Thermal Analysis of Solidifying Steel Shell in Continuous Casting Process

Texte intégral

Figure

Documents relatifs

Des exemples d'images compressees sous JPEG, a des taux plus ou moins eleves sont donnes dans les pages suivantes : les photos originales sont numerisees avec les criteres

Table III provides two puncturing masks, both yielding minimum Hamming distance 8, as shown in Table IV: mask I was chosen because it maximizes the num- ber of non-punctured

Keywords : Finite elements method, Three-dimensional heat fluxAjout mot clé, TIG welding, 304L steel, Heat affected zone, Fusion Zone. Centre de Recherche en Technologies

Among the principal factors which contains in the continuous casting process, there are two things, the molten steel level in the ingot and the extraction speed, the variation of

Les soviets du Kazym et de Polnovat repris en main, 88 autochtones sont arrêtés en deux mois, 34 relâchés « faute de preuve » ou parce que « secondaires dans l’affaire et

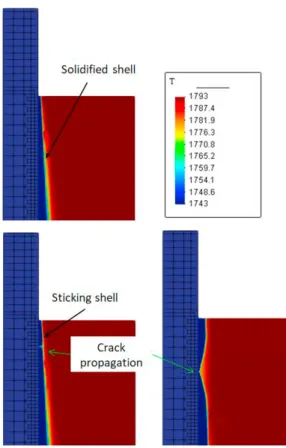

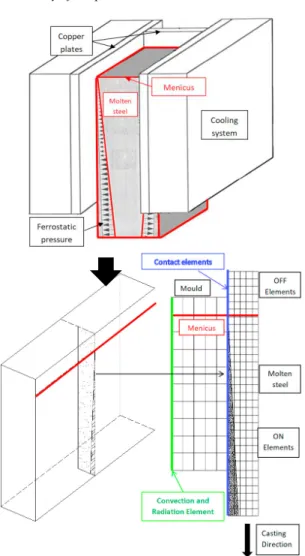

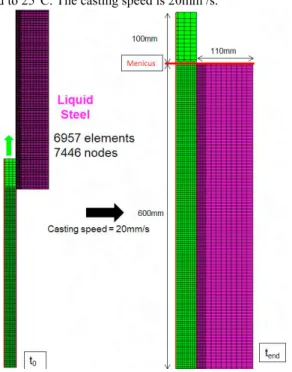

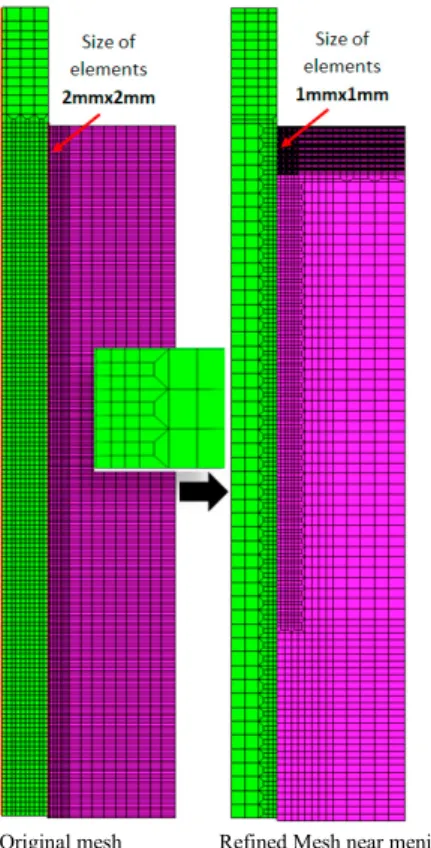

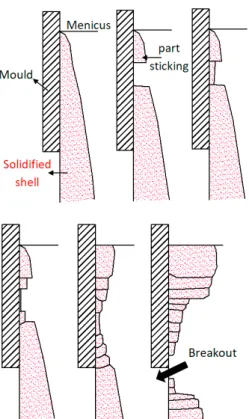

Abstract: The principal function of a continuous casting mold is to receive the liquid steel, and ensure its cooling in order to permit the formation of a solidified skin,

In this work we have focused our attention to evaluate covering powders for continuous casting steel.The aim is utilization of Algerian diatomite as a covering powder in the tundish;

Through the identification of thermal proprieties by many thermal analysis methods, we have obtained high insulting properties in high temperature up than 1400°C when the beginning