an author's

https://oatao.univ-toulouse.fr/26733

https://doi.org/10.1016/j.jcomc.2020.100004

Castanié, Bruno and Bouvet, Christophe and Ginot, Malo Review of composite sandwich structure in aeronautic

applications. (2020) Composites Part C: Open Access, 1. ISSN 2666-6820

Review

of

composite

sandwich

structure

in

aeronautic

applications

Bruno

CASTANIE

a,∗,

Christophe

BOUVET

a,

Malo

Ginot

a,ba Institut Clément Ader (ICA), Université de Toulouse, CNRS UMR 5312, INSA, ISAE Supaéro, IMT Mines Albi, UPS, Toulouse, France b Elixir Aircraft, Batiment D1 - 6 rue Aristide Bergès, 17180 Périgny, France

Keywords: Composite Sandwich structures Aeronautic

a b s t r a c t

Thispaperpresentsareviewoftheissuesconcerningsandwichstructuresforaeronauticalapplications.Themain questionsraisedbydesignersarefirstrecalledandthecomplexityofsandwichstructuredesignforaeronautics ishighlighted.Thena reviewofapplicationsispresented,startingwithearlyexamplesfromthe1930sand theSecondWorldWar.Thegrowthintheuseofsandwichmaterialsincivilandmilitaryapplicationsisthen developed.Recentresearchandinnovationsconcludethepaper.

1. Fundamentalsofsandwichstructuresforaircraftapplications

1.1. Definition,symmetricandasymmetricsandwiches

“Thecharacteristicfeatureofthesandwichconstructionistheuse ofamultilayerskinconsistingofoneormorehigh-strengthouterlayers (faces)andoneormorelow-densityinnerlayers(core)”.This defini-tion,proposedbyHoff andMautnerinoneofthefirstarticlesdevoted tosandwichconstruction,in 1944[1],remainscurrentandhasbeen takenupinvariousformsintheworksdevotedtothistypeofstructure

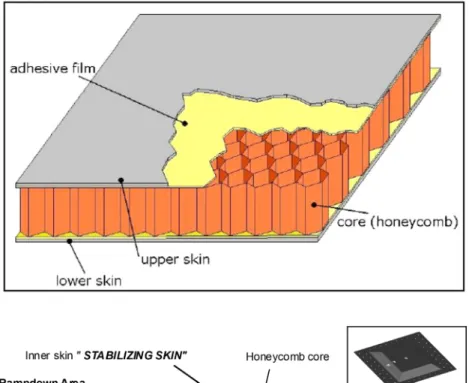

[2–7]. Greatnumbersofcombinationsof materialsandarchitectures arepossibletoday,bothforthecoreandfortheskins[8].However,for aeronauticalapplications,certificationgreatlyrestrictsthepossibilities. Today,onlyhoneycombcoresmadeofNomex,aluminiumalloyora limitednumberoftechnicalfoamsofverygoodqualityareused. Sim-ilarly,forskins,wemainlyfindaluminiumalloysandlaminatesbased onglass,carbonorKevlarfibres.AccordingtoGuedra-Degeorges[9], andalsointhecaseofsomestackingdescribedin[10](seealsoFig.22), foraeronauticalapplications,theskinshaveathicknessoflessthan2 mm.Sandwichesfallintotwocategories.Symmetricalsandwiches,such astheoneillustratedinFig.1,areusedmainlyfortheirresistanceto bucklingandtheirbendingstiffness.Thistypeofsandwichisperfectly suitedtopressurizedstructuresorthosesubjectedtoanaerodynamic loadand,generallyspeaking,itisbyfarthemostwidelyused.

Another,somewhatlesspopular,typeof sandwichis alsousedin aircraftconstruction:the asymmetricalsandwich(seeFig. 2). Asfor theclassicfuselagescomposedofathin skinstabilizedbystiffeners, anasymmetricalsandwichismadeupofafirstskinincarbonlaminate calledthe“WorkingSkin”,whichtakesmostofthemembranestresses fromthestructure.Thebucklingresistanceofthisskinisprovidedbya

∗Correspondingauthor.

E-mailaddress:bruno.castanie@insa-toulouse.fr(B.CASTANIE).

coreandasecondskindesignedattheminimumallowedandconsisting ofoneortwopliesofcarbonorKevlar,calledthe“StabilizingSkin”.

Inadditiontoitsparticularlyhighmechanicalcharacteristics,this solutionhastheadvantageofitsjunctionzonesbeingsituatedinpure laminateareas,thuscircumventingthedelicateproblemofthepassage oflocalizedforcestothetwoskinsbyinserts.Ontheotherhand,its useislimitedtonon-pressurizedandmoderatelyloadedstructuresof thehelicopter,lightaircraftordronetype. Anotherfundamental dif-ferenceisthegeometricnon-linearbehaviourduetotheoffsetofthe neutralline(inbeamtheory)withrespecttotheloadinglinelocatedin themiddleoftheworkingskin.Thisoffsetinducesabendingmoment thatisallthegreaterwhenthedeflectionishigh.Therefore,aforce/ displacementcouplingoccurs,whichgeneratesatypicalgeometric non-linearresponseandrequiresanadaptedapproach[11–14].Accordingto theexperienceoftheauthors,thistypeofstructureisoptimalfromthe masspointofviewfornon-pressurizedstructuressubjectedtolowloads. Ithasbeenappliedinmilitaryandcivilhelicopters[16]anddrones,and hasbeenstudiedfortheSolarImpulseplanes[17].

1.2. Basicmechanicsandsizingissues Linearstaticehaviour

Theideabehindsandwichconstructionistoincreasetheflexion in-ertiawithoutincreasingthemasstoomuch,asshownbyD.Gay[7]in asimplenumericalapplicationof3-pointbendingonastainlesssteel beamandthenusingthesamebeamwitha20mmthickhoneycomb sandwichcore(seeFig.3).Themassaddedisverylow(20%),whilethe deflectionunderbendingisdividedby22(Eq2ofFig.3).Itwouldhave beendividedby90(𝛿skins)ifthedisplacementduetotransverseshear

hadnotbecomepreponderantbecauseoftheweaknessofthemodulus ofthecore(Gcore=46MPa).Here,wearetouchingonthesubtletyof sandwichstructures,wheretheexpectedbenefitsareoffsetbythe

Fig.1. Sandwichconstruction.

Fig.2. Asymmetricsandwichstructures.

Fig.3. Bendingcalculationofasandwichbeam.

plexitiesgeneratedbyalightcore.Allcasesoflinearcalculationsunder simplestaticstresseshavebeenwidelydevelopedintheliterature[2–7], enablingsizingoftheskinsandthecore.

Thecorerequiresspecialattentionbecausetheallowablesarevery low,oftheorderofoneMPa,whereastheskinsgenerallysupportloads ofseveralhundredMPa.Therefore,therelativeorderofmagnitudeof thestressesinthecoreis1%orless.Thisphenomenonisparticularly sensitivein thecase ofcurvedsandwiches,e.g.forthetailboomsof helicoptersorincurvedfuselages[18–20],andalsofortaperedareas.

Globalandlocalbuckling

Asafirstapproximation,theincreaseinthebendingstiffness[EI] promisesaproportionalincreaseinthecriticalloadforbucklingifwe re-fertoEuler’sformula:FcEuler=𝜋2EI/L2forasimplysupportedbeam(L

isthelengthofthebeam).But,hereagain,theinfluenceofthecorehas tobetakenintoaccountandtheformulabecomesFCSandwich=FcEuler

/(1+FcEuler/tc.Gc),whereGcisthetransverseshearmodulusofthe

coreandtcisthethicknessofthecore.Thissignificantlyreduces buck-lingresistanceasshownbyKassapoglou[5].Inaddition,thepresence ofalightcorealsogenerateslocalbucklingmodesoftheskin (wrin-kling)orglobalbucklingmodescontrolledbythecore(shearcrimping). Thesemodesareoftencriticalandcanbethecauseofprematurefailure iftheyarenotgivenproperconsideration.Theymustimperativelybe theobjectofin-depthinvestigationevenifthisinvolves3Dfinite ele-mentmodelling.Forpre-sizing[4–6],aformula(Eq.1)resultingfrom arudimentaryanalyticaltheorywithrestrictiveassumptionsdeveloped byHoff andMautnerin1945[21]is usedforthecaseofwrinkling. Althoughthisformulagivesthetrendscorrectly,theresultsitprovides canprovetobeveryfarfromthoseofexperimentaltestsandasafety factorisrequired.Zenkerts[4]proposesreplacing0.91by0.5 accord-ingtohisexperienceinthenavalindustry.Kassapoglou[5]discusses therelevanceofthisformulavsfiniteelementmodellinginthecaseof compositeskinsandtests,andalsoproposesknockdownfactors.In

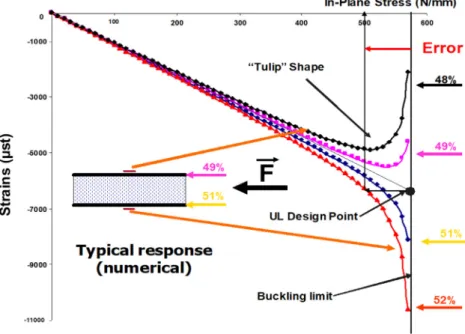

aero-Fig.4. Non-linearin-planecompressionresponseof symmet-ricsandwichstructures.

nautics,itiscommontotakeasafetyfactorof3toallowfortheintrinsic limitationsoftheformulaandtheeffectofinitialshapeimperfections

[22].

𝜎𝐶𝑟𝑖𝑡𝑖𝑐𝑎𝑙=0.91√3𝐸𝑆𝑘𝑖𝑛⋅ 𝐸𝐶𝑜𝑟𝑒⋅ 𝐺𝐶𝑜𝑟𝑒 (1) Eventhoughitsage,itssimplicityanditsrelativerelevancecause thisformulatoremainthemostused,manyotherapproacheshavebeen developedrecently[23–30],forexample)andwoulddeservemore ex-perimentalandnumericalevaluation.Moreover,thesizingof aeronau-ticalstructurescurrentlyusesaGFEM(GlobalFiniteElementModel) thatdoesnotcapturelocalbuckling.Thereforestrategiesofglobal/ lo-calcalculations[31]orapproachesusinganalyticalcriteriaremainto bedefined.Notealsothatcertainenvironmentaleffects,suchas tem-perature,cansignificantlyreducethecriticalstressoflocalbucklingin thecaseofasandwichwithafoamcore[32],whichcanbecriticalfor thestrengthoflightstructuressuchasglidersorprivateplanes.

Nonlinearstaticbehaviour

Ingeneral,nonlinearcalculationofsandwichesisnotnecessary be-causetheyaresubjecttobendingandtheirhighstiffnessmeansthat thestructureremainsundertheassumptionofsmalldisplacementsand strains.However,foraeronauticalstructures,inparticularthosethatare notpressurized,membraneloadsaredominant.Thisisparticularlythe caseforasymmetricalsandwichstructuresloadedbytheworkingskin, whichnaturallyhavethisbehaviour[11–15].Forexample,whenthe workingskinisloadedincompression,thestabilizingskinmaybreak intension.Ontheotherhand,itislessknownthatevensymmetrical sandwichstructurescanexhibitnon-linearbehaviourincompression, whichcanstronglyinfluencethedesign[13,33,34].Thiscaseisshown inFig.4,wherethesoftwaredevelopedin[11–13]wasusedtocompute thecompressionresponseofanasymmetricallyloadedsandwichbeam withadistributionoftheforceintheskinshavingtheratios49-51%or 48-52%.Thestrainsweretakenatthecentreofeachofthetwoskinsand typicaltulip-shapedcurveswerefound.Thesecurvesarealsoobtained undercompressiontestsonbeamsorsandwichplates.Thisphenomenon hadbeenidentifiedveryearlybyHoff andMautner[1],whoattributed thenonlinearresponseintheteststotheloadingoftheskinsnotbeing strictlyidentical.Thisseemstobeconfirmedbythepresent computa-tion.Hoff andMautnerperformedacheckofdissymmetryofthestrains intheskinsupto5timesbeforecarryingoutatesttofailure.Forthis reason,grindingofthefacesofthetestpiecesisrecommendedbefore performingthistypeoftest.Someauthorshaveattributedthisnonlinear responsetoanimperfectinitialshape[35]whichmayalsohave

con-tributedtothephenomenon.Inpractice,thereareseveralotherpossible causes,suchasvariationsinmanufacturingduetosmallstackingerrors, ordifferencesinfibrevolumeand/orsurfacefinishduetothe manufac-turingmethod.Itisalsopossiblethatdifferencesinloadingbetweenthe skinswillappearifataperedareaisused.

Thetulipcurvesareboundedbythecriticalforceofthestructure. ItisclassicaltouselinearassumptionstosizethesandwichattheUL designpoint(UL:Ultimateload).InFig.4,thispointcanbefoundatthe intersectionbetweenthelinearresponse,inblack,andthecriticalforce (verticalline).Sizingisgenerallydonewithadamagetolerancepolicy (seenextsubsection)insuchawaythat,atthispoint,thestraindoes notexceedanallowablevalue(forexample,about6000μstrainhere). However,witha nonlinearcalculationasproposed,itcanbe shown that thisvaluemaybe reachedmuchearlier,at around500N/mm, wellbeforethecriticalload.Thereforeadesignthatdidnottakethis behaviourintoaccountwouldbewrong.Thisphenomenonis,however, lessnoticeableforplatesthanforbeamsandnaturallydecreaseswith thebendingstiffnessofthesandwich[33].

1.3. Damagetolerance

Lowspeed/low energyimpacts,duetohandlingoperations dur-ingmanufacturingortodroppedtoolsduringmaintenanceoperations, aregenerallyconsidered.Aeronauticalsandwichstructuresaccordingto theGuedra-Degeorgesdefinition[9]areverysensitivetoimpact,asare laminatedstructures.Theimpactgeneratesavarietyofdamageinthe coreandtheskins,andtheresidualstrengthcanbegreatlyreduced.So adamagetolerancepolicymustbefollowed(seeFig.5and[10]),which dependsontheaircrafttype(FARorEASAfrom23to29).Giventhe securitychallenges,itmustbepragmaticandconservative.Themethod wasinitiallydevelopedforthefirstcertifiedprimarystructure:theATR 72compositewingbox[36]andisnowwidelyused[10,37].Theidea istodistinguishundetectabledamagefromdetectabledamage.Forthe former,thestructuremustbetoleranttodamagefromthepristinestate andis thereforecertifiedtoultimateloads(UL).Forthesecond,the damagemustberepaired,butadistinctionismadebetweendamage thatrequiresathoroughinspectiontobedetected(loadsofthedesign structurewithdamage:LimitLoad)andthoseimmediatelydetectable (often0.85LL).Thedetectabilitythreshold,calledBVID(BarelyVisible ImpactDamage),isdeterminedbybenchmarkswithpreciseinspection times.Foradetailedinspection,Airbushassetitat0.3mmand,fora quickinspection,at1.3mm[38].

Fig.5. Damagetolerancepolicy(reproducedfrom[10]).

Fig.6. CompressionAfterImpactapparatuswithanti-bucklingknives.

Theallowablescorrespondingtothevariouscasesareobtainedin CompressionAfterImpact(CAI).Thedeterminationisaboveall exper-imentalinordertosatisfytherequirementsofthecertificationand de-terminethevaluesAorB.AtestsetupasshowninFig.6isusedwith aspecimenofdimensions100×150mm2.Thespecimenisimpacted

initscentreaccordingtointernalAirbusorBoeingstandardsoralso ASTM. Theallowable thencorresponds tothemaximum strain𝜀Max

measuredduringthetest.Thesizingwithrespecttodamagetolerance isthereforesimplyreducedatallpointsofthestructuretotherelation: 𝜀Structurecompression<𝜀Max.

Inthiscontextposedbyaeronautics,numerousstudieshavebeen carriedoutinordertobetterunderstandandmodelthephenomena in-volved.Onlyafewarementionedhere-inparticularthesummarywork oftheFAAorNASA[39–43].Whenanaeronauticalsandwichstructure receivesanimpact,thedamagetotheskinsissimilartothaton compos-itelaminatesbutthecoreiscrushedlocally(seeFig.7).Thecrushingof Nomexhoneycombstructuresisverycomplex,withwrinkling,tearing anddamagetothephenolicresinlayer[46].Thiscomplexbehaviour canbemodelledaccordingtovariousstrategies[40,44]:detailedmodel

[45],discretestrategiesbased onnonlinearsprings[46–50]or dam-agemechanicsusinganorthotropiccontinuum[51,53].Whendamage afterimpactiswellcaptured,itisrelativelyeasytodevelopefficient modelsforcompressionafterimpact.Thecriteriaforfailurearemost oftenmaximum straincriteriaon theskin[51]orthemore original

Fig.7. Impactdamageonanaeronautic sandwichforseveral energylevels (reproducedfrom[9]).

corecrushcriterion[52].Thebehaviourincompressionafterimpact iswellunderstood.Itisacombinationof3non-linearities:ageometric non-linearcouplingwiththeindentedzone,whichwillcauselocal bend-ingandcompressthehoneycomb;anon-linearresponsetothecrushing ofthehoneycomb;and,finally,thedamagedbehaviourwithinthe com-positeskinsortheplasticityofmetallicskins.Unlikerigidbodies,which tendtocreateadentshapesimilartotheimpactor,softbodiescreate analmostuniformcorecrushundertheimpactzone.Thistypeof im-pactseemstobemoresevereforthestructuralstrengthofthesandwich panel[54].

1.4. Joiningsandwiches

Although,forcompositestructuresingeneral,itissaidthat"thebest wayofjoiningisnojoining", inpractice,makingjointsis inevitable. ThefirsttypeofjointconsideredhereissandwichtosandwichwithT,L oredgetoedgejoints[55–62]forexample).Therearenumerous tech-nologicalpossibilities,whichmustbeexaminedbeforedeterminingan optimuminagivencontext.Feldhusenetal.([57]andFig.8)analysed 783initialsolutionsbeforeconvergingononly18"promisingconcepts" accordingtothefollowingcriteria:

• Theconnectionmustbeabletotransmitallforcesandmomentsthat occur.

Fig.8. Edgejunctions(from[57]).

• Thedimensionsofthejointshallbeassmallaspossibleyetaslarge asnecessary.

• Elasticdeformationsthatwilloccurunderloadmustnotbecomeso largeastoharmthejoint.

• Theprincipleofuniformstrengthshallbe appliedtosandwich el-ementsandjoint.Thefatiguelifeofallpartsinvolvedshallbethe same.

• Thejointshallbeaslightweightaspossible.

• Theintersectionareabetweensandwichandjointshallbedesigned insuchawaythatsharpdeflectionsoftheforceflowlinesorstrong changesintheirdensityareavoided.

Anotherinterestingstudyworth mentioningis thatoftheRobust CompositeSandwichStructure(RCSS)programmecarried outin the USAin the late1990sfor thedesign of anF22 fighter plane struc-ture.Thedesigncriteriawere:loadtransfer,producibility,durability, repairabilityandfuelsealing[56].

Anotherveryeffectivewaytoachievethejunctionsistodesigna skintolaminatetransition.Thejoinisoffsetintoalaminate,whichis simplertodesignandmorerobust(seeFig.2andFig.9,solution12,

[63–68]).AlthoughnotchosenfortheRCSSprogramme,thistypeof so-lutioniswidelyusedinhelicoptersorconvertibles[11,16,65]forboth symmetricalandasymmetricalsandwiches.Despiteitsinterest,thistype ofsolutionhasbeenlittlestudiedbecauseitgeneratesadditional com-plexitieswithnumerousnonlinearcouplingsthatcangenerate prema-turefailures.Inaddition,itisanareathattransfersloadsandmustbe sizedaccordingly,especiallyinthepresenceofreinforcingplies[34].

Themostcommonlyusedjoiningmethodforsandwiches,whether foraeronauticsorspace,is theuse ofinserts[69–83].Aninsertisa localreinforcementofthecorethatmakesitpossibletotolerate con-centratedforces,mostoftenviabolts.Insertscanbeusedeithertojoin sandwichestogether,tojoinasandwichparttotherestofthestructure (highlyworkinginserts)ortofixsystems,cablesorhydraulicpipes(low workinginserts).Theirstudyisstilllargelysemi-empirical,beingbased eitheronexperimentalresultsgivenbysuppliersoronanalytical mod-els[69–71]thataresometimesveryefficient[72–73].Theseapproaches havethemaindrawbackofremaininglinearandthereforeveryfarfrom

thecomplexfailurescenariosidentifiedintheliterature[74–77]: buck-ling,postbucklingandtearingofNomexHoneycombcores,compression andcrushingofthepotting,punchingoftheskins,localdebonding(see

Fig.10).Thesephenomenaarealsodifficulttotacklebecausethereis astrongdispersionlinkedtothemanufacturingmethods,which gener-atenumerousdefects[78–80].Intherarerecentpapers,twomodelling strategiesareemployed:refinedhoneycombmodels[81]orevenlighter modelsusingdamagemechanicsandvolumicelements[82],which al-lowthecreationoffailuremodemaps[83].Itisinterestingtonotethat, accordingtoMezeixetal.[84],thepull-outbehaviourafterimpactof theinsertsisverygood,withlimitedreductionoftheorderof10-15%. 1.5. Manufacturingandcontrol,repairs,moistureandotherissues

Manufacturing

Therearethreeusualwaysofmakingsandwichstructuresinan au-toclavetoensureaeronauticalquality:

• Co-curing:bothskinsfreshandbondedtothecore,withorwithout anadhesivefilm,duringcuring(Onecuring).

• Co-bondingprocess:oneskincured,anotherfreshbondedtothecore whilecuring(Twocurings).

• Secondarybonding: thetwo skinsare curedseparately andthen bondedtothecorewithanadhesivefilm(Threecurings).

Usually,thecuringpressureinthepresenceofNomexhoneycombis limitedto3barstoavoidcorecrush,especiallyintherampdownarea

[85].Despitetheimportanceofthesubjectinpractice,alimitednumber ofstudieshavebeenpublished,probablybecause,eventoday,the man-ufactureofcompositestructuresreliesheavilyonindustrialknow-how, whichisjealouslyguarded.In1997,KarlssonandAstrom[86]presented andmadeaqualitativecomparisonofthemaintechnologiesavailable tomakesandwichstructures,inparticularinthenavaland aeronau-ticalindustries.D.A.Crumpetal.[87]comparedthemethodsinand outsideautoclaveforthemanufactureofsecondarystructuresandfound thatthemethodoutsideautoclave(ResinFilmInfusion)offeredthebest economicequation.Theproblemoftheairtrappedintheclosedcellsof

Fig.9. Robustcompositesandwichstructures(reproducedfrom[56]).

Fig.10. Failurepatternofanaeronauticinsertusedfor land-inggeardoorunderpull-outloading(reproducedfrom[76]).

thehoneycombwasalsostudiedandmodelled,payingparticular atten-tiontostudyingtheevolutionofthepressureduringcuring[88–92].In arecentstudy,Andersetal.[93]showedspectacularfilmsofthe poly-merizationoftheadhesivefilmaccordingtotheparametersofcuring andthegoodorbadrealizationofthemenisci,thusconfirmingthe em-piricalfindingsoftheindustry.Unlikethesituationforlaminate[94], thereisnoadvancedthermokinetic,thermochemicalor thermomechan-icalmodelofthecuringofaeronauticalsandwichesthatcanbeusedto predictshapedefectsafterspring-back[95]orspring-in[96].The avail-ablestudiesareessentiallythermomechanicalandanalytical[97–100]. Anothercommonmanufacturingdefectiscalled“telegraphing”.Itisa shapedefectinvolvinglocalundulationwithrespecttothehoneycomb cells.However,aeronauticalstructuresarelessconcernedthanspace structuresbecausethetechnologicalminimaareatleasttwopliesfor theskinsandthecellsizesaresmall.

Despite the necessarily limited extent of this bibliographical overview,itisclearthat,giventhecurrentstateoftheartinthe mod-ellingoflaminatecuring,muchresearchremainstobedonewithregard tothemanufactureofsandwichstructures.Thisactioncouldalso pro-motetheirdevelopmentbysecuringindustrialization.

Non-destructivetesting

Inaeronautics,allstructuralpartsmustbecheckedtoensuretheir initial quality. Inthecertification processof theBeechcraftStarship

[10],itisstated:“Acceptancecriteriawereestablishedforstructurewith porosity,voids,anddisbondstoaccountforinitialquality(flaws) devel-opedduringthemanufacturingprocess.Damagemodessuchasporosity, voids,anddisbondsweresubjectedtospecifiedacceptancecriteria.This initialqualityisintrinsictothemanufacturingprocessandthe inspec-tionstandardsandrepresentstheas-deliveredstate,andtherefore,the structuremustbecapableofmeetingallrequirementsofstrength,

stiff-Fig.11. Schematicofa scarfrepair appliedtoa sandwich component.Top:topview,bottom:sectionview(Reproduced from[103]).

ness,safety,andlongevitywiththisinitialquality”.Today’sinspection methodsinanindustrialcontextaremainly:visualinspection, ultra-sonicandX-rayinspection,[101,102].TheManualTapTest,Automated TapTest,MechanicalImpedanceAnalysisandC-Scanhavebeen com-pared[103]and,accordingtotheauthors,“Themoresophisticatedthe method,themoreaccurateitwasindeterminingthesizeofthe dam-age”.Theacousticmethodsaremainlyusedtodeterminethe manufac-turingqualityoftheskinsortodetectskin/coreseparation.These meth-odsaregenerallydifficulttoimplementinthecaseofsandwichesand requiregoodknow-how.Othersexist,suchasinfraredorholographic methods[104],butarelessinuseinindustry.

Repair

Inlinewiththedamagetolerancepolicy(seeFig.5and[10]),assoon asdamageisdetected,itmustberepaired.Repairinstructionsaccording tothetypeofdamagearegivenintheSRM(StructuralRepairManual) ofthevariousmanufacturers.Theprinciplesofrepairareexplainedin

[103–107]accordingtowhetherthedamageisminorormajoranda typicalrepairisshowninFig.11.Althoughtherepairprinciplesmaybe simple,thesizingoftheserepairsiscomplexandconcernsthescientific problemsofbondedjointswithcomplexgeometries[103–112].Despite everything,ifcorrectlycarriedout,repairsallowmorethan90%ofthe initialresistancetoberecovered,eveninthecaseofrepeatedimpacts

[109].Thus,forgliders,thelifetimecanreach50yearswithrepairs. Moistureingression

Sandwich structures have a bad reputation because a number of problems or incidents have been reported in the open literature

[113]andprobablymanymore byrumour.Theproblemismost of-tenlinkedtoclosedhoneycombcellsthattrapmoisture.Thehumidity canthencausepatchesofcorrosiononthemetallichoneycombcores, decreasesintheresistanceofthebondedjointbetweentheskinandthe core,ordegradationoftheNomexduringthefreeze-thawcyclesthat accompanychangesinexternaltemperaturesduringflights[113–118]. Thecausesofmoisturediffusioncanbelinkedtotheverynatureof hydrophilicepoxyresins[116],topoordesignofthecoreclosure,to

poorsealingafterarepair,oreventoimpactsbelowtheBVID[114]. From[151],theUSNavybannedtheuseofaluminiumhoneycombon theV22 andF/A 18programmes. However,asthenumberof flying sandwichstructures shows,these problemsareperfectly manageable

[114].Onemethodistodesigntheskinswithaminimumnumberof pliesoffabriconthesandwichtoensureagoodseal.Forcertification authorities,WaterIngressionTestswererequiredforthecertificationof theBeechcraftStarship[10]:

“Twelve-inch-squarepanelswithinflictedpuncturesofonefacesheetwere immersedinwatertoallowwaterintothecoreinthepuncturedregions.They werethensubjectedtofreeze/thawcycleswithvacuumappliedduringfreeze tosimulatehighaltitudeflightandtheninspectedtoensurethatwaterdid notpropagatebeyondthepuncturedregions.”

1.6. Summary

Inthissection,themainproblemsspecifictothedesignof aeronau-ticsandwichstructureshavebeenbrieflypresented.Others,like light-ningstrikesorcertificationtests,havevoluntarilynotbeentreated be-causetheyaregenerallyhandledinasimilarwaytothoseonlaminated structures[10].Itisclearthatthepotentialgainofferedbysandwich structuresisverylargebuttheircomplexityisgreaterandtheymustbe approachedwithprudenceandhumilityand,ifpossible,bycapitalizing onexperiencetoguarantee success.Inthefollowinghistorical devel-opments,wewillgraspthiscomplexitythroughanumberofexamples. Fromtheresearcher’spointofview,itisinterestingtonotethatmany areas,fromcalculationtomanufacturingandenvironmentaleffects, re-maintobestudiedandimproved.

2. Theverybeginning:Woodconstruction

AccordingtoProfessorHGAllen[119],civilengineeringhasused sandwichconstruction (called“doubleskin” at thetime)since1849 andseveralsourcesclaim thatapatentmayhavebeentakenout in 1915byHugoJunkers(ProfessoratAachenuniversityandthefuture

Fig.12. Gliderwoodsandwichconstruction(reproducedfrom[123]).

fatheroftheJu-52)forasandwichstructurewithhoneycombcore. How-ever,asfarastheauthorsknow,heneverwentontoexploititforhis ownaircraft[120]. In1924,apatentfora gliderfuselagewasfiled byTheodoreVonKarmanhimselfandP.Stock[121]andis citedin thepapersofNicholasJ.Hoff[1,122,123].AccordingtoHoff,“It in-dicatesthattheglidingsocietyofthePolytechnicInstituteofAachen musthaveplanned,ifnotbuilt,afuselage havingasandwichskin”. Thus,gliders wereprobably thefirst flying structurestohave afull sandwichconstruction.Therequiredcriteriawere:aerodynamic refine-ment,lightweight,inexpensiveproduction,sturdinessandeaseof re-pair,andalsomanufacturingabilitytomakedoublecurvedstructures. Themanufacturingprocessusedawoodenmouldandalargenumber of clamps.Themouldwas linedwithmetalresistanceheatingpads, thetemperatureof whichwascontrolledbyathermostat. Auniform pressurewasmaintainedbymeansofavacuumbagtocurethe ther-mosettingphenol-formaldehydegluethatwasused.Itisimportantto noteherethatthefirstdevelopmentofawoodsandwichstructurewas rootedintheapplicationofefficientgluesforbondingwoods.The urea-formaldehydeadhesiveknownbythecommercialnameof“Aerolite” wasdevelopedbyDeBruyne[124],whowouldlaterinventtheRedux films.

AsandwichD-Sparandatypicalfuselage ofa gliderofthetime areshownFig.12.Itisremarkablethattheadvantagesofsandwichor compositestructures,suchasthesimplificationofthedesignandthe reductioninthenumberofparts,werealreadyhighlightedasindicated bythesleekdesignoftheD-Spar.AccordingtoHoff andMautner“an interestingdesignfeatureisthelocalreinforcementofthestructureto

with-standtheconcentratedloadsimposedbytowingandlanding.Backoftowing hookAandaboveskidCintheregionmarkedB,thecoreofthesandwich skinisspruce.Thedensityofthisspruceinsertischangedthroughthe appli-cationofcompressionduringthemanufacturingprocessinsuchawaythat thespecificweightis1.2nearhookAwhileitdecreasesgraduallyto0.5near bulkheadD.Elsewherethecoreisbalsawithitsthicknessdecreasingfromthe highlystressedbottomportionofthefuselagetowardthelightlystressedtop portion.ThewingisattachedtothetwomainframesDandEofthefuselage. BetweentheframestwobeamsFarearrangedtosupportthelandingwheel”. Itshouldbenotedthattheexamplegivenin[123]andreproducedhere isnotdatedandisprobablyrelatedtoSecond-World-Warorearlier glid-ers.Today’sgliderstructuresarestillmadewiththinsandwichbutthe coresareoffoamandtheskinsofglassorcarbon.

Someparts of aircraftwerepunctuallymanufacturedwith wood-basedsandwichstructuresinthenineteen-thirties.Hoff[122]reported pontoonsoftheSundstedtplanedevelopedintheUSAin1919,the Sky-dineaileronin1939,thefuselageoftheDeHavillandComet(DH88) in1934andDeHavillandAlbatrosin1938andthewingsofaFrench airplanedevelopedbySE.Mautnerin1938.TheDeHavillandAlbatros DH91wasafour-enginetransatlanticmailplaneabletocarry22 pas-sengers,whichmadeitsfirstflightin1937(seeFig.14(a)).The sand-wichwasdesignedwithplywoodskinsandabalsacore.FortheFrench aircraft,aFrenchpatent,“theBrodeauprocess”,datingfrom1934is de-tailedin[125](seeFig.13).Thesandwichismadeupof2plywoodskins andacorkcoredrilledwithholestooptimizethemass.Thisprocessis believedtohavebeenappliedtoaLignelaircraftin1938.

ItisnotwellknownthattheMorane-Saulnier406(seeFig.14(b)), asingle-seatinterceptorfighterbuiltFrance,whichfirstflewonAugust 8th,1935,wasdesignedwithawingmadeof“Plymax”.Thisisa

sand-wichstructurewithaluminiumskinsandanOukoumé plywoodcore. However,thistechnologicalchoicewascomplexfromamanufacturing pointofviewandpenalizedtheramp-upinproductionoftheaircraft. Inaddition,thisaircraftprovedtobeinferiortotheMesserschmittBf 109intheBattleofFrancein1940.Thistypeofplywood/aluminium structurehasalsobeenrediscoveredrecentlyandshowsverygood me-chanicalqualities[126]incompressionandcompressionafterimpact

[127].

Theplanethatismostfamousandmostcitedforitsplywoodskin andbalsacoresandwichstructuresisthedeHavilland“Mosquito” DH 98(seeFig.14(c)).Itturnedouttobeoneofthebestplanesofthe Sec-ondWorldWar,bothforitspureperformanceandfortheextraordinary missionsitachieved.AsProfessorHGAllennotesin[119],itisoften wrongly presented asthefirstplanewithprimary partsin sandwich structures.However,itsdesigncomesfromtheexperienceacquiredby deHavillandwiththeDH88andDH91.ItisverysimilartotheDH88, whichhadbeenproposedtotheBritishWarMinistryinalightbomber versionbutrefused.However,deHavillandpersistedandshowed fore-sightinanticipatingthealuminiumshortagethatoccurredduringthe SecondWorldWar.

The detailed design of the structure is perfectly explained in

[128]andreproducedhere:“LiketheCometandAlbatrossmainplanes,de HavillandconstructedMosquitomainplanesoutofshapedpiecesofwoodand plywoodcementedtogetherwithCaseinglue.Approximately30,000small, brasswoodscrewsalsoreinforcedthegluejointsinsideaMosquitomainplane (another20,000orsoscrewsreinforcedgluejointsinthefuselageand em-pennage).Theinternalmainplanestructureconsistedofplywoodboxspars foreandaft.Plywoodribsandstringersbracedthegapsbetweenthespars withspaceleftoverforfueltanksandengineandflightcontrols.Plywood ribsandskinsalsoformedthemainplaneleadingedgesandflapsbutde Hav-illandframed-uptheaileronsfromaluminiumalloyandcoveredthemwith fabric.Sheetmetalskinsenclosedtheenginesandmetaldoorsclosedover themainwheelwellswhenthepilotretractedthelandinggear.Tocoverthe mainplanestructureandaddstrength,deHavillandwoodworkersbuilttwo topmainplaneskinsandonebottomskinusingbirchplywood.Thetopskins hadtocarrytheheaviestloadsothedesignersalsobeefedthemupwithbirch orDouglasfirstringerscutintofinestripsandgluedandscrewedbetweenthe

Fig.13. "Brodeau"process,1934[125].

Fig.14. Picturesofsomeaircraftwithsandwichstructures(a)deHavilland88"Albatros",(b)MoraneSaulnier406,(c)deHavilland98"Mosquito",(d)Sandwich typemouldedfuselage(Pictures(a),(b),(c)fromWikipedia,(d)from[122]).

twoskins.Thebottomskinwasalsoreinforcedwithstringers.Togetherthe topandbottomskinsmultipliedthestrengthoftheinternalsparsandribs.A Mosquitomainplanecouldwithstandrigorouscombatmanoeuvringathigh G-loadswhentheaircraftoftencarriedthousandsofadditionalpoundsof fuelandweapons.Tomaintainstrength,trimweight,andspeedfabrication time,theentiremainplaneandsparwasfinishedasasinglepiece,wingtipto wingtip,withnobreakwherethewingbisectedthefuselage.Afinishedand paintedmainplanewaslightandstrongwithasmoothsurfaceunblemished bydrag-inducingnailorrivetheads.”

Itis quiteremarkabletosee thattheconstructionwas really op-timizedintermsof“stacking” according totheareasof theaircraft, withasimplebirchplywoodskinfortheundersideofthewingand asandwichconstructionfortheupperside.Manufacturingwasa one-shotprocess,whichisnowsoughtbymanufacturerstoreducecosts(see

Fig.14(d)).Therearealsoglued/boltedjointsthatarestillused to-dayincertainstructuresofmilitaryhelicoptersandarethesubjectof activeresearchtoreducethenumberoffastenersandbringdowncosts ([129,130]forexample).Forthesereasons,beyondjustsandwich struc-tures,theMosquitoisoneofthemostimportantprecursorsofmodern, composite-structureplanes.

3. SandwichhoneycombstructuresforMACH2andMACH3

aircraft

Inthe1950sand1960stheColdWarragedonandauthorizedthe developmentofextraordinaryaircraftprogrammesintheUnitedStates (andprobablyalsointheUSSR,buttheauthorhasnoinformationon Sovietaircraft).Thefirstthatcaughttheattentioninthisarticleisthe

Convair B-58bomber,which madeitsfirstflight onNovember11th,

1956andwhichcouldreachMach2.4.OnehundredandsixteenB-58s werebuiltbeforethebomberwaswithdrawnfromoperationalservice in1969.Thestructurewasextremelylight,makinguponly0.24per centoftheaircraft’sgrossweight,anexceptionallylowfigureforthe era[56].Itwaslighterthanlateraircraft(F16:0.328,F14:0.422,F15: 0.361).Thedetailofitsstructureisexplainedin[131].Thewingsurface consistedofasandwichstructurewithaluminiumskinsandaphenolic resinfiberglassclothhoneycombcore.Theuseofthistypeofsandwich allowedsealing,thusreducingthenumberofsparsinthewingwhile enablingoperationbetween-55°Cand+126°C.Aspecificadhesivethat couldcreateameniscuswasdevelopedtomakethissandwich.Forthe fuselage,thistypeofstructurewasalsoused,exceptforthehottestparts, whichweremadewithasandwichhavingstainlesssteelskinanda hon-eycombcore.

The XB-70“Valkyrie” wasa MACH3supersonic bomber studied andmanufactured(inonlytwoprototypes)byNorthAmerican Avia-tion(NAA),seeFig.15.ThefirstflightwasonSeptember21st,1964. DuetoitsMACH3speed,theskintemperaturesrangedfrom246°Cto 332°C.Toavoidusingrareandexpensivetitanium,NAAusedastainless steelhoneycombsandwichskin(seeFig.15),whichprovedtobevery efficient,notonlyfromastructuralpointofviewbutalsoforthermal insulation(especiallyforfueltanks)athighspeedwithalowweight penalty[133].Itwasalsointerestingforaerodynamicsmoothnessand acousticfatigueintheinlet.Itcoveredasurfaceareaof2000m2,68% oftheairframe[134].Thesandwichusedwasallstainlesssteelandthe skins werebrazedtothehoneycombinthesamealloyfollowingthe explanationsprovidedin[135]:

Fig.15. (a)and(b):PicturesoftheXB70from[136],(c)typicalsandwichconstructionfrom[135],(d):improveddesignforsealingfrom[134]and[137].

Fig.16. CompositeHoneycombareasoftheSR71,shownin black(from[139]and[140]).

1) preparingthebasiccomponents(core,skins,brazingfoil,closeout edgememberifany)

2) Assemblingtheseelementsundersurgicallycleanconditions 3) Placingtheassemblyinanairtightsteelcontainer,calledaretort,

whichisthenevacuatedandsubsequentlyfilledwithaninertgas, suchasargon.

4) Placingtheretortcontainingthepanelinaheatsourcefortheactual brazingprocess.

Afterdifferenttrials,theelectricblanketbrazingmethodwas pre-ferred.Ittookabout15minutesforapanelandthetemperaturereached about950°Ctomaketheweld.Thenthetemperaturewascarefully re-ducedandasecondcurewascarriedoutformetaltreatment.

However, the process was not immediately efficient and some skins became detached in flight, fortunately without causing ir-reparabledamage.Similarly,improvements totheprocesswere sub-sequently implemented to guarantee the sealing of the tanks (see

Fig. 15). The complete history of this aircraft can be found in

[132].

Despitetheprogrammebeingdowngradedtoaresearchprogramme, probablybecauseofitscostandthearrivalofintercontinentalmissiles, theaircraftsatisfiedtheinitialrequirements,andthetechnologiesfor makingthesandwiches,whichtook5yearstodevelop,havespreadto manyotherprogrammes(727,C141,ApolloandtheSaturnspace ve-hicle)andcreatednumerousspinoffs.Forexample,thebrazingalloy waslaterusedtoattachcarbideandtungstencarbidetoolfaces[135]. Laterstudieswerecarriedoutontitaniumsandwichesbrazedfora su-personic transportplanewerecarriedout...buttheresults werenot usedin practicebecauseof thewithdrawal oftheprogramme[138]. Concorde,whichflewforthefirsttimein1968andreachedMACH2.2, alsousedaluminiumsandwichesforitsrudder[132]andcarbonskin sandwichesforailerons.Thetotalmassofcompositesfortheaircraft alreadyreached500kg[162].

Fig.17. (a)HorizontalstabilizerofF14 madewith boron/epoxy skin andaluminium honeycomb core, (b) DassaultMirage F1carbonandboronsandwich structureoverview.

Itisnotpossibletogiveevenarapidoverviewofthisperiodand thistypeofaircraftwithoutmentioningthefamousSR71“Blackbird”

[141].Despitetheextremelyhighsurfacetemperatures,whichmeant thatthestructurewasmainlymadeoftitanium(unwittinglyprovided bytheRussians),somepartsof theSR71weremadeofasandwich composedofasbestosskins/fiberglass,aluminumnidacore (accord-ingto [140]). These parts werenon-structural butdesigned to pro-videstealth functionsasshown by thetriangularshapes in Fig.16. Afterthefirsttitaniumversions,thismaterialwasalsousedforthe2 rudders.

4. Secondarycompositesandwichstructures

Safetybeingoneofthemainconstraintsinaeronautics,the introduc-tionof sandwichmaterialswithcompositeskinswasperformedvery graduallyin civilaviation,starting withthenon-structuralpartslike interiorparts,sidewalls,bagracks,andgalleys,orflooring(whichis stillinusetoday[81]).Thesewerefollowedbysecondarystructures likespoilers,rudders,ailerons,andflaps,andfinallytheprimary struc-tures, which willbe discussedin thenextsection[142,143]. Inthis sense,militaryprogrammesservedasprecursors,andcomposite

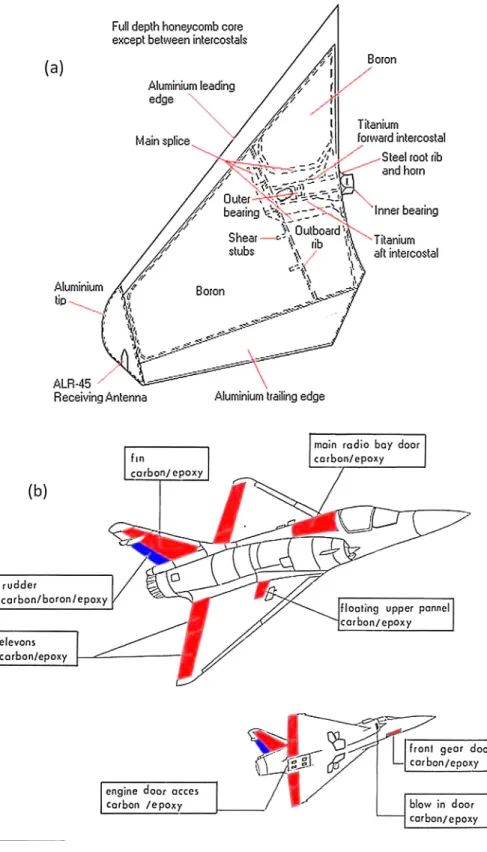

sand-Fig.18. B747overviewofsandwichstructures.

wichstructureshavebeensuccessfullyapplied inmanymilitary pro-grammesaroundtheworldsincethe1960s,whenfibresofboronand carbonbegantobeavailable.Intheannexof[146],acomprehensive reviewofcompositepartsmadeforresearchorproductionisprovided but,mostofthetime,itisnotstatedwhetherthedesignisinsandwich ornot.However,plane-by-planeresearchhasrevealedthatsecondary structuressuchasthelandinggeardoor,speedbrake,flaps,andrudder, werebuiltinaluminiumhoneycomb/boron-epoxyskinandwere ap-pliedtoprogrammesliketheMcDonnelF4,NorthropF5,DouglasA4, GeneralDynamicsF111,GrummanF14(seeFig.17)andmanyothers. InFrance,theDassaultMirageF1horizontalstabilizerswerealso madewithboronepoxyskinsandaluminiumhoneycombcore,for ex-ample.Infact,untilthemid-1970s,boronfibrewasindeedcheaperand moreavailablethancarbonfibre.However,carbonfibreveryquickly supplanteditandmanycarbonsandwichapplicationsstarted,asonthe Mirage2000(firstflightMarch10th,1978).InFig.17(b),thefin,

rud-derandaileronaremadeofsandwichstructureswithaluminium hon-eycomb.However,fromtheMirage4000onwards,thefinwasbuiltin monolithicself-stiffenedlaminatemadeofT300-914carbon-epoxyplies

[147].

Asfaraslargecivilaircraftareconcerned,theBoeing747(firstflight February9th,1969)isdesignedwithalargeproportionofsandwich(see

Fig.18).Ithasabouthalfthesurfaceofthewing,includingtheleading andtrailingedges,madeofglassfibreandNomexhoneycomb,which isalsousedforthelargebellyfairing.Mostoftheflapsaremadewith thesamesandwichbutaluminiumhoneycombandskinsarealsoused. However,thewingbox,theverticaltailboxandthefuselagearestill madeofaluminiumstiffenedpanels.

Theuseofcompositeshassinceincreasedsignificantlywith,in par-ticular,theATR72(firstflightonOctober27th,1988),whichwasthe

firstcivilaircrafttohaveacarbonprimarystructure(thewingbox) cer-tified[36].Italsoincorporatesmanycompositesandwichstructuresfor secondarystructuresbutwithawidevarietyofskins:glass,Kevlarand carbon(seeFig.19).

ThesesolutionshavealsobeenappliedintheA320,A330andA340 programmes. However,in themost recent programmes, the propor-tionofsandwichmaterialsinsecondary structureshasbeen decreas-ing,as shown in Fig.20. Forthe A380,theBoeing 787 or the Air-busA350 only thebellyfairing, thenacelles,the frontlandinggear doors,someaileronsandtherudderarestillmadewithsandwich struc-tures[144,145].Theotherpartsareself-stiffenedmonolithicstructures, whichcertainlypresentaneconomicadvantagetoday.

5. Primarycompositesandwichstructures

Themost famous aircraftinsandwich structureis theBeechcraft Starship,whichmadeitsfirstflightonFebruary15th,1986[10,149– 152].Itwasthefirstinitscategoryandithasgreatlyhelpedtoreclaim thefieldandcontributedvaluableexperience,whichhasbeenbeneficial

notonlytoBeechcraftbutalsototheentireaeronauticalindustry.As KevinRetzpointsout[152]:“Only53Starshipswereproducedbefore productionendedin1995.Thiscouldnotbeconsideredafinancially productiveprogrambutitgaveRaytheon/Beechaverysound founda-tiontobuildon.BeechusedthistowinC17contracts,andonitsother aircraft.ForRaytheontheStarshipprovedtobeabonanzaof knowl-edge”.TheStarshipconfigurationwasoriginallyconceivedin1982by BurtRutanandwentintoproductionin1988[151].Itwascertifiedon June14th,1988andwasthefirst“allcomposite” aircraftcertifiedbythe FAA,fouryearslaterthanoriginallyscheduled.About72%ofthemass ofitsstructurewasintheformofcompositematerial,mainlyepoxy car-bonskinsandNomexhoneycombcoresinHEX,OXorFLEXforms.The densitywas48kg/m3butitcouldreach72,90or144kg/m3locally. Thefuselagewasmadeupoftwomanuallydrapedhalf-shells,whilethe wingcoverswere16mlongone-shotpieces.Itisinterestingtoseethe numberofteststhatwerenecessarytocertifythisaircraft[149]:

•Fullscalestatictests...99

•Environmentaleffects,fullscaleandcomponents...29

•Damage tolerance, full scale and components (9 × 2 lifetime)... 360000h •Residualstrengthafterfatigue...18

•Jointstesting...335 •Parts...20 •Bucklingpanels...39 •Delaminationpanels...72 •Impactpanels...160 •Solareffect...47 •Couponlevel...8000 Thenumberoftests,andthusthecostofcertification,wasveryhigh. Moredetailsonthesecertificationtestsaregivenin[10].Inthispaper,a typicalstackingtechniquemergingunidirectionaltapeandplainwave is shown(seealsoFig.22).Notealsothepresenceofacoppermesh onthesurfaceforlightningstrikes.Thecertificationprocessisalmost thesametodaywithseveraltensof thousandsoftests fortheA350. ThedevelopmentwasdifficultbecausetheFAAregulationsondamage toleranceevolvedduringtheprogramme,generatingdelays.Inaddition, aprematurefailureoccurredduringstructuraltestingandthestructure thereforehadtobemodifiedindepth.Theentiremanufacturingprocess alsohadtobecertified[151].

However,manylessonswerelearnedfromthisexperienceandled tothesuccessoftheRaytheonPremier.Thefuselageissimilartothat of theStarship(see, forexample,twotypicalstackingsequencesfor thesetwoplanesinFig.22[10]) but,fortheRaytheonPremier,itis obtainedbyAdvancedFibrePlacement(AFP).Inaddition,the manu-facturingmethodwasstudiedwellbeforethecertificationprocessby combiningtheexperiencegainedontheStarshipandthatoftheAFP ma-chinemanufacturer(Cincinnati).AccordingtoKevinRetz[152]:“The entirefuselageismadeintwopiecesandweighslessthan600lbs(272kg); thisisaweightsavingofover20%whencomparedwithametallicaircraft.

Fig.19. ATR72compositematerials.

Fig.21. Left:BeechcraftStarshipNC51infligth,Right:Fuselageunderconstruction(from[150]).

Fig.22. Typicalstackingsequenceforpressurizedfuselage: (a)forBeechcraftStarship(b)forRaytheonPremier (repro-ducedfrom[10]).

Withthecombinationofadvancedfibreplacementandlargehand layed-upparts,thePremierIhasreducedthepartscountfrom16000partsdown toaround6000partsfortheentireaircraft,areductionofover60%.By usingfibreplacement,materialscraperateisbelow5%comparedto50% fora hand-lay-upfuselage...production costswerereducedby 30% for

thefuselage.Toseethisfactorclearly,ittakes4technicianslessthanone weektoproducetheentirefuselage”.However,thewingofthePremier remainsinaluminium.Otheraircrafthavefollowedthisexample,such astheADAMAircraftA500&A700,theCIRRUSSR20&SR22,which arealsobusinessjets.Theseprogrammeshavebenefitedfromthedata

Fig.23. Transportaircraftwide-bodyfuselage (Repro-ducedfrom[156]).

bankofmaterialscertifiedbytheFAAthroughanAGATE(Advanced GeneralAviationTransportExperiments)programme.Otherplanesof thesamekindhaveprobablybeendevelopedaroundtheworld.In Eu-rope,aresearchprogrammecalledFUBACOMB(FUllBArrelCOMPosite) tookplaceintheearly2000sandstudiedacompositesandwich fuse-lageproducedbyAFPforbusinessjets[153,154].Theobjectivesofthe programmewere:

• TodevelopfibreplacementknowledgeandcapabilityinEurope • Tovalidate innovativeconceptsforcompositefuselage structures

withhighintegrationandautomatizationthroughfibreplacement technology

• Todemonstrateaffordable,large,complexcompositetooling • Todevelopinprocessmonitoringandvisualizationtechniquesfor

fibreplacement

Theresultwasafullyintegrated,fullcompositesandwich,front fuse-lage,inparticularthecanopy(firstofitskindinEurope).However,to thebestoftheauthors’knowledge,therehasbeennopractical appli-cationofthisprogrammesince,unlikeRaytheon,somemanufacturers believethatgreatermasssavingsarepossiblewithcompositewings.

Theintroductionofsandwichstructuresforprimarystructureson largeaircrafthasnotprogressedbeyondtheframeworkofAmerican re-searchprogrammes.TheACT(AdvancedCompositeTechnology,[155– 158])programmestudiedaciviltransportaircraftfuselagetypeinthe 1990s.A“fourshellconcept” structurewasstudiedand,accordingto thecriteriaofthetime,theresultwasaskin/stringerconfigurationfor thecrownquadrantandasandwichconstructionforthekeelandside quadrants(seeFig.23).Itshouldbenotedthatthesestudiesdidnotlead

toapracticalapplication;thefuselagesoftheA350andB787arenotin sandwichconstruction(seeFig.20).Otherstudiescarriedoutunderthe HSR(HighSpeedResearch)programme[158]inthe1990sincludeda fuselageandawingofasupersoniccivilsandwichaircraftusingskins inIM-7/PETI-5.PETI-5isaNASA-patentedpolyimideresin.

Sandwich technology and its advantages have finally spread to lightaviationwiththeaircraftmanufacturerElixirAircraftbasedinLa Rochelle(France),whichreceivedEASACS23certificationonMarch 20th,2020foritstwo-seatercarbonaircraftcalledthe“Elixir"[159].The

Elixirwasdevelopedaroundsandwichtechnologyappliedtothe One-Shotproductionmethod.Thistechniqueconsistsofdesigningand man-ufacturingcomplexelements(suchasawing)inonepartandone oper-ationwithoutcomplexstructuralassemblies.TheOne-Shottechnology usedherewastakenfromcompetitivesailing,whereithasbeeninuse formorethan15years.Thedevelopment,couplingsandwich technol-ogywithOne-Shotandtheinfluenceofcompetitivesailingdesign,has allowedthegeneralizationofmonoblockstructuresinthisaircraft(see

Fig.24).Innovativedefinitionslimitingthenumberofassemblieshave beenintroduced,andbreakwiththetraditional“blackmetal” widely usedinaviationcompositedesign.Forexample,thewingoftheElixir ismadewithoutribsorspars.Traditionalmechanicalassembly meth-ods,suchasscrewing,rivetingandgluingareeliminated.Thecomplete wing(fullspan)isentirelyinOne-Shotandmonoblock.Thefuselage, canopyarchandcontrolsurfaces(ailerons,flapsandverticalstabilizer) arealsomadeinOne-Shot.Themainadvantageofsuchanapproachis thedrasticreductioninthenumberofelements.Asaresult,theaircraft consistsofonly600parts,againstmorethan10,000withconventional light aircraftmetallicconstruction.Fewerpartsandfewerassemblies

Fig.24. (a)The"Elixir",(b)One-Shotfuselage,(c)CrosssectionalviewoftheOne-Shotwing.

meanfewerpotentialfailures.Thus,safetyisenhancedbythe simplic-ityofthestructureandperformanceisimprovedbythereducedweight. ElixirAircraftpresenttheElixirastheOne-Shotcarbon4thgeneration oflightaviation,after1stwoodandcanvas,2ndaluminiumandrivets, and3rdcompositesandaluminium[160].

Forthepast25years,ScaledCompositesInc.,ledbyBurtRutan,has beeninvolvedinthedesignandfabricationofmanyall-composite proof-of-conceptandcompetitionaircraft.Theseaircraft,whicharemadein CFRP/foamsandwichconstruction,arenotincludedinthisreport.They includetheVoyager,whichwasthefirstplanetoflyaroundtheworld withoutrefuelling,thePondRacer,theNASAAD-1obliquewing re-searchaircraft,thescaledemonstrationT-46,andtheStarship[151].

In conclusion, sandwich structures are now well established as primary structures for business aircraft thanks to their excellent cost/reliability/weightratio.Thissolutionisalsostartingtospreadin generalaviation. However, theshare of sandwichstructureshas de-creasedonthecommercialaircraftandstiffened compositesolutions arepreferred.

6. Thecaseofhelicopters

Helicoptersmustbetreatedseparatelybecausethestressesactingon thefuselagesareoftheorderofahundredN/mm,whereastheyare10 timeshigherforbusinessjetsandhelicoptersarenotpressurized.Onthe otherhand,thevibratoryconstraintsontheblades,theeconomic con-straintsforcivilhelicoptersortheoperationalconstraintsformilitary helicoptersledtocompositematerialsbeingadoptedveryearly,with ratesalmostat100%sincethe1990s.

Thefirstapplicationwasrotorbladesmadeofhoneycomborfoam coreswithfiberglassskins.ForVosteenetal.[151],thefirstcomposite sandwichbladesweretestedontheXCH-47byVERTOLin1959then, followingresearchprogrammes,allthe4,130steelbladesofthese he-licoptershadbeenreplacedbycompositebladesbythemid-1970s.For J.Cinquin[164],thelifespanofacompositehelicopterbladeislonger thanthelifespanofthehelicopter.Inaddition,thepossibilityof pro-ducingoptimizedaerodynamicshapes(camberedandtwistedsections) bymouldingmakesitpossibletoincreasethetake-off weightand re-ducefuelconsumption.Forexample,onanAS330,thetake-off weight isincreasedby400kg(+6%)andthegainincruisingflight by ap-proximately6%.Theuseofoptimizedstackingsequencesalsoallows thefrequenciesofthebladestobeclearlyseparated.Finally,thesaving inmanufacturingcostismorethan20%comparedtothecostpriceof thesameblademadeofmetallicmaterial.Therefore,inFrance,thefirst

compositebladesbroughtintoserviceinserieswereontheGazelle he-licopterproducedbyAerospatiale(nowAirbusHelicopter)whosefirst flighttookplaceonApril7th,1967(seeFig.25).Thistechnologywas

thenappliedtoallthefollowingprogrammes.

Asstatedin[162],thistechnology,incombinationwith STARFLEX-typecompositerotors(see[8])hassignificantlyreducedoperatingcosts (13% for thePUMAhelicopter). Inaddition,compositetechnologies havealsoreducedthecostofowningandmanufacturinghelicopters, openingthemuptothecivilianmarketfromthe1970swith,in partic-ular,theEcureuil(firstflightonJune27th,1974),whichwasdesigned

withautomobiletechniquestoreducecostsandwhichalready incorpo-rated25%ofitsmassincomposite.Anotheradvantageofthese compos-itebladeswastheirtolerancetodamage,whichhadbeenemphasized sincetheirintroductioninthe1970s.Thenewdesignsmakeitpossible toabsorbhardprojectileslaunchedat150m/s,whetherinfrontalor razingimpact.Theyarealsoresistanttothedetachmentoficeblocks fromthefuselageintheeventofflightsinicingconditions[165–167]. Today,researchismovingtowardslessnoisy“BlueEdge” typeblades, which havethestructuralcharacteristicof havingtwointernalspars

[168–170].

Therelativeproportionofcompositehasincreasedrapidlyin heli-copterstructures,withamajorityofsandwichstructures.TheEC135, broughtintoservicein1990alreadyincorporated50%compositeand theEC155“Dauphin” broughtintoservicein1997hadaround60%of itsstructureincomposite.ThemainpartofthestructurewasinNomex honeycomb/metallicskinsandwichstructures(inyellow,Fig.26) be-causethissolutioniseconomicalandhasbettervibratoryqualities, es-peciallyforthetailboom.Wecanalsonotethatthefloorwasmadeof honeycombwithaluminiumskinsbecauseitisalsoamore economi-calsolution.Theweightsavingwithacarbon/Nomexhoneycombfloor wouldbe20%butthecostwouldbeincreasedby70%.Ingeneral,the introductionofsandwichandcompositepartsintohelicopterstructures hasresultedinweightreductionsof15to55%andcostreductionsof 30to80%[164].InthelatestAirbusHelicopterprogramme,theentire structurewasmadeofcompositematerials.

ThemostinnovativecompositestructureiscertainlythatoftheTiger combat helicopter(firstflight,April27th, 1991).TheTigerwas the firstall-compositehelicopterdevelopedinEurope.Composite materi-alsareusedfor90-95%ofitsstructure[163],alargeproportionbeing inNomexhoneycombcorewithcarbonskins.Thisneedforlightness is duetooperational requirements,inparticulargreat manoeuvrabil-ityandahighrateofclimb.TheTigercanwithstand+4/-1g,which makesitoneoftherarehelicopterstobeabletoflyloops.Thestructure

Fig.25. Left:photoofhistoricalblades(thesmaller:Gazellehelicopter,thelarger:Pumahelicopter),from[161,162];Right:typicalsectionofablademanufactured atInstitutClémentAderwithafrontsparusedforimpactresearch[158–160].

Fig.26. StructureoftheEC155"Dauphin",reproducedfrom

[163].

weight/maximumtake-off weightratioisexceptionalevenifitcannot begivenhere.TheAH-64Apachehelicopterisareferenceinthisfield andtheTigerweighs40%less[171].

Despitethisextremelightness,theTigerwascertifiedwithfatigue testsonanewstructurethathaddeliberatelybeengivendamage (im-pactsandmanufacturingdefects)correspondingtoseveraltimesthe ser-vicelife,thenastatictestatextremeloadwasconductedonthesame structureandfinallyacrashtestwasperformed,againonthesame struc-ture.Intheeventofacrash,thehelicoptermustensurethesurvivalof thecrew,whichithasdoneinoperationalconditionsseveraltimes.The crashcalculationoncompositestructureswasextremelynewinthelate 80sandearly90s,yetthechallengewastakenupbyengineersofthe time.TigertechnologieshavealsobeenappliedtotheNH90transport helicopter,whichhasaslightlylowerrateofcomposites[163].

7. Futureofaeronauticsandwichstructures

Researchismainlyfocusedonstructuralimprovement,the integra-tionoffunctionsandthemultifunctionalityofsandwichstructures.

Re-gardingstructuralimprovement,manyinnovativecoreshavebeen de-velopedorrediscoveredinrecentyears.Abrief,non-exhaustivereview ofmanysandwichcorescanbefoundin [8]:foams,balsa,cork, ply-wood, honeycomb,andothershapes, latticecores(Kagome, tetrahe-dral,pyramidalorother),corrugated,folded,X-Cor,Hierarchical,Nap Core,Entangledcarbon fibresamongprobableothers.Only afewof thesepossibilitiescouldbeinterestingtoreplaceNomexoraluminium honeycombs,whichareveryefficient.Ullahetal.[172]studieda tita-niumkagomecorethatoutperformedtraditionalhoneycombsinshear andcompression.Thissolutionisproposedforailerons(seeFig.27). Italsohastheadvantageofbeingventilated,whicheliminatesthe po-tentialproblemsofmoistureingression.Areviewofthedifferent possi-bilitiesofthistypeofcore,inparticularfromthemultifunctionalpoint of view,wasmadebyHanetal.[176]. Foldedcores havealsobeen widelystudiedinrecentyears,especiallyintheVeSCo(VentableShear Core,[145,173])programme.Theyhavethemajoradvantageofbeing ventilatedbuttheycanalsobeoptimizedtoimprovethemanufacturing andtheskin/corebondingstrength[174],seeFig.27.These origami-typestructuresofferawidevarietyofmaterialsandpossiblepatterns

Fig.27. Top,kagomecoreforanaileron(reproducedfrom

[172]);bottom,foldedcoresolution(reproducedfrom[174]).

Fig.28. Definitionofamultifunctionalmaterialorstructure(from[184]).

[175].Theyhavealsobeenoptimizedforsoundabsorption,innacelles inparticular[174,177].Notethathoneycombcoreshavelongbeenused asaHelmholtzresonatorforsoundabsorption.However,todate,the foldedcorehasnotfoundapplicationsasfarastheauthorsknow, prob-ablyduetoamasspenalty.NASAX-Corcorehasinterestingmechanical characteristicsbutseemstobemainlyintendedforspaceapplications

[178,179].It isalsopossible tooptimize thedampingof astructure byaddingverydampingcore,suchasentangledcores,atkeylocations

[180].

Itisinterestingtorecallthedefinitionofamulti-functional struc-turegivenbyFerreiraetal.[184](seeFig.28):“Amultifunctional ma-terialsystemshouldintegrateinitselfthefunctionsoftwoormoredifferent componentsand/orcomposites/materials/structuresincreasingthetotal sys-tem’sefficiency”.Inthissense,manyofthesandwichstructurespresented in the previous sections are multifunctional in that, generally, they naturallyintegrate 2physical functionspassively:mechanics + ther-malinsulation(seeSection3);mechanics+stealth(seeFig.16); me-chanical+moistureingression,mechanical+acousticabsorption, me-chanical+vibrationdamping.Hermannetal.[145]andSascheetal.

[173]emphasizeanotherimportantfunctionthatsandwichstructures couldprovide:damagetolerance.Ofcourse,amoreresistantcorecanbe usedbutthissolutionisoftenalsoheavier.Anotherwayistooptimize thedesignofthecoresothatitcanactasacrackarrestor.Thisfunction hasbeenstudiedformarinestructures,forexample,in[181–183].The internalribofthebladeshowninFig.25actsasadamagearrestorin caseofhighvelocityimpact[165–167].

Inthepreviousexamples,theintrinsicpropertiesofthecoresorlocal designsareusedformultiphysicalapplicationslimitedtothe conjunc-tionoftwofactorsratherthanbeingmultifunctionalinthesystemsense. There areultimatelyfewreal multifunctionalapplicationswherethe sandwichisdesignedaprioritofulfilawidevarietyoffunctions.Rion etal.[17]studiedthepossibilityofusingsolarcellsasworkingskins fortheSolarImpulseproject(seeFig.29(a)).Smyers[185]presentsa droneapplicationofasandwichwhosecoreisanRFantennain addi-tiontoplayingastructuralrole.Boermans[186]presentsasandwich allowingsuctionoftheboundarylayerforaglider(seeFig.29(b)).The suctionisprovidedbyapumpandthefoldedsandwichisperforated.It shouldbenotedthat,inmanyotherareas,sandwichstructuresserveas mechanicalsupportsforotherfunctions:energyharvesting[187],heat exchange[188],microwaveabsorption[189,190],integratedelectronic device[192],batteryintegration[193–195],dampingwithresonator in-tegration[191],fireprotection[196],or(typicallyBalsacorefornaval militarystructures),crash[197].

Aspartofthe“SUGAR” (forSubsonicUltraGreenAircraftResearch) programmetheGeneralElectric,GeorgiaTech,Cessnateamproposed theconceptof“protectiveskin” showninFig.30[198].Thesolution isanasymmetricsandwichfromthefunctionalandmechanicalpoint ofview.Theinnerskinplaysthestructuralrole,thecoreandtheouter skinintegratealargenumberoffunctions,including:aerodynamic opti-mization,acousticandthermalinsulation,protectionagainstlightning strikes,moistureinsulation,damageprotection,andinstallationofice protectionsystems,wires,antennasorothersensors.

Inconclusion, arealisticprospecton fuselagesis proposed byA. Tropisin[199]:“...,thenextgenerationoffuselagesmustcombinethe2 pre-viousdomains(“loadcarryingstructureplusdamagetolerance/robustness”) plusa“multifunctionalcapability” i.e.electricalconductivity,...In conclu-sion,todefineafullyoptimizedfuselage,multifunctionalmaterialsmustbe

Fig.29. Twoexamplesofmultifunctionalsandwichstructures (a)from[17]and(b)from[186].

Fig.30. GE/GeorgiaTech/CessnaProtectiveskin con-ceptintheSUGARProgramme(from[198]).

furtherdevelopedcombinedwithimproveddamagetolerance/largedamage capabilitiesproperties.Itwillbethechallengeofthenextdecade”.

8. Conclusions

Fromthe1920sandTheodoreVonKarman’spatent,uptothepresent day,sandwichstructureshavebeenpresentinaeronauticsforalmost 100years.Despitetheirundeniablequalities,theircomplexityfroma mechanicalpointofview,togetherwiththechallengesofmanufacturing andcontrol,sloweddowntheirintroduction,whichwasdoneina care-ful,gradualmanner.Thedifficultiesencounteredincertainprogrammes allowedengineerstolearnalotandthenbouncebacksuccessfullywith

newapplications.Today,sandwichstructures,mainlywithcomposite skinsandNomexhoneycombs,dominatelighthelicopterstructuresand havesomeapplicationsinbusinessjetswithoutbeinggeneralized. De-spitethedifficultiesofcertifyingasandwichstructure,smallinnovative companies,suchasElixirAircraft,produceall-sandwichpassenger air-craftinOne-Shot.Incontrasttheiruseistendingtodecreasein single-ordouble-aislecivilaircraft,whereitislimitedtosomesecondary struc-turesandcommercialequipment.

Thedesign ofa sandwichcompositestructureis partof the gen-eral difficultyof designingcomposite structuresdetailedin theGAP (acronymofGeometry,Architecture,Process)method[8].In particu-lar,thechoice,notonlyofmaterialsbutalsoofarchitectures,isvery

vastandnorealmethodologyhasbeenestablished.However,this “hy-perchoiceof materialsandarchitectures” canprovetobe an advan-tageintheintegrationoffunctions,whichwillbethefutureof compos-iteaeronauticalstructures.Beyondmulti-physicalsolutions,sandwich structurescouldenablearealintegrationofsystemstobeachieved,as isbeginningtobeanalysedinthespacedomain[200]andproposedin theSUGARprogramme.Thiswillrequireadaptationoftheindustrial organization.Thelaunchofnewresearchprogrammescanprovideand experiencethisnewparadigmandencouragelearninganddialogue be-tweenspecialistsinsystemsandstructures.

DeclarationofCompetingInterest

Theauthorsdeclarethattheyhavenoknowncompetingfinancial interestsorpersonalrelationshipsthatcouldhaveappearedtoinfluence theworkreportedinthispaper.

Acknowledgements

Thispaperisaresultof25yearsofexperienceinthefieldof aero-nauticcompositestructuresattheInstitutClementAder,Toulouse,and strongrelationshipswiththeAircraftIndustry.Thefirstauthorwishes tothankmorespeciallyhisformeradvisorsduringhisPhDwith Euro-copter:Jean-PierreJaouen(Nowretired)andAlainCrouzet(now Da-her).TheauthorsalsothanktheirPhDstudentswhohavecontributed totheknowledgeofsandwichstructures:JaimeRivera(FuerzaAerade Chile),YulfianAminanda(nowUniversitiTeknologiBrunei), Phachara-pornBunyawanichakul(KasetsartUniversity,Thailand),LaurentMezeix (BuraphaUniversity,Thailand),JohnSusaisnathan(Universityof Ne-brija,Spain)andJuandeDiosRodriguezRamirez.SpecialthankstoJ. Leibacher(WebmasterofSoaringMagazinearchiveandprofessoratthe UniversityofTucson)andNicolasMahuet(HeadofengineeringofElixir Aircraft)fortheirhelp.

References

[1] N.J. Hoff, S.E. Mautner , Sandwich construction, Aeronaut. Eng. Rev. 3 (1944) 1–7 . [2] H.G. Allen, Analysis and Design of Structural Sandwich Panels. Pergamon Press,

Oxford 1969

[3] F.G. Plantema , Sandwich Construction, John Wiley & Sons, New-York, 1966 . [4] D. Zenkerts, The Handbook of Sanwdich Construction. E-MAS Publishing, London

1997

[5] C. Kassapoglou , Design and Analysis of Composite Structures (with application to aerospace structures), Wiley, Chichester UK, 2010 .

[6] L.A. Carlsson , G.A. Kardomateas , Structural and Failure Mechanics of Sandwich Composites, Springer, Dordrecht NL, 2011 .

[7] D. Gay , Composite Materials Design and Applications, CRC press, Boca Raton FL, 2015 .

[8] F. Neveu, B. Castanié, P. Olivier, The GAP methodology: A new way to design composite structure Mater. Des. 172, 107755, doi: https://doi.org/10.1016/j.matdes.2019.107755 .

[9] D. Guedra-Degeorges , P. Thevenet , S. Maison , Damage Tolerance of Aeronauti- cal Sandwich Structures, in: A. Vautrin (Ed.), Mechanics of Sandwich Structures, Kluwer Academic Publisher, 1998, pp. 29–36 .

[10] J. Tomblin, T. Lacy, B. Smith, S. Hooper, A. Vizzini, S. Lee, Review of damage tolerance for composite sandwich airframe structures, FAA Report DOT/FAA/AR- 99/49, 1999.

[11] B. Castanié, J.-J. Barrau, J.-P. Jaouen, Theoretical and experimental anal- ysis of asymmetric sandwich structures, Comp. Struct. 55 (2002) 295–306, doi: 10.1016/S0263-8223(01)00156-8 .

[12] B. Castanié, J.-J. Barrau, J.-P. Jaouen, S. Rivallant, Combined shear/compression structural testing of asymmetric sandwich structures, Exp. Mech 44 (2004) 461– 472, doi: 10.1007/BF02427957 .

[13] B. Castanié, Contribution à l’étude des structures sandwichs dissymétriques, PhD Supaéro 2000. http://oatao.univ-toulouse.fr/4282/ .

[14] J. Zhang, Q. Qin, X. Han, W. Ai, The initial plastic failure of fully clamped geo- metrical asymmetric metal foam core sandwich beams, Comp. Part B 87 (2016) 233–244, doi: 10.1016/j.compositesb.2015.10.027 .

[15] J. Deng, A. Peng, W. Chen, G. Zhou, X. Wang, On stability and damage behavior of asymmetric sandwich panels under uniaxial compression, J. Sandwich Struct. Mater. On line (Feb 2020), doi: 10.1177/1099636220905778 .

[16] A. Fink, C. Einzmann, Discrete tailored asymmetric sandwich structures, Comp. Struct. 238 (2020) 111990, doi: 10.1016/j.compstruct.2020.111990 .

[17] J. Rion, Y. Leterrier, J.-A.E. Månson, J.-M. Blairon, Ultra-light asymmet- ric photovoltaic sandwich structures, Comp. Part A 40 (2009) 1167–1173, doi: 10.1016/j.compositesa.2009.05.015 .

[18] K.E. Evans, The design of doubly curved sandwich panels with honeycomb core, Comp. Struct. 17 (1991) 95–111, doi: 10.1016/0263-8223(91)90064-6 . [19] S. Smidt, Bending of curved sandwich beams, a numerical approach, Comp. Struct.

34 (1996) 279–290, doi: 10.1016/0263-8223(95)00149-2 .

[20] O.T. Thomsen, J.R. Vinson, Conceptual design principles for non-circular pressurized sandwich fuselage sections – a design study based on a high- order sandwich theory formula-tion, J. Comp. Mater. 36 (2002) 313–345, doi: 10.1177/0021998302036003468 .

[21] N.J. Hoff, S.E. Mautner, The buckling of sandwich type model, J. Aeronaut. Sci. 12 (July 1945), doi: 10.2514/8.11246 .

[22] L. Fagerberg, D. Zenkert, Imperfection-induced wrinkling material fail- ure in sandwich panels, J. Sand. Struct. Mat. 7 (2005) 195–219, doi: 10.1177/1099636205048526 .

[23] E.E. Gdoutos, I.M. Daniel, K.A. Wang, Compression facing wrinkling of composite sandwich structures, Mech. Mater. 35 (2003) 511–522, doi: 10.1016/S0167-6636(02)00267-3 .

[24] L. Fagerberg, D. Zenkert, Effects of Anisotropy and Multi-axial Loading on the Wrinkling of Sandwich Panels, J. Sand. Struct. Mater. 7 (2005) 177–194, doi: 10.1177/109963205048525 .

[25] B.K. Hadi, F.L. Matthews, Development of Benson-Mayers theory on the wrin- kling of anisotropic sandwich panels, Comp. Struct. 49 (2000) 425–434, doi: 10.1016/S0263-8223(00)00077-5 .

[26] R. Vescovini, M. D’Ottavio, L. Dozio, O. Polit, Buckling and wrinkling of anisotropic sandwich plates International, J.Eng. Sci. 130 (2018) 136–156, doi: 10.1016/j.ijengsci.2018.05.010 .

[27] K. Niu, R. Talreja, Modeling of wrinkling in sandwich pan- els under compression, J. Eng. Mech. 125 (1999) 875–883, doi: 10.1061/(ASCE)0733-9399(1999)125:8(875) .

[28] K. Yu, H. Hu, S. Chen, S. Belouettar, M. Potier-Ferry, Multi-scale techniques to analyze instabilities in sandwich structures, Comp. Struct. 96 (2013) 751–762, doi: 10.1016/j.compstruct.2012.10.007 .

[29] M.A. Douville, P. Le Grognec, Exact analytical solutions for the local and global buckling of sandwich beam-columns under various loadings, Int. J. Sol. Struct. 50 (2013) 2597–2609, doi: 10.1016/j.ijsolstr.2013.04.013 .

[30] L. Léotoing, S. Drapier, A. Vautrin, Nonlinear interaction of geometrical and mate- rial properties in sandwich beam instabilities, Int. J. Sol. Struct. 39 (2002) 3717– 3739, doi: 10.1016/S0020-7683(02)00181-6 .

[31] J. Bertolini, B. Castanié, J.J. Barrau, J.P. Navarro, C. Petiot, Multi-level experimental and numerical analysis of composite stiffener debonding. Part 2: Element and panel level, Comp. Struct. 90 (2009) 392–403, doi: 10.1016/j.compstruct.2009.04.002 .

[32] S. Zhang, J.M. Dulieu-Barton, O.T. Thomsen, The effect of temperature on the fail- ure modes of polymer foam cored sandwich structures, Comp. Struct. 121 (2015) 104–113, doi: 10.1016/j.compstruct.2014.10.032 .

[33] B. Castanié, J-F. Ferrero , Nonlinear response of symmetric sandwich structures sub- jected to in-plane loads, in: Proceedings of the 10th International Conference on Sandwich Structures ICSS, Nantes, France, 2012, pp. 27–29. August 2012 . [34] B. Castanié, J.-J. Barrau , J.-F. Ferrero , J.-P. Jaouen , Analyse non linéaire et struc-

turale des poutres sandwichs dissymétriques, Revue des Composites et des Materi- aux Avances 10 (2000) .

[35] P. Minguet, J. Dugundji, P.A Lagace, Bucking and failure of sandwich plates with graphite-Epoxy face and various core, in: Proceedings of the 28th AIAA/ASME/ASCE/AHS Structures, Structural Dynamics and Materials Confer- ence, 6-8 April 1987 Paper AIAA-87-07, doi: 10.2514/3.45573 .

[36] A. Tropis , M. Thomas , J.L. Bounie , P. Lafon , Certification of the composite outer wing of the ATR72, J. Aerospace Eng. Proc. Inst. Mech. Eng. Part G 209 (1994) 327–339 10.1243/PIME_PROC_1995_209_307_02 .

[37] J. Rouchon , Certification of Large Aircraft Composite Structures, in: Proceedings of the 17th ICAS, Recent Progress and New Trends in Compliance Philosophy, Stock- holm, Sweden, 1990 .

[38] E. Morteau, C. Fualdes. Composites @ Airbus, damage tolerance methodology. FAA Work-shop for Composite Damage Tolerance and Maintenance, Chicago IL, 2006. https://www.niar.wichita.edu/niarworkshops/Portals/0/Airbus%20Composites %20-%20Damage%20Tolerance%20Methodolgy%20-%20Fualdes.pdf?ver = 2007- 05-31-095449-530 Accessed 05/26/2020

[39] J.B. Chang, V.K. Goyal, J.C. Klug, J.I. Rome, Composite Structures Damage Toler- ance Analysis Methodologies. NASA/CR-2012-217347

[40] T.D. McQuigg. Compression After Impact Experiments and Analysis on Honeycomb Core Sandwich Panels with Thin Facesheets. NASA/CR–2011-217157.

[41] J.S Tomblin, K.S. Raju, J. Liew, B.L Smith. Impact Damage Characterization Damage Tolerance of Composite Sandwich Airframe Structures. FAA Report DOT/FAA/AR-00/44, 2000.

[42] J.S Tomblin, K.S. Raju, J.F. Acosta, B.L. Smith, N.A. Romine, Impact Damage Char- acterization And Damage Tolerance Of Composite Sandwich Airframe Structures- phase II. FAA Report DOT/FAA/AR-02/80, 2002.

[43] J.S Tomblin, K.S. Raju, G. Arosteguy. Damage Resistance and Tolerance of Com- posite Sand-wich Panels —scaling Effects. FAA Report DOT/FAA/AR-03/75, 2003. [44] Serge Abrate , Bruno Castanié, DS Yapa , Rajapakse, Dynamic failure of composite

and sandwich structures, Springer, Dordrecht NL, 2012 .

[45] S. Heimbs, Virtual testing of sandwich core structures using dynamic finite element simulations, Comput Mater Sci 45 (2009) 205–216, doi: 10.1016/j.commatsci.2008.09.017 .

[46] Y. Aminanda, B. Castanié, J.-J. Barrau, P. Thevenet, Experimental analysis and modeling of the crushing of honeycomb cores, App. Comp. Mat. 12 (2005) 213– 217, doi: 10.1007/s10443-005-1125-3 .

![Fig. 5. Damage tolerance policy (reproduced from [10] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/5.892.58.505.88.677/fig-damage-tolerance-policy-reproduced.webp)

![Fig. 8. Edge junctions (from [57] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/6.892.63.525.84.502/fig-edge-junctions-from.webp)

![Fig. 9. Robust composite sandwich structures (reproduced from [56] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/7.892.101.787.85.501/fig-robust-composite-sandwich-structures-reproduced.webp)

![Fig. 11. Schematic of a scarf repair applied to a sandwich component. Top: top view, bottom: section view (Reproduced from [103] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/8.892.59.529.82.537/schematic-scarf-repair-applied-sandwich-component-section-reproduced.webp)

![Fig. 12. Glider wood sandwich construction (reproduced from [123] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/9.892.67.422.81.638/fig-glider-wood-sandwich-construction-reproduced.webp)

![Fig. 13. "Brodeau" process, 1934 [125] .](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/10.892.57.745.82.606/fig-brodeau-process.webp)

![Fig. 16. Composite Honeycomb areas of the SR 71, shown in black (from [139] and [140] ).](https://thumb-eu.123doks.com/thumbv2/123doknet/2948819.80044/11.892.56.518.451.821/fig-composite-honeycomb-areas-sr-shown-black.webp)