Transitions in This Indirect Semiconductor” J. Phys. Chem, vol. 99, pp. 16646– 16654, November 1995.

AUTHORS’ PROFILE

Mohamed Benchikhi is a PhD student in Laboratoire de

Physico-Chimie des Matériaux Inorganiques, Faculté des Sciences Ain chock, Université Hassan II Casablanca, Maroc.

Dr. Rachida El Ouatib is a Professor in the Laboratoire de

Physico-Chimie des Matériaux Inorganiques, Faculté des Sciences Ain chock, Université Hassan II Casablanca, Maroc

Sophie_Guillemet-Fritsch is a Researcher Director in the

Institut Carnot CIRIMAT, CNRS Université de Toulouse, 118 route de Narbonne, 31062 Toulouse Cedex 9, France.

Dr. Lahcen Er-Rakho is a Professor in the Laboratoire de

Physico-Chimie des Matériaux Inorganiques, Faculté des Sciences Ain chock, Université Hassan II Casablanca, Maroc.

Dr. Bernard_Durand is a Professor in the Institut Carnot

CIRIMAT, CNRS Université de Toulouse, 118 route de Narbonne, 31062 Toulouse Cedex 9, France.