Resources,ConservationandRecycling108(2016)107–133

ContentslistsavailableatScienceDirect

Resources,

Conservation

and

Recycling

j ou rn a l h o m epa g e :w w w . e l s e v i e r . c o m / l o c a t e / r e s c o n r e c

Review

Pulp

and

paper

mill

sludge

management

practices:

What

are

the

challenges

to

assess

the

impacts

on

greenhouse

gas

emissions?

Patrick

Faubert

a,∗,

Simon

Barnabé

b,

Sylvie

Bouchard

a,

Richard

Côté

a,

Claude

Villeneuve

aaChaireenéco-conseil,Départementdessciencesfondamentales,UniversitéduQuébecàChicoutimi,555,boulevarddel’Université,Chicoutimi,Québec,

CanadaG7H2B1

bChairederechercheindustrielleenenvironnementetbiotechnologie,Départementdechimie,biochimieetphysique,UniversitéduQuébecà

Trois-Rivières,3351,boul.desForges,C.P.500,Trois-Rivières,Québec,CanadaG9A5H7

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:Received29June2015

Receivedinrevisedform8January2016 Accepted11January2016

Availableonline6February2016 Keywords: Biosolid Climatechange Landfilling Landapplication Energyrecovery Lifecycleanalysis

a

b

s

t

r

a

c

t

Pulpandpapermillsludge(PPMS)isanorganicresidualgeneratedfromthewastewatertreatments.PPMS managementinvolveseconomic,environmentalandsocialcoststhatwilllikelyincreaseinthefutureas landfillingtendstobereducedorbannedincertainjurisdictions.Thereductionorthebanningof landfill-ingmaybeconsideredasaclimatechangemitigationmeasuresinceorganicwastedisposalisnormally associatedwithgreenhousegas(GHG)emissions.Thiscriticalreviewaimsto(1)describethevarietyof thecurrentandemergingPPMSmanagementpracticesthatarealternativestolandfillingand(2) under-linethecrucialneedforGHGemissionassessments.ThemanagementpracticesofthethreemainPPMS types(primary,secondaryandde-inking)comprisedinthisreviewarelandapplication(agriculture, silvi-culture,landreclamationandcomposting),energyrecovery(combustion,anaerobicdigestion,pyrolysis, bioethanol,hydrogenproductionanddirectliquefaction)andintegrationinmaterials(biocomposite, cement,asphaltandadsorbent–absorbent).Futureresearchshouldfocustoincreasethecomprehension ofknownGHGdeterminantsfromthePPMSmanagementpracticesandrevealunknownfactors.Life cycleanalyses,basedondirectGHGemissionmeasurements,areneededtodetermineGHGemissions fromcurrentandemergingpracticesandplanaresponsiblefuturereductionorbanningoflandfilling. SuchanalyseswillcontributetoassistdecisionmakersinimplementingthebestPPMSmanagement practiceswiththeleastimpactonclimatechange.

©2016ElsevierB.V.Allrightsreserved.

Contents

1. Introduction...108

2. PPMS:types,propertiesandoverviewofend-of-lifeoptions...109

3. LandapplicationofPPMS...110

3.1. LandapplicationofPPMSinagriculture...110

3.2. LandapplicationofPPMSinsilviculture...114

3.3. LandapplicationofPPMSforlandreclamation...115

3.4. PPMScompostingpriortolandapplication...115

4. PPMSenergyrecovery...115

4.1. CombustionofPPMS...117

4.2. AnaerobicdigestionofPPMS:biogasproduction...117

4.3. PPMSpyrolysis...117

4.4. BioethanolproductionfromPPMS ... 118

4.5. Otherenergyrecoverypractices...118

∗ Correspondingauthor.

E-mailaddress:patrick1faubert@uqac.ca(P.Faubert). http://dx.doi.org/10.1016/j.resconrec.2016.01.007 0921-3449/©2016ElsevierB.V.Allrightsreserved.

108 P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133

5. IntegrationofPPMSinmaterials...119

5.1. Biocomposite:PPMSinwoodandplasticmaterials ... 119

5.2. PPMSintegratedincementandasphaltproductions...121

5.3. PPMSusedinadsorbent–absorbentproductions...121

6. DeterminantsofGHGemissionsfromPPMSmanagementpractices:knownsandunknowns...122

7. Conclusionsandrecommendations...127

Acknowledgments ... 128

References...128

1. Introduction

Pulpandpapermillsludge(PPMS)isthemainorganicresidual

generatedfromthewastewatertreatmentsofthepulpandpaper

industry.Theannualworldproductionofpaperandpaperboardis

estimatedto400milliontons(FAOSTAT,2015)andispredicted

toreachupto550million tonsby 2050,which couldincrease

thePPMSproductionby48–86%comparedwiththeactualrates

(MabeeandRoy,2003).PPMSmanagementanddisposalinvolve

economic,environmentalandsocialcoststhatwilllikelyincrease

inthefuture.Somejurisdictionsactuallytendtoreduceorban

land-fillingoforganicresidualsbyimprovingtheefficiencyofresource

useandrecycling(CounciloftheEuropeanCommunities,1991;

USEPA,1994;LjunggrenSöderman,2003;EC-BiPRO,2007;Fytili and Zabaniotou, 2008; Monte et al., 2009; MfE, 2010; MDDEP, 2011;GouvernementduQuébec,2012),whichwilllikelyinducea

changeintheactualmanagementpractices(MabeeandRoy,2003;

PervaizandSain,2015).Theactualgreenhousegas(GHG)emissions

fromthevarietyofPPMSmanagementpracticesareunknownand

shouldbeaddressedespeciallyinthelightofupcomingchanges,

consequenceofreducingorbanninglandfilling.

The actual and common PPMS management practices are

landfilling, land application for agricultural, silvicultural and

reclamationpurposes,andenergy recoverythroughcombustion

(CANMET,2005;Camberatoetal.,2006;Gavrilescu,2008;Likon andTrebˇse,2012;MDDELCC,2015;PervaizandSain,2015).The

proportionsofPPMSdirectedtooneofthesepracticesvarywith

timeandjurisdictionpolicies.Forinstance,intheU.S.,upto87%of

PPMSwaslandfilledin1979(Amberg,1984)whereasthis

propor-tionhasnowdecreasedto52%(PervaizandSain,2015).Nowadays

intheprovinceofQuebec,Canada,theannualproductionof1.4

milliontonsofPPMSaremanagedat29%bylandfilling,31%by

landapplication,35% byenergy recoveryand5%byother

prac-tices(MDDELCC,2015).TheQuebec’sgovernmentpoliciesaimto

banlandfilling ofPPMSby 2020(MDDEP, 2011;Gouvernement

duQuébec,2012)resultinginmajorchallengesfortheindustry

tochangetheirPPMSmanagementpracticesinordertomeetthe

governmentobjectives.Thepracticeoflandfillingwillalsotendto

decreaseinotherjurisdictions followingtheapplicationofsuch

policiesandpressurefromthelowpublicacceptance(Wangetal.,

2008;Jooetal.,2015;PervaizandSain,2015).Dependingonthe

localcontextforeachpapermill,thetonnagesactuallydirectedto

landfillsitesmaynotbeonlymanageablebycurrentenergy

recov-ery installations and land availability. Energyrecovery through

combustionbenefitstopulpandpaperindustry(e.g.,heatand

elec-tricityproduction)but itcan becostlyduetothe implantation

ofcombustionfacilitiesand theprior PPMSdewatering process

(CANMET, 2005;MahmoodandElliott, 2006;Xuand Lancaster,

2008). Land application is generally feasible (Camberato et al.,

2006;PervaizandSain,2015)andwellacceptedbutthisoption

canbepracticallyandeconomicallydifficultforcertainpapermills.

Forinstance,somepapermillsarelocatedatgreatdistancesfrom

agriculturallands,leading tohigh management costsand GHG

emissionsrelatedtotransport.Moreover,theheavymetalcontents

ofsometypesofPPMSandtheodor,especiallywhenthe

spread-ingisdoneinthevicinityofresidentialareas,canbeenvironmental

andpublicacceptanceissuesinrareexceptions(Rashidetal.,2006;

PervaizandSain,2015).

ThereisaneedtointegratenovelPPMSmanagementpractices

aslandapplicationand/orenergyrecoverythroughcombustion

maynotbethecommonalternativestodisposethePPMStonnages

actuallydirectedtolandfillsites.Severalalternativemanagement

options,otherthancombustionforenergyrecovery,areemerging,

suchasanaerobicdigestionforbiogasproduction,pyrolysisand

bioethanolproduction (Monte etal.,2009;Meyerand Edwards,

2014).PPMScanalsobeintegratedasa componentof

biocom-posites,bioplastics,cementandasphalt,aswellasbeingusedfor

adsorbent-absorbentproductions(Beauchampetal.,2002;Mari

etal.,2009;Monteetal.,2009;Lietal.,2011;Yanetal.,2011; LikonandTrebˇse,2012;AlmquistandQin,2013;Soucyetal.,2014; Pervaizand Sain, 2015).These emerging options alsohave the

potentialof beingopportunitiesforindustrialsynergies,leading

tomutualeconomicbenefits.Theresidualofoneindustrybecomes

theprimarymatterforanotherindustry,fittingwiththeconcept

ofindustrialecology.

ThereductionorthebanningofPPMSlandfillingcould

repre-sentapotentialabatementforGHGemissions,especiallyinNorth

America(Fischedicketal.,2014).Sofar,theGHGemissionsfrom

PPMSlandfillinghaveonlybeentheoreticallyestimated(1tonof

landfilledlow-ashPPMScouldrelease2.69tonsofCO2and0.24ton

ofCH4duetoaerobicandanaerobicdecomposition;Buswelland

Mueller,1952;LikonandTrebˇse,2012)androbustdataseriesfrom

directGHGmeasurementsarenon-existentfordifferentlandfill

conditionsandmilloperations(NCASI,2005;IPCC,2006).TheGHG

emissions fromwastewater treatmentplants canbe estimated

withmodelsandlifecycleanalyses(Ashrafietal.,2013a,2013b,

2015;O’Connoretal.,2014;Zangetal.,2015)buttheemissions

fromPPMSmanagementareunknownoutsidethemilloperations.

Theimpactsonclimatechangefromthepulpandpaperindustry

canalsobeestimatedthroughitsGHGemissionsusing

calcula-tiontoolssuchas theonebuiltbytheNationalCouncil forAir

andStreamImprovement(NCASI,2005).However,datafromdirect

GHGemissionmeasurementsthatisolatethecontributionofPPMS

managementpracticesontheGHGemissionbudgetsaremissing

intheNCASIcalculationtoolandarenotconsideredinthe

guide-lines ofthe IntergovernmentalPanel onClimate Change (IPCC)

fornational greenhousegasinventories(IPCC,2006).Therefore,

directmeasurementslinkedtovariousPPMSmanagement

prac-ticescouldbeusedindatabasessuchastheEcoinventdatabase

utilizedby theSimaPro softwareforexample (Ecoinvent,2013;

PRéConsultants,2014),ortobuildmodelssimilartothebiosolids

emissionsassessmentmodel(BEAM)thatestimatesGHGemissions

frommunicipalbiosolidmanagement(SYLVIS,2009;Brownetal.,

2010).

Thisreviewaimstodescribethevarietyoftheactualand

emerg-ingPPMSmanagementpracticesthatarealternativestolandfilling.

Moreover,theobjectiveistounderlinethatGHGemission

P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133 109

Table1

Physicalandchemicalpropertiesofprimary,secondary,mixed(primary-secondary)andde-inkingpulpandpapermillsludge(PPMS).

Parameter PrimaryPPMS SecondaryPPMS MixedPPMS De-inkingPPMS Referencesc

Drymatter(%FMa) 15–57 1–47 19–60 32–63 1–23

Ashcontent(%drysolids) 10–15 10–20 20 40–60 8,13

Nitrogen(%DMb) 0.045–0.28 1.1–7.7 0.7–3.6 0.15–1.0 1–3,6,7,9–13,15–17,19–28 Phosphorus(%DM) 0.01–0.06 0.25–2.8 0.22–0.74 0.0012–0.16 1–3,7,9,11,12,15–17,19,20,22,25–28 Potassium(%DM) 0.02–0.09 0.078–0.7 0.03–0.33 0.0029–0.2 1–3,7,9–11,15–17,19,20,22,26–28 C:Nratio 111:1–943:1 8:1–50:1 13:1–31:1 34:1–344:1 1–3,6,9–11,15–17,19–31 pH 5.0–11.0 6.0–8.5 3.8–8.1 7.2–9.2 1–3,5–7,9–12,14–16,19–22,24–26,28,32 Heatingvalue(MJkg−1DM) 5.5 0–25 14–19 1.5–5.7 8,12,23 aFreshmatter. bDrymatter.

c References:1–Aitkenetal.(1998);2–Simardetal.(1998);3–Charbonneauetal.(2001);4–IPPC(2001);5–Calaceetal.(2003);6–Allahdadietal.(2004);7–

Legendreetal.(2004);8–CANMET(2005);9–Geaetal.(2005);10–Curnoeetal.(2006);11–N’Dayegamiye(2006);12–ElliottandMahmood(2007);13–Gavrilescu (2008);14–OchoadeAlda(2008);15–PriceandVoroney(2008);16–RatoNunesetal.(2008);17–N’Dayegamiye(2009);18–Yanetal.(2011);19–GagnonandZiadi (2012);20–Gagnonetal.(2012);21–Chantignyetal.(2013);22–Ziadietal.(2013);23–Navaee-Ardehetal.(2006);24–Chantignyetal.(1999);25–Fierroetal.(1999); 26–CharestandBeauchamp(2002);27–Feldkirchneretal.(2003);28–Cabraletal.(1998);29–Dolaretal.(1972);30–Fieldetal.(1996);31–Trépanieretal.(1996); 32–Méndezetal.(2009b).

• Determinetheimpactsofthecurrentscenariosthatareactually

unknown,aswellasfromthefuturescenariosinwhichlandfilling

willnotbepossible.

• Build upcoming approved protocols that could be used in a

cap-and-tradeprogramsuchastheoneoftheWesternClimate

Initiative(WCI)aimingtoreduceandoffsetindustrialGHG

emis-sions.

2. PPMS:types,propertiesandoverviewofend-of-life options

Pulpandpaper productionrequires largeamountsof water,

ranging between 15 and 100m3Mg−1 dry pulp, used as

reac-tionmediaandwashwater(Ackermannetal.,1999;IPPC,2001;

CANMET,2005;Ashrafietal.,2015),whicheffluentneedstobe

treated beforebeing releasedto theenvironment. PPMS is the

organicresidualmaterial remainingafterwastewater treatment

inthepulpandpapermills.ThreemaintypesofPPMSare

pro-duced:primary,secondaryandde-inking(Thompsonetal.,2001;

Pokhreland Viraraghavan,2004;CANMET,2005;Mahmoodand Elliott,2006;Monteetal.,2009).PrimaryandsecondaryPPMSare

oftencombinedindifferentratios(PervaizandSain,2015)toform

“mixed”PPMS(Table1;theterm“mixedPPMS”isusedhereafteras

acombinationofprimaryandsecondaryPPMS).Inrarecases,PPMS

and municipalbiosolids canbecombined(Gagnonet al.,2010)

butthistypeofPPMSisnotdocumentedinthisreview.

Proper-tiesofthemaintypesofPPMSaresummarizedinTable1;studies

showthatthesecanbequitevariable.Pulpandpaper

manufac-turingprocessesareoffivemaintypes:mechanical(i.e.,grinding

andrefiningprocesses),chemical(i.e.,Kraftandsulfiteprocesses),

chemo-mechanical(i.e.,batchandcontinuoussystems),

thermo-mechanicalandpapermaking(CANMET,2005;Ashrafietal.,2015).

Thus,thevariabilityinthePPMSpropertiesreflectsthequalityand

compositionofthewastewatereffluentsthatare,uptoacertain

extent,particulartoeachmilldependingonthetypeofraw

mate-rialandinput,papermakingprocessand wastewatertreatment

(CANMET,2005;PervaizandSain,2015).However,certain

proper-tiessuchastheashcontent,carbon:nitrogenratio(C:N)andheating

valuecanbeusedtocharacterizeeachtypeofPPMS(Table1).

PrimaryPPMSistheresiduefromtheprimarytreatmentwith

highfibrousand organiccontents(i.e.,highC:Nratio,Table1),

consisting mainly of a mixture of coarse and fine fibers and

fillersobtainedbygravitythroughaprimaryclarificationprocess

(CANMET,2005;PervaizandSain,2015).Wastewatertreatments

leadingtoprimaryPPMSaremainlyphysicochemicalconsistingof

sedimentationandfloatation(Thompsonetal.,2001;Pokhreland

Viraraghavan,2004;CANMET,2005).

Secondary PPMS (also called biological sludge, biosludge or

wasteactivatedsludge–WAS)istheresidueleftafterthe

biolog-icaltreatmentofthewastewater,wheremicroorganismsareused

toreducethechargeindissolvedorganicmatter,chemical

oxy-gendemandandbiochemical oxygendemand(Thompsonetal.,

2001;PokhrelandViraraghavan,2004;CANMET,2005;Mahmood andElliott,2006).TheamountofsecondaryPPMSgeneratedisless

thanthatofprimaryPPMSasalltheresidualcellulosicfibersand

inorganicmaterialsareremovedbytheprimaryclarification

pro-cess(CANMET,2005).Nitrogen,phosphorusandoxygenmustbe

addedtotheprocesstomaintainmicroorganismactivity,which

explainsthelowC:Nratioandhighphosphoruscontent(Table1).

ThemostcommontreatmentleadingtosecondaryPPMSisaerobic

(e.g.,activatedsludgeprocess),aerationisperformedintobasins,

tanks,pondsorlagoonscontainingaerobicbacteriathatdecompose

andremoveorganicsubstances(Thompsonetal.,2001;Pokhrel

andViraraghavan,2004;CANMET,2005).Watereffluentsresulting

fromthesecondarytreatmentandclarificationprocessdonotneed

anyfurthertreatmentandareusuallyreleasedtotheenvironment

(CANMET,2005).Existingoremergingtechnologiescancontroland

reducethequantityofsecondarysludgefrompulpandpapermills

(MahmoodandElliott, 2006), whichcoulddecreasetheamount

ofPPMStomanage.However,moreresearchwouldbeneededto

enhancethesereductiontechnologiesandtheircommon

utiliza-tionbytheindustry(Jooetal.,2015).PrimaryandsecondaryPPMS

areoftencombinedtobedewateredbyamechanicalprocess,and

furtherdisposedorrecycledbydifferentmeans(Table1).

Paperrecyclingproduces de-inking PPMSwhich is a

combi-nationoftheviscousfloatorscum createdbythedissolvedair

floatation processused toremove inksand dyes fromrecycled

paperfibersandtheprimaryandsecondaryclarificationprocesses

(CANMET,2005).De-inkingPPMScontainsfibers,inorganic

com-poundssuchasinkparticles(colorpigments),de-inkingagents,

adhesive componentsand fillers (e.g., kaolin, clay and calcium

carbonate;CANMET,2005;Gavrilescu,2008;Monteetal.,2009).

Heavymetalsand mineralcontents ofde-inkingPPMS arehigh

whereasheatingvaluesaretypicallylow(Table1;CANMET,2005;

Rashidetal.,2006).De-inkingPPMSisusuallycharacterizedbya

highC:Nratioexplainedbythehighorganiccontentofwastepaper

(Table1).

PPMScontainssomeheavymetals,whichcanbean

environ-mentalissueregardingtheirdisposal(IPPC,2001;CANMET,2005;

Camberatoetal.,2006;Rashidetal.,2006;Gavrilescu,2008;Monte et al., 2009; Mäkelä et al., 2012; Pervaiz and Sain, 2015). For

instance,PPMSappliedasasoilamendmentmustfollow

regula-torystandardsinordertoavoidsoilandwatershedcontaminations

110 P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133

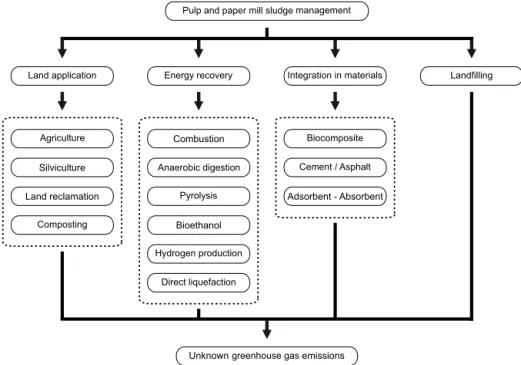

Fig.1.Overviewoftheactualandemergingmanagementpracticesforpulpandpapermillsludgeregardingtheunknowneffectsonthegreenhousegasemissions.

areusuallylessthanmunicipalbiosolidsandastheyarewithinthe

regulatorylimitsofallprovincestheycanbeusedassoil

amend-ments(Camberatoetal.,1997,2006).Itisalsoimportanttotake

intoaccountheavymetalcontentsofPPMSwhenusingitinenergy

recoverypractices(CANMET,2005;Tsuparietal.,2007;Gavrilescu,

2008).EmissionsandashesfromthePPMScombustioninbiomass

boilersaretreatedbymoderntechnologiesandrespectthe

regula-torystandardsinCanada(CANMET,2005).

Thefollowing sections willdescribe the actualand possible

futurepracticesforPPMSmanagement. Thepractices presented

inthispapercanbeeconomicallyandenvironmentallyattractive

optionsand/oralternativestotheactualdisposal bylandfilling,

whichisbeingreducedorbannedinsomejurisdictions(Council

of the EuropeanCommunities, 1991; US EPA, 1994; Ljunggren Söderman, 2003; EC-BiPRO, 2007; Fytili and Zabaniotou, 2008; Monteetal.,2009;MfE,2010;MDDEP,2011;Gouvernementdu Québec,2012).These PPMSmanagement practices are

summa-rizedinFig.1whichunderlinesonecrucialandimportantquestion

regardingclimatechange:whatwillbetheimpactofthesePPMS

managementpracticesonGHGemissions?Severalcountriesmake

someorgreateffortstoapplyGHGemissionreductionplans.These

plansneedtoconsiderGHGemissioncontributionsfromthe

cur-rentPPMSmanagementpracticesinordertocomparetheformer

emissionstothoseoffuturemanagementpracticesasestimated

inlifecycleanalyses.Thus,oneofthefuturechallengeswillbeto

integratePPMSmanagementpracticesinscenarioswithlowerGHG

emissionsthanthecurrentscenarioswithoutincreasingthe

over-allmanagementcostsforpulpandpapermills.Lifecycleanalyses

willbecomeakeytooltoassessthechangesinPPMSmanagement

practicesandtheirimpactonGHGsbutatthemomentdataare

missingtofeedthemodels.

It is important to define which GHGs are targeted in

cur-rentandfuturescenariosofPPMSmanagementpractices.Inthis

review,GHGemissionsrefertocarbondioxide(CO2;Global

warm-ing potential for 100 years – GWP100=1), nitrous oxide (N2O;

GWP100=265)andmethane(CH4;GWP100=28),threeimportant

GHGsincludedinusualGHGinventories(IPCC,2006,2013).CO2

emissionsfrombiogenicsources(e.g.,biomass)areexcludedfrom

GHGinventories,asfarastheyareincludedinthecarbonstock

changesifthereisachangeofthelandusecategory(IPCC,2006).

Thus here,GHG inventoriesrefer to CO2 emissions from

non-biogenic sources (e.g.,fossilfuel), and N2O and CH4 from both

biogenicandnon-biogenicsources(IPCC,2006).

3. LandapplicationofPPMS

LandapplicationofPPMS isa commonalternativeoptionto

landfilling.PPMSisusedasanorganicsoilamendmentin

agricul-ture,silvicultureandlandreclamation,andcanbecompostedprior

tolandapplication(Table2).Onceappliedontotheland,PPMS

nutrients(Table1)arerecycledfromthebiomasstothesoil.

3.1. LandapplicationofPPMSinagriculture

Acompleteliteraturereviewhasbeenpublishedonthe

ben-efitsofusingPPMSasanorganicsoilamendmentinagriculture

(Camberatoetal.,2006),butfewstudiesreportedontheimpactof

thispracticeonGHGemissions(Baggsetal.,2002;Chantignyetal.,

2013).LandapplicationofPPMSinagricultureisperformedatthe

beginningand/ortheendofthegrowingseasonbyspreadingand

incorporatingtheorganicmatterintothesoil.Benefitsof

apply-ingPPMSarewellknowninagricultureasitincreasessoilquality

andconsequentlycropyield(Tables2and3).PPMSlandapplication

improvessoilfertilitybyincreasingorganicmattercontent(i.e.,

car-bon),nutrientcontent(e.g.,nitrogen,phosphorusandpotassium),

pH,aggregatesandwaterholdingandcationexchangecapacities

(Table3;Camberatoetal.,2006).PPMScanalsobeusedasaliming

agent(Camberatoetal.,2006;RatoNunesetal.,2008),whichcan

substitutecommerciallime.

LandapplicationofPPMSincreasessoilmicrobialactivityand

biomass as well as the abundance of invertebrates (Table 2).

Chantignyetal.(2000)reportedthatappliedde-inkingPPMS

stim-ulatedmicrobialgrowthandactivitywhileenzymeactivityleveled

off ata rateof 50Mgdryha−1 resulting froman excessive

car-boninput.Similarly,alaboratorystudyrevealedthatapplication

ofsecondaryPPMSfromKraft millatratesrangingbetween10

and50Mgwetha−1(PPMScollectedfromthelandfillsiteafterone

yeardisposal)increasedmicrobialandenzymeactivities(Gallardo

etal.,2010).However,thesametypeofPPMSappliedinafield

P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133 111

Table2

Summaryofthebeneficialusesofpulpandpapermillsludge(PPMS)forlandapplicationinagriculture,silviculture,landreclamationandcomposting.

TypeofPPMS Beneficialuses References

Agriculture

-Alltypes -ReviewsonthebeneficialusesofPPMSasasoilamendmentanda plantnutrientsource

Cabraletal.(1998) Camberatoetal.(2006) -Alltypes -Effectsonyieldsofvariouscrops(corn,barley,wheat,soybean,

cranberrydrybean,oat,sugarcane,turfgrass,tallwheatgrass,meadow foxtail,hardfescue,galega,blackmedic,yellowsweetclover,and strawberry)andsoilpropertiesoffineandcoarse-texturedsoils

Dolaretal.(1972) Fieldetal.(1996) NorrieandGosselin(1996) Trépanieretal.(1996) Fierroetal.(1997) Aitkenetal.(1998) Simardetal.(1998) Zibilskeetal.(2000) Legendreetal.(2004) Curnoeetal.(2006) N’Dayegamiye(2006,2009) PriceandVoroney(2007) RatoNunesetal.(2008) Tripathyetal.(2008) Fanetal.(2010) Gagnonetal.(2010) Aminietal.(2012) GagnonandZiadi(2012) Gagnonetal.(2012) Ziadietal.(2013) -Primary

-Secondary

-DefinitionofaPPMSapplicationindexusingGIStools Ribeiroetal.(2010) -Secondary(extractedfrom

alandfillsiteafter1year)

-Effectonsoilproperties(volcanicsoils),microbialcommunityand yields(crop:LoliumperenneL.)

Gallardoetal.(2010) Gallardoetal.(2012) -De-inking -DynamicsofPPMSdecompositionanditsroleonsoilmicrofloraand

structureinfine-texturedsoils: •Aggregateformation •Microbialbiomass •Enzymeactivity •Activecarbonpool

Chantignyetal.(1999) Chantignyetal.(2000)

-De-inking -Effectsoninvertebrates(variousearthwormspecies)infineand coarse-texturedsoils

PiearceandBoone(1998) PriceandVoroney(2008) -De-inking -Effectondinitrogenfixationinforagelegumes(alfalfa,birdsfoot

trefoil,redcloverandsweetclover)

Allahdadietal.(2004)

Silviculture

-Alltypes -Effectsonforeststandgrowth(variousstands:radiatapine,redpine, lodgepolepine,whitespruce,Douglas-fir,maple,alder,aspenand shrubwillow)andsoilproperties

Henry(1991)

KraskeandFernandez(1993) Henryetal.(1994) Cabraletal.(1998) Macyk(1999) Jacksonetal.(2000) Feldkirchneretal.(2003) Filiatraultetal.(2006) Quayeetal.(2011) -Primary -PPMSusedasherbicideonclear-cutareas Loetal.(1996) -Mixed -Effectofthetoxicchlorinatedorganiccompound

2,3,7,8-tetrachlorodibenzo-p-dioxinonbreedingbirdsandsmall mammals

VeraandServello(1994)

-De-inking -DevelopmentofaforestsoilamendmentcombiningPPMSwith residuesfromsteelandpulpandpaperindustries

Mäkeläetal.(2010)

Landreclamation

-Alltypes -ReviewsonthebeneficialusesofPPMSasanorganicamendmentfor therestorationandrehabilitationofreclaimedsites

Camberatoetal.(2006) LarneyandAngers(2012) -Alltypes -Effectsonthevegetation(species:bermudagrass,tallwheatgrass),

soilpropertiesandrunoffwaterqualityofreclaimedsites

Feagleyetal.(1994) Fierroetal.(1999) ShipitaloandBonta(2008) -De-inking(byproductof

paperrecycling)

-Effectsoninvertebrates(variousearthwormspecies)inthe restorationofaformerlandfillsite

Piearceetal.(2003)

Composting

-Alltypes -ReviewspresentingsomebeneficialusesofcompostedPPMS Camberatoetal.(2006) Hubbeetal.(2010) -Alltypes -VermicompostingofPPMSaloneorcombinedwithmunicipal

biosolidsordairysludge

Elviraetal.(1998) Quintern(2014) -Secondary

-De-inking

-Effectsofco-compostingwithotherresidues(i.e.,poultrymanure, chickenbroilerfloorlitter,hogmanure)on:

•Compostandsoilproperties •Crops(snapbean,potatoandwheat)

BaziramakengaandSimard(2001) CharestandBeauchamp(2002) Lalandeetal.(2003)

Charestetal.(2004) Geaetal.(2005)

112 P. Faubert et al. / Resources, Conservation and Recycling 108 (2016) 107–133 Table3

Summarizedresultsfromselectedstudiesontheeffectsoflandapplicationofpulpandpapermillsludge(PPMS)inagricultureonsoilandcropproperties.

TypeofPPMS C:N Applicationrate Soiltextureand

location

Crop MainPPMSeffects Reference

-Secondary −11:1 -Control,38,88and

120Mgha−1,equivalentto 0–40gkg−1 -188days,greenhouse study -CambicArenosol (cmAR)

-SandyloamCromic Cambisol(crCM) -Portugal

-Wheat -Soil:

IncreaseofpH,organicCandNcontents,availableP andexchangeableK

-Crop:

Rateof38Mgha−1:increaseofgrainyieldincrCM

soil

Rateof120Mgha−1:32%and36%decreaseofgrain

yieldincmARandcrCMsoils,respectively IncreaseofwheatNcontent

DecreaseofwheatZn,MnandCucontents

RatoNunesetal. (2008)

-Secondary −16:1–27:1 -Control,15and 25Mgdryha−1 -5-yrfieldstudy

-Sandyloam -Ontario,Canada

-Corn -Soil:

Increaseoforganicmatterbutlittleevidencefor long-termaccumulation

-Crop:

Rateof15Mgdryha−1:123%increaseofgrainyield Rateof25Mgdryha−1:152%increaseofgrainyield IncreaseofplanttotalNcontent

Curnoeetal.(2006)

-Mixed(frombleached Kraftpulp)with3% additionofmunicipal biosolids

−13:1–16:1 -Control,30,60and 120Mgwetha−1 -3-yrfieldstudy

-Loamysand -Ontario,Canada

-Silagecorn -Soil:

IncreaseofNO3-NcontentandPsaturationindex Increased(oratleastmaintained)organicmatter CdandZnaccumulations

Recommendationtonotexceedarateof60Mgwet ha−1tolimitcontaminationbyNO3−,Pandmetals -Crop:

Rateof120Mgwetha−1:50%increaseofcornyield inthe3rdyear

Ratesof30Mgwetha−1withreducedmineralNand 60Mgwetha−1resultedinyieldscomparablewith thoseobtainedwithcompletemineralNfertilization CdandZnaccumulationsinplanttissues

Gagnonetal.(2010) -Mixed(60% primary–40% secondary) −14:1 -Control,18,36and 54Mgwetha−1 -6-yrfieldstudy

-Sandyloam -Clayloam -Quebec,Canada -Graincorn -Silagecorn -Barley -Soybean -Soil:

Sandyloam:increaseofNmineralization,microbial respirationratesandCcontent

Clayloam:increaseofthemacroaggregatesizes, meanweightdiameterofwaterstableaggregates, microbialrespirationratesandCcontent -Crop:

Sandyloam:increaseofsilageandgraincornyields Clayloam:increaseofgraincornyield

N’Dayegamiye (2009) -Mixed(60% primary–40% secondary) −19:1–24:1 -Control, 20–60Mgwetha−1 -3-yrfieldstudy

-Siltloam -Quebec,Canada

-Corn -Soil:

Rateof40Mgwetha−1:22%and16%increasesofC andNcontents,respectively

Rateof60Mgwetha−1:26%and16%increasesofC andNcontents,respectively

-Crop:

35–65%increaseofgrainyieldcomparedtothe control

N’Dayegamiye (2006)

P. Faubert et al. / Resources, Conservation and Recycling 108 (2016) 107–133 113 Table3(Continued)

TypeofPPMS C:N Applicationrate Soiltextureand

location

Crop MainPPMSeffects Reference

-ND −22:1–25:1 -Control,30,60and

90Mgwetha−1

-6-yrfieldstudy

-Loam -Quebec,Canada

-Graincorn -Soil:

IncreaseoforganicPavailability

PromotedtransformationofresidualPtomorelabile Pforms

IncreaseoftotalCandNcontents SupplyofCa

Fanetal.(2010)

-Mixed −22:1–26:1 -Control,30,60and 90Mgwetha−1 -9-yrfieldstudy: Years1–3:mixedPPMS fromthermo-mechanical pulp

Years4–9:mixedPPMS frombleachedKraftpulp

-Loam -Quebec,Canada

-Graincorn -Cranberrydrybean -Nattosoybean

-Soil:

Increaseoforganicmatterandallmajornutrients, exceptKandMg

-Crop:

Rateof90Mgwetha−1:19%increaseofgraincorn yield;26%increaseofcranberrydrybeanyield

GagnonandZiadi (2012)

-Twotypesofmixed PPMS

-De-inking

-Mixed:31:1,14:1 -De-inking:65:1

-Control,30and 60Mgwetha−1formixed andde-inkingPPMS -Greenhousestudy -Combinationofsandy soils:Gleyed Humo-FerricPodzol andOrthic Humo-FerricPodzol -Quebec,Canada -Mixed:

DrybeanwithPPMS atC:N31 BarleywithPPMSat C:N14 -De-inking Soybean -Soil: Mixed:

Rateof60Mgwetha−1(C:N=14):increaseofNO3-N availability

De-inking:

NO3-Nimmobilization;littlechangeinothersoil properties

-Crop: Mixed:

Drybean:rateof60Mgwetha−1increasedtotal plantN,PandCaaccumulations

Barley:increaseofgrainyield,strawandroot biomass,andtotalplantN,P,CaandMg accumulations

De-inking:

Soybean:higherstrawyieldat30Mgwetha−1than withthecontroland60Mgwetha−1;nosignificant effectongrainyield

Ziadietal.(2013) -Mixed (primary–secondary) -De-inking -Mixed:13:1–21:1 -De-inking: 50:1–71:1 -Mixed: Control, 4.24–6.90Mgdryha−1 -De-inking: Control, 25.9–38.1Mgdryha−1 -3-yrfieldstudy

-Clay

-Quebec,Canada

-Silagecorn -Soil:

De-inkingPPMSincreasedZnavailability -Crop:

MixedPPMS(2–3-yraverage): Yield:34%higherthancontrol

N-useefficiency:16kgdrymatterkg−1Napplied N-accumulation:30%higherthancontrol P-accumulation:13%higherthancontrol De-inkingPPMS(2–3-yraverage): Yield:43%lowerthancontrol

N-useefficiency:−20kgdrymatterkg−1Napplied N-accumulation:12%lowerthancontrol P-accumulation:34%lowerthancontrol

Gagnonetal.(2012)

-De-inking −219:1 -Control,50and 100Mgdryha−1 -3-yrfieldstudy

-Clayloam -Siltyclayloam -Quebec,Canada

-Alfalfa -Bromegrass -Sweetcorn

-Soil:

IncreaseofCcontentafter2years ResidualCattributedtode-inkingPPMS: Particulatefraction:remainedconstantat70–90% Lightfraction:decreasefrom>95%to<50% Increaseoftheproportionofsoilwater-stable aggregates(>1mm)from2to6times.Effectswere stilldetectableafter3years.

Chantignyetal. (1999)

114 P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133

Table4

Summarizedresultsfromselectedstudiesontheeffectsoflandapplicationofpulpandpapermillsludge(PPMS)insilvicultureonsoilandstandproperties.

TypeofPPMS Applicationrate Standdescription MainPPMSeffects Reference

-Primary(composted) -Control,20,40and 60Mgdryha−1 -1-yrfieldstudy

-Radiatapine(Pinus radiata)

-Soil:

•NreleasefromcompostedPPMSwas mostlyabsorbedbyplantrootswithin the20cmsoildepth;nosignificant movementbelowthisdepthwas measured

-Stand:

•Increaseofstemdiameterby40–66%, withthehighestapplicationrate resultinginhighergrowth •Increaseof17–37%ofthefoliarN concentration

•Decreaseofwaterstress

Jacksonetal.(2000)

-Mixed -Control,40Mgdryha−1

-2-yrfieldstudy

-Redpine(Pinusresinosa) -Soil:

•IncreaseofforestfloorpHby approximatelyoneunit

•IncreaseofexchangeableCa2+and

Mg2+by100%and60%,respectively

•Increaseofcation-exchangecapacity andbasesaturationby60%and34%, respectively

•OneyearaftermixedPPMS application,onlyN+andSO2− 4

concentrationsamongbasecations remainedfiveandthreetimeshigher thanthecontrol

•Whencomparedtotheharvesting operations,PPMShadmuchlessimpact onsoilbiogeochemicalprocesses

KraskeandFernandez (1993)

-Mixed -Ratesinthe1styear: Control,16and 33Mgwetha−1

-Ratesinthe2ndyear: Control,32and 64Mgwetha−1

-2-yrfieldstudy

-Maplestandsdominated bysugarmaple(Acer saccharum)

-Aspenstandsdominated byquakingaspen(Populus tremuloides)

-Soil: •Maplestands:

•Inthesoillayer0–10cm:increaseof soilpHby10%andCaconcentration with64Mgwetha−1

•IncreaseofunderstoryFeandMg concentrationswith64Mgwetha−1

•Aspenstands:

•IncreaseofsoilpH(0–10cmlayer)by 15%with64Mgwetha−1

•Forbothstands:

•IncreaseofunderstoryNandP concentrationswith64Mgwetha−1

-Stand:

•IncreaseoffoliarNconcentrationfor bothstandswith64Mgwetha−1

•NoPPMSeffectsonstandgrowths

Feldkirchneretal. (2003)

-De-inking -Control,73Mgwetha−1 -3-yrfieldstudyontwosites

-Shrubwillow(Salix dasyclados)

NoPPMSeffectsonsoilandstand properties

Quayeetal.(2011)

greatlythesoilmicrobialcommunityoffungiandbacteria(Gallardo

etal.,2012).Appliedde-inkingPPMSalsoincreasestheabundance

ofearthworms,thusimprovingsoilproperties(PiearceandBoone,

1998;PriceandVoroney,2008).

Severalstudieshavereportedanincreasedcropyieldfollowing

landapplicationofPPMS(Tables2and3).Oneoftheconclusions

fromthesestudieswasthatrepeatedapplicationsofmixedPPMS

withreducednitrogenfertilizerratewasasustainableagricultural

practice withthe potential to maintain crop quality and yield

andimprovesoilproperties(N’Dayegamiye,2006,2009;Gagnon

and Ziadi, 2012). It is important to consider the effect of the

PPMS C:N ratio on soil nitrogen immobilizationwhich in turn

affects crop yield (Camberato et al., 2006).Problems with soil

nitrogenimmobilizationcanbeavoidedbytheadditionofmineral

nitrogenfertilizercombinedwithappliedPPMSoruseoflegumes

(Camberatoetal.,2006).Optimumnitrogenrateswilldependon

thecrop,soilandPPMScharacteristics(Camberatoetal.,2006).

LandapplicationofPPMSinagricultureisgenerallywellaccepted

andcommoninareaswherepulpandpapermillsarelocalizedbut

somefactorscanlimitthispractice(Camberatoetal.,2006;Rashid

etal.,2006).Forinstance,heavymetalcontentisoneofthemajor

publicconcernsalthoughitisusuallylessthanmunicipalbiosolids

andbelowtheregulatorylimits(Camberatoetal.,2006).Insome

cases,other considerationssuchassite and soilcharacteristics,

distance from surface water and wells, depth to groundwater,

potential erosion and runoff, and proximity to floodplains or

wetlandscanbeobstaclestolandapplication(Camberatoetal.,

2006).However,PPMSlandapplicationisusuallywellmonitored

forthedosagesandtimesofapplicationandmustrespectthestate

rulesinordertoavoidsoilandwatercontamination(Camberato

etal.,2006;Rashidetal.,2006).

3.2. LandapplicationofPPMSinsilviculture

LandapplicationofPPMSispracticedinsilviculturetoimprove

soilpropertiesafterharvestingand promotestandregeneration

(Tables 2 and4).However,this practiceseemstobeless

com-monthantheapplicationonagriculturallandsaccordingtothe

fewerstudiesonthetopic(Tables2and4).Asitdoesonto

agri-culturalland,PPMSappliedasanorganicamendmentinmanaged

forestsaffectsoilpropertiesbyincreasingnitrogencontentaswell

P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133 115

applicationhasalsopositiveeffectsonmanagedstandgrowthsand

foliarnutrientstatus(Table4;Macyk,1999).Macyk(1999)reported

thatPPMSapplication(frommechanicalpulpmill)increasedwhite

spruce(Piceaglauca)andlodgepolepine(Pinuscontortavar.

latifo-lia)seedlingheightanddiameterbyupto2.5timescomparedwith

thecontrol.Applicationofcomposted primaryPPMS couldalso

beanacceptablerecyclingalternativeasitwasfoundtoimprove

plantationproductivity(Jacksonetal.,2000).However,contrasting

resultswerealsoreportedontheeffectofmixedandde-inking

PPMSapplicationsasitdidnotbenefitmaple,aspenandwillow

standgrowthsandaffectsoilproperties(Feldkirchneretal.,2003;

Quayeetal.,2011).

PrimaryPPMScanalsoactasherbicideonclear-cutareas

tar-getedforstandregenerations(Table2).Loetal.(1996)applied

primaryPPMSasasubstituteforherbicides,oneyearpriortothe

plantationofhybridpoplarcuttings.Weedgrowthwasdecreased

by75–90%andtheeffectlastedduringthesecondyearwithout

additionalapplication.

The use of mixed PPMS on forest soil for stand

regener-ation could have adverse effects on wildlife as they contain

2,3,7,8-tetrachlorodibenzo-p-dioxin(TCDD),achlorinatedorganic

compound,knowntobetoxicand/orsublethalonadultanimals

andbirdembryos(Table2).Nevertheless,VeraandServello(1994)

reportedthatmixedPPMSapplicationatarateof45Mgdryha−1on

regeneratingspruce-fir(Piceaspp.–Abiesbalsamea)foreststands

didnotaffectbreedingbirdsor smallmammalcommunities in

thefirstandsecondyearsfollowingapplication.However,species

knowntobeaffectedbyTCDDwereinnegligibleabundanceinthe

studiedforests,whichmostlikelyexplainedtheabsenceof

notice-ableadverseeffects(VeraandServello,1994).TCDDlevelsinPPMS

usedinsilvicultureshouldthereforeremainacauseforconcernas

moreresearchisneededontheirimpactsonthesurroundingfauna.

PPMScanbecombinedwithvariousindustrialresiduestobe

usedas forest soilamendments (Table2).Mäkelä et al.(2010)

developedsuchanamendmentbyincorporatingde-inkingPPMS

asareactiveaggregatewithotherresiduesfromFinnishsteeland

pulpandpaperindustries.Theresultingforestsoilamendmenthad

propertiescomparabletocommercialgroundlimestoneproducts

(Mäkeläetal.,2010).Thetotalconcentrationofchromeexceeded

theFinnishstatutorylimitvalueforforestsoilamendmentonly

undersevereleachingtests(Mäkeläetal.,2010).Thus,therecould

beapotentialtointegratePPMSwithresiduesfromdifferent

indus-triestoproduce forestsoil amendments as longas it doesnot

counteractclimatechangemitigationactions.

3.3. LandapplicationofPPMSforlandreclamation

PPMSisavaluablesoilorganicamendmentforland

reclama-tion(Table2).Examplesofdegradedsoilsareerodedagriculture

sites,oilandgaswellsites,minetailingsites,abandonedquarries

andtemporaryroadsonmanagedforestsites(LarneyandAngers,

2012).Suchtypesofsoilslackorganicmatter,whichcanbe

reme-diatedbythehighorganiccontentofPPMS(ShipitaloandBonta,

2008;LarneyandAngers,2012).Sludgeapplicationondegraded

soilscanalsoincreaseitsbiotabysustainingearthworm

commu-nities(Piearce etal., 2003).Moreover,soilaggregate formation

favoredbyPPMSapplicationcanbecomehotspots formicrobial

andfaunalactivity(LarneyandAngers,2012).Nitrogencontent

immediatelyavailable for plant growth(i.e., mineralized

nitro-gen)isalsoincreased,aslongasahighC:Nratiodoesnotfavor

nitrogenimmobilization(Larneyand Angers,2012;Thangarajan

etal.,2013),whichcouldseriouslyhinderalandreclamation

opera-tion.Cation-exchangecapacityofamendeddegradedsoilincreases,

especiallyifthePPMScompostedpriortotheirapplication(Fierro

etal.,1999;LarneyandAngers,2012).Asmeasuredforagricultural

land,PPMSapplicationondegradedsoilsincreaseswater-holding

capacity(Fierroetal.,1999;LarneyandAngers,2012),whichcanbe

animportantimprovementforcoarsetexturedsoils.Therefore,the

positiveeffectsofPPMSamendmentsondegradedsoilproperties

candecreaseitserosionandfavorplantgrowthonreclaimedland

(ShipitaloandBonta,2008;LarneyandAngers,2012).Shipitaloand Bonta(2008)showedthatmixedPPMSappliedtoreclaima

surface-coal mine at rates of 224 and 672Mgdryha−1 increased plant

growthanddecreasedsoilerosionfrom47Mgha−1 to1Mgha−1

comparedwiththecontrol.Althoughwaterrunoffwasdecreased,

itcontainedsignificantamountsofdissolvedorganiccarbonand

increasedthechemicaloxygendemand(ShipitaloandBonta,2008).

The authors concluded that PPMS application for surface-mine

reclamationcouldreducetheoperationalcostsasthesizeofthe

sedimentbasinscouldbesmallerthanstandardpracticesdueto

lowerwaterrunoff(ShipitaloandBonta,2008).

3.4. PPMScompostingpriortolandapplication

Composting of PPMS prior to land application enhancesits

overallqualityasasoilamendment(Table2;Jooetal.,2015).

Com-postingisabiologicalprocessthatconvertslignocellulosicresidues,

suchasPPMS,intoastabilizedandnon-hazardousmaterial,richin

humic-likesubstancesdevoidofpathogens(Hubbeetal.,2010).

Compostingofprimaryand de-inkingPPMSwithothertypesof

nitrogen-rich wastesdecreasesC:Nratio,preventssoil nitrogen

immobilizationandrenderstheresultingamendmentsuitablefor

plantgrowth(Camberatoetal.,2006;Hubbeetal.,2010).Some

studiesreportedontheco-composting ofPPMSwithmunicipal

biosolids,fertilizers,animalmanuresandchickenbroilerfloor

lit-ter(Table2).De-inkingPPMSwascompostedwithpoultrymanure

andchickenbroilerfloorlitterduring24weeksatthreeinitial

nitro-gencontentsof0.6%,0.7%and0.9%(CharestandBeauchamp,2002;

Charest et al.,2004).Results showed thatthe composting

pro-cessoccurredintwosteps:thefirsteightweeksconsistedofhigh

celluloseandhemicellulosedegradationfollowedbythe

decompo-sitionofresistantcarbonfractions(Charestetal.,2004).Microbial

biomasswasatthehighestlevelatthe12thweek(Charestetal.,

2004).Thecomposting mixturewithaninitialnitrogencontent

of0.6%yieldedthelowestC:Nratioafter24weeksandwasthe

besttoenhancede-inkingPPMScompostingbymechanicalturning

(CharestandBeauchamp,2002).TheinitialpHandC:Nratiowere

foundtobethekeyfactorsinthecompostingprocesshowever,the

24-weekcompostingperiodwasnotlongenoughtoproducefull

maturecompost(CharestandBeauchamp,2002).Thefinalproduct

mettherequirementsoftypesAAandAoftheCanadianCompost

Standards,exceptforcopperconcentrationcorrespondingtotype

B(CharestandBeauchamp,2002).Geaetal.(2005)showedthe

feasibilityofcompostingde-inkingandsecondaryPPMSaloneand

combinedwitheachotherbothatthelaboratoryandpilotscales.

Nobulking agentswereneededwhen secondaryPPMS was

co-compostedwithde-inkingPPMS.Compostingofde-inkingPPMS

didnot needanyamendments orbulking agents,which would

reducetheoperatingcostsiftheprocesswastobeappliedona

largerscale(Geaetal.,2005).Thepilotscalecomposting

experi-mentshowedthatC:Nratioofthede-inkingPPMSwasdecreased

(Geaetal.,2005).

4. PPMSenergyrecovery

PPMSisatypeofbiomassthatallowsavarietyofenergy

recov-erypractices(Table5),therebyreducingthevolumethatwouldbe

otherwisedirectedtolandfilling.Thesubstratesresultingfromthe

energyrecoveryofPPMS,suchasashesandbiochar(seeSection

4.3below),canalsoberecycledorreclaimedassoilamendments

116 P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133

Table5

Summaryofthetechnologiesinwhichpulpandpapermillsludge(PPMS)isusedinenergyrecoverypractices.

TypeofPPMS Technologies References

Combustion

-Alltypes -ReviewsorreportspresentingtechnologiesforPPMScombustion CANMET(2005)

Oraletal.(2005) Gavrilescu(2008) -Alltypes -Technologiesondryingpretreatmentsthatincreasetheenergyrecoveryfrom

combustion Krogerusetal.(1999) Freietal.(2006) Navaee-Ardehetal.(2006) Stoicaetal.(2009) Velisetal.(2009) -ND -Effectsofcombustionparameters(i.e.,watercontent,feedingrate,secondary

airinjection;lab-scaleexperimentwithaninternallycyclonedcirculating fluidizedbed)oncarbonconversionratio,meancarbonconversiontime, pollutantemissionratioandestimatedarealmassburningrate

Shinetal.(2005)

Anaerobicdigestion

-Alltypes -ReviewontheanaerobicdigestionofPPMS MeyerandEdwards(2014) -Alltypes -Modelingapproachevaluatingthepotentialforthesubstitutionoffossilfuelby

biogasfromthepulpandpaperindustryinSweden

MagnussonandAlvfors(2012) -Alltypes -ModelingapproachesestimatingGHGemissions Ashrafietal.(2013a)

Ashrafietal.(2013b) O’Connoretal.(2014) Ashrafietal.(2015) -Secondary -PretreatmentsaimingtoincreasethePPMSdigestibilityanddecreasedigester

sizes

ElliottandMahmood(2007) Woodetal.(2009) ElliottandMahmood(2012) -Secondary -MicroSludgeprocess:analkalinepretreatment(900mgL−1NaOHfor1h)to

weakenthecellmembranecombinedwithhighpressurehomogenizer(≈ 83MPa)tolysethecells,resultinginanincreasedbiogasyield

RabinowitzandStephenson(2005) Stephensonetal.(2005) Woodetal.(2009) Sahaetal.(2011) Caulfield(2012) -Secondary -Co-digestionwithmunicipalbiosolids:thesubstitutionofupto50%ofthe

mixturewithsecondaryPPMSdidnotdecreasetheCH4yieldcomparedwitha

fullmixtureofmunicipalbiosolids

Hagelqvist(2013)

-ND -Pretreatmentswithrumenmicroorganismstoincreaselignocellulose degradation

Gijzenetal.(1988) Gijzenetal.(1990) Pyrolysis

-Alltypes -AssessmentsofPPMS:

•Characteristicsforpyrolysis:e.g.,pH,electricalconductivity,cationexchange capacity,metalcontent,organicmatterandCaCO3contents

•Pyrolysisbehavior:e.g.,maximumweightlossrateanditstemperature •Products:gases,bio-oil,biochar

Méndezetal.(2009b) StrezovandEvans(2009) JiangandMa(2011) Louetal.(2012) Hossainetal.(2013) Ouadietal.(2013) Reckampetal.(2014) Bioethanolproduction -Fermentationprocesses:

•Separatehydrolysisandfermentation(SHF)

-De-inking Marquesetal.(2008)

-FromableachedKraftprocess PengandChen(2011)

-Fromachemicalpulpingprocess Zhuetal.(2011)

•Simultaneoussaccharificationandfermentation(SSF)

-Primaryandde-inking Kangetal.(2010)

-De-inking Larketal.(1997)

Marquesetal.(2008)

-FromableachedKraftprocess Fanetal.(2003)

FanandLynd(2007a,2007b) •Simultaneoussaccharificationandco-fermentation(SSCF)

-Primaryandde-inking Kangetal.(2010)

-ND ZhangandLynd(2010)

•Consolidatedbioprocessing(CBP)

-Primary Moreauetal.(2015)

Otherenergyrecoverypractices

-Hydrogen–biologicalproduction

-Primary Moreauetal.(2015)

-Secondary Valdez-Vazquezetal.(2005)

-ND Kádáretal.(2003)

Kádáretal.(2004) -Hydrogen–Productionwithsupercriticalwaterprocesses:

•Supercriticalwatergasification(SCWG)

-Secondary Zhangetal.(2010)

•Supercriticalwateroxidation(SCWO)

-Alltypes •ReviewontheprocessesforPPMS MahmoodandElliott(2006)

-ND Crainetal.(2000)

-Directliquefaction–productionofliquidfuel

-Secondary XuandLancaster(2008)

Zhangetal.(2011) ND:PPMStypenotdeterminedorspecifiedinthestudy.

P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133 117

practiced directlyby combustionor indirectly by

microbiologi-caland physicochemical processesleadingtotheproduction of

biogas(throughanaerobicdigestion)andbiofuel(through

pyrol-ysisandbioethanolproduction).AcompleteprocessofPPMSto

energyrecoverytypicallyincludes(1)dewateringand(2)drying

toincreasetheeffectivethermalheatcapacity,(3)thermal

conver-sionorrecoveryofbiofuelordirectuseoftheaqueousphasein

whichPPMSisprocessedforbiofuelproduction(CANMET,2005).

Theintensityofthedewateringanddryingprocessesdependon

thetechnology.Combustionrequiresdewateringanddryingprior

toburning,dewateringisalsoneededforanaerobicdigestionfor

biogasproductionwhereasfermentation forethanol production

canusePPMSwithlowsolid content(aslow as20%),reducing

energyconsumptionforpretreatments(CANMET,2005;Meyerand

Edwards,2014).

4.1. CombustionofPPMS

SomepapermillsusePPMSasarenewablesourceoffuelin

biomassboilersandrecoveryfurnaces(Table5).Themainbenefits

ofusingPPMSasfuelare:thehygienicdisposal,volumereduction,

recoveryofthermalenergybyproductionofsteamorsuperheated

water usedfurtherforheat inthepaperproduction operations

and power generation, for instance electricity (CANMET, 2005;

Gavrilescu,2008).PPMS combinedwithotherbiomassresidues

fromthepulpandpaperindustrycanbeaneconomicallyattractive

option.Theuseofbiomassinsteadoffossilfuelreducestheoverall

operatingcostsatthemillsandmayleadtofuelself-sufficiency

(Gavrilescu,2008).ThereportfromCANMET(2005)suggeststhat

5–34%ofthethermalloadfromfossilfuelmaybesubstitutedwith

PPMS,basedonadrysludgegenerationrateof5–15%ofmill

pro-ductionanddependingonthenetenergyconsumptionofthemill.

OneofthemainlimitingfactorsofusingPPMSasfuelisthe

highwatercontent(CANMET,2005;Gavrilescu,2008).Dewatering

thesludge isessential inorder toachieve anefficient

combus-tion(CANMET,2005;Ruohonenetal.,2010).PPMStypeaffectsthe

dewateringpotential:mixedPPMS,whichcontainshigher

propor-tionsofcellulosicfibers,iseasiertodewaterthande-inkingPPMS

containinginkparticles,adhesives,mineralfillers(e.g.,kaolin,clay

and calcium carbonate) and some cellulosic fibers (Gavrilescu,

2008;Mäkinenetal.,2013).Mechanicaldewateringisacommon

practiceresultingindrycontentsbetween15%and50%whereas

thecriticallevelis ∼42%for anefficientandstablecombustion

(Krogerus et al.,1999; Navaee-Ardeh et al.,2006; Stoica et al.,

2009).Biologicaldrying(biodrying)isapracticethatconsistsof

dryingPPMSwithventilatedheatgeneratedbymicrobialactivity

fromthePPMSitself (Navaee-Ardehetal.,2006).Biodryingisa

promisingtechnologythatcanbecost-effective(Freietal.,2006;

Navaee-Ardehetal.,2006).

ThelowheatingvalueofPPMSisalsoalimitingfactorfor

com-bustion(Table1).Sludgeisusuallyco-firedinsmallproportions

withother residues from paper mills (Gavrilescu, 2008; Stoica

et al., 2009). Dewatered PPMS has a heating value commonly

rangingbetween0and6MJkg−1 drysolidsbutcanreachupto

25MJkg−1drysolidsinrarecases(Table1;ElliottandMahmood,

2007).Thus,thecommonPPMSheatingvaluesarelowcompared,

forinstance,withwoodthathasheatingvaluesrangingbetween

17 and 21MJkg−1 dry solids (Raitio, 1992; Mabee and Roy,

2003).TheheatingvalueofmixedPPMSondrybasiscanreach

14–19MJkg−1,whichissimilartowoodandpeat,butonlyifthe

sludgeisdriedtoabovethecriticallevelof42%drynessforgood

combustion(Navaee-Ardehetal.,2006).WhenPPMSismixedwith

barkandotherligninresiduesfromthepapermills,theheating

value can reach up to 26MJkg−1 dry solids (Mabee and Roy,

2003).Combustioninfluidizedbedboilerseemstobethemost

efficienttechnologytorecoverenergyfromPPMSnowadayswhen

consideringthelowheatingvalue,economicandenvironmental

aspects(MabeeandRoy,2003;CANMET,2005;Gavrilescu,2008).

4.2. AnaerobicdigestionofPPMS:biogasproduction

Anaerobicdigestionoforganicmaterialisabiologicalprocess

leading tobiogasproduction, which is furtherusedtoproduce

energy.Severaltypesoforganicwastescanbeprocessedby

anaer-obicdigestionsuchasfoodwastes,municipalbiosolids,manure

andagriculturalwastes(Wangetal.,2008;MagnussonandAlvfors,

2012).MagnussonandAlvfors(2012)investigatedthepotentialof

usingPPMSasasubstrateforbiogasproductioninSweden.The

modelingapproach demonstratedthatonethird ofthenational

biogasproductioncouldbeachievedifallpulpandpapermillsin

SwedenwouldusePPMSasasubstrateforanaerobicdigestion.This

biogascouldbeusedinthetransportsectortosubstitutefossilfuel,

whichwouldbeastepforwardtoreducetheimpactofthissector

onclimatewarming(MagnussonandAlvfors,2012).

The modeling approach of Magnusson and Alvfors (2012)

encourages togo forward withanaerobic digestion, but biogas

production fromPPMS isin itsinfancy and facestechnicaland

economicchallengessuchasinvestmentcoststoinstallthe

tech-nologyandtheappropriatepretreatmentleadingtoanincreased

biogas yield (Elliott and Mahmood,2012; Meyer and Edwards,

2014;Ashrafietal.,2015;Sawatdeenarunatetal.,2015).Actual

biogasproductionfromPPMS canbecostlyfor papermillsdue

tolongretentiontimesrequiredbytheprocessandlarge

invest-mentstoinstallefficientbioreactors(ElliottandMahmood,2012;

MeyerandEdwards,2014;Sawatdeenarunatetal.,2015).However,

thereviewofMeyerandEdwards(2014)showedthatpretreated

PPMS leadstoincreasedbiogas yield,themost effective

meth-odsbeingthermalandmicrowavetreatmentsandhigh-pressure

homogenization.Severalstudiesreportedonpretreatmentsthat

candecreasetheretentiontimeanddigestersizetoproduce

bio-gasandincreasethebiodegradabilityofPPMS(Table5;Carlsson

etal.,2012).RetentiontimesforanaerobicdigestionofPPMSin

conventionalbioreactorsusuallyusedformunicipalbiosolidscan

rangefrom20to30days,butaseriesofpretreatmentshavebeen

reviewedandappliedatthelaboratoryscaletoreducethe

reten-tiontimedowntothreetosevendays(ElliottandMahmood,2007,

2012).Rumenmicroorganismswerefoundtohavehighcellulolytic

activityandincreasetherateoflignocellulosedegradation

com-paredwithconventionalinoculasuchasanaerobicsewagesludge

(Gijzenetal.,1990;Yueetal.,2013;Sawatdeenarunatetal.,2015).

MeyerandEdwards(2014)concludedthatfutureresearchshould

focusontherelationshipsbetweentheanaerobicdigestibilityand

PPMSproperties,asbiogasyieldsfromnon-pretreatedPPMSare

largelyvariable.Moreover,moreresearchshouldbeconductedon

theanaerobicdigestionofprimaryPPMSasitisthemost

abun-dant(MeyerandEdwards,2014).Forinstance,inCanadianpulp

andpapermills,theaverageratioprimary:secondaryPPMSis

esti-matedtobe70:30(ElliottandMahmood,2005),althoughitcan

differamongmills(e.g.,50:50,40:60or67:33;Rashidetal.,2006;

Stoicaetal.,2009;MeyerandEdwards,2014;PervaizandSain,

2015).Futureresearchshouldalsofocusontheanaerobic

diges-tionofthehighcontentoflignocellulosicmaterialinPPMS(Meyer

andEdwards,2014;Sawatdeenarunatetal.,2015).Thus,new

tech-nologiesforbiogasproductionfromPPMSareemergingandhave

aconcretepotentialtobeusedinthenearfuture.

4.3. PPMSpyrolysis

Pyrolysisdecomposesorganicmatterbythermochemical

con-versionpracticedatelevatedtemperatureintheabsenceofoxygen.

Theendproductsofpyrolysisaregasesandliquidsthatareused

118 P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133

charcoal,commonlynamedcharorbiochar.Energyproducedby

pyrolysiscanbeusedinpulpandpapermillsorsustainsthe

pyrol-ysisitself.Forinstances,bio-oilcanbeadaptedandusedinmodified

dieselengines,orinconventionalengines,ifblendedwith

conven-tionalfuel(Ouadietal.,2012,2013).Therearestudiesreportingon

theuseofPPMSasanorganicinputforpyrolysis(Table5),another

alternativetolandfilldisposal.

De-inkingPPMScanbeusedforenergyrecoverybypyrolysis

(Louetal.,2012;Ouadietal.,2013).Papermillsthatrecyclepaper

needhighamountsofenergywhichcouldbepartlyproducedby

pyrolysisofde-inkingPPMSatthemillsite(Ouadietal.,2013).Lou

etal.(2012)reportedthattubularfurnacepyrolysisofde-inking

PPMS,asa low-qualitybiomass,producedhigh-qualityfueland

chemicalsonapilotscale.Yieldsfrompyrolysisat800◦Cof

de-inkingPPMSwere46%assolids,30%asgaseousproducts(CO2,CO,

CH4,C2H4andH2)and24%asbio-oil(Louetal.,2012).Thus,some

ofthegasescanbeconsideredasfuelandenergysources(Louetal.,

2012).Ouadietal.(2013)addressedsomeoftheresearchquestions

raisedbyLouetal.(2012)byapplyinganintermediatepyrolysis

techniqueusingdriedandpelletizedde-inkingPPMStoproduce

combinedheatandpower.Bio-oilproducedbythistechniquehad

ahighheatingvalueof36–37MJkg−1,similartobiodiesel.This

bio-oilwasfullymisciblewithbiodieselandcouldbeusedinmodified

orconventionaldieselengines(Hossainetal.,2013;Ouadietal.,

2013).Theobtaingaseshadaheatingvalueof5–6MJNm−3(Ouadi

etal.,2013).Thisintermediatepyrolysistechniquedidnotfully

decomposetheorganicmatterfromde-inkingPPMS,which

pro-ducedsolidresidueswithaheatingvalueof3–5MJkg−1(Ouadi

etal.,2013).Thistechnique wasfeasiblein principleandcould

beappliedatsecondaryfiberpapermillswithapotentialpayback

periodoflessthanfiveyearsintermsofsavingsfromthechanges

inthedisposalpracticesandenergyrecovery(Ouadietal.,2013).

Bio-oilandbiocharcanbeusedforotherpurposesthanenergy

recovery.Componentsofthebio-oilproducedbythepyrolysisof

de-inkingPPMShavethepotentialformanyusesonceisolated(Lou

etal.,2012).Forinstance,toluenecanbeusedasanorganicsolvent

(Louetal.,2012).Thecompoundo-cresolcanbeusedinthe

syn-thesisofantioxidants,adhesivesandexplosives(Louetal.,2012).

Phenolscanbeusedforthesynthesisofphenolicresinand

syn-theticfiberwhereasnaphthaleneisactuallyusedinspices,plastics,

syntheticdyesandasanintermediateforcertaindrugs(Louetal.,

2012).

4.4. BioethanolproductionfromPPMS

PPMS is a source of lignocellulosic biomass which is used

forbioethanolproduction,classifiedassecond-generationbiofuel

(Mtui,2009;Demirbasetal.,2011;Joshietal.,2011;Nigamand Singh,2011;Guoetal.,2015).Materialsusedforsecond-generation

biofuel generally are from the biological or thermochemical

processingofagriculturallignocellulosicresidues,whichare

non-ediblecropresidues(NigamandSingh,2011).Second-generation

biofueldoes not competefor arable landsas it is thecase for

first-generationbiofuelproducedfrombasicfeedstock(i.e.,sugar,

starch,vegetableoiloranimalfat;Demirbasetal.,2011;Nigam

andSingh,2011;Guoetal.,2015).Commercial-scaleproduction

ofsecond-generationbioethanolfromlignocellulosicbiomasshas

recentlybeenreached(Guoetal.,2015),althoughfurtherresearch

isneededontheprocessestobeeconomicallyviable(Baeyensetal.,

2015).Briefly,thereviewofBaeyensetal.(2015)discussedonfive

possibleinterventionsthatcouldimprovebioethanolproduction:

(1)energyintegrationwithinthecurrentproductionprocess,(2)

useofveryhighgravityfermentation,(3)developmentofhybrid

systems,(4)finalethanoldewateringtofuelgradeand(5)other

developmentssuchascross-flowfiltrationofbioethanol

fermen-tationbroth,noveldistillationconceptsandimprovedbioethanol

productionplant.Thus,PPMScouldbeanoptionfortheproduction

ofsecond-generationbiofuel,whichwouldincreasethelanduse

efficiencyandhavelowerenvironmentalimpactscomparedwith

first-generationbiofuel(Fargioneet al.,2008;NigamandSingh,

2011;Moralesetal.,2015;Nandaetal.,2015).

SeveralstudiesreportedonPPMSconversionintobioethanol

(Table 5). Bioethanolproduction is economically feasible when

the process leads to concentrations above 4% (w/v) which is

achievableandcanbesurpassed(ZacchiandAxelsson,1989;Fan

etal., 2003;Kanget al.,2010; Zhangand Lynd,2010).

Conver-sionintobioethanoliscontrolledbydifferentfactorssuchasthe

fermentation process, thecellulose and hemicellulose contents

and the type of PPMS. Three common fermentation processes

havebeenappliedtoPPMSfortheirconversionintobioethanol:

separate(orsequential)hydrolysisandfermentation(SHF),

simul-taneoussaccharificationandfermentation(SSF),andsimultaneous

saccharificationand co-fermentation(SSCF;Table5).Moreover,

consolidated bioprocessing(CBP), which is the direct microbial

conversionofcellulosetoethanol,wasrecentlyperformedwith

primaryPPMS(Moreauetal.,2015).Differentbacteriaareusedin

theSHF,SSF,SSCFandCBPprocessesaffectingthebioethanolyields.

Energyrequiredfortheconversioncanalsodependontheprocess

used,asithasbeenreportedforsugarcanebagassefollowingan

exergyanalysis(Ojedaetal.,2011).Asmentioned,PPMSconversion

intobioethanolalsodependsonthecellulosecontentasitwill

pro-portionallyaffecttheconcentrationsinfermentablesugars(Monte

etal.,2009;ZhangandLynd,2010)andthePPMStypes(e.g.,from

Kraftvs.thermo-mechanicalprocesses)affectthebioethanolyields

(Monteetal.,2009).Technologicaladvanceshavebeenachievedto

convertPPMSintosecond-generationbioethanol.Thefive

inter-ventionsdiscussedbyBaeyensetal.(2015)couldbeconsideredto

upscaletheproductionatlowcostsforpulpandpapermills.

4.5. Otherenergyrecoverypractices

Biowastes,biomassandindustrialwastewaterhavebeenused

for thebiological productionof hydrogen(Mizunoet al.,2000;

Noikeetal.,2002;Kádáretal.,2003,2004;Valdez-Vazquezetal., 2005;Kotharietal.,2012;RamaMohan,2015;SharmaandGhoshal,

2015).Hydrogenisanenergycarrier(notafuel)andisoneofthe

potentialoptionstoreplacefossilfuel,asitisarenewablesource

withamoderatefootprintonGHGemissionsfollowingcombustion

(Kotharietal.,2012;AmooandFagbenle,2014).PPMShasbeen

investigatedasa potentialresiduefor thebiological production

of hydrogen (Table 5). Anaerobic fermentation of PPMS using

thermophilebacteriahadahydrogenyieldthatremainedlower

comparedwithothertypesofsugars,suchasglucoseandxylose

(Kádáretal.,2003,2004).Asuccessiveapplicationofthree

incu-bationcyclesofPPMSwithmicrobialconsortiaofsolidsubstrate

anaerobicdigestersincreasedthehydrogenyieldcomparedwith

oneincubationcycle(Valdez-Vazquezetal.,2005).Thisprocedure

wasnamed as“intermittently vented solid substrate anaerobic

hydrogengeneration”(IV-SSAH)andclaimedtobeafeasible

strat-egyforobtaininghigherhydrogenyieldsfromthefermentationof

industrialsolidwastes(Valdez-Vazquezetal.,2005).Moreauetal.

(2015)succeededinproducingbiohydrogenfromprimaryPPMS

fermentation,buttheirworkwasconductedatthelaboratoryscale.

Biological production of hydrogenfrom PPMS and other types

ofbioindustrialwastesisstillinitsearlystageandneedfurther

developments(Kotharietal.,2012).Inidealconditions,about40%

ofthechemicalenergyinindustrialwastewatercanbeconverted

intohydrogenenergywhileby-productsfromtheprocess(acids

andalcohols)requirefurthertreatmentsforfullenergyrecovery,

which requires the development of a sustainable technology

(Kotharietal.,2012).Isolationsofnewbacterialstrainsresulting

P.Faubertetal./Resources,ConservationandRecycling108(2016)107–133 119

combinationwithgeneticengineering,reactoroptimizationand

useoflowcostrawmaterials(Kotharietal.,2012).

Technologies involvingsupercritical water can also produce

hydrogenfrombiomass.Supercritical water hasa pressure and

temperaturethatare,atorabovetheircriticalpoints(22.1MPa

and374◦C).Inthesupercriticalphase,waterhasahighdiffusion

capacity,alowviscosityandactsasasolventfororganicmolecules

(Gloynaetal.,1994;Matsumuraetal.,2005;MahmoodandElliott, 2006;Yaniketal.,2007;Zhangetal.,2010).Supercriticalwater

treatmentsweresuccessfullyappliedtoPPMStoproduceenergy

andremovecontaminants(Table5).Supercriticalwater

gasifica-tion(SCWG)produceshydrogenfromthebiomasswiththemain

advantageofhavingahighsolidconversion,i.e.,withloworno

for-mationofcharandtar(XuandAntal,1998;Matsumuraetal.,2005;

Yaniketal.,2007;Zhangetal.,2010).SCWGfrombiomassalso

producesothergasessuchasCH4,CO2andCO(Yaniketal.,2007).

Unlikecombustionandpyrolysis,biomasstreatedwith

supercriti-calwaterdoesnotneedtobedewatered/driedpriortotheprocess

(Furness et al.,2000; Mahmoodand Elliott, 2006; Zhanget al.,

2010),whichisoneofthebenefitsofthistechnologyasPPMS

dewa-teringcanbecostly.Zhangetal.(2010)reportedthatsecondary

PPMStreatedbySCWGhadthehighestgasyieldwith37.7%ofPPMS

(ondrybasis) convertedintogases,fromwhichhydrogenyield

was14.5molH2kg−1.GasyieldfromsecondaryPPMSwashigher

thanmunicipalbiosolids treatedby SCWG(Zhang et al.,2010).

Supercriticalwateroxidation(SCWO)ofsecondaryPPMShasbeen

reviewedbyMahmoodandElliott(2006).SCWOproduceswater,

CO2,nitrogen(withouttheformationofNOXandSOX),acidsand

salts(MahmoodandElliott,2006;Wangetal.,2008).SCWOwas

efficientin removingcontaminantsfromvarioustypesofPPMS,

whichcouldbeappliedinsludgeremediationtechnology(Crain

etal.,2000).SCWOalsohasthepotentialtoproduceenergy(hot

waterandhigh-pressuresteam)asreportedforthetreatmentof

municipalbiosolids (Svanströmet al.,2004;Wangetal.,2008).

SCWGandSCWOprocessesappliedonvarioustypesofwetbiomass

(e.g.,sewagesludge,woodsawdustandglucose)werereportedto

beeffectivefortheproductionofhydrogen(Xuetal.,1996;Xuand

Antal,1998).

Directliquefactionisaone-stepprocessthatconvertsbiomass

intoliquidfuelwithoutthegasificationstep(Behrendtetal.,2008).

Directliquefactionispracticedattemperaturesvaryingbetween

150and420◦C,lowerthanpyrolysis,andpressuresrangingfrom

0.1to24MPa(Behrendtetal.,2008).Watercanbeaneffective

sol-ventforliquefaction,whichisoneofthebenefitswhentheprocess

isappliedtoPPMSasdewateringisnotrequired(Table5;Zhang

etal.,2011).Catalystsarealsousedduringliquefactioninorderto

improvethefuelyieldanddecreasetheformationofchar(Xuand

Lancaster,2008;Zhangetal.,2011).XuandLancaster(2008)

per-formedliquefactionexperimentsondriedsecondaryPPMSpowder

insuspensionindistilledwaterusingabombreactor(temperature

rangeof250–380◦C),withandwithoutcatalysts.Yieldsofheavy

andwatersolubleoilwereaffectedbytheliquefaction

tempera-ture,residencetime,initialbiomassconcentration,catalystsand

liquefactionair(inertorreducing).Thehighestheavyoilyieldwas

26%withaheatingvalueabove35MJkg−1,obtainedinthe

pres-enceofacatalyst(0.1MCa(OH)2)andapressurizedhydrogenous

(2MPaofH2)air(XuandLancaster,2008).XuandLancaster(2008)

pointedoutthattheyfirstaimedtounderstandthecontrolling

fac-torsoftheprocessandthatfutureworkshouldberealizedatthe

commercial-scale,wheresecondary PPMSistreated asreceived

(i.e.,withoutanydrying treatment).Zhanget al.(2011)

experi-mentedontheco-liquefactionofvariousratiosofsecondaryPPMS

mixedwithwastenewspapersusingdifferentcatalysts.Theheavy

oilyieldincreasedattemperaturesrangingbetween250and350◦C

withamaximumof28%at350◦C.Theheavyoilyieldincreasedto

34.4%whenusingthemosteffectivecatalystHCO2H(Zhangetal.,

2011).Theirexperimentswereperformedinabench-scalebatch

reactor.

5. IntegrationofPPMSinmaterials

TherearenumerousoptionsforusingPPMSasamaterial

com-ponent(Table6).Itisintegratedinavarietyofmaterialssuchas

biocompositesofwoodandplasticandotherconstruction

materi-als.PPMSisalsousedintheadsorbent–absorbentproductions.

5.1. Biocomposite:PPMSinwoodandplasticmaterials

PPMScontainsorganic(e.g.,cellulosefibers)andinorganic

com-ponents(e.g.,clay,calciumcarbonate)thatimprovestheproperties

of composites such as polypropylene, polyethyleneand rubber

(Table6).Forinstance,PPMScanreplacetheinorganicfillersin

theproductionofrubberandpolypropylene–ethylenepropylene

dieneterpolymer(PP-EPDM;usedinrubberindustry)composites

toimprovetheproductpropertiesandreducetheproductioncost

(Ismailetal.,2005,2006).Theirincorporationincreasedthetensile

modulus(i.e.,Young’smodulusorelasticity)butdecreasedthe

ten-silestrengthandelongationatbreak(Ismailetal.,2005,2006).The

sludgealsoincreasedthethermalstabilityabove500◦Candwater

absorptionofPP-EPDMcomposites(Ismailetal.,2005).

PPMScanbeusedinthecompositionofwoodand

polyethyl-enematerials(Table6).Soucyetal.(2014)determinedtheimpact

ofusingprimaryandsecondaryPPMS,fromthermo-mechanical,

chemithermomechanicalandKraftpulping,onthedevelopmentof

highdensitypolyethylene-wood-plasticcomposites(HDPE-WPC).

HDPE-WPCpropertieswerebetterwhenusingPPMSfromKraft

pulping,withitshighcellulosiccontentandlongerfibers,compared

withPPMS produced bythermo-mechanical and

chemithermo-mechanicalpulping(Soucyetal.,2014).Thecompositestrength,

waterabsorptionandthicknessswellingimprovedbyincreasing

PPMS proportion (Soucy et al., 2014). However,Hamzeh et al.

(2011)reportedthatwaterabsorptionandthicknessswellingwere

decreasedwithincreasingPPMSproportionusingdifferent

PPMS-composite formulationsthanSoucyetal.(2014).PrimaryPPMS

fibersreinforcedHDPE-WPCwhereassecondaryPPMScontent

neg-ativelyaffectedthephysicalandmechanicalHDPE-WPCproperties

(Soucyetal.,2014).

PPMScanalsobeusedtosubstitutewoodintheproduction

ofpallets(Table6).IntheU.S.,palletsmadeofwoodrepresent

approximately95%ofthepalletmarketshareandtheannual

pro-ductionisestimatedto450millionnewpallets(Kimetal.,2009).

Thesubstitutionof10%ofwoodparticlebyPPMSresultedin

pal-letshavingthesamemechanicalpropertiesthanpalletsmadewith

onlywoodparticlesandmeetingtheminimumrequirementsfor

standardmanufacturing(Kimetal.,2009).

Some studies demonstrated that PPMS can be incorporated

(partlyortotally)intheproductionofmediumdensityfiberboards

(MDF)andparticleboards(Table6).PrimaryandsecondaryPPMS

havenaturaladhesivepropertiesenabledbytheirfiberandprotein

contents,whichcanbeusedasafibersourceandparticlebinders

inMDFandparticleboardproductions(Migneaultetal.,2011a,

2011b; Pervaizand Sain,2011,2012;Xing etal.,2012a, 2012b,

2013).SecondaryPPMSwastestedasaco-adhesiveinMDFresin

(Migneaultetal.,2011b;Xingetal.,2012a,2012b,2013),itsuse

reducedtheformaldehydeemissionsbyupto68%comparedwith

controlpanelsanddidnotaffecttheinternalbondstrengthofthe

MDFproduct(Migneaultetal.,2011b).However,theshortfibers

lengthandthehighnon-fibrouscontentofthesecondaryPPMS

negativelyaffectedthemechanicalpropertiesoftheMDF,although

itstillmetthehigheststandardsoftheAmericanNationalStandard